Anti-crystallization compact type urea mixing device

A mixing device and a compact technology, applied in the field of anti-crystallization compact urea mixing device, can solve the problems of high risk of urea crystal blockage and poor mixing effect, reduce the risk of premature wall collision, avoid urea crystallization and mixing The effect of increasing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

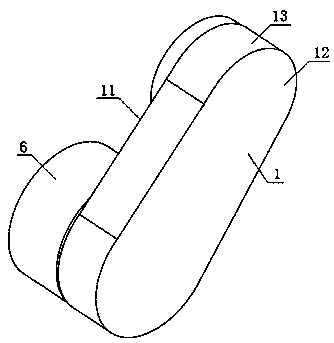

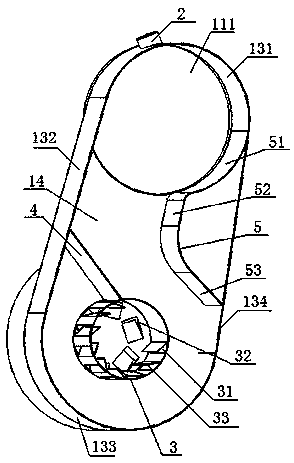

[0039] see Figure 1 to Figure 4 , an anti-crystallization compact urea mixing device, the mixing device includes a No. 1 mixing device 1, and the No. 1 mixing device 1 includes a top plate 11, a bottom plate 12, and an annular side wall 13, and the top plate 11, the bottom plate 12 and the annular The side wall 13 surrounds the inner cavity 14 of the No. 1 mixer 1, and the annular side wall 13 is formed by connecting the No. 1 arc-shaped plate 131, the No. 1 straight plate 132, the No. 2 arc-shaped plate 133, and the No. 2 straight plate 134 sequentially. A through hole 111 connecting the DPF unit and the inner cavity 14 is opened on the top plate 11 near the first arc-shaped plate 131, and the first arc-shaped plate 131 is provided with a The urea injection port 2 arranged on the No. 1 straight plate 132, the inner cavity 14 is provided with the swirl mixer 3 arranged near the No. 2 arc-shaped plate 133, and the sloping plate connecting the outer wall of the swirl mixer 3 an...

Embodiment 2

[0041] The difference with Example 1 is:

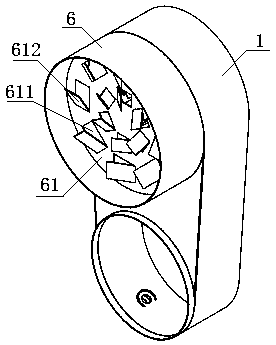

[0042] The mixing device also includes a No. 2 mixing device 6 located between the air outlet 32 and the SCR post-processor. The inside of the No. 2 mixing device 6 is provided with a swirl disc 61, and the outer wall of the swirl disc 61 is in contact with the mixing device. The inner walls of the device 6 are attached together, and a plurality of mixed gas outlets 611 and second swirl vanes 612 corresponding to them are evenly arranged on the swirl disk 61. The inlet and exhaust ends of the mixed gas outlets 611 are respectively connected to the The outlet 32 is in communication with the SCR post-processor, one side of the second swirl vane 612 is fixedly connected to the inner wall of the mixed gas outlet 611, and the other side of the second swirl vane 612 is arranged toward the outside of the No. 2 mixing device 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com