Biomass particle fuel with high calorific value and preparation method

A biomass particle, high calorific value technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of biomass particle fuel being susceptible to moisture, affecting combustion quality, and insufficient combustion, avoiding poor combustion calorific value, enhancing Burning effect, storage-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

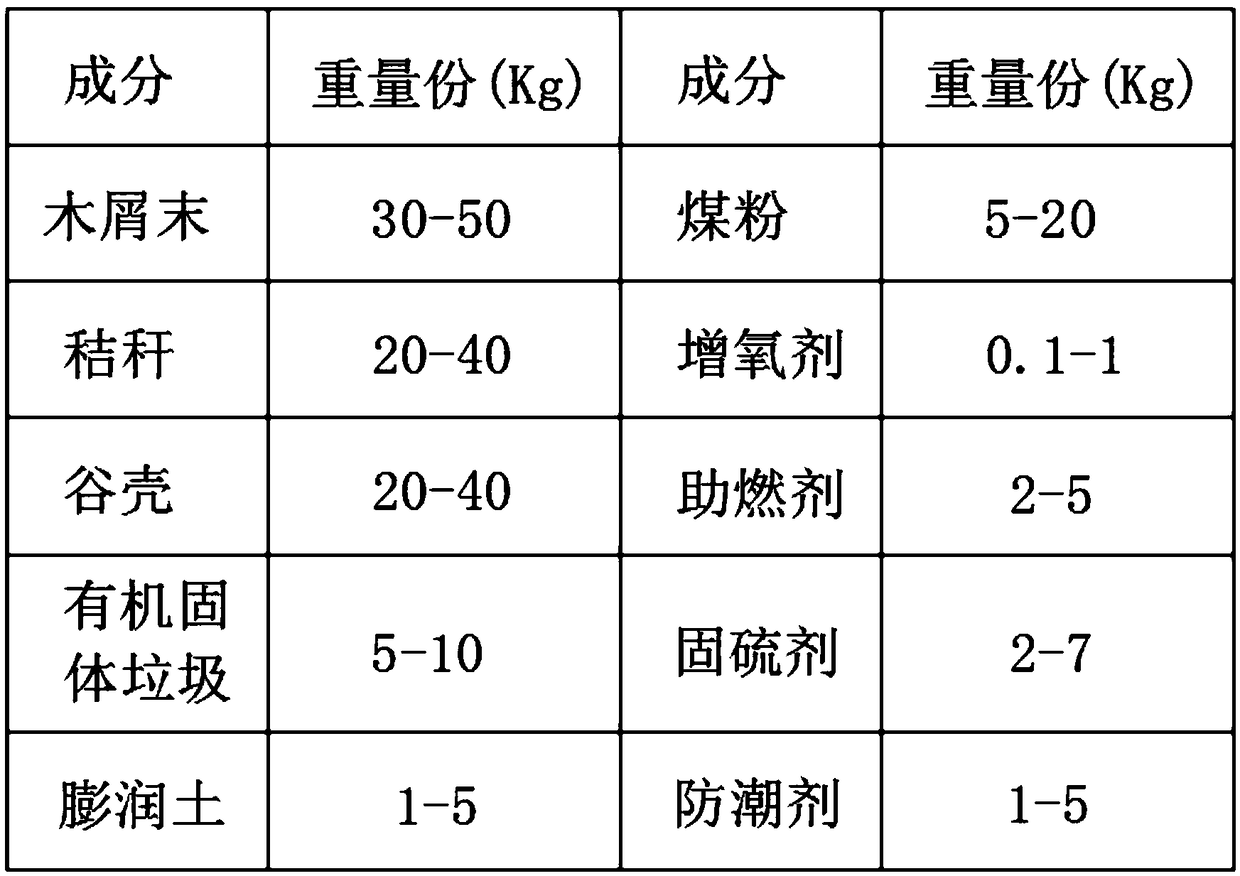

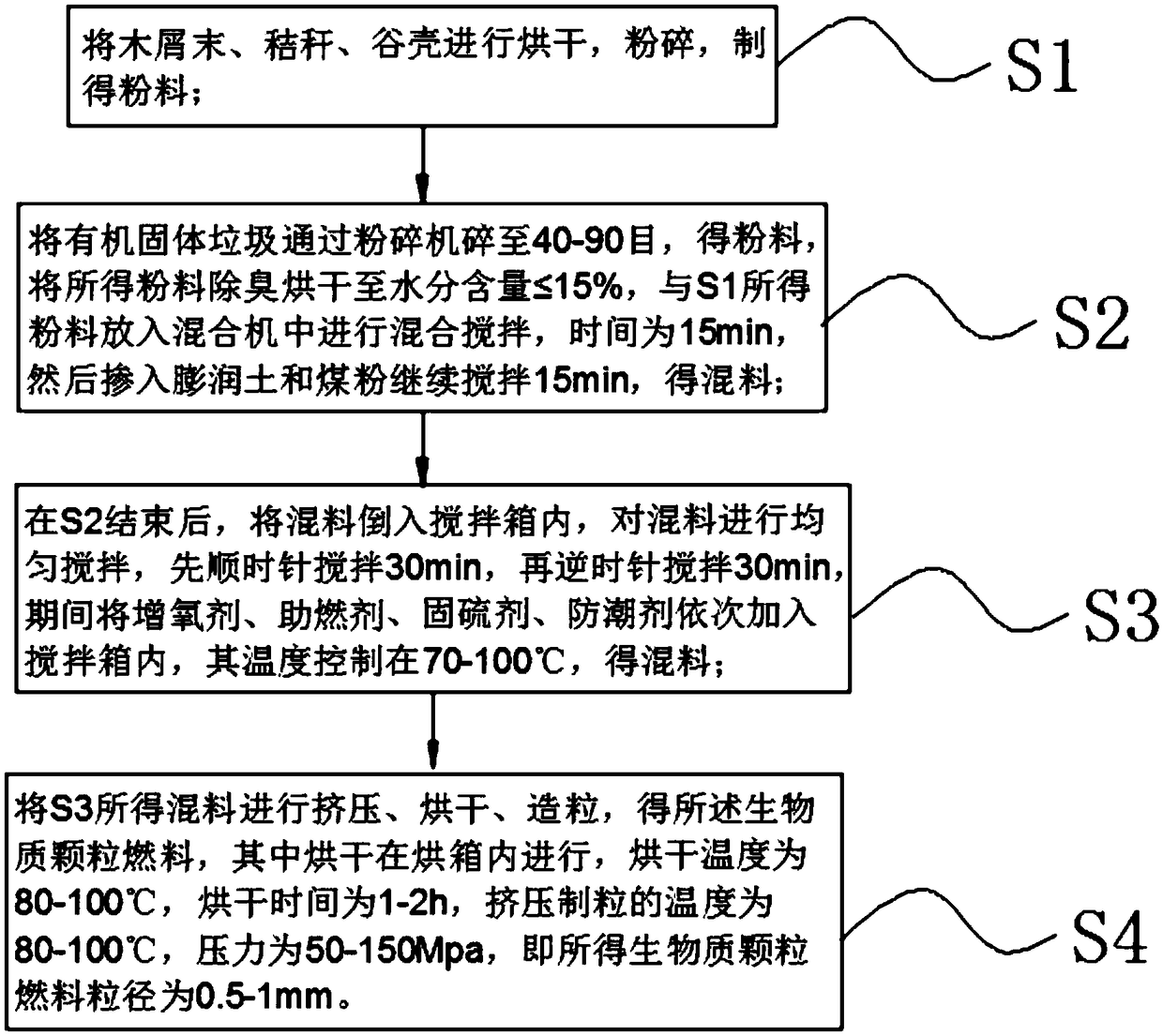

[0025] A biomass pellet fuel with high calorific value, comprising the following components in parts by weight: 30-50 parts of wood chips, 20-40 parts of straw, 20-40 parts of chaff, 5-10 parts of organic solid waste, and bentonite 1-5 parts, 5-20 parts of pulverized coal, 0.1-1 parts of oxygen enhancer, 2-5 parts of combustion enhancer, 2-7 parts of sulfur-fixing agent, and 1-5 parts of moisture-proof agent.

[0026] Further, the sawdust is mixed with one or more of pine sawdust, miscellaneous wood sawdust, larch sawdust, poplar sawdust and willow sawdust.

[0027] Still further, the straw is mixed with one or more of wheat straw powder, corn straw powder or sunflower straw powder.

[0028] Still further, the rice husk is mixed with one or more of rice husks, bean husks, peanut husks and the like.

[0029] Still further, the sulfur-fixing agent is selected from one or more mixtures of quicklime and calcium carbonate.

[0030] Further, the moisture-proofing agent is composed...

Embodiment 2

[0038] A biomass pellet fuel with high calorific value, comprising the following components in parts by weight: 35-45 parts of wood chips, 25-35 parts of straw, 25-35 parts of chaff, 6-8 parts of organic solid waste, and bentonite 2-4 parts, 10-15 parts of pulverized coal, 0.4-0.8 parts of oxygen enhancer, 3-4 parts of combustion enhancer, 4-6 parts of sulfur-fixing agent, and 2-4 parts of moisture-proof agent.

