A device for self-positioning and automatically pressing power-in components and its installation method

A self-positioning technology for power-in components, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of shortening the service life of power-in components, irregular operations by operators, and affecting the life of power-in components, etc. problems, to achieve protection stability, reduce product scrap rate, and ensure the effect of electrode contact stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0049] The stability of the coating process of each electrode in the deposition furnace requires that the electrode contact of the plasma-enhanced chemical vapor deposition device must be good. According to the principle of leverage, this invention designs a new type of self-positioning and automatically pressing power-in components device, which can reduce the manpower and material resources required for production and maintenance, improve the service life of power-in components and reduce production without affecting the original functions. cost. In addition, the self-positioning and automatically pressing power-feeding component device can make the electrodes contact better.

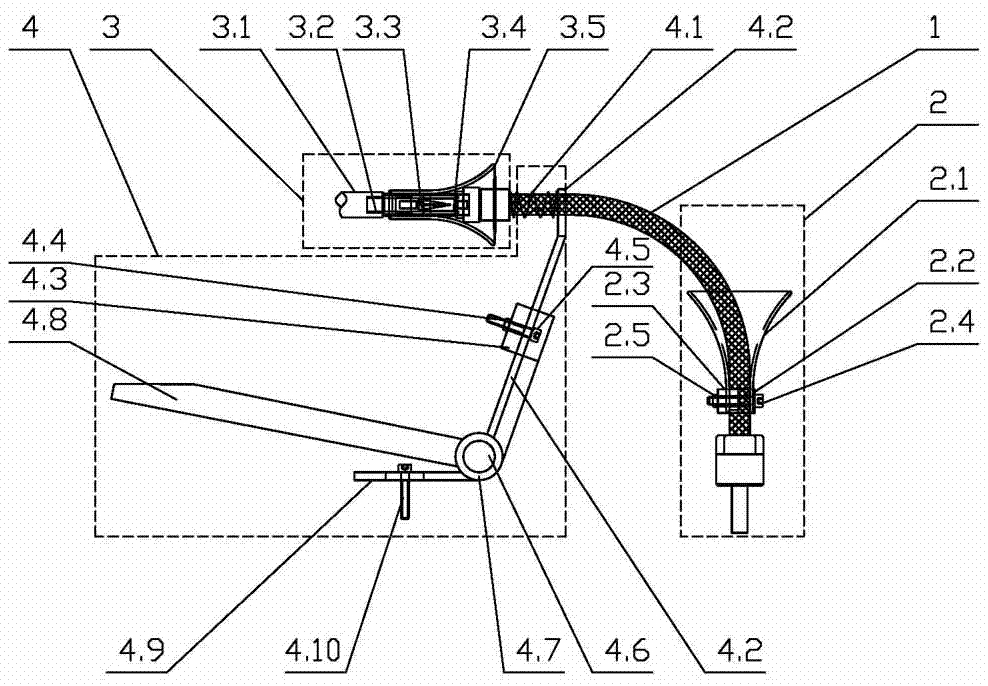

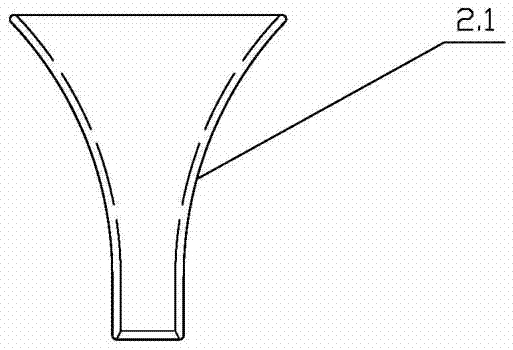

[0050] like Figure 1 to Figure 14 As shown, this kind of self-positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com