Low surface gloss polyvinylidene fluoride film and preparation method thereof

A polyvinylidene fluoride and gloss technology, which is applied in the field of low surface gloss polyvinylidene fluoride film and its preparation, can solve the problems of high surface gloss of the film, affecting the automatic lamination process of the backplane, etc., so as to reduce the surface gloss degree, meet the requirements of use, and increase the effect of tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

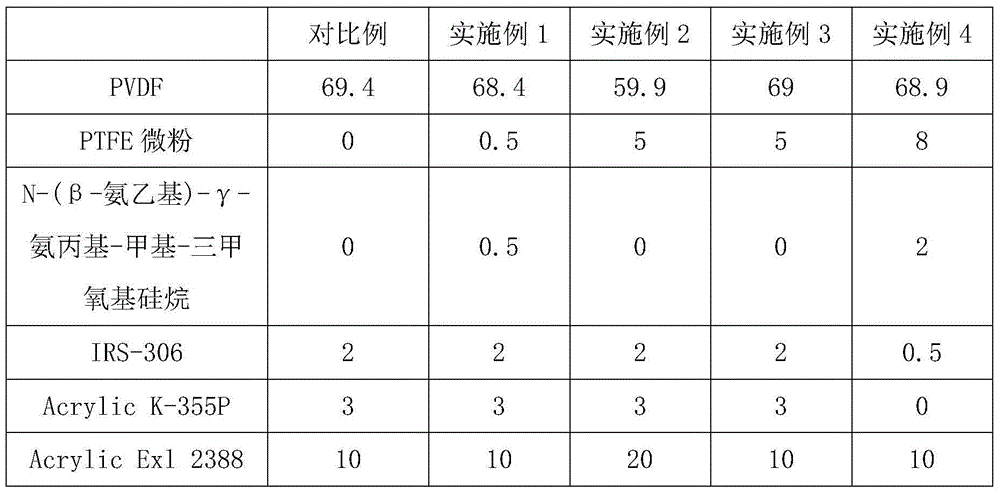

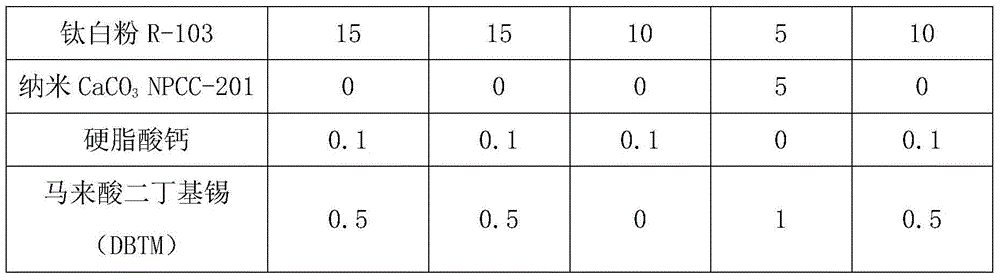

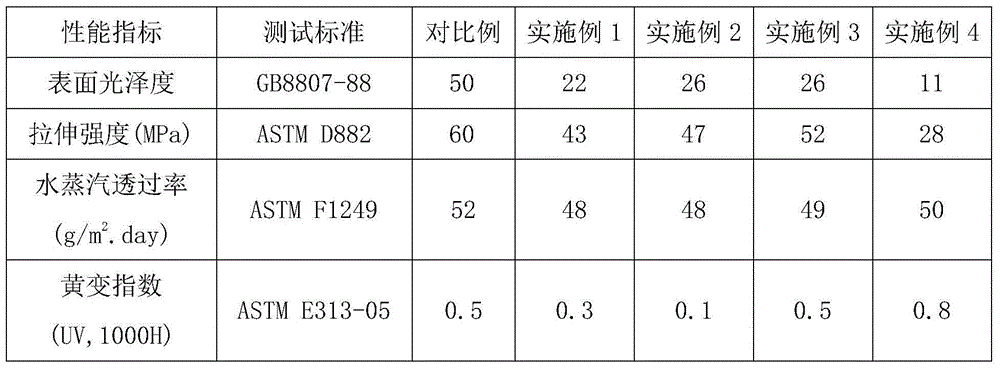

[0023] See Table 1 for formulations of low surface gloss PVDF films. The raw materials adopted in each embodiment are as follows:

[0024] 1. Polyvinylidene fluoride (PVDF): The trade name is PVDF DS206, the supplier is Shandong Huaxia Shenzhou New Material Technology Co., Ltd., and the melt index is 20g / 10min (test conditions: 230°C, 5kg).

[0025] 2. The matting agent is any one or a combination of solid matting agents and liquid matting agents. The solid matting agent is polytetrafluoroethylene (PTFE) micropowder, and the supplier is American Sanye Technology Co., Ltd.; the average particle diameter of the micropowder is 2 microns; the liquid matting agent is N-(β-aminoethyl)-γ-aminopropyl Base-methyl-trimethoxysilane, the supplier is Nanjing Xiangqian Chemical Co., Ltd.

[0026] 3. The processing aid is any one or any combination of acrylics. The trade name of one of the processing aids is: IRS-306, and the supplier is Mitsubishi Rayon (Nantong) Polymer Co., Ltd., with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com