[0039] Further, the sawdust is mixed with one or more of pine sawdust, miscellaneous wood sawdust, larch sawdust, poplar sawdust and willow sawdust.

[0040] Still further, the straw is mixed with one or more of wheat straw powder, corn straw powder or sunflower straw powder.

[0041] Still further, the rice husk is mixed with one or more of rice husks, bean husks, peanut husks and the like.

[0042] Still further, the sulfur-fixing agent is selected from one or more mixtures of quicklime and calcium carbonate.

[0043]Further, the moisture-proofing agent is compose...

Embodiment 3

[0051] A biomass pellet fuel with high calorific value, comprising the following components in parts by weight: 40 parts of wood chips, 30 parts of straw, 30 parts of chaff, 7 parts of organic solid waste, 3 parts of bentonite, 12 parts of pulverized coal, 0.5 parts of oxygen enhancer, 3 parts of combustion enhancer, 5 parts of sulfur-fixing agent, and 3 parts of moisture-proof agent.

[0052] Further, the sawdust is mixed with one or more of pine sawdust, miscellaneous wood sawdust, larch sawdust, poplar sawdust and willow sawdust.

[0053] Still further, the straw is mixed with one or more of wheat straw powder, corn straw powder or sunflower straw powder.

[0054] Still further, the rice husk is mixed with one or more of rice husks, bean husks, peanut husks and the like.

[0055] Still further, the sulfur-fixing agent is selected from one or more mixtures of quicklime and calcium carbonate.

[0056] Further, the moisture-proofing agent is composed by weight parts: 15 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com