Resistance testing equipment

A resistance test and voltage test technology, applied in the direction of measuring resistance/reactance/impedance, measuring devices, measuring electrical variables, etc., can solve the problems of uncertainty in the use of the test object, the cost cannot be reduced, and the test object is destroyed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

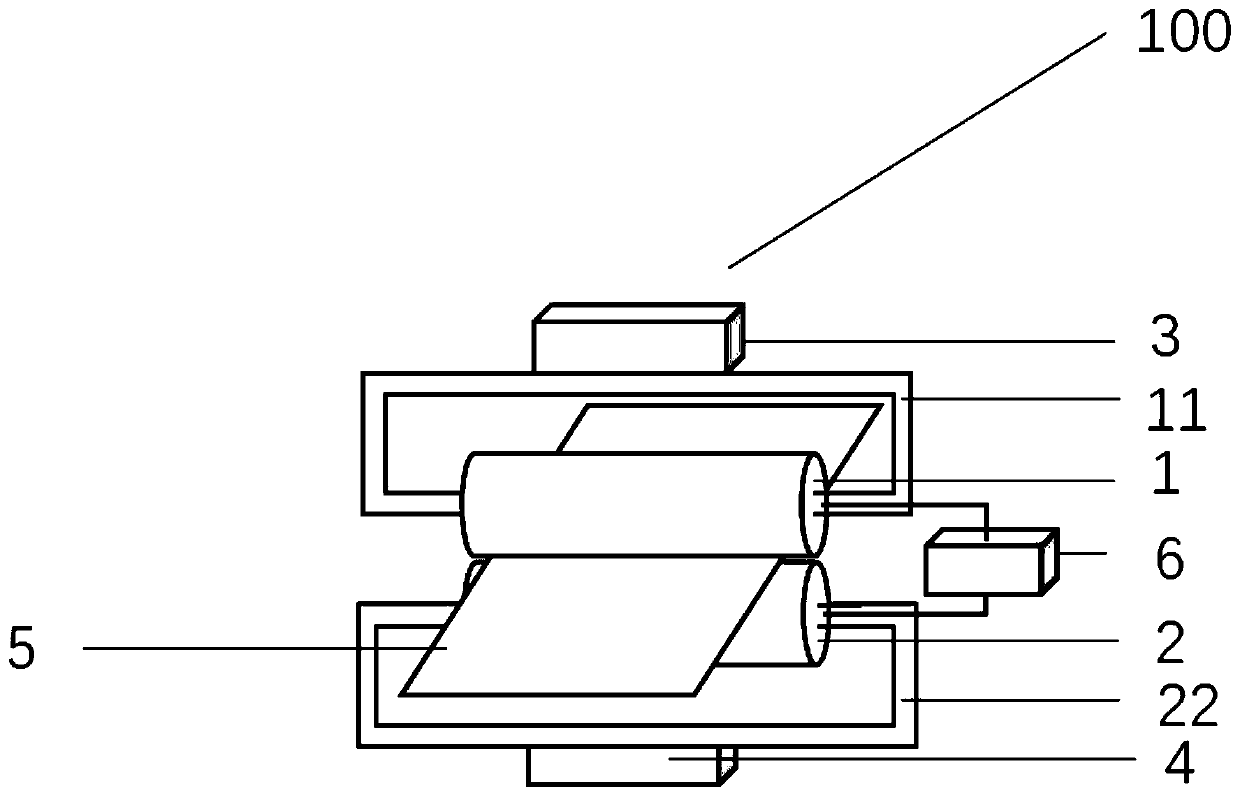

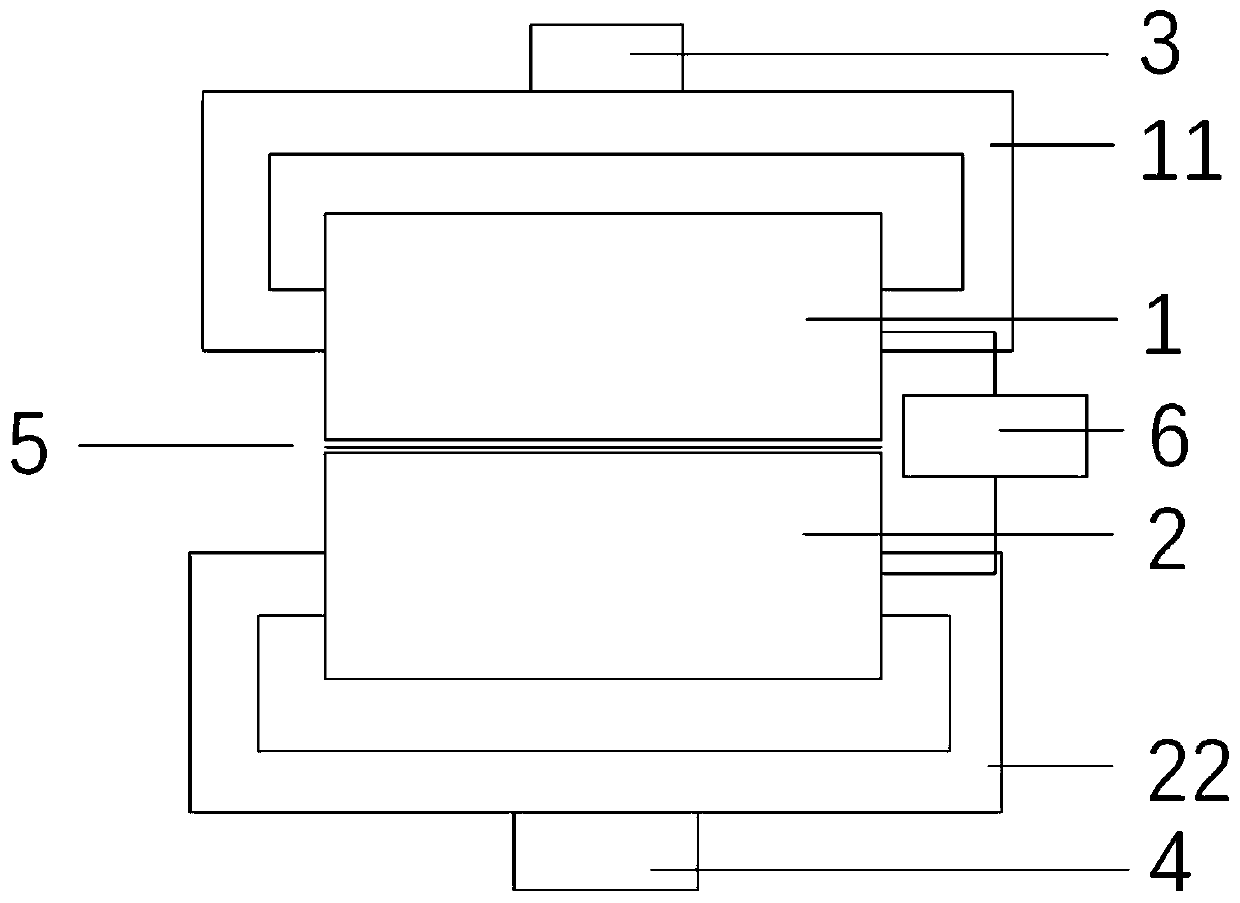

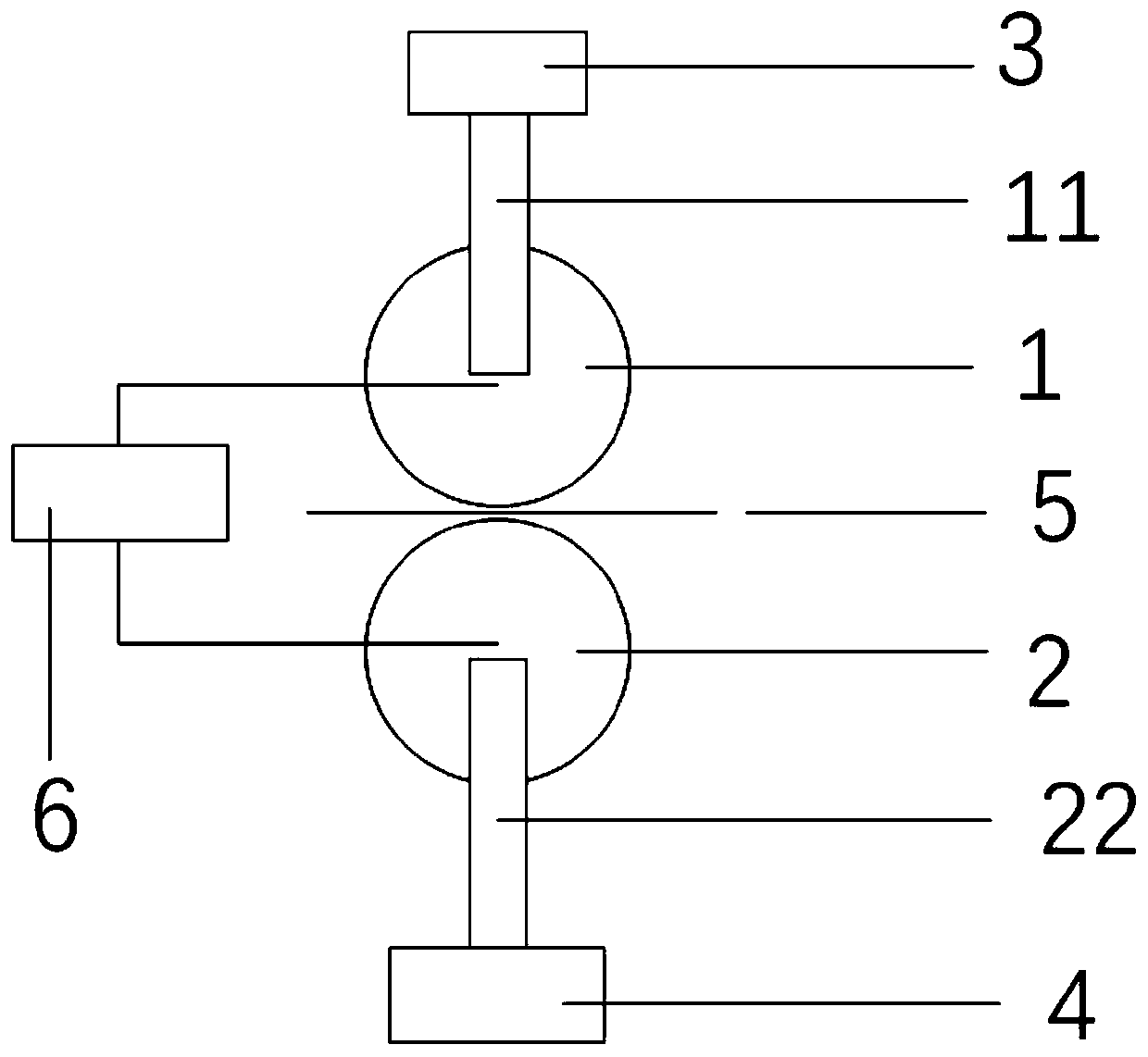

[0067] Please refer to Figure 1 to Figure 3 , figure 1 It is a schematic diagram of a three-dimensional structure of a specific embodiment of the resistance testing equipment provided by the present invention; figure 2 It is a schematic front view of a specific embodiment of the resistance testing equipment provided by the present invention; image 3 It is a schematic diagram of a right side view of a specific embodiment of the resistance testing equipment provided by the present invention. The contact interface between the first pressure member 1 and the first supporting member 2 is a line interface. In the present invention, the contact interface when the first