Water-bottom mine shield tunnel combination butt joint structural form and construction method thereof

A technology of shield tunneling and structural forms, applied in tunnels, tunnel linings, mining equipment, etc., can solve the problems of inflexible construction organization, high construction period requirements, and affecting project progress, etc., and achieve good control of stratum deformation and structural stability. The effect of reducing the amount of abandoned projects and saving project costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

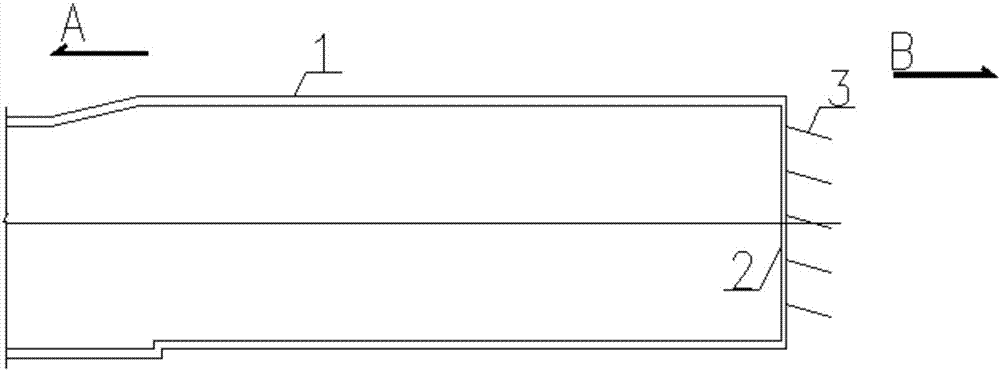

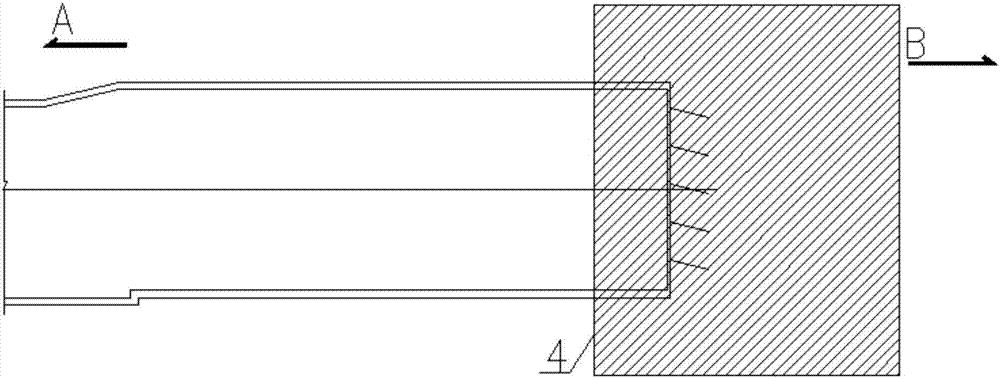

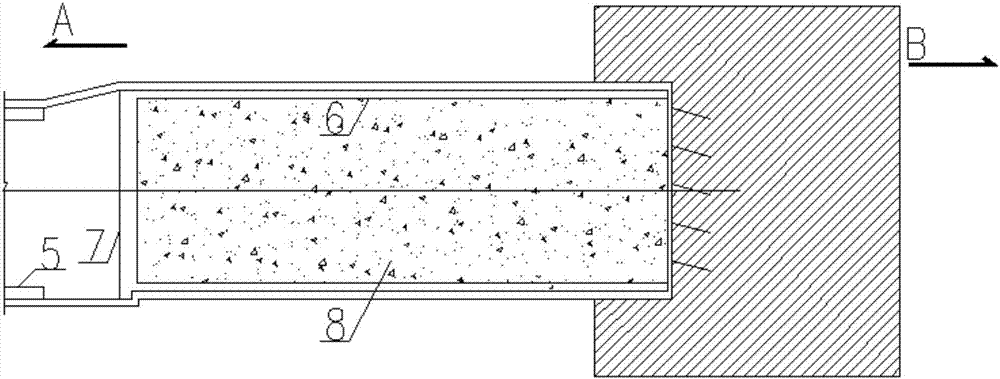

[0042] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those skilled in the art, other drawings can also be obtained according to these drawings without any creative effort.

[0043] see as figure 1 —— Figure 7 As shown, a combined docking structure form of an underwater mine shield tunnel, which includes a mine section and a shield section, one end of the mine section is provided with a shield section; the mine section includes the initial support of the tunnel in the receiving section, the plug wall , Reinforcement of bolts, reinforcement of receiving stratum, secondary lining of mine tunnel, tunnel box lining of receiving section, box lining end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com