Filling device and method for filling down-hole goaf by same

A technology for filling devices and gobs, which is applied in the direction of fillings, safety devices, mining equipment, etc., can solve the problems of high cost and high cost, and achieve the effects of low cost, widening width and saving filling materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

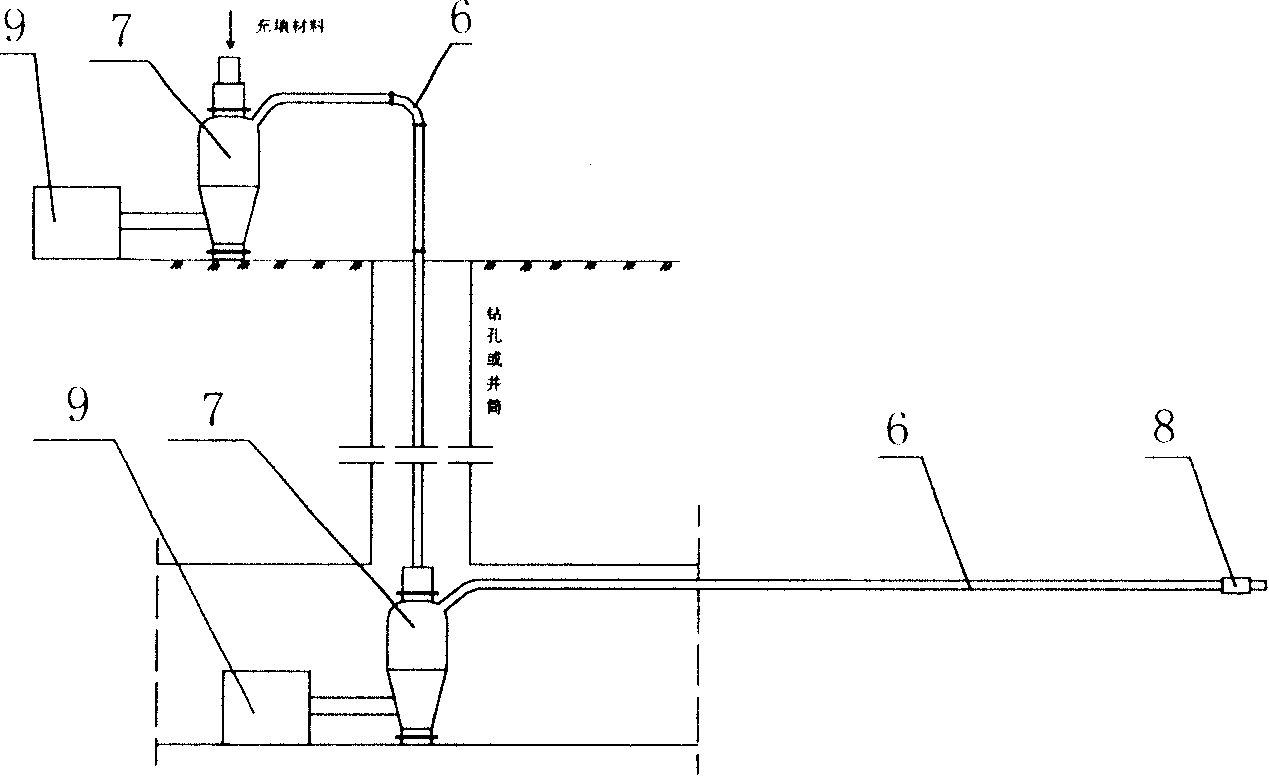

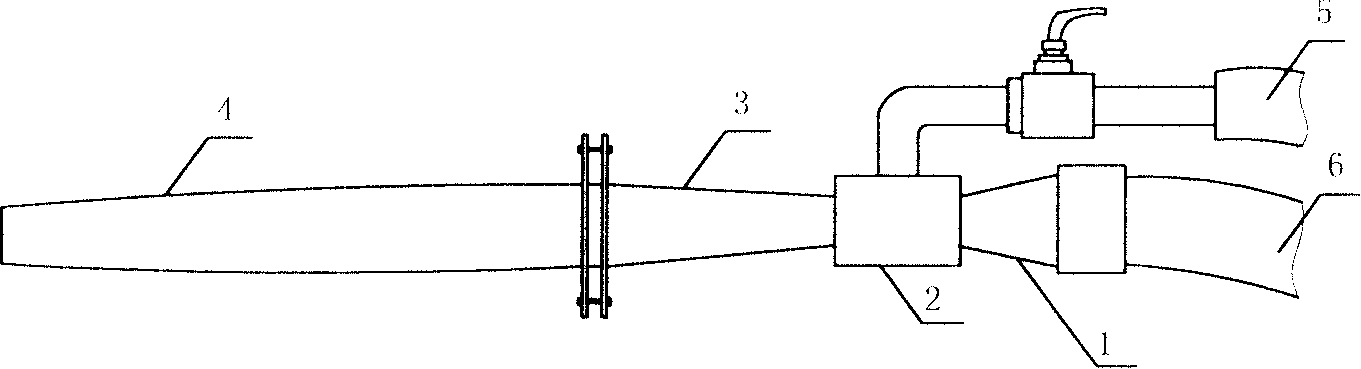

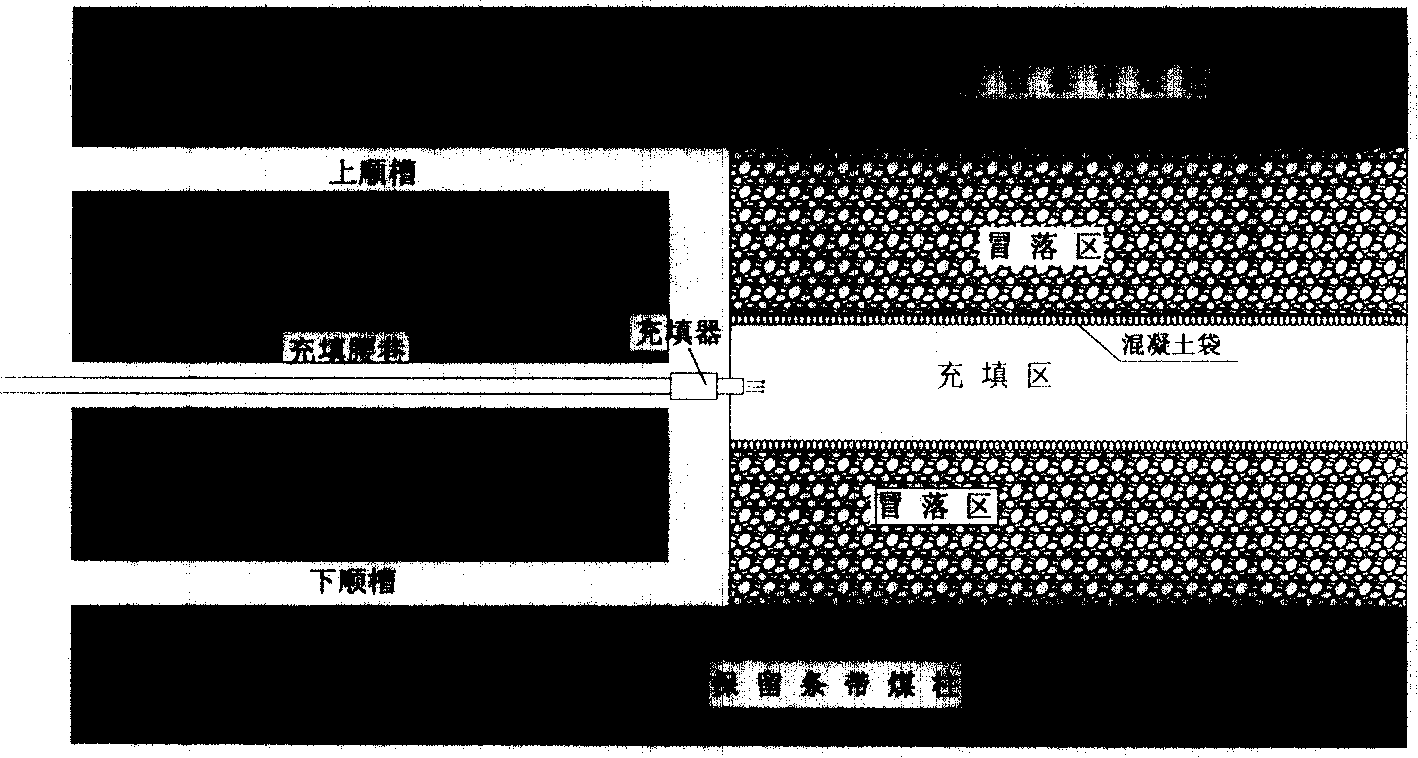

[0026] A preferred embodiment of the filling device of the present invention is as follows: figure 1 As shown, it includes a compressor 9, a bin pump 7, an ash conveying pipeline 6, and a filler 8. The bin pump 7 receives and stores powdered filling materials supplied from the outside. After the compressor 9 adds compressed air to the bin pump 7, The filling material in the bin pump 7 is blown into the filling device 8 through the ash conveying pipeline 6, and the filling material is ejected by the filling device 8 to realize filling of the filling area. The ash conveying pipeline 6 here includes a ground part, a ground-to-downhole part, and a downhole part.

[0027] Storehouse pump 7 can be one, also can have multiple parallel connection or series connection, a plurality of storehouse pumps 7 can have a compressor 9 air supply, also can have many compressors 9 air supply.

[0028] Wherein, the compressor can adopt VFY-6 / 7-KB type air compressor, or the compressor of other mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com