Box body lining type mudslide discharging and guiding groove and application and construction method thereof

A technology for draining guide troughs and debris flow, which is applied in botany equipment and methods, water conservancy projects, artificial waterways, etc. It can solve problems such as high maintenance costs, damage to the bottom of guide troughs, and failure to use normally, so as to reduce later maintenance The cost, the post-maintenance cost reduction, and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

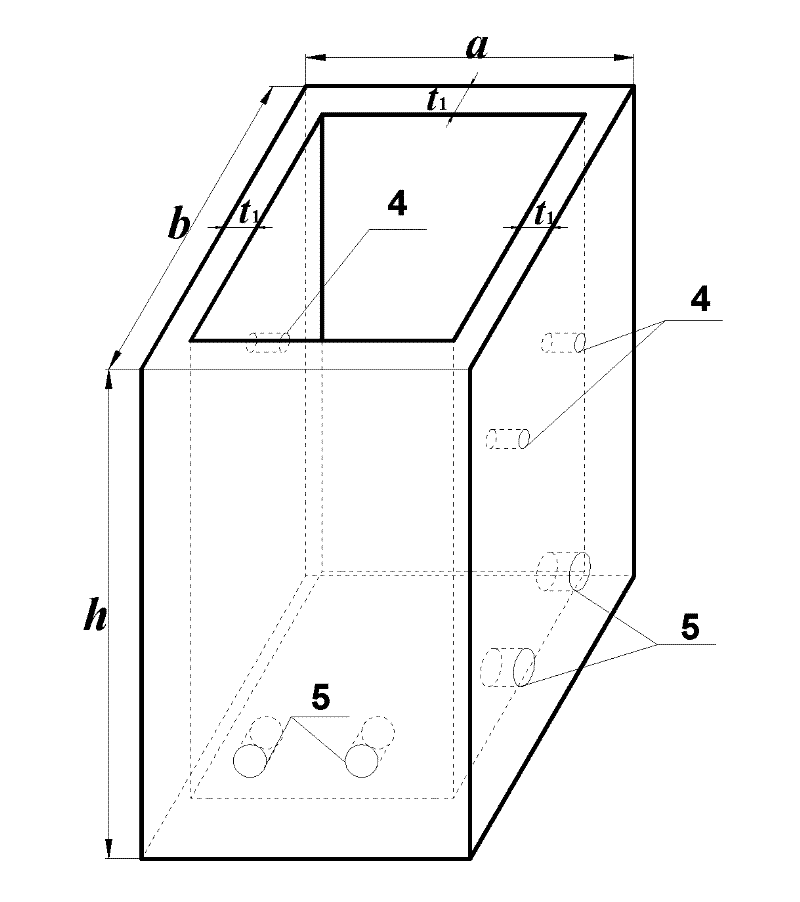

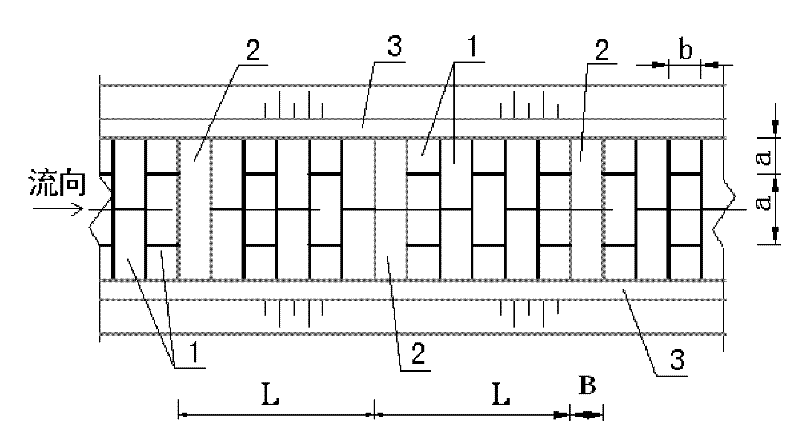

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 shown. The drainage area of a debris flow ditch is 1.5km 2 , in order to control debris flow disasters, it is planned to set up 5 Gufang, 2 sand dams and 400m drainage channels in the middle of the basin. For the row guide groove, the following construction methods are adopted:

[0033] The first step is to plan and design a debris flow drainage channel with a width of 5.0m at the bottom of the channel and a vertical gradient i of 0.50 according to the situation of the debris flow channel. Since the vertical slope i≥0.15 of the row of guide grooves, it is planned to adopt the box-lined debris flow drainage groove of the present invention. The box-lined debris flow drainage channel includes the bottom of the drainage channel and the side walls 3 of the drainage channel on both sides. There are several levels of energy-dissipating sills distributed in steps in between, and each level of energy-dissipating sills ...

Embodiment 2

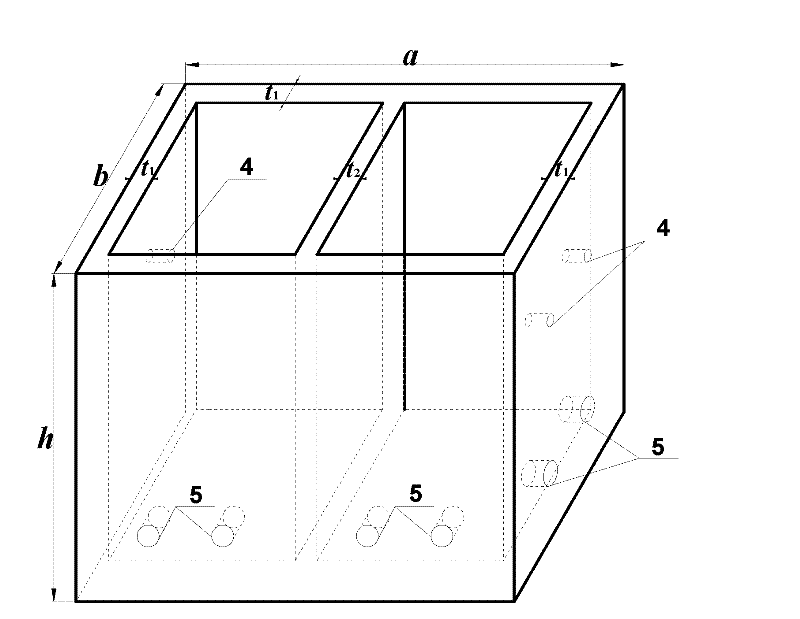

[0042] Such as figure 1 , figure 2 , image 3 , Figure 4 shown. The same as Embodiment 1 will not be repeated, the difference is: for the debris flow ditch drainage area 5.6km 2 , it is planned to set up 12 valley squares, 6 sand retaining dams and 800m drainage channels in the middle of the basin. For the row guide groove, the following construction methods are adopted:

[0043] The first step is to plan and design a debris flow drainage channel with a bottom width of 7.5m and a vertical gradient i of 0.15 according to the conditions of the debris flow ditch.

[0044] According to the vertical gradient i of the trench bed at the bottom of the trench, the parameters of rib sill 2 are planned: the distance L between the upstream and downstream rib sill 2 is 20m, the foundation depth H of rib sill 2 is 2.5m, and the width B of rib sill 2 along the longitudinal slope is 2.0 m; rib sill 2 is a reinforced concrete structure with a reinforcement ratio of 0.5%; the top 0.1m o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com