Terminal batch assembler for wire harness

A terminal and batch technology, applied in circuit/collector parts, electrical components, circuits, etc., can solve problems such as troublesome and laborious operation, and achieve the effect of easy operation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

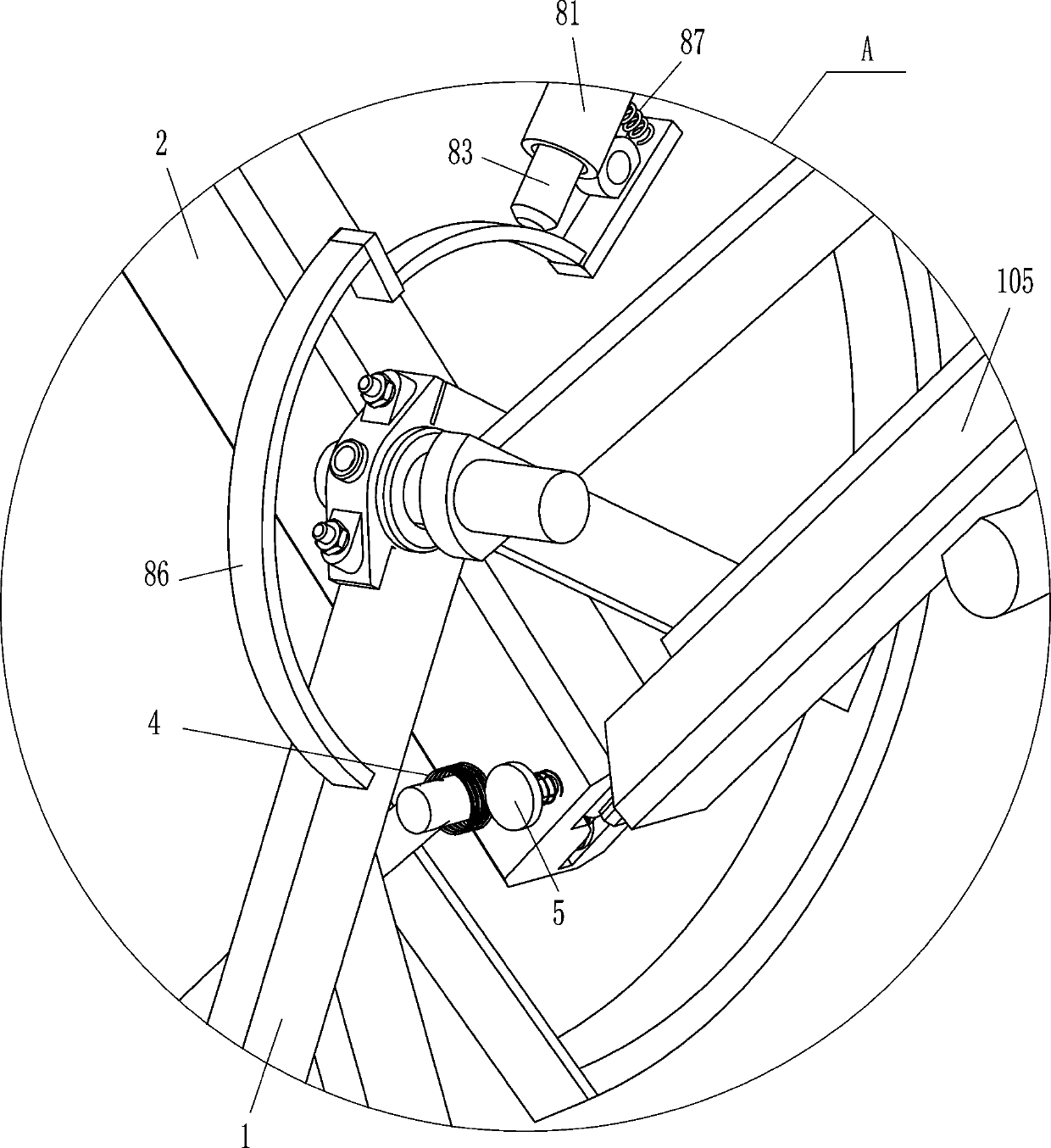

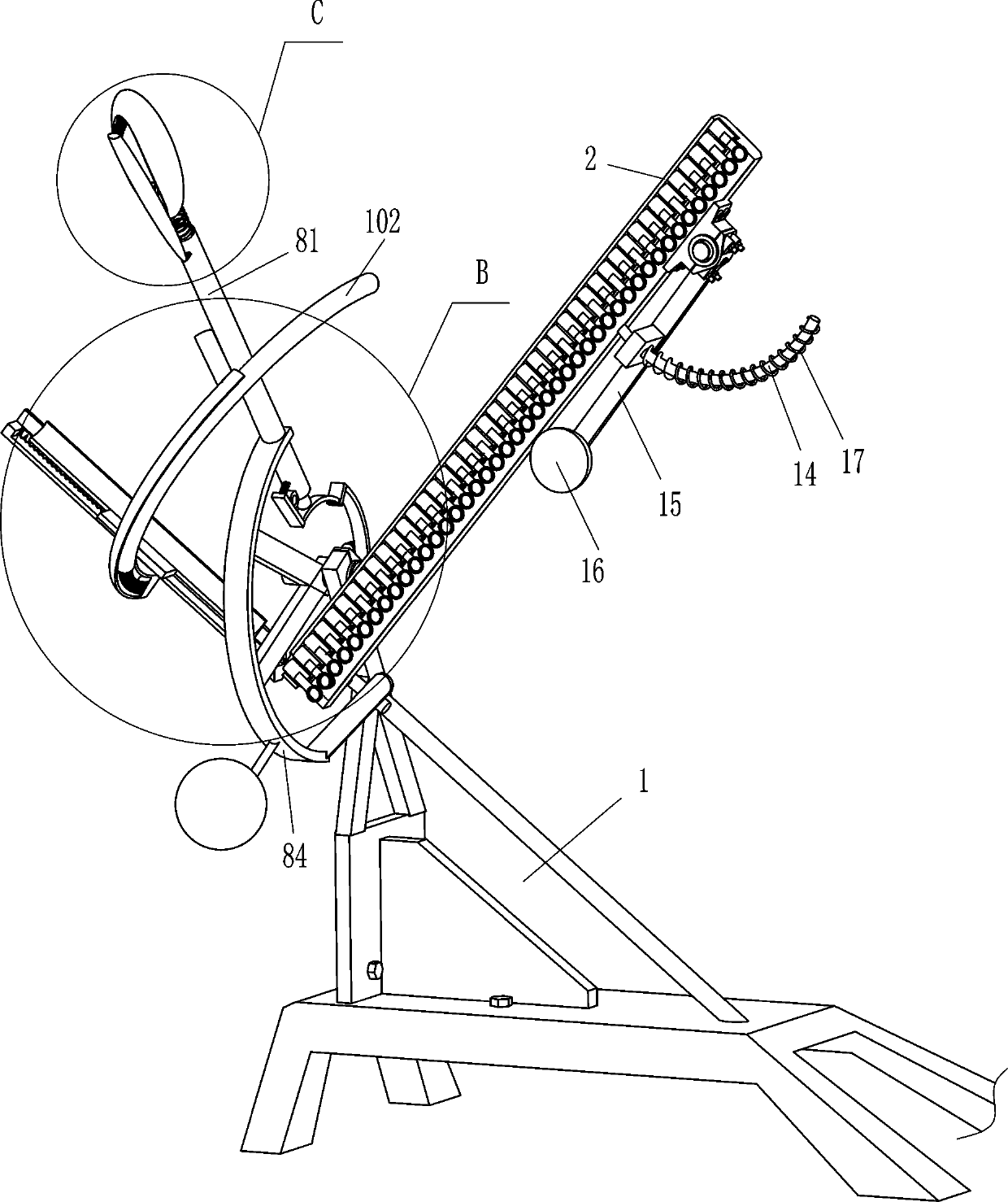

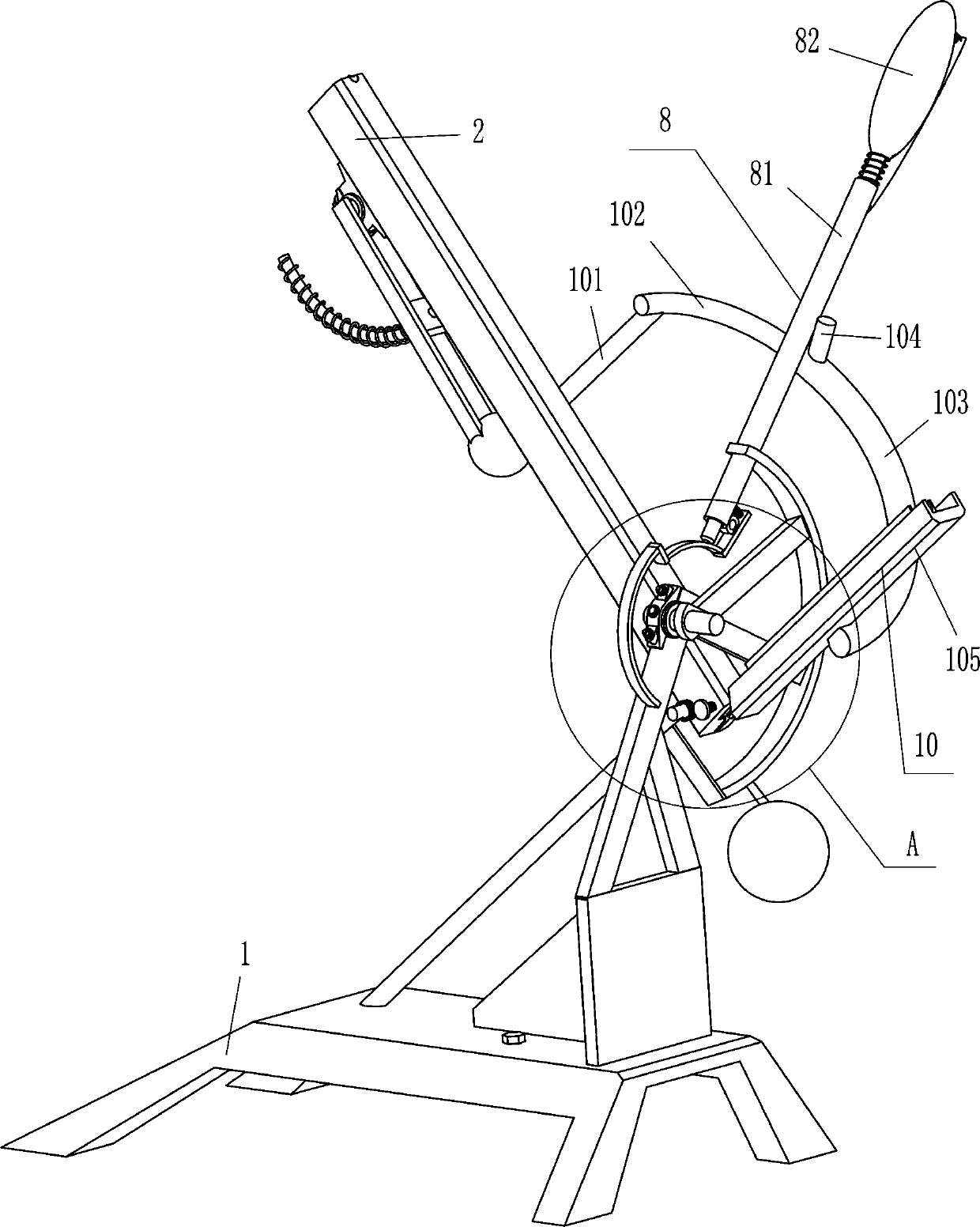

[0022] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 6 , a terminal batch assembler for wire harnesses, including a bracket 1, a placement frame 2, an L-shaped clamping rod 3, a first spring 4, a contact rod 5, a rolling head 6, a second spring 7, a driving mechanism 8 and a blocking mechanism 9. The upper part of the rear side of the bracket 1 is fixedly connected with a placement frame 2 for placing terminals. The bottom of the placement frame 2 is provided with a blocking mechanism 9 that can block the terminals. The L-shaped clamping rod 3, the first spring 4 is wound between the front part of the L-shaped clamping rod 3 and the outer front side of the placement frame 2, and the lower part of the front