Gas dynamic-static pressure mixing bearing system for high-speed motor and electric rotating machinery

A gas dynamic and static pressure, hybrid bearing technology, applied in the direction of bearings, electrical components, shafts and bearings, etc., can solve the problems of complex electronic control and manufacturing, low reliability, high manufacturing precision requirements, etc., and achieve the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

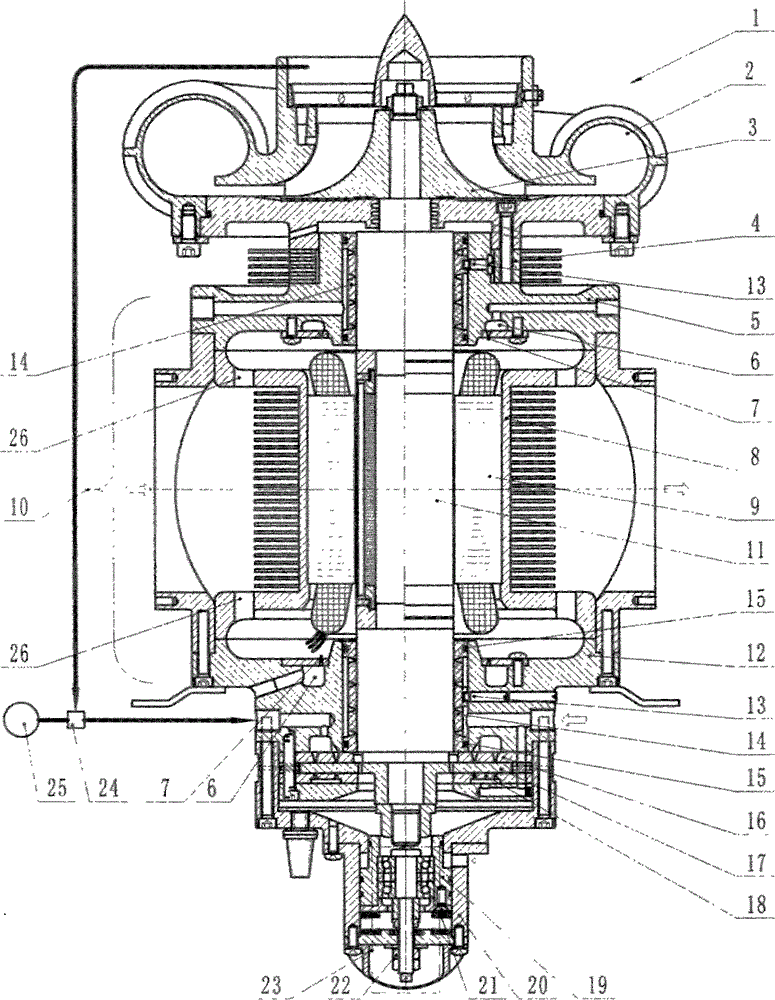

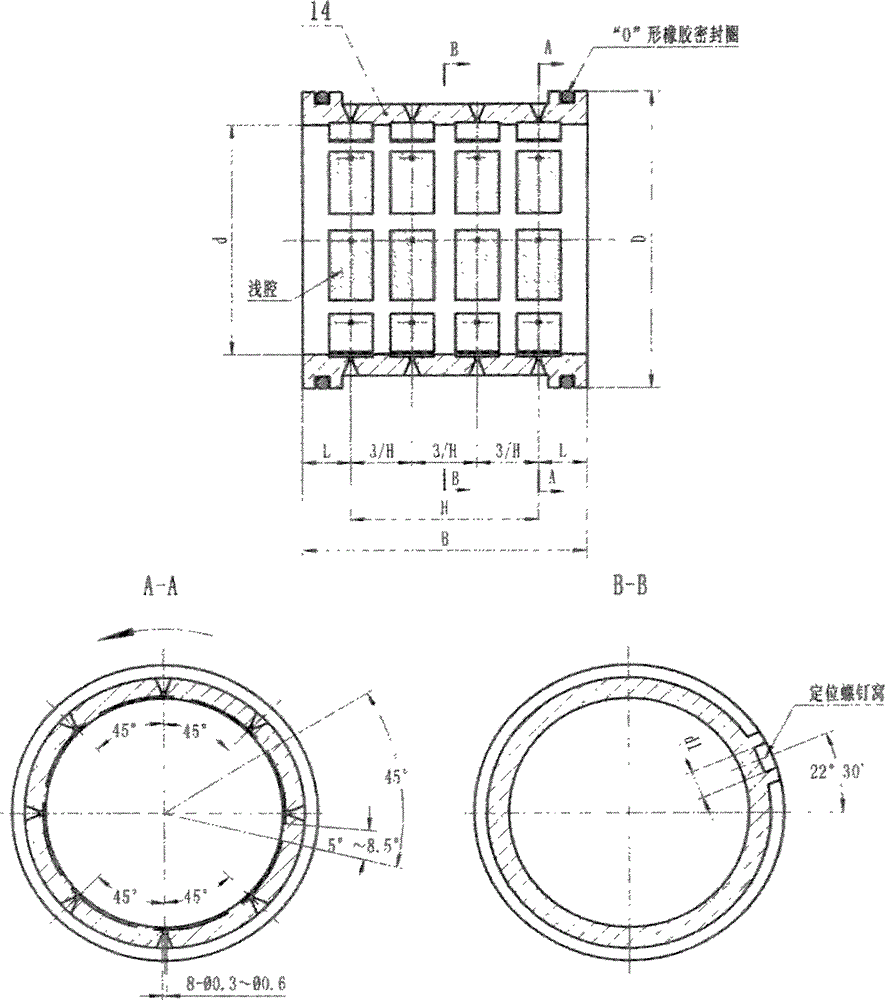

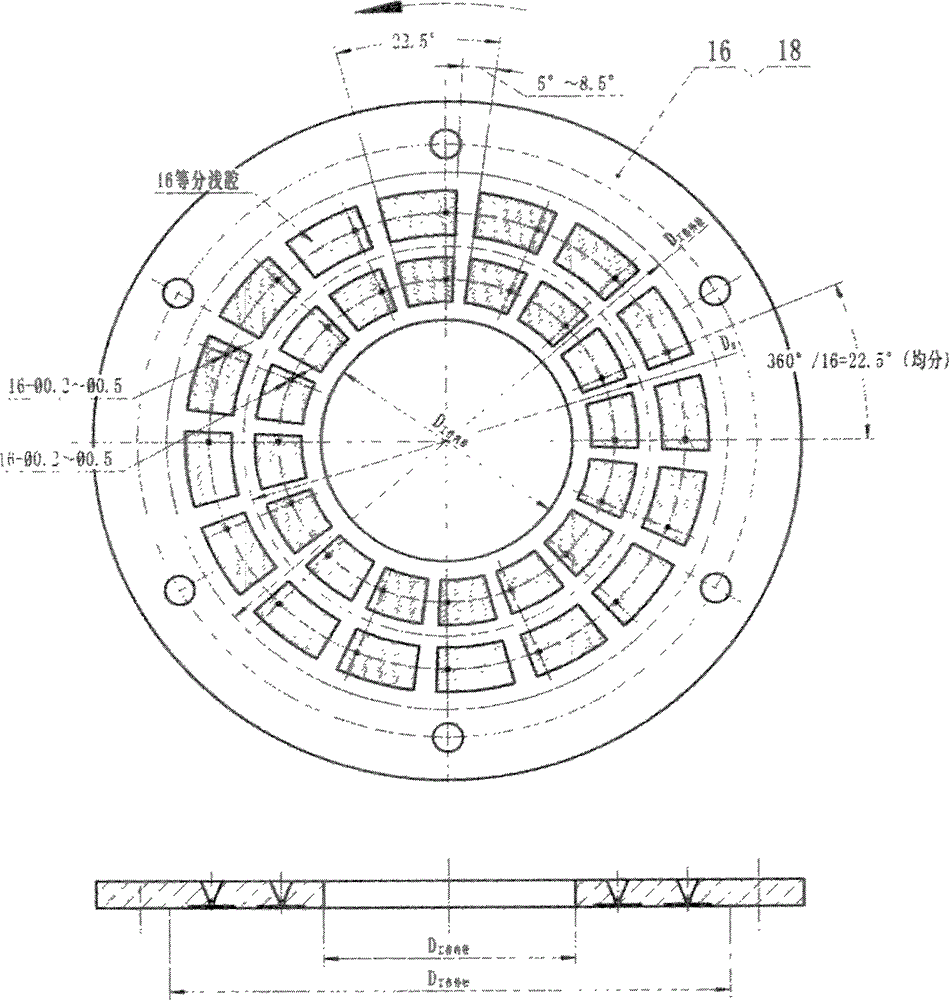

[0010] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings. figure 1 Shown as a front view of a centrifugal compressor 1, the compressor 1 is placed vertically, the upper end of which is a centrifugal compressor assembly 2, and a motor 10 supported by a gas dynamic and static pressure hybrid bearing system of the present invention passes through a partition The heat sleeve 4 is connected with the centrifugal compressor assembly 2, and the compressor impeller 3 in the centrifugal compressor assembly 2 is connected to the end of the motor rotor 11, and the two rotate coaxially. figure 1 Among them, the compressor 1 includes an electric motor 10 in its middle. The motor 10 includes a motor rotor 11 and a motor stator 9 . A semi-floating radial dynamic and static pressure hybrid bearing 14 is placed on the journals at the upper and lower ends of the motor rotor 11; The upper annular axial dynamic and static pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com