Quantitative filling device for cosmetic production

A filling device and cosmetic technology, which is applied in the field of quantitative filling devices for cosmetic production, can solve the problems of easy overflow of filling bottles, insufficient filling volume, and reduced reliability of filling process, so as to avoid foam accumulation and improve uniformity. performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

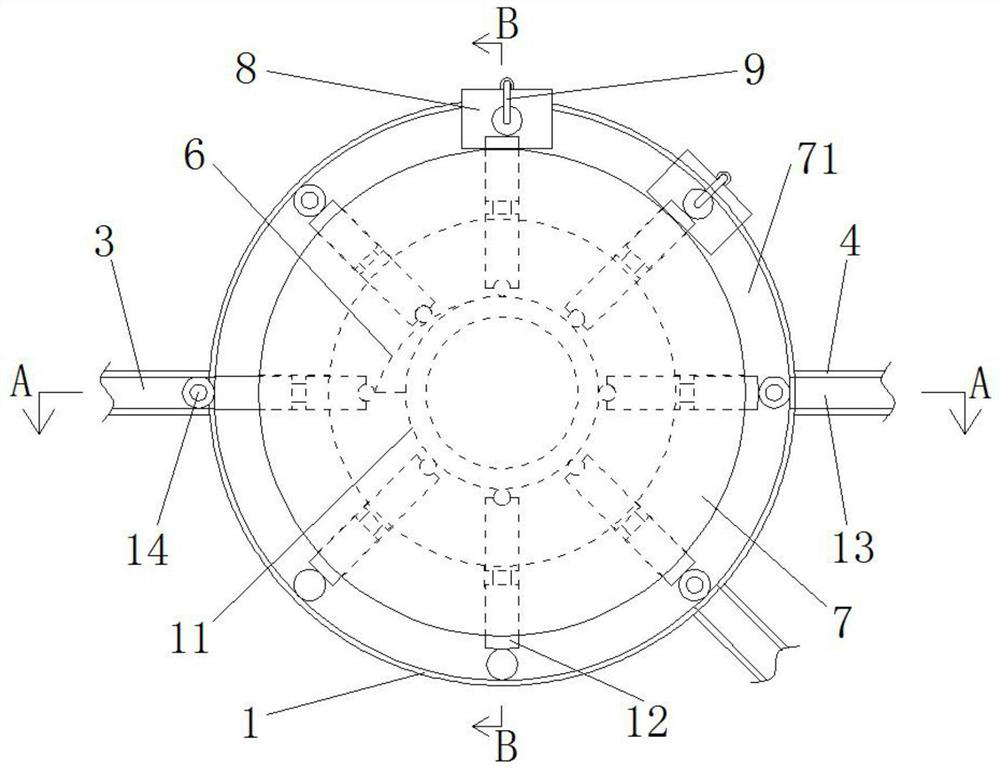

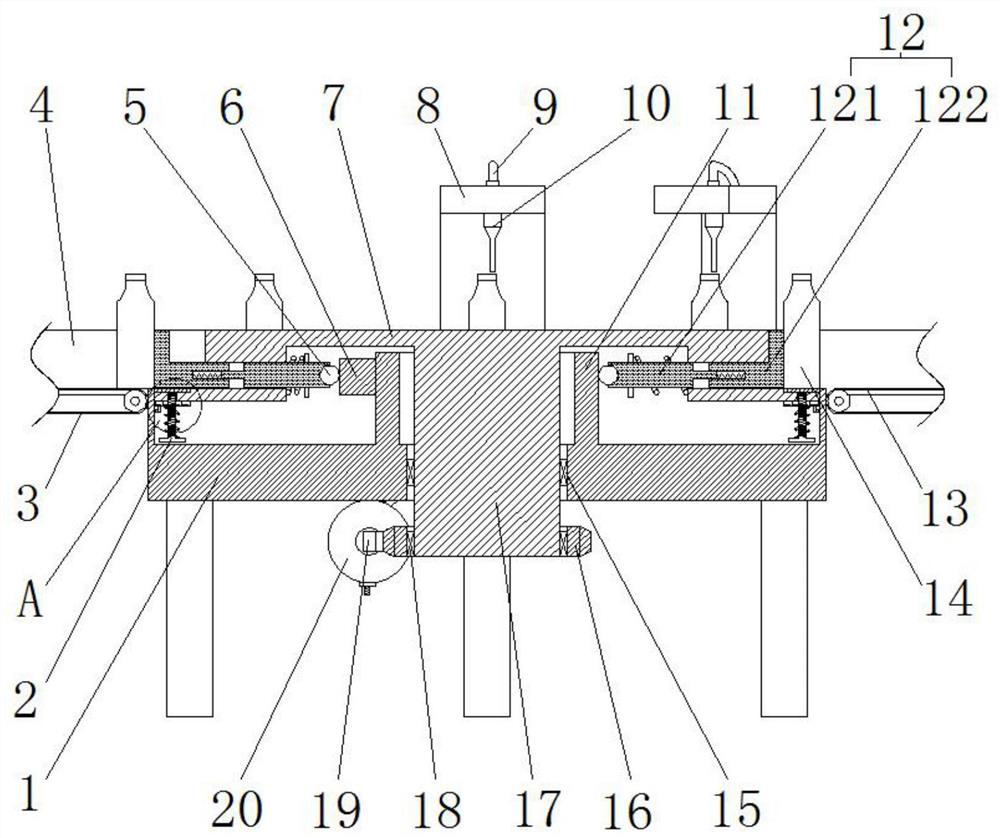

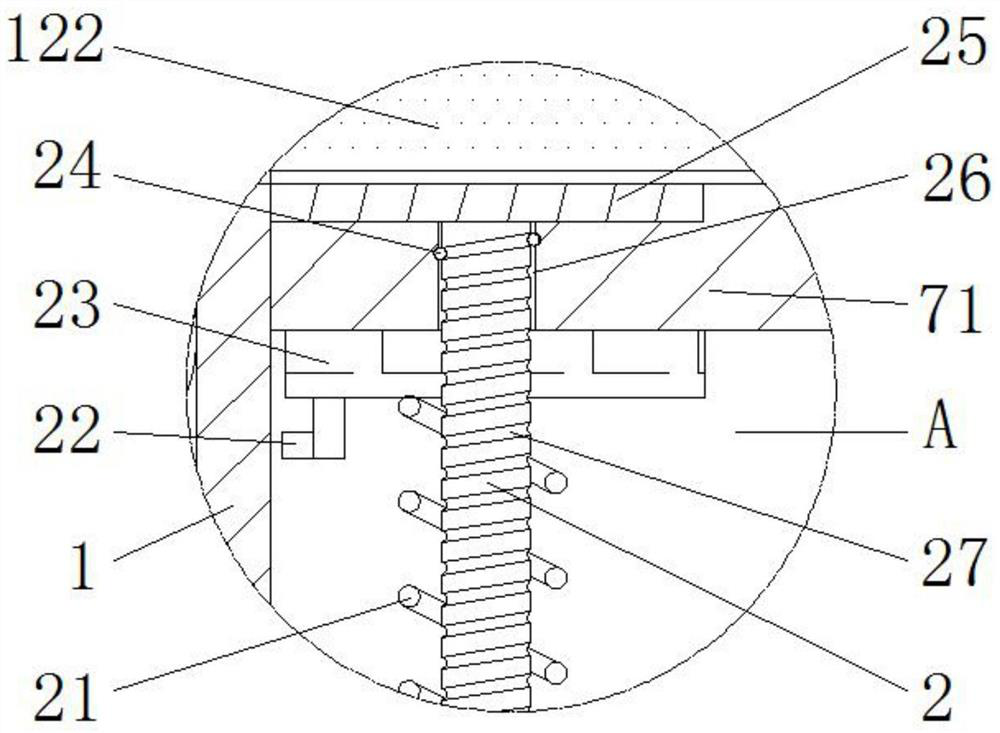

[0034] Such as figure 1 , figure 2 and Figure 4 The shown quantitative filling device for cosmetic production includes a conveying mechanism for conveying the filling bottle 14 and a filling mechanism for filling liquid cosmetics. The filling mechanism includes a storage cylinder 20 and communicates with it. The filling head 10; the conveying mechanism includes a fixed support platform 1 with support legs at the bottom and a rotatable rotary platform 7 located at the upper end of the fixed support platform 1, and the fixed support platform 1 has a circular groove shape , and its inner center is fixed with a support cylinder 11 supported below the turntable 7, and the center of the bottom surface of the turntable 7 is fixed with a center that vertically passes through the inner side of the support cylinder 11 and extends to the bottom of the fixed support platform 1. A rotating shaft 17, the lower end of the central rotating shaft 17 is connected to a rotating drive mechani...

Embodiment 2

[0049] The difference between this embodiment and embodiment 1 is:

[0050] In this example, if Figure 6 As shown, the energization switch 34 is arranged on one side of the cavity of the storage cylinder 20 corresponding to the side where the telescopic rod 38 is located, and the energization switch 34 is provided with a slope for the telescopic rod 38 to interfere. In the initial state, the energization The switch 34 is located between the telescoping rod 38 and the piston plate 36 . Before the telescopic rod 38 moves to contact the piston plate 36, it will first conflict with the slope of the power switch 34, and then as the telescopic rod 38 continues to move, the power switch 34 can be pressed to energize the static contact 39; When the reset moves to break away from the energization switch 34, the energization switch 34 can reset automatically. Then there is no need to additionally press the energization switch 34 to energize the static contact 39 .

[0051] In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com