Ball type self-induction self-rotation fire extinguishing device

A fire extinguishing device and self-sensing technology, applied in the field of ball-type self-induction and self-rotating fire extinguishing devices, can solve the problems of high storage requirements, poor fire extinguishing effect, suffocation of personnel, etc., and achieve the goal of increasing safety, reducing safety, and preventing re-ignition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

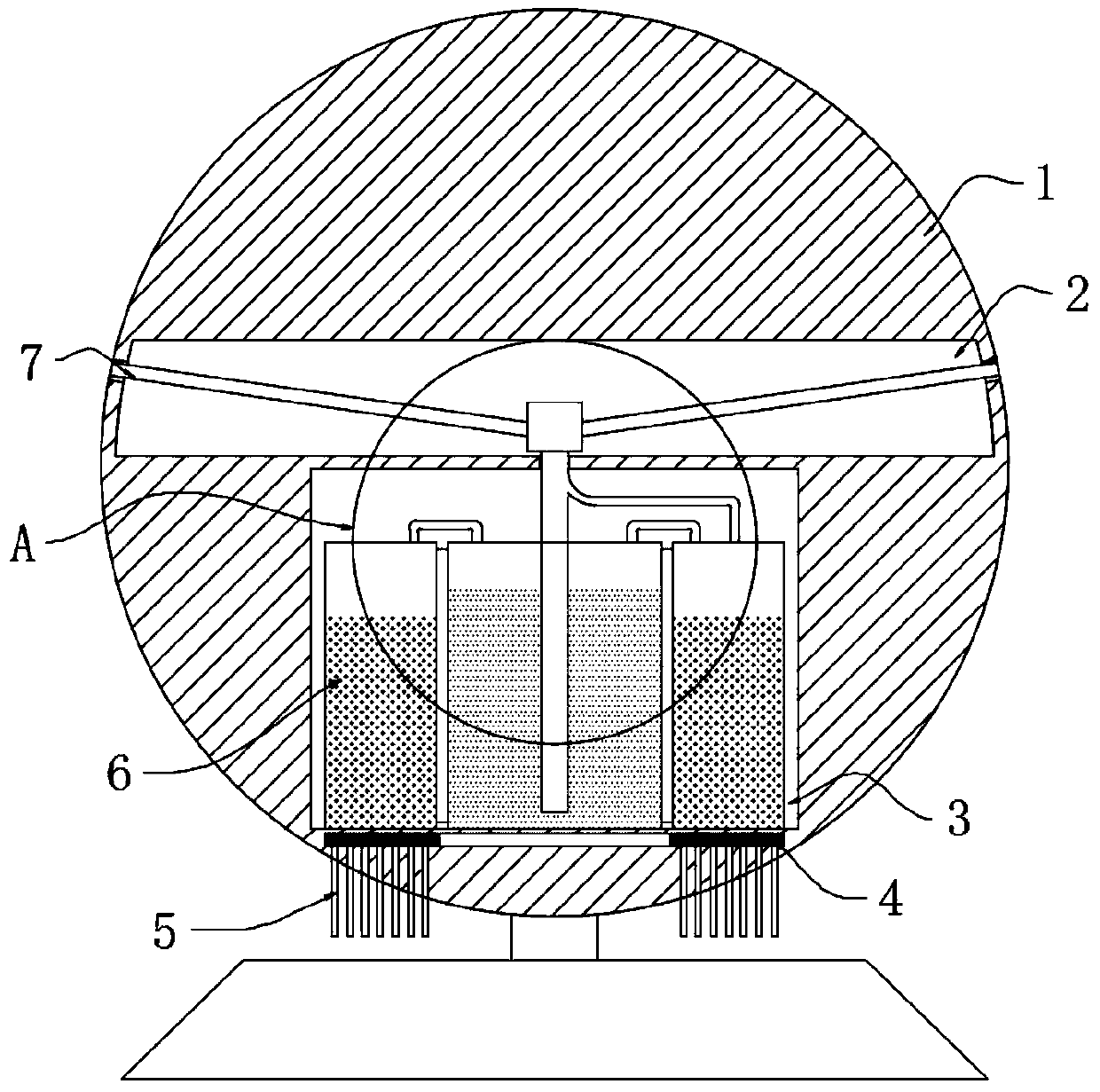

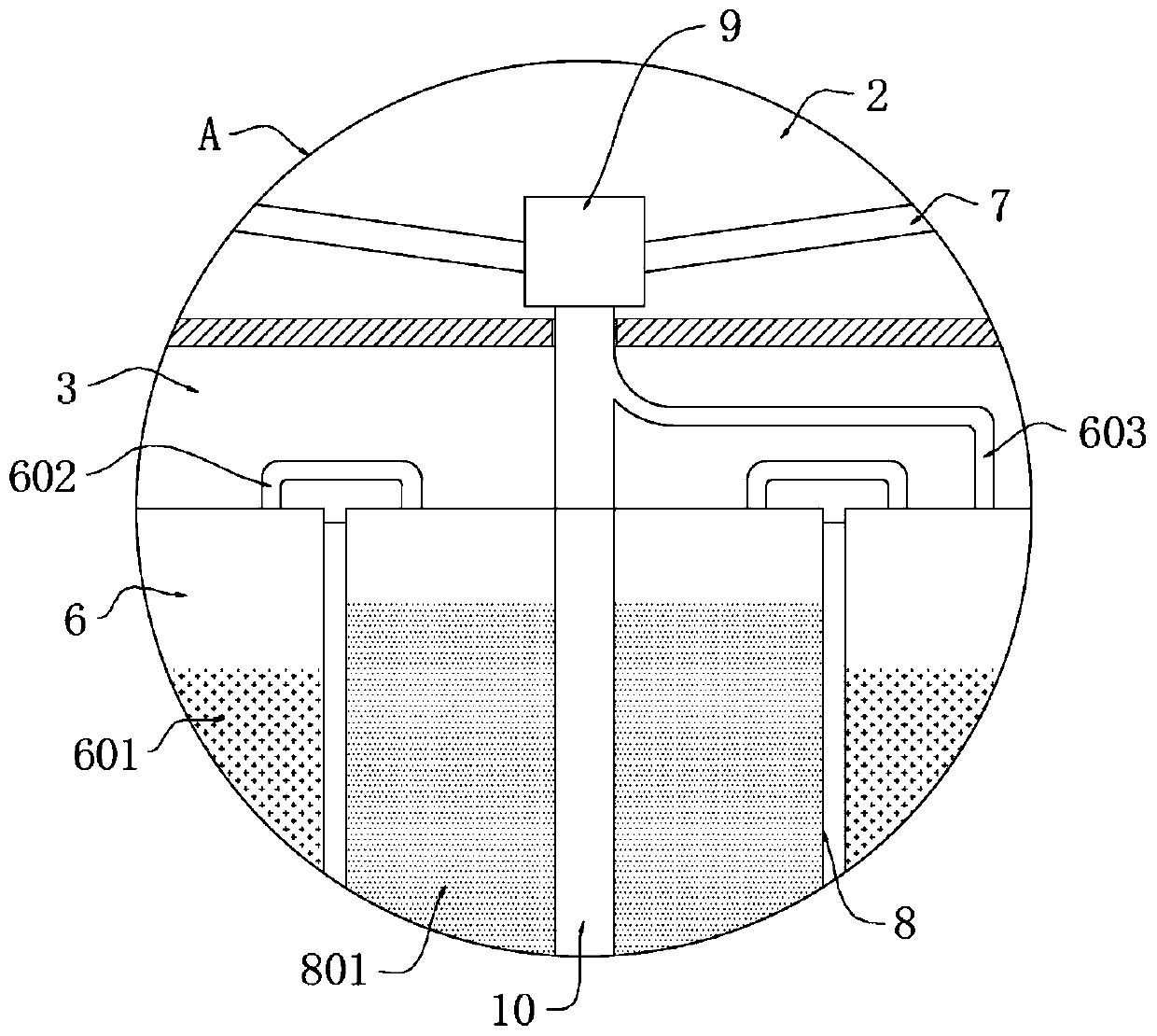

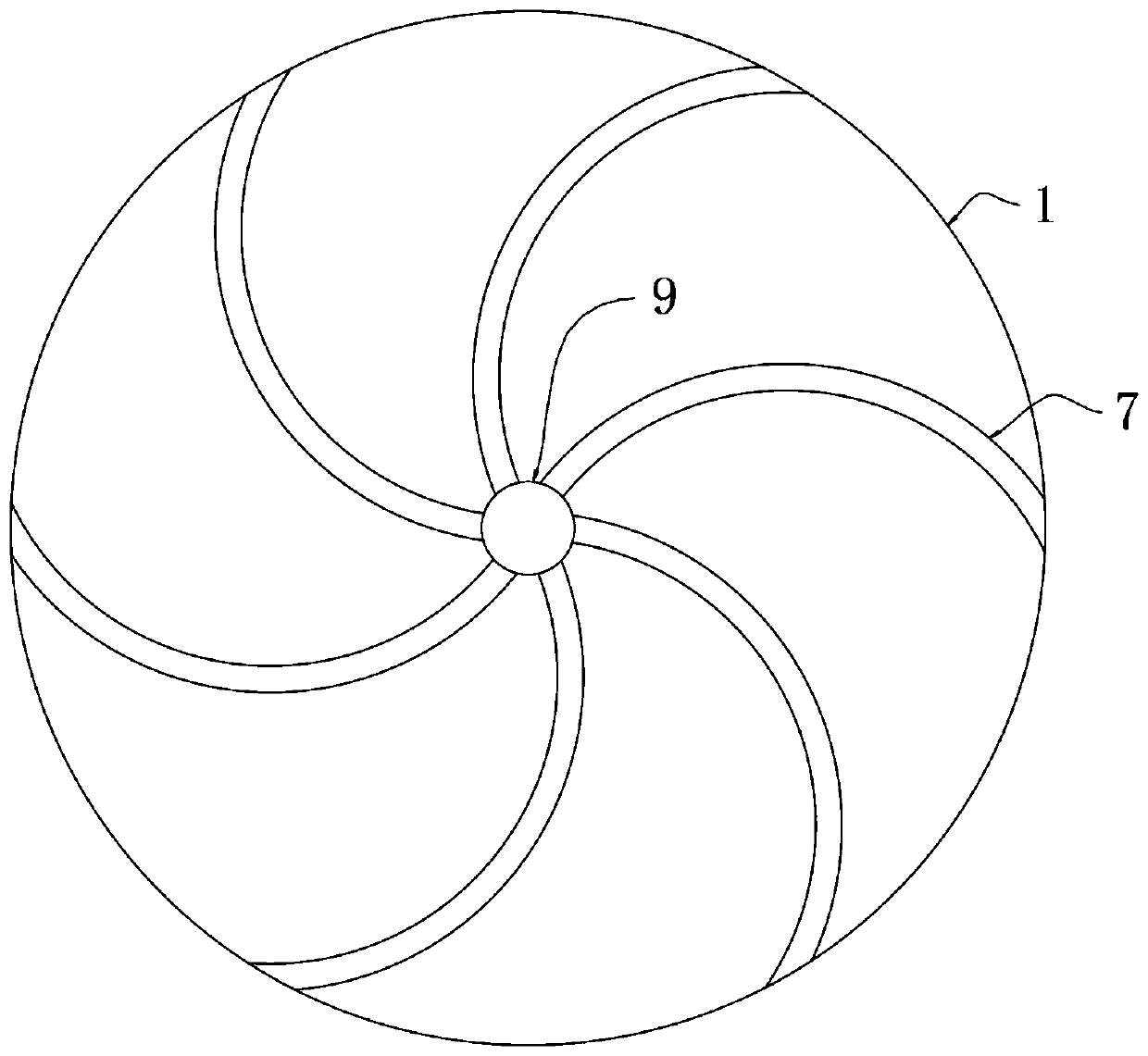

[0031] refer to Figure 1-3 , a ball type self-induction self-rotating fire extinguishing device, comprising a sphere 1, a tube cavity 2 and a storage cavity 3 respectively opened in the sphere 1, an annular heat conducting plate 4 is embedded in the bottom of the storage cavity 3, and the upper end of the annular heat conducting plate 4 An annular high-pressure tank 6 is installed, and a material storage tank 8 is installed in the center of the storage cavity 3, and the material storage tank 8 is located in the middle of the annular high-pressure tank 6, and the upper ends of the material storage tank 8 and the annular high-pressure tank 6 are symmetrically installed with multiple The pressure pipe 602, the annular high-pressure tank 6 is filled with evaporating liquid 601, the storage tank 8 is filled with metal powder 801, and the powder discharge pipe 10 is sealed and inserted on the storage tank 8, and the upper end of the powder discharge pipe 10 extends to the tube A pr...

Embodiment 2

[0042] refer to Figure 4 , a ball-type self-induction self-rotating fire extinguishing device, which is basically the same as Embodiment 1, the difference is that:

[0043] A fixed frame 101 is installed on the inner wall of the lower end of the powder discharge pipe 10, and a rotating shaft 102 is inserted into the fixed frame 101 for rotation. ;

[0044] The upper end of the powder discharge pipe 10 generates negative pressure so that the direction of the airflow flows from bottom to top, and the flowing airflow passes through the diversion groove 104 to make the diversion cone 103 rotate, and the rotating diversion cone 103 loosens the surrounding copper powder, making it easier for the copper powder to The copper powder is extracted, and the copper powder flows along the diversion groove 104 and the air flow at the same time, so that the copper powder is extracted more uniformly, and the ejected copper powder covers the fire area more uniformly, increasing the effect of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com