Roofing materials

a technology of roofing and materials, applied in the direction of roads, traffic signals, transportation and packaging, etc., can solve the problems of increasing the cooling cost of the roofed structure, exposing the softened layer to foot traffic damage, and affecting so as to improve the reflectivity and improve the reflectivity of the roof and/or siding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

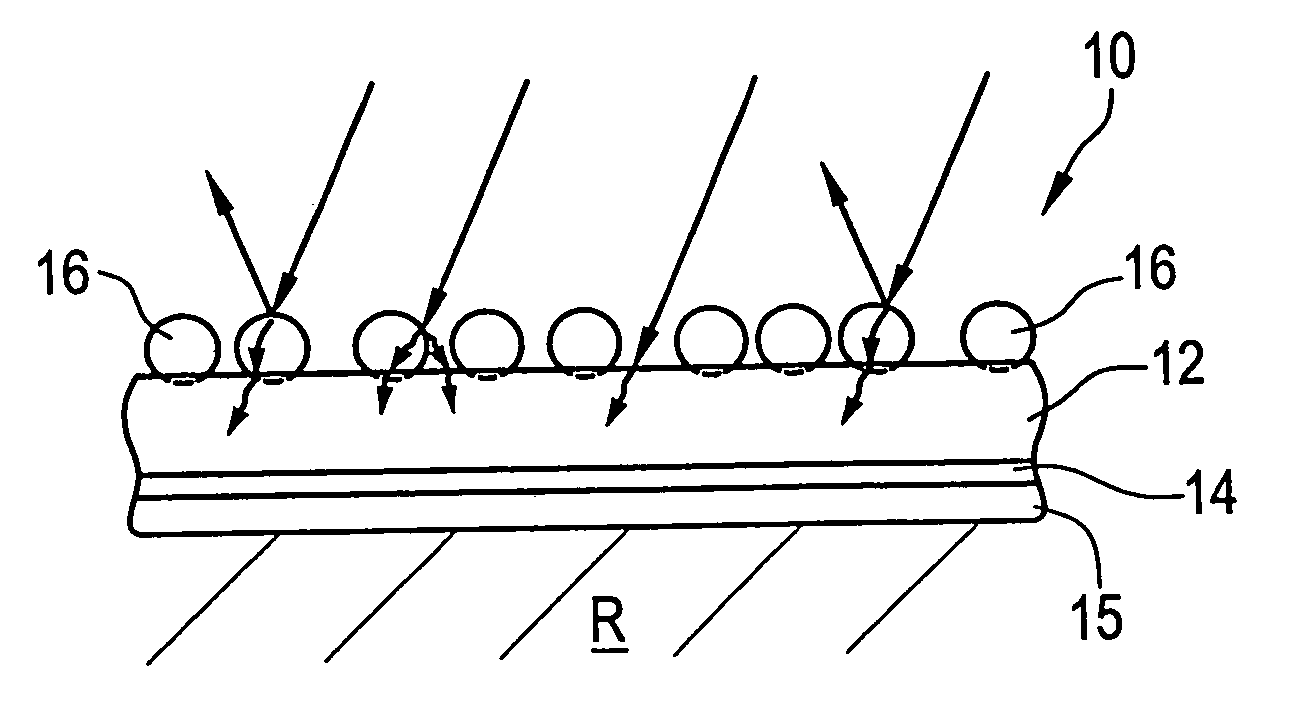

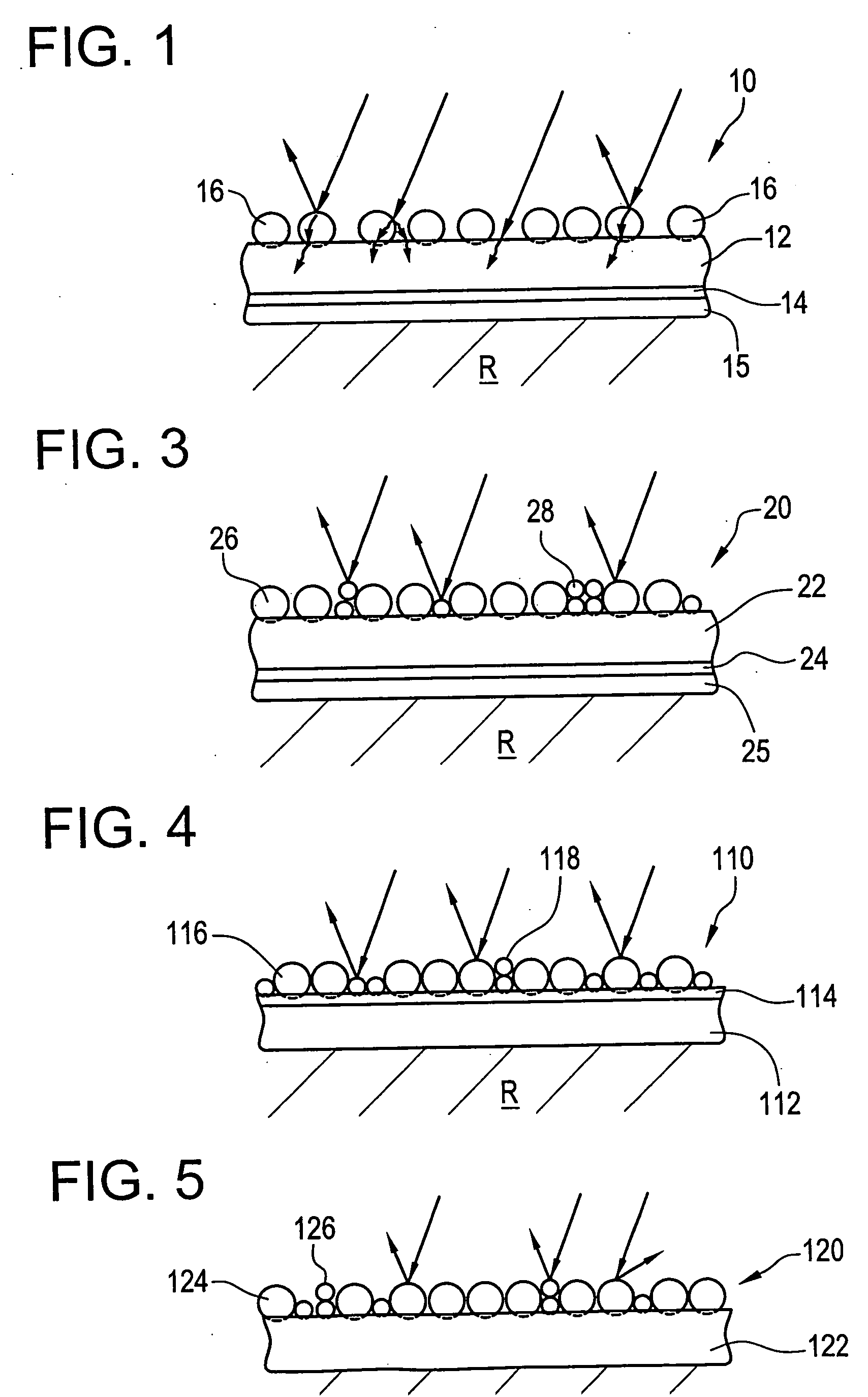

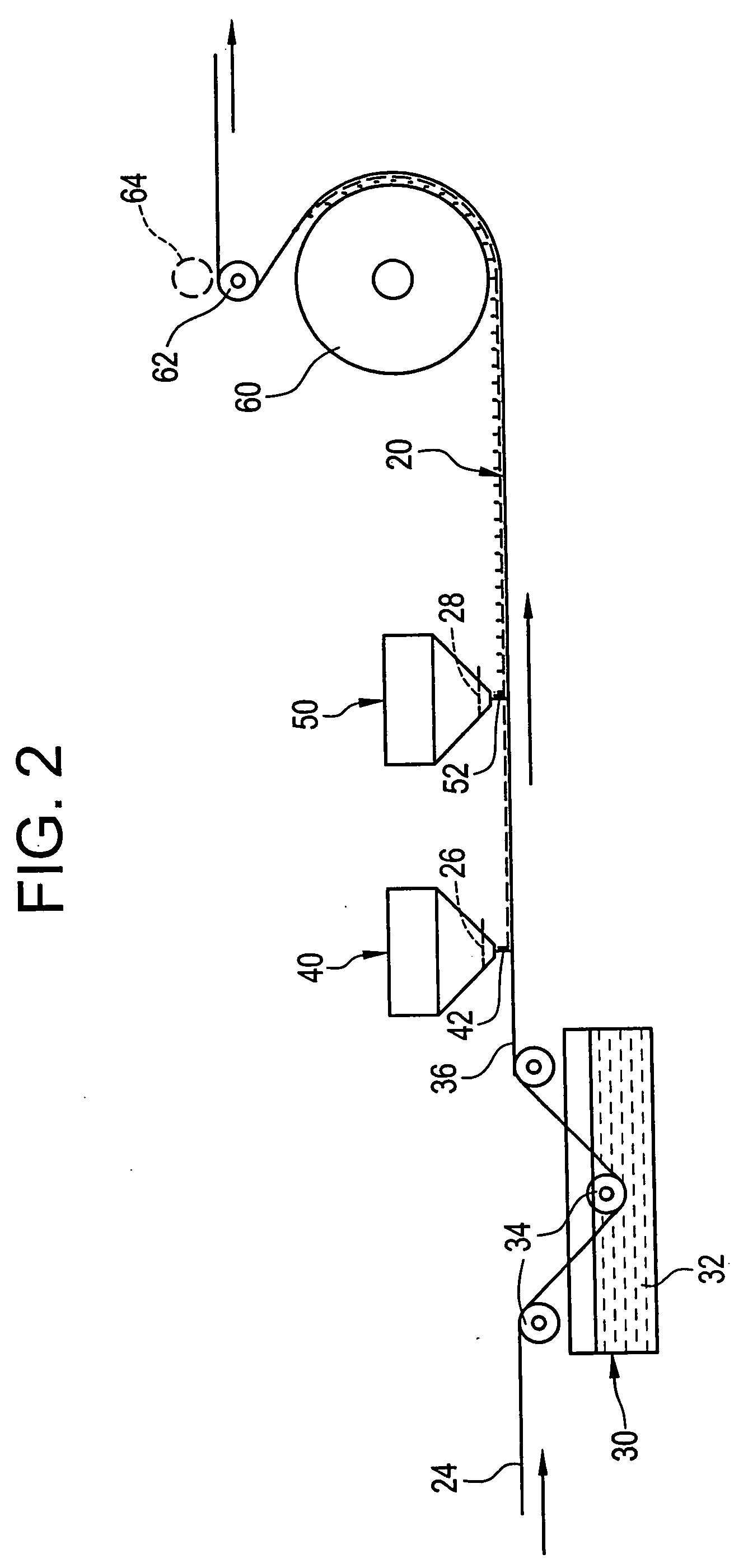

[0050] Referring now to the drawings wherein the showings are for the purpose of illustrating a preferred embodiment of the invention only and not for the purpose of limiting same, FIG. 1 illustrates a prior art roofing system 10. The roofing system 10 is secured to a roof, roof substrate (e.g., base sheets), or subroof R by any suitable arrangement. The roofing system 10 is a shingle that includes a bitumen- or asphalt-based material 12, 15, a reinforcement material 14 therebetween, and layer of granules 16. The reinforcement material 14 is typically a felt or fiberglass material that is commonly used in the art. The reinforcement material 14 is shown as being fully embedded in the bitumen- or asphalt-based material 12. The granules 16 are illustrated as being partially embedded and secured in the bitumen- or asphalt-based material 12. The granules are typical granules used in roofing materials. The granules are generally derived from a mineral base rock such as greenstone, greysto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| reflectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com