Blast furnace tuyere equipment and periphery furnace body lining corrosion state patrol system and method thereof

A patrol inspection system and blast furnace technology, applied in the field of metallurgy, can solve problems such as easy burning, steam explosion, molten iron outflow production accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

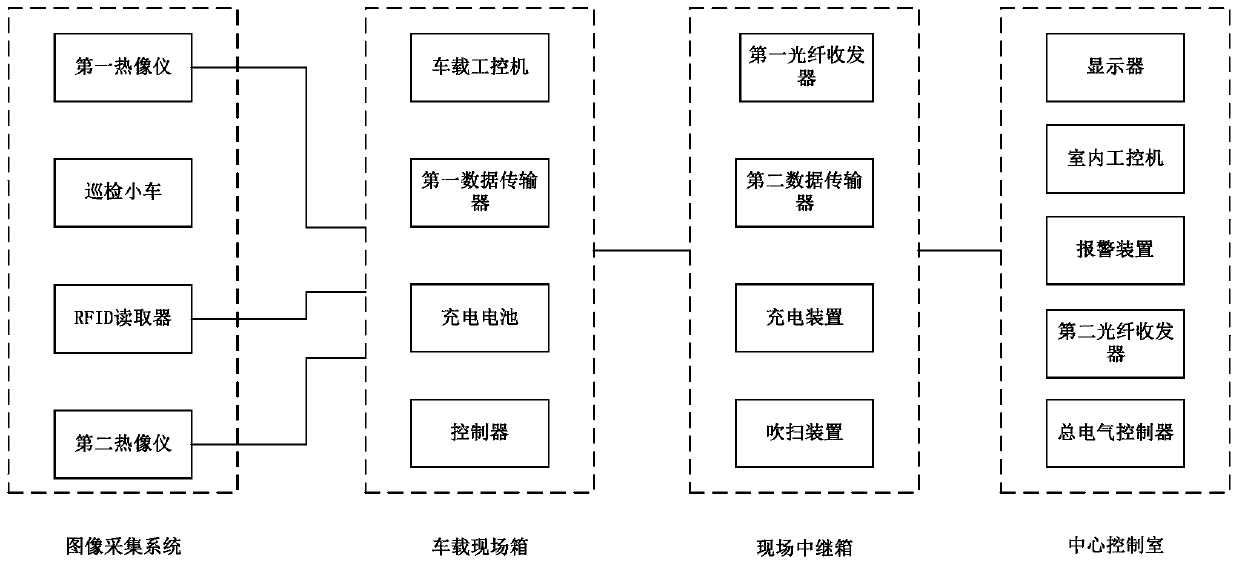

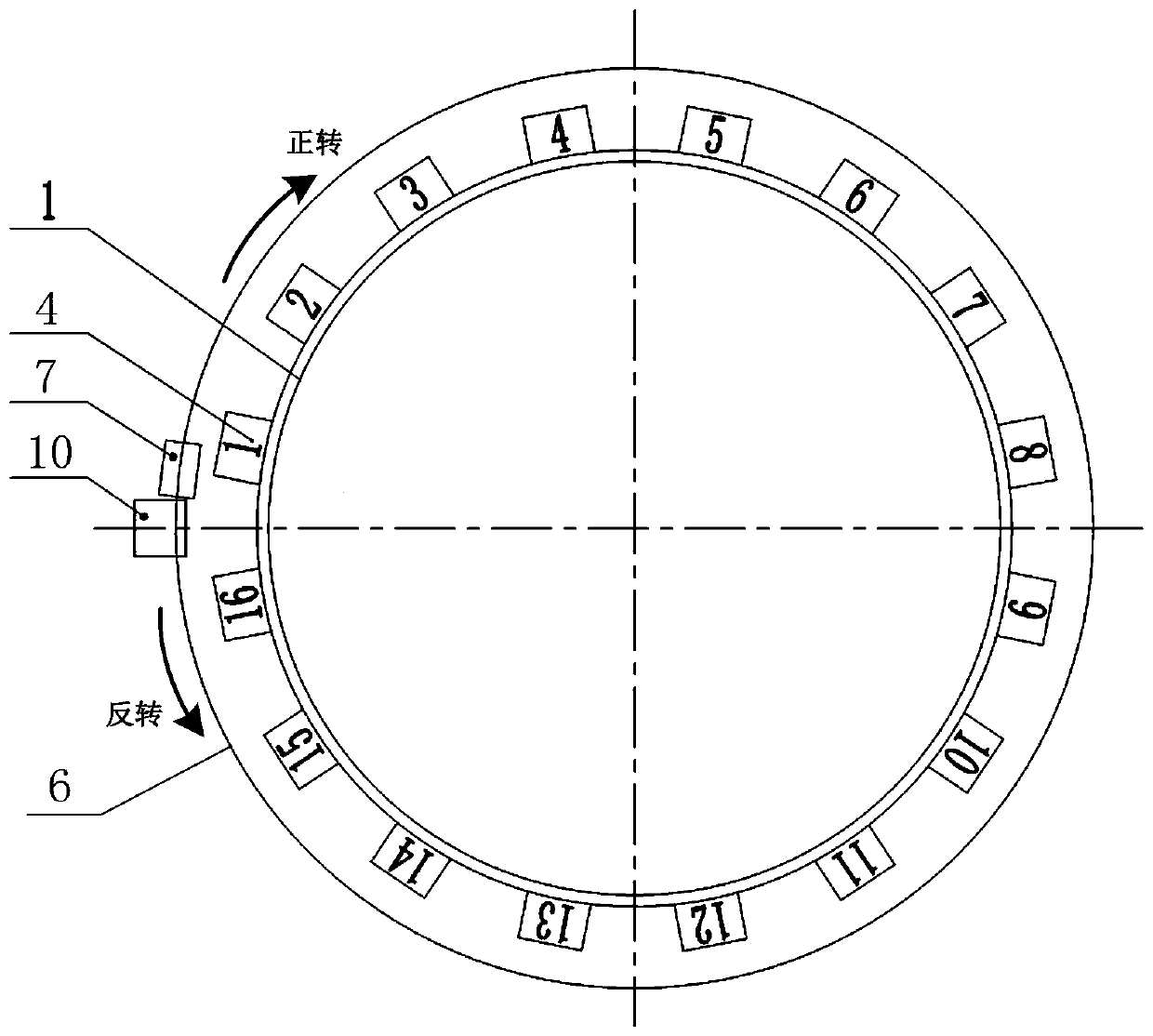

[0033] like figure 1 Shown is a blast furnace body with 16 tuyere devices 4 installed on the tuyere device and its surrounding furnace lining erosion status inspection system, including an image acquisition system and an image processing system.

