High-pressure direct injection type double-layer fine mist spray head

A fine water mist, double-layer technology, applied in fire rescue and other directions, can solve the problems of limited coverage, short spray distance, unsatisfactory effect, etc., and achieve the effect of improved atomization range, uniform distribution, and good atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

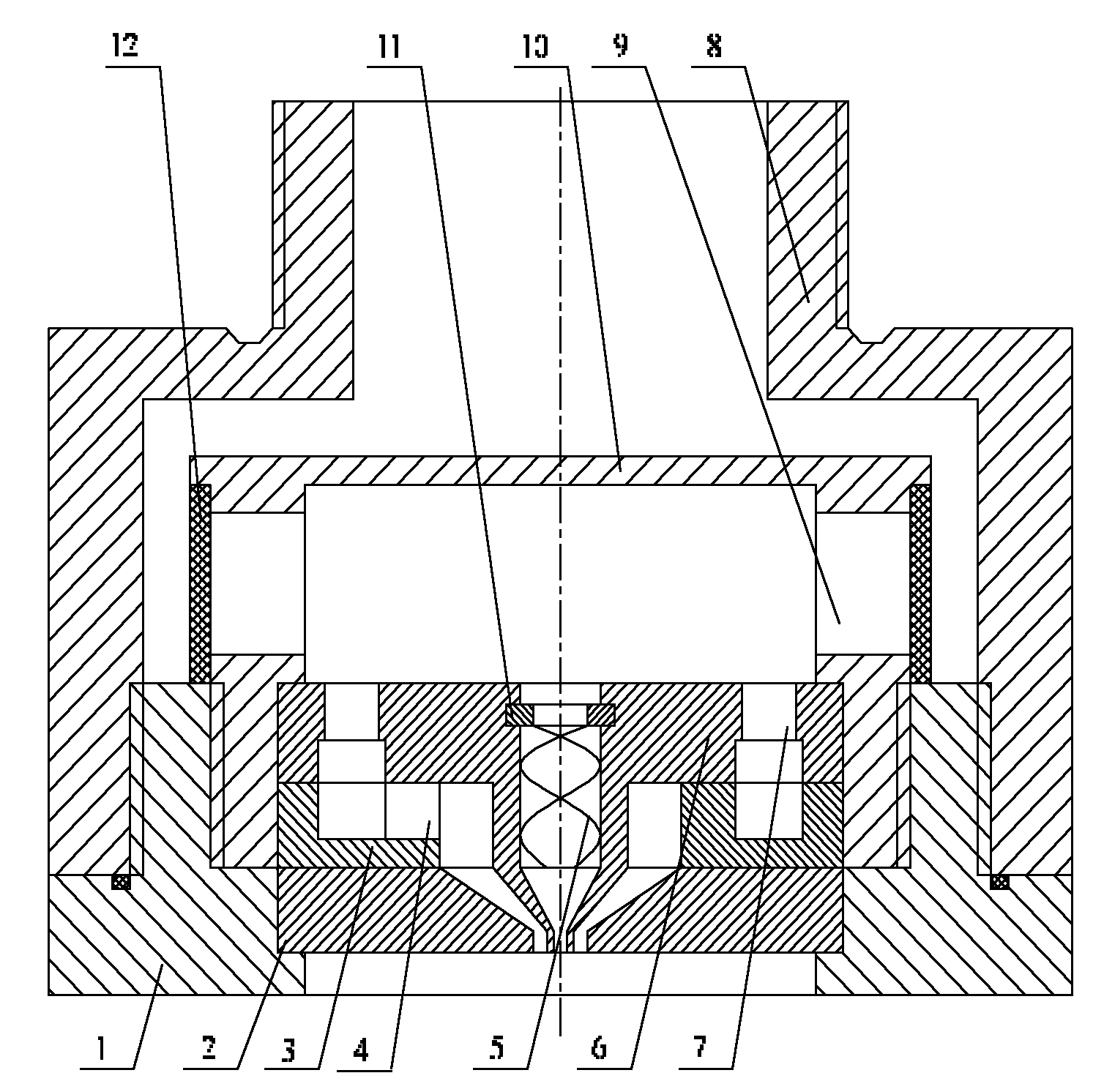

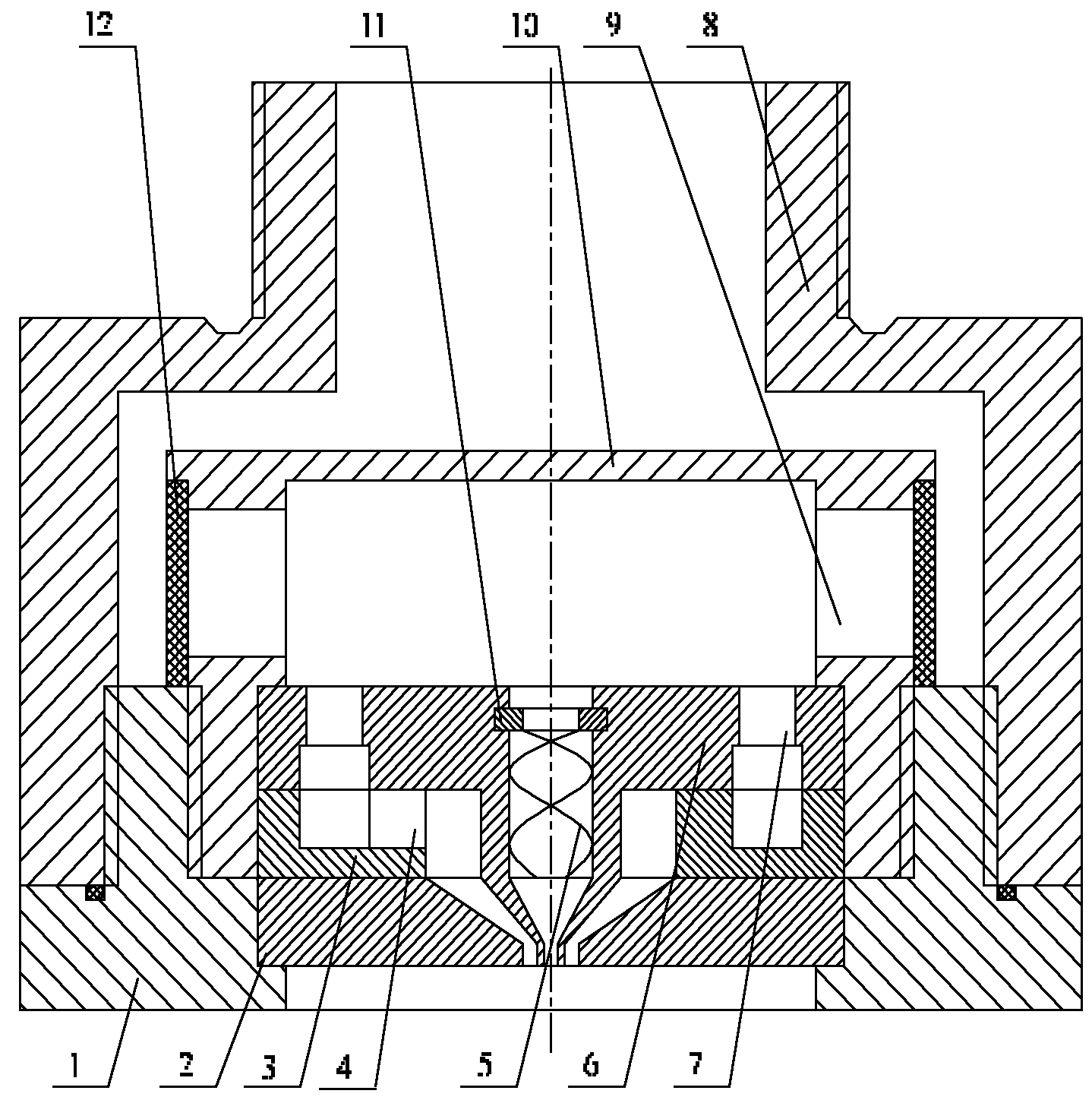

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

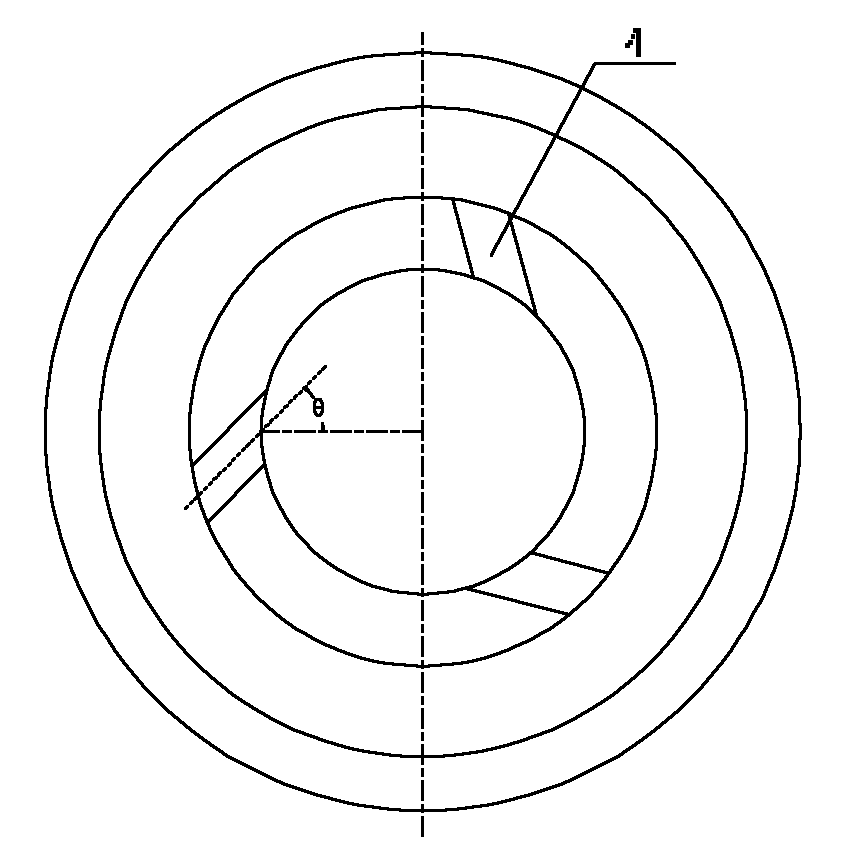

[0018] combine figure 1 with figure 2 . The present invention is mainly composed of a nozzle cap 1, an atomizing sheet 2, a swirl sheet 3, a diversion column 5, a diverter sheet 6, a nozzle seat 8, a filter cylinder 10, a snap ring 11, a filter screen 12, and the like. One end of the nozzle seat 8 water inlet is tapped with an external thread, which can be connected with a spray gun or a water inlet pipe, and the other end is tapped with an internal thread, which can be connected with the shower cap 1. The nozzle cap 1 is tapped with internal and external threads at the same time, and is connected with the nozzle seat 8 and the filter cylinder 10 respectively. The atomizing sheet 2, the swirl sheet 3 and the diverter sheet 6 are placed on the nozzle cap 1 in sequence, and the other side is fixed by the filter cylinder flange. There is a ring groove on the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com