Preparation method of moisture-proof high-energy biomass granular fuel

A biomass particle and fuel technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems that biomass particles are susceptible to moisture, affect the combustion effect, and mildew, so as to avoid moisture, avoid combustion heat value difference, Good for storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

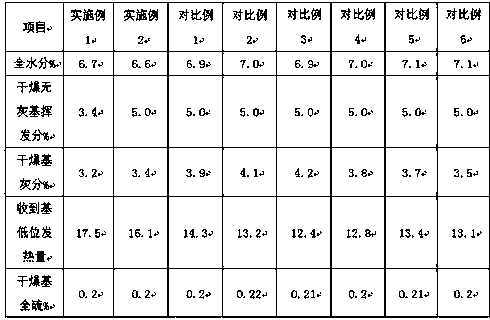

Examples

Embodiment 1

[0021] The present invention is achieved through the following technical solutions:

[0022] Step 1. Hydrothermal treatment of modified activated sludge:

[0023] In parts by weight, water was added to 93 parts of modified activated sludge to make the water content 71.2%, and 138 parts of plant straw powder and 5.4 parts of sodium ethylenediamine di-o-phenyl macroacetate were pulverized to 400 mesh, Grind 31 parts of charcoal slag powder to 300 meshes, prepare 20 parts of edible alkaline water with a mass fraction of 5% for later use; mix the crushed plant straw powder and ethylenediamine di-o-phenyl macroacetate mixture with edible alkaline water evenly , to obtain mixture A after stacking for 10 hours; mix mixture A with the obtained modified activated sludge, charcoal slag powder, and active agent evenly, and then heat it in a microwave hydrothermal kettle at 200°C for 1.5~2 hours while stirring, and then cool down. After reaching 105°C, keep warm for another 0.8h, and obt...

Embodiment 2

[0034] The present invention is achieved through the following technical solutions:

[0035] Step 1. Hydrothermal treatment of modified activated sludge:

[0036] In parts by weight, water was added to 82 parts of modified activated sludge to make its moisture content 67.3%, and 115 parts of plant straw powder and 2.1 parts of sodium ethylenediamine di-o-phenyl macroacetate were pulverized to 400 mesh, Grind 22 parts of charcoal slag powder to 300 mesh, and prepare 15 parts of edible alkaline water with a mass fraction of 2% for later use; mix the crushed plant straw powder and ethylenediamine di-o-phenyl macroacetate mixture with edible alkaline water evenly , to obtain mixture A after stacking for 6 hours; mix mixture A with the obtained modified activated sludge, charcoal slag powder, and active agent, and then heat it at 180°C in a microwave hydrothermal kettle for 1.5 hours while stirring, and then cool it down. After 100°C, keep warm for 0.8h, and after cooling, obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com