A performance testing system for connecting rod big-end needle roller bearings

A needle roller bearing and detection system technology, which is applied in the direction of mechanical bearing testing, etc., can solve problems such as difficult detection, outer ring offset, accuracy of measurement results, and product assembly effects, so as to improve instability and comprehensive detection results precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

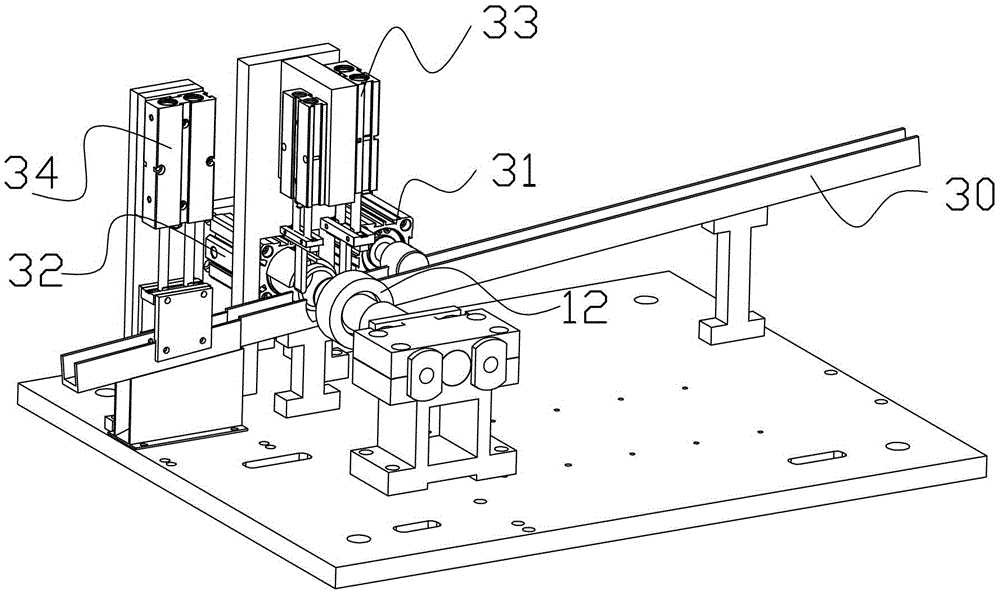

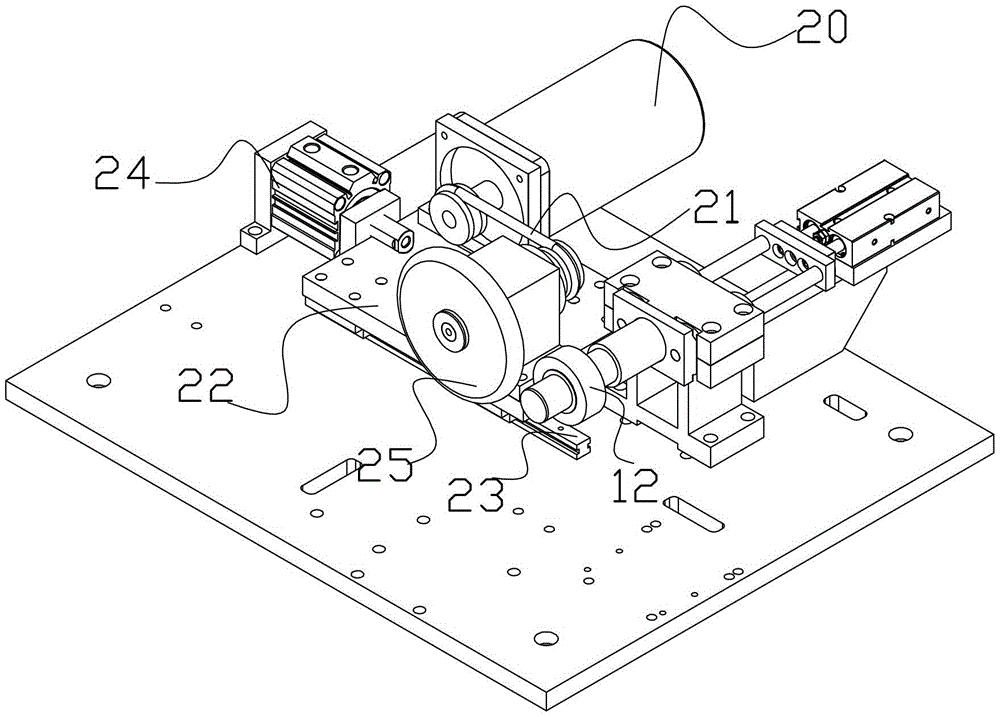

[0019] In conjunction with the accompanying drawings, a performance testing system for connecting rod big-end needle roller bearings of the present invention is mainly aimed at the performance testing of needle roller bearings without inner and outer rings. It forms a bearing testing sleeve 12 by putting the needle bearings in the testing inertia wheel , suspend it on the detection mandrel 11, use the detection inertia wheel as its outer ring, use the detection mandrel 11 as its inner ring, and use the motion information of the bearing detection sleeve 12 to indirectly obtain the information of the needle roller bearing, To achieve the purpose of performance testing.

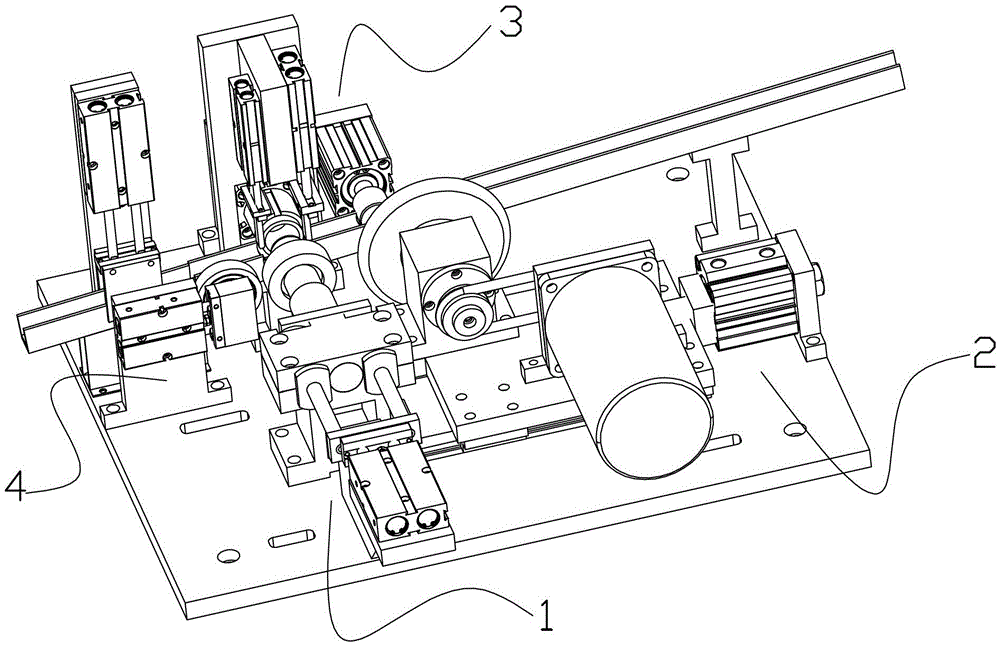

[0020] Refer to attached figure 1 , the detection system mainly includes a bearing access mechanism 3, an inertia wheel drive mechanism 2, a bearing detection mechanism 1, a data acquisition and processing device and an inertia wheel brake mechanism 4, except that the data acquisition and processing device can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com