Female mold anti-sticking structure

A master mold and male mold technology, applied in the field of master mold anti-sticking structure, can solve the problems of affecting product assembly, reducing efficiency, and high cost, and achieve the effect of preventing products from sticking to the master mold, improving efficiency and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

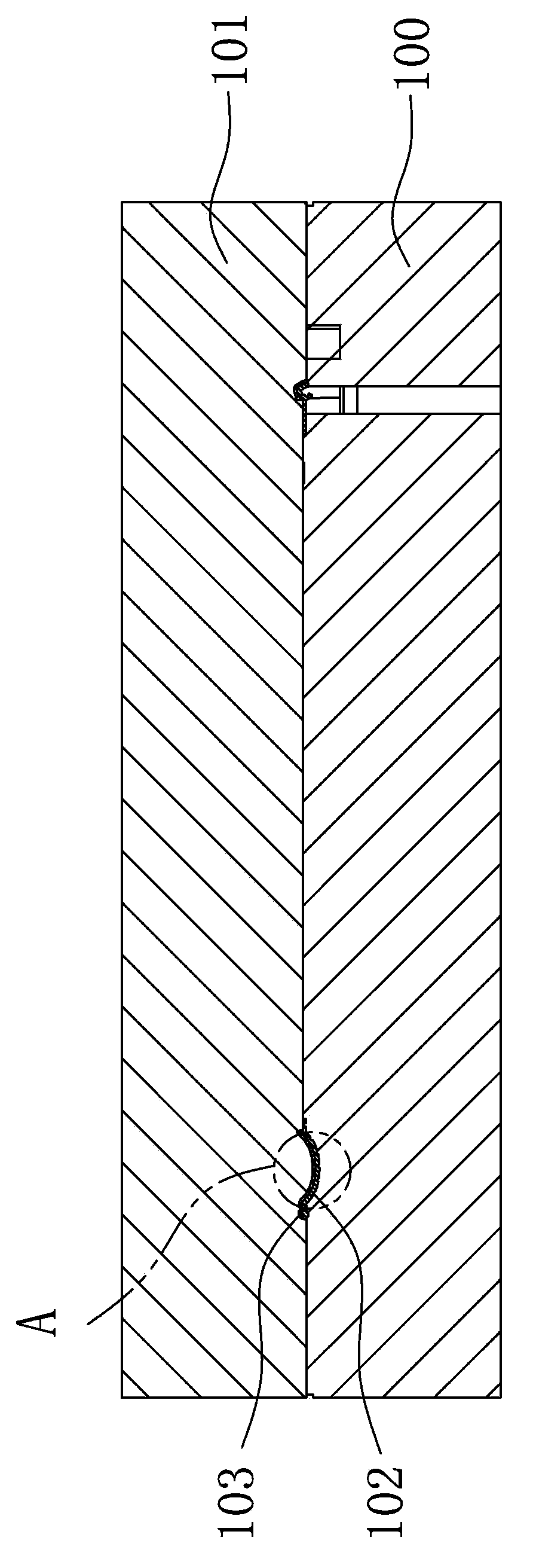

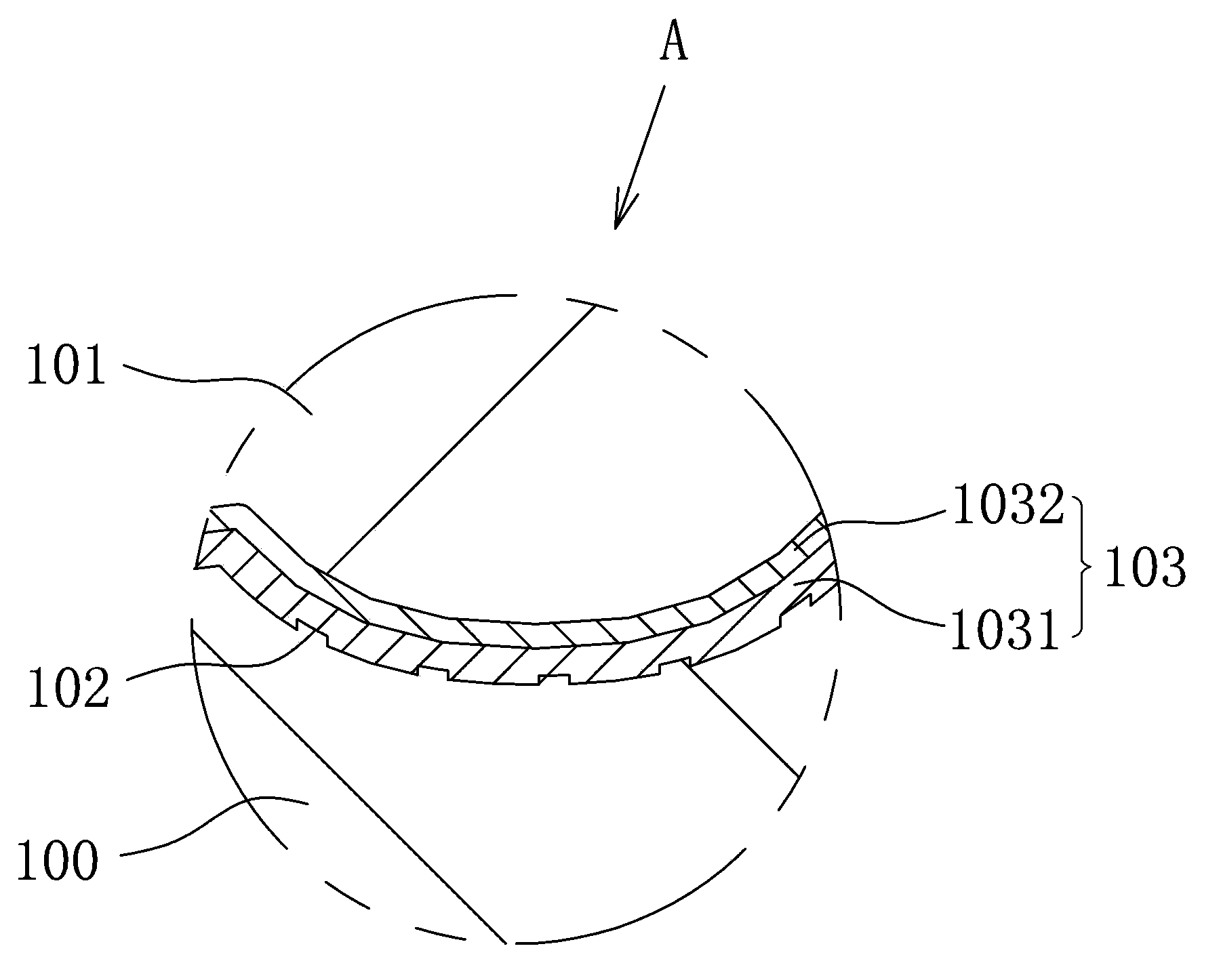

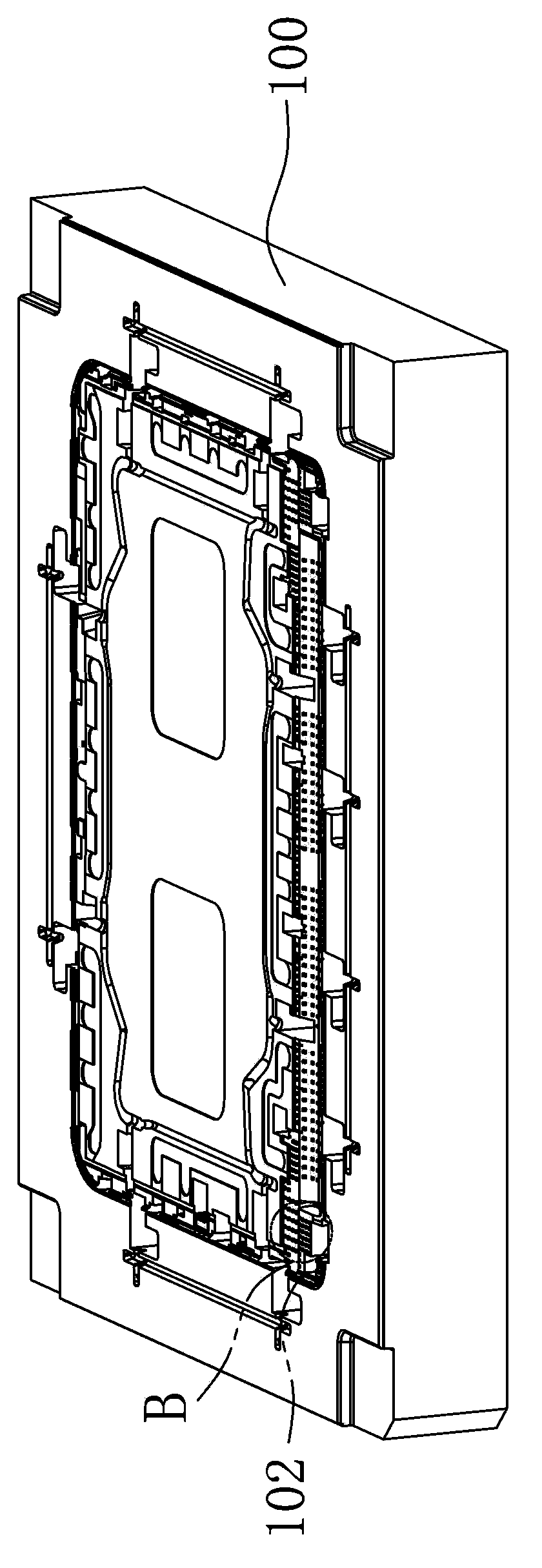

[0020] see figure 1 , figure 2 , image 3 with Figure 4 shown, where figure 1 It is a schematic cross-sectional view of the anti-sticking structure of the master mold of the present invention, figure 2 for figure 1 The enlarged schematic diagram of A in the middle, image 3 It is a three-dimensional schematic diagram of the anti-sticking structure of the master mold of the present invention, Figure 4 for image 3 The enlarged schematic at B in the middle.

[0021] The anti-sticking structure of the master mold of the present invention is applied in a two-color mold. The two-color mold includes a first injection master mold, a second injection master mold and two identical male molds. In this embodiment, the master mold is anti-sticking. Sticky structures include:

[0022] Several bosses 102, the bosses 102 are columns, the bosses 102 are respectively vertically arranged on the male die core 100 of the male mold, the bosses 102 are recessed in the product 103, ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com