pressure member 1 is in contact with the first support member 2 can be a line-line interface, or a point-point interface or a point-line interface, and the line-line interface or point-point interface or point-line interface can be respectively 1 or more.

[0068] like Figure 1 to Figure 3 As shown, the presen...

Embodiment 2

[0089] Please refer to Figure 4 to Figure 5 , Figure 4 It is a schematic diagram of the three-dimensional structure of another specific embodiment of the resistance testing equipment provided by the present invention; Figure 5 It is a schematic front view of another specific embodiment of the resistance testing equipment provided by the present invention; Image 6 It is a schematic diagram of the right side view of another embodiment of the resistance testing equipment provided by the present invention.

[0090] The difference from Embodiment 1 is that the first pressure member 1 and the first supporting member 2 are in indirect contact through the test object 5, and the contact interface during contact is two line-line interfaces. Therefore, the first pressure component 1 and the first support component 2 are two, and as in Embodiment 1, they are independently installed on the first pressure component support frame 11 and the first support component support frame 22 res...

Embodiment 3

[0097] Please refer to Figure 7 to Figure 8 , Figure 7 It is a schematic diagram of the three-dimensional structure of yet another specific embodiment of the resistance testing equipment provided by the present invention; Figure 8 It is a schematic diagram of the right side view of yet another embodiment of the resistance testing equipment provided by the present invention;

[0098] The difference from Embodiment 1 is that the specific shapes of the first pressure member 1 and the first support member 2 are different, they are all spherical, and the first pressure member 1 and the first support member 2 are in indirect contact through the test object 5, and the contact When the contact interface is a point interface; at the same time, the resistivity of the first pressure member material and the first support member material is 6.5×10- 8 Ω·m, the surface hardness is 800HV, the roughness Ra is 0.4um; the others are the same.

[0099] The method of using the resistance tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com