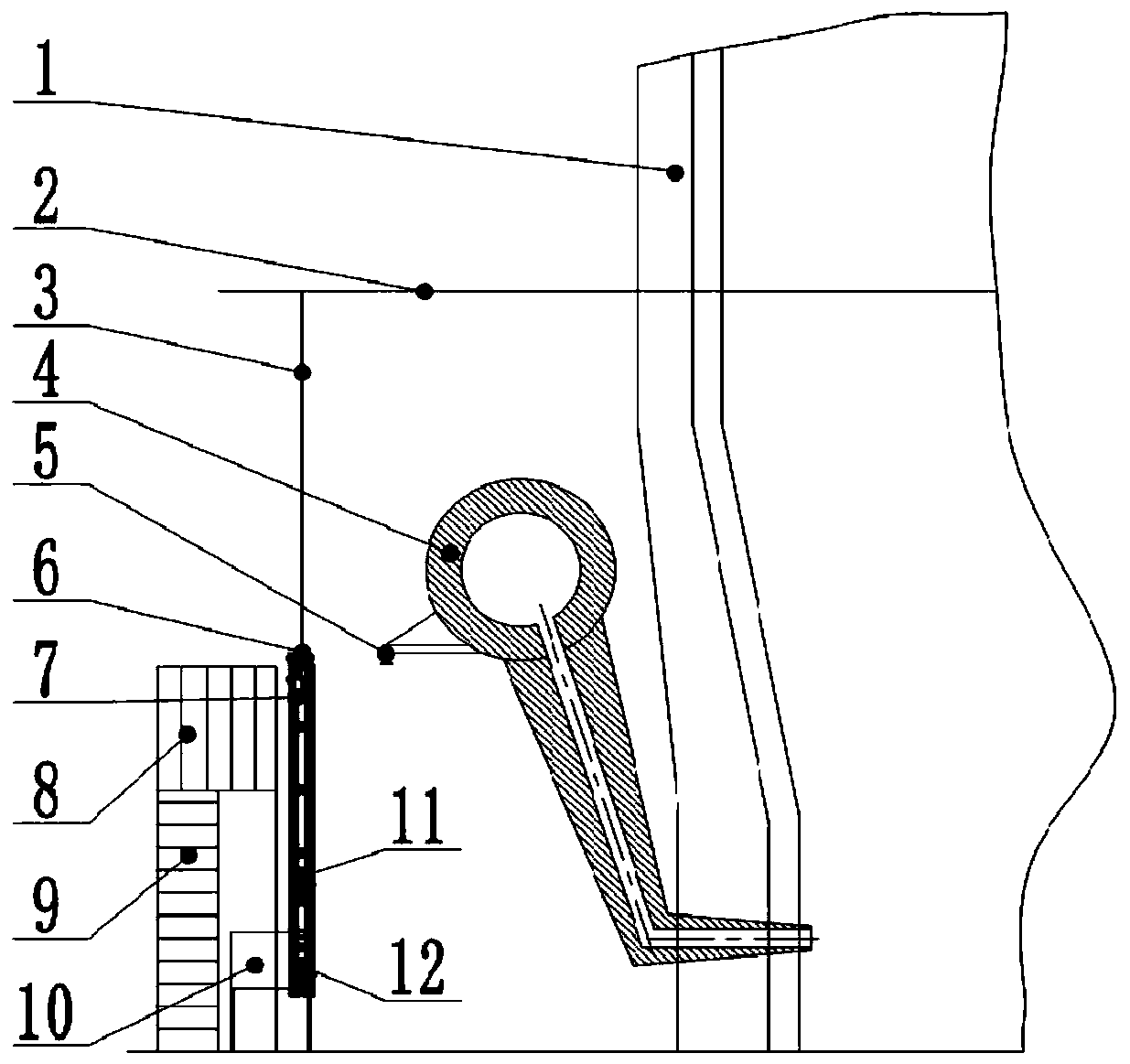

[0034] The image acquisition system is set on the blast furnace operation site, which includes image acquisition equipment, inspection trolley 7, circular track 6 and on-site relay box 10 arranged on the circular track 6; wherein,

[0035]The circular track 6 is arranged on the outer periphery of the blast furnace body 1 along the circumferential direction of the blast furnace body 1; the inspection trolley 7 is arranged on the circular track 6 and runs clockwise or counterclockwise along the circular track 6; On the ceiling 2 of the tuyere platform above the tuyere device 4, a plurality of ring track supports 3 are arranged at intervals along the circumferential direction, so that the ring track 6 is fixed on the bottom of the plura...

Embodiment 2

[0046] A method for detecting the erosion state of the blast furnace lining realized by using the blast furnace tuyere equipment 4 and its surrounding furnace lining erosion state inspection system in the above embodiment 1, the steps are as follows:

[0047] S1. The inspection trolley 7 travels at a constant speed along the circular track 6, and adopts the same interval time to obtain the infrared thermal images collected by the thermal imager in real time; wherein, the interval time for obtaining the infrared thermal images satisfies the requirements of two consecutive images collected by the same thermal imager. There is a slight overlap between the images of the infrared thermography of the furnace body;

[0048] At the same time, during the operation of the inspection trolley 7 along the circular track 6, the RFID reader on it sequentially reads the RFID electronic tags set on each blast furnace tuyere device, and records the corresponding RFID tags. The reading time of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com