side of the placement frame 2 is slidingly provided with a contact rod 5, and the contact rod 5 is located at On the right side of the L-shaped clamping rod 3, a second spring 7 is wound between the inner front side of the contact rod 5 and the outer front ...

Embodiment 2

[0029] see figure 1 , figure 2 , Figure 4 and Figure 5 , a terminal batch assembler for wire harnesses. Compared with Embodiment 1, the main difference between this embodiment and this embodiment is that it also includes a placement mechanism 10. The placement mechanism 10 includes a fixed rod 101, an arc rod 102, an arc Sleeve 103, blocking rod 104, frame body 105, sliding frame 106, fifth spring 107 and sixth spring 108, a fixed rod 101 is affixed to the middle of the outer top of the placement frame 2, and an arc rod 102 is affixed to the right end of the fixed rod 101 The lower part of the arc rod 102 is slidingly provided with an arc sleeve 103, a sixth spring 108 is connected between the inner bottom of the arc sleeve 103 and the bottom end of the arc rod 102, and the outer side of the lower part of the arc sleeve 103 is fixedly connected with Frame body 105, the bottom end of frame body 105 is positioned at blocking mechanism 9 right sides, is provided with slidin...

Embodiment 3

[0032] see figure 1 , figure 2 and Figure 6 , a terminal batch assembler for wire harnesses. Compared with Embodiment 1 and Embodiment 2, the main difference of this embodiment is that this embodiment also includes a movable rod 11, a seventh spring 12, an insertion rod 131, and a grip rod 82 The middle part of the rear side is hinged with a movable rod 11, the seventh spring 12 is connected between the upper part of the front side of the movable rod 11 and the inner front side of the grip bar 82, and the lower part of the front side of the movable rod 11 is fixedly connected with an insertion rod 131, and the outer rear side of the hollow cylinder 81 The upper part is provided with a slot 13 for matching with the insertion rod 131 , and the insertion rod 131 is located in the slot 13 .

[0033] Also comprise arc guide rod 14, sliding frame 15, spheroid 16 and the 8th spring 17, place frame 2 outer left side surface top hinged with sliding frame 15, sliding frame 15 bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com