Large-flow compressed air and foam mixing device

A technology of compressed air foam and mixing device, used in fire rescue and other directions, can solve the problems of affecting the spray distance of compressed gas foam, insufficient to ensure full mixing of gas and liquid, affecting the fire extinguishing effect of fire extinguishing device, etc., to achieve good atomization effect and kinetic energy. The effect of large, increased blending range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

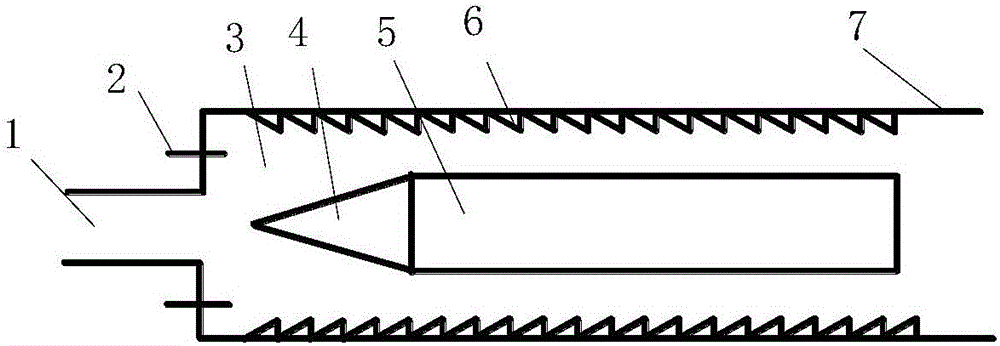

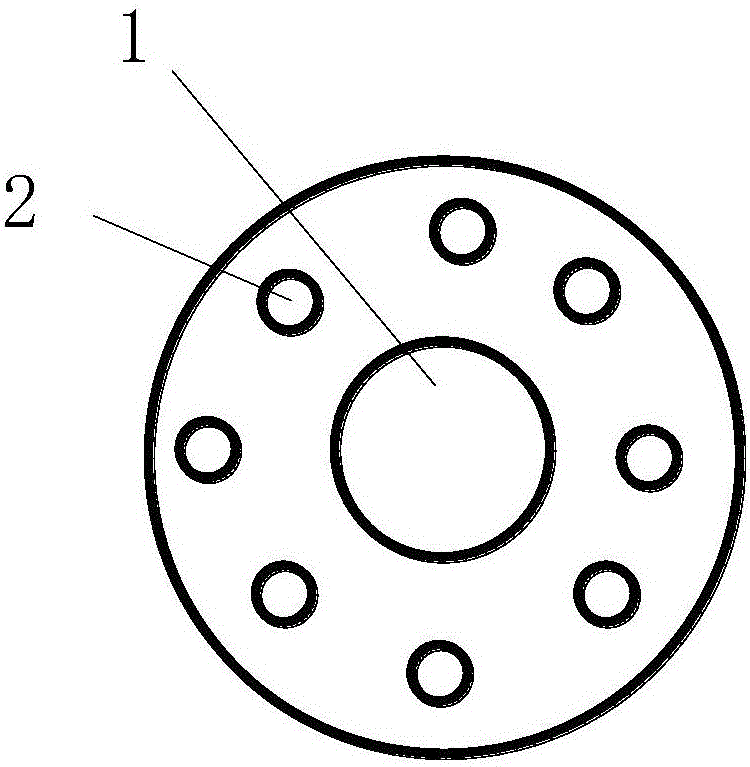

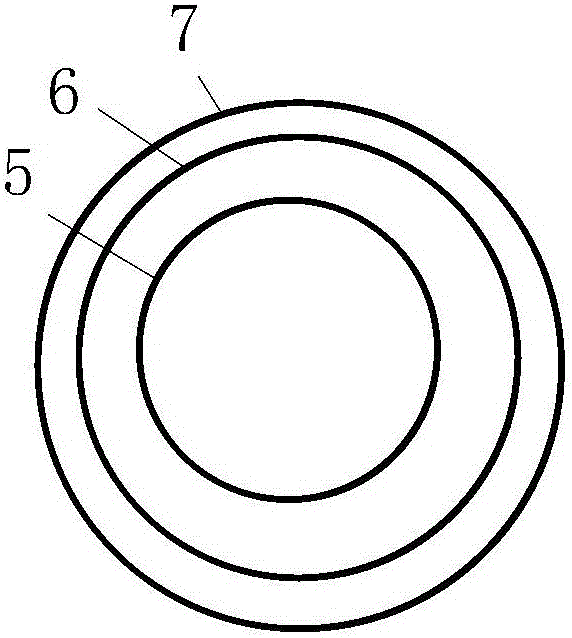

[0020] Such as Figure 1-3 As shown, a large-flow compressed air foam mixing device includes a foam mixture nozzle 1, the foam mixture nozzle 1 is connected with a mixing chamber 3, and the mixing chamber 3 is provided with a conical spoiler 4 and a conical spoiler 4 The cone angle is 20°, and the distance between the tip of the cone and the foam mixture nozzle 1 does not exceed the radius of the foam mixture nozzle 1. The end of the conical spoiler 4 is connected with a secondary spoiler 5, and the cylinder diameter of the secondary spoiler 5 is equal to the diameter of the cone of the conical spoiler 4. The inside of the tube wall of the mixing chamber 3 is provided with an inner wall surface boss 6, the inner wall surface boss 6 is a right triangle, and the long right angle side is fixedly connected with the inner wall ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com