Chipper with detachable facing knives

a chipper and knife technology, applied in the field of logslabbing chippers, can solve the problem of face having to be further processed, and achieve the effect of reducing the number of chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

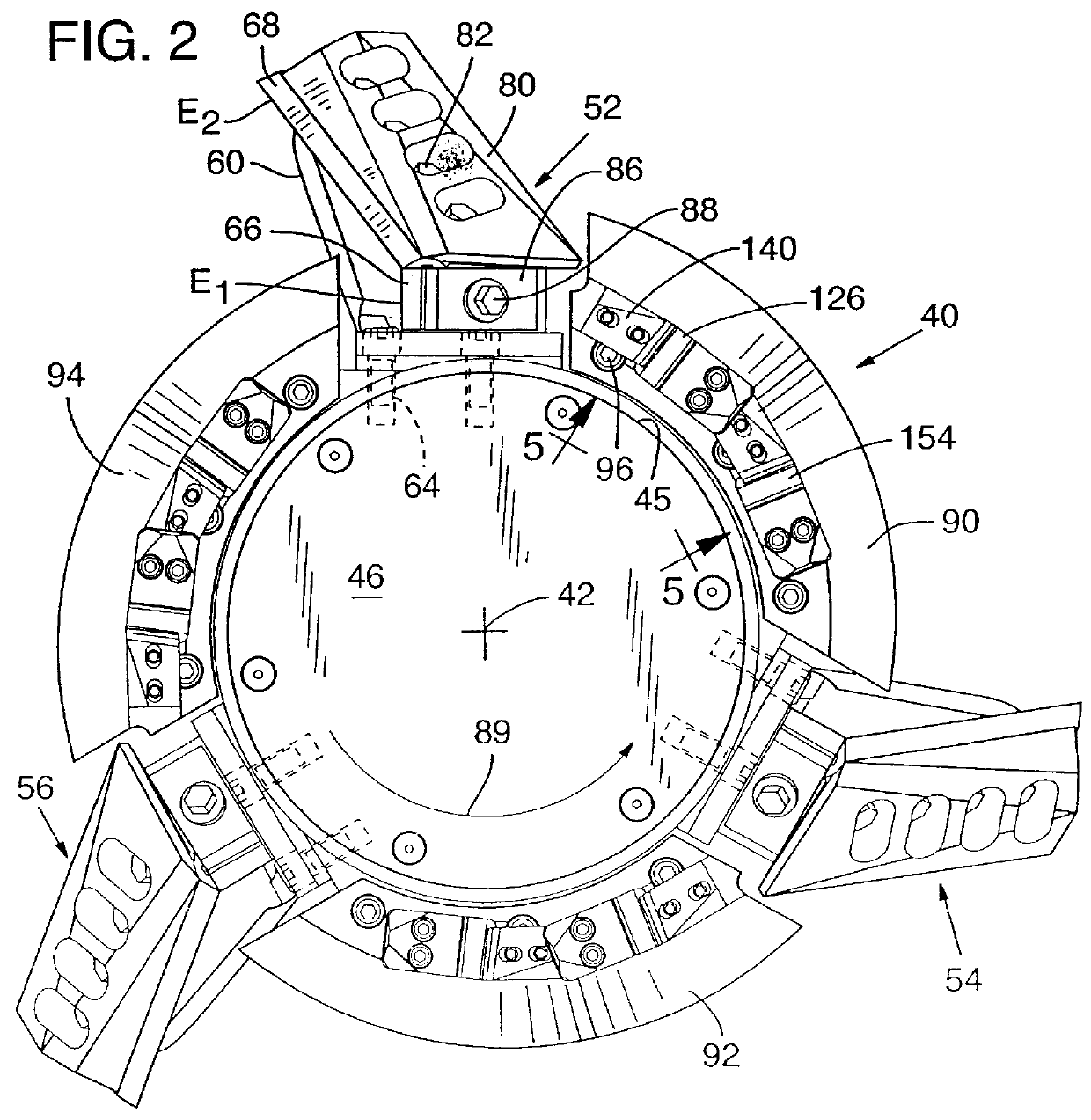

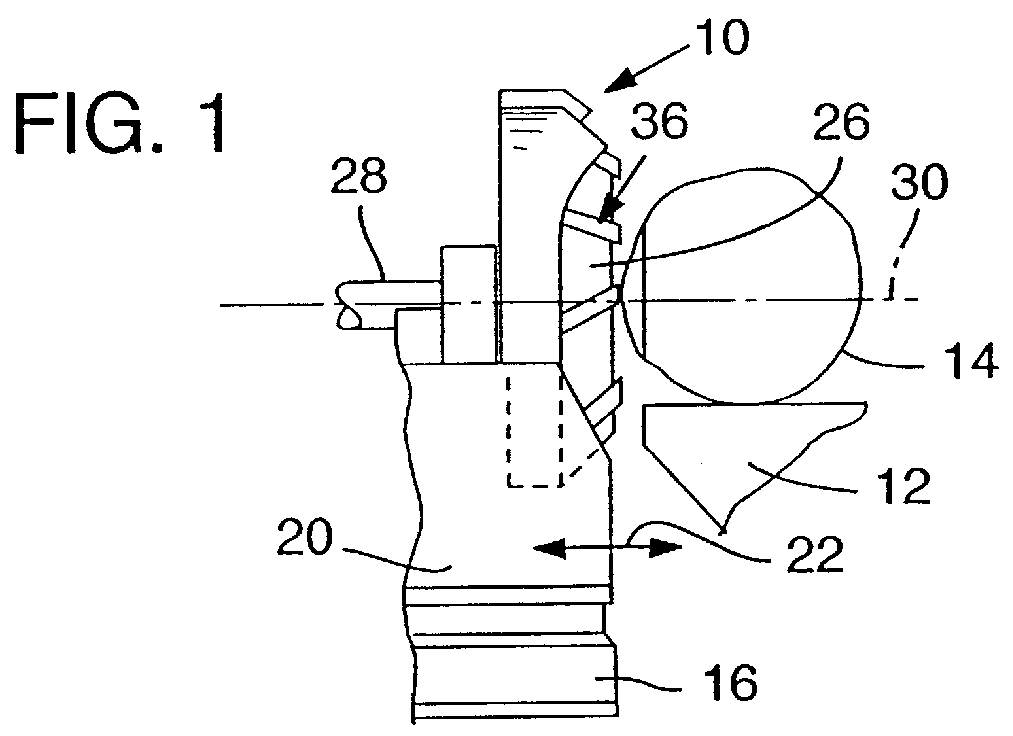

