Matting resin modified polyvinyl chloride (PVC) matt film

A technology of matting resin and matting film, applied in the field of matting resin-modified PVC matting film, can solve the problems of increased process, poor effect and small quantity of coating method, and achieves good mechanical strength and processing dimensional stability. Surface matting effect, the effect of good matting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A PVC matting film modified by matting resin is characterized in that: the PVC matting film comprises the following components, which consist of,

[0028] 70 parts by weight of polyvinyl chloride resin;

[0029] Matting resin (VinnolitC 100V) 30 parts by weight;

[0030] Bisphenol A antioxidant 0.4 parts by weight;

[0031] 0.5 parts by weight of UV-531 ultraviolet absorber;

[0032] Dioctyl phthalate 30PHR;

[0033] Epoxidized soybean oil 2PHR;

[0034] Barium zinc heat stabilizer 2.5PHR.

[0035] The processing process of the matting film modified by the matting resin in this example: After weighing each component, put the resin, stabilizer and plasticizer in the high-speed mixer at a low speed, and stir at a high speed at about 105°C to discharge the material, and then cold stir , and then to the middle barrel to the planetary extruder for thermal plasticization, and then fully mixed and exhausted in two open plastic mixers respectively, after being filtered by ...

Embodiment 2

[0037] A PVC matting film modified by matting resin, comprising the following components, consisting of:

[0038] 80 parts by weight of polyvinyl chloride resin;

[0039] Matting resin (VinnolitC 100V) 20 parts by weight;

[0040] 0.4 parts by weight of UV-531 ultraviolet absorber;

[0041] Dioctyl phthalate 30PHR;

[0042] Epoxidized soybean oil 2PHR;

[0043] Barium zinc heat stabilizer 2.5PHR.

[0044] The processing of the matting resin-modified matting film in this example is produced by the process of Example 1.

Embodiment 3

[0046] A PVC matting film modified by matting resin, comprising the following components, consisting of:

[0047] 80 parts by weight of polyvinyl chloride resin;

[0048] 20 parts by weight of ordinary matting resin;

[0049] Dioctyl phthalate 30PHR;

[0050] Epoxidized soybean oil 2PHR;

[0051] Barium zinc heat stabilizer 2.5PHR.

[0052] The processing of the matting resin-modified matting film in this example is produced by the process of Example 1.

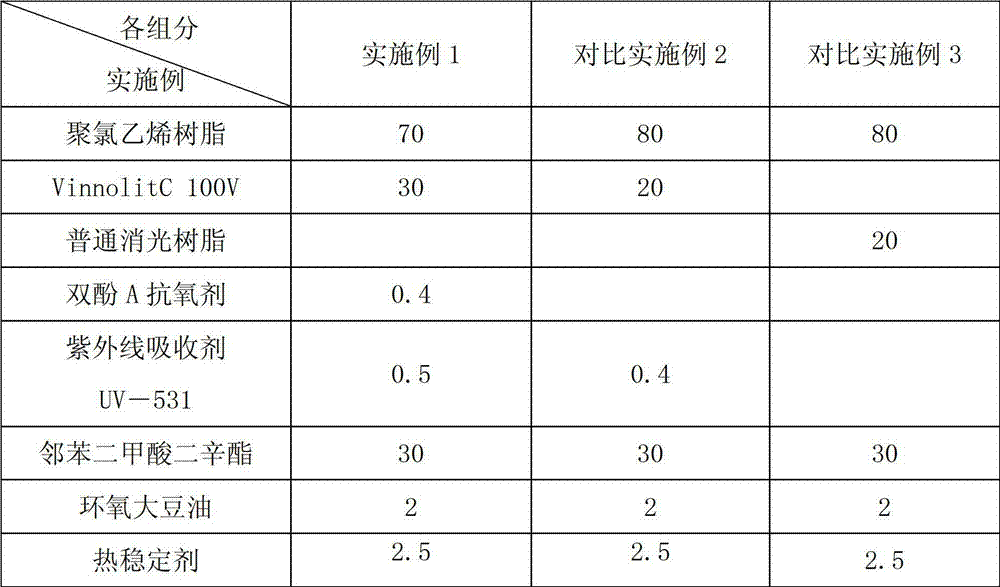

[0053] The composition and product performance of embodiment 1, comparative example 2 and comparative example 3 are shown in the following table:

[0054] Table 1. Composition of Embodiment 1, Comparative Example 2 and Comparative Example 3

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com