Self-suction pulse water jet ejection device

A technology of spraying device and water jet, which is applied in the direction of spraying device and liquid spraying device, can solve the problems of increased investment and use, limitation of spraying distance of erosion effect, etc., and achieves long spraying distance, improved erosion performance and good erosion effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further described in conjunction with example (accompanying drawing):

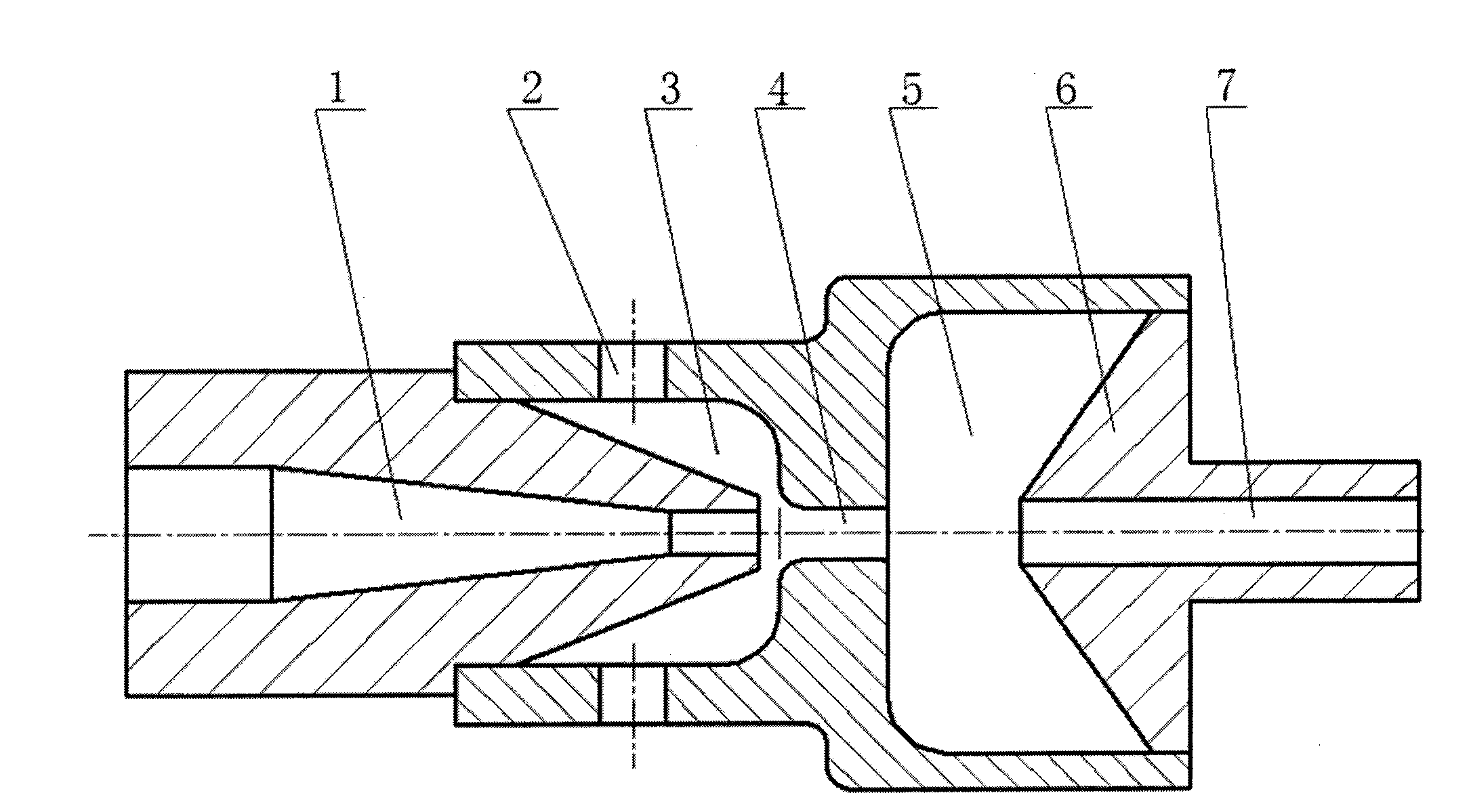

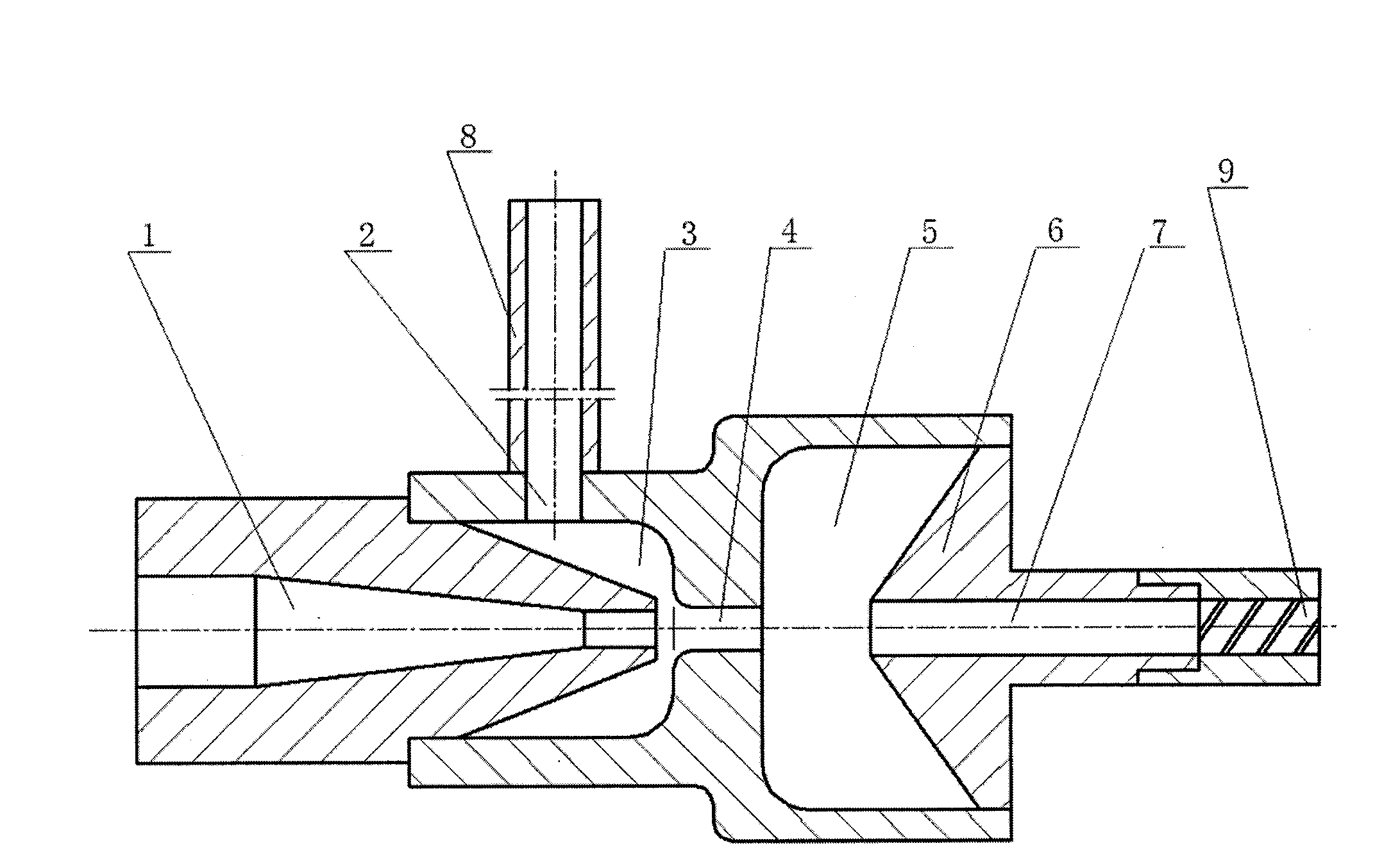

[0019] Such as figure 1 , a self-aspiration pulsed water jet injection device, which has a water inlet nozzle (1), an air suction hole (2), an air suction chamber (3), a throat pipe (4), an oscillation chamber (5), and a reflection cone body (6) and mixed flow tube (7). The nozzle (1), suction chamber (3), throat pipe (4), oscillation chamber (5) and mixed flow pipe (7) are in the order of nozzle (1) in the upstream direction and mixed flow pipe (7) in the downstream direction set up. The nozzle (1) extends to the downstream end of the suction cavity (3), and the nozzle (1) is facing the upstream end of the throat (4); the mixed flow pipe (7) is arranged at the center of the reflection cone (6), and the mixed flow pipe ( 7) Directly facing the downstream end of the throat (4); the throat (4) connects the suction chamber (3) with the oscillation chamber (5). An air suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com