Air-purification, humidifying, self-cleaning, antimicrobial and healthy shell powder biomass dry powder coating

A dry powder coating and air purification technology, applied in the field of air purification, humidity control and self-cleaning, antibacterial and healthy shell powder biomass dry powder coating, can solve the problem of poor water resistance, coating adhesion, low water resistance, low natural corrosion resistance, and poor water resistance. It has the functions of active removal, adsorption and decomposition of harmful substances, insect repellent and deodorization, etc., to achieve the effect of increasing functional materials, removing pesticide residues, and benefiting human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

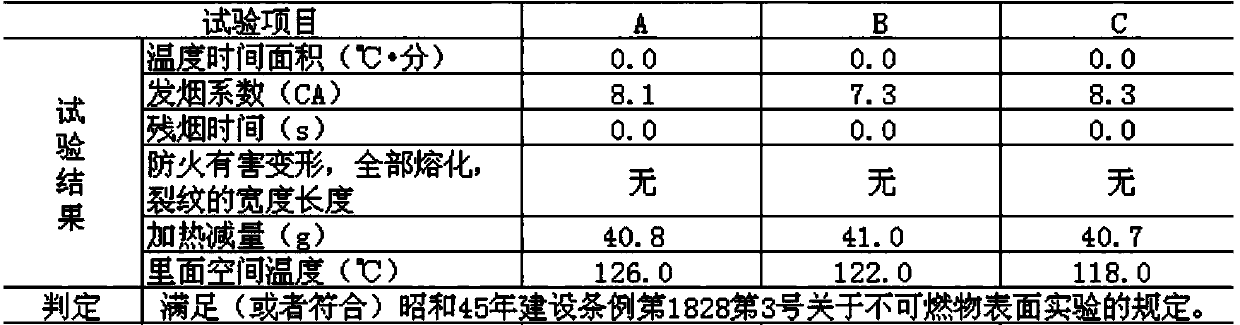

Image

Examples

Embodiment 1

[0044] The air purification, antibacterial and humidity-regulating, self-cleaning shell powder healthy biomass dry powder coating of the present invention includes nano-scale medical king stone anion powder and shell powder, and the raw material weight ratio of the biological dry powder coating is:

[0045] 25-40 parts of shell powder; 0.5-2.0 parts of nano-scale medical stone anion powder; 10-20 parts of titanium dioxide; 0.8-2.5 parts of solid defoamer; 0.5-10 parts of pigments and fillers; 7-13 parts of adhesive; 0.5-5.0 parts of cellulose ether; 0.5-1.5 parts of wetting and dispersing agent; 1.5-2.0 parts of dry film antifungal agent; 0.5-1.5 parts of auxiliary agent.

[0046] Wherein the weight ratio of each material in the adhesive is: 8-10 parts of sodium alginate, 15-18 parts of guar gum, 20-25 parts of carrageenan, 3-5 parts of sodium hexametaphosphate, 45-45 parts of water 53 copies. The cellulose ether is one or a mixture of methyl cellulose, carboxymethyl cellulos...

Embodiment 2

[0052] Embodiment two: it is basically the same as embodiment one, and its difference is:

[0053] A kind of biomass dry powder coating comprises nano-scale medical stone anion powder and shell powder, and the raw material weight ratio of described biological dry powder coating is:

[0054] 25-30 parts of shell powder; 0.5-0.7 parts of nano-scale medical stone anion powder; 10-15 parts of titanium dioxide; 0.8-1.5 parts of solid defoamer; 0.5-5 parts of pigments and fillers; 7-9 parts of adhesive; 0.5-3.0 parts of cellulose ether; 0.5-1.0 parts of wetting and dispersing agent; 1.5-1.8 parts of dry film antifungal agent; 0.5-0.9 parts of auxiliary agent.

Embodiment 3

[0055] Embodiment three: it is basically the same as embodiment one, and its difference is:

[0056] A kind of biomass dry powder coating comprises nano-scale medical stone anion powder and shell powder, and the raw material weight ratio of described biological dry powder coating is:

[0057] 35-40 parts of shell powder; 0.8-1.0 parts of nano-scale medical stone anion powder; 15-20 parts of titanium dioxide; 1.4-2.5 parts of solid defoamer; 5-10 parts of pigments and fillers; 9-13 parts of adhesive; 3.5-5.0 parts of cellulose ether; 1.0-1.5 parts of wetting and dispersing agent; 1.9-2.0 parts of dry film antifungal agent; 0.8-1.5 parts of additives.

[0058] For the above-mentioned embodiments 1-3, the present invention also provides a method for preparing air-purifying, antibacterial and humidity-adjusting, self-cleaning shell powder healthy biomass dry powder coatings. Specifically, the method includes:

[0059] Step S1, providing a shell, and preparing the shell to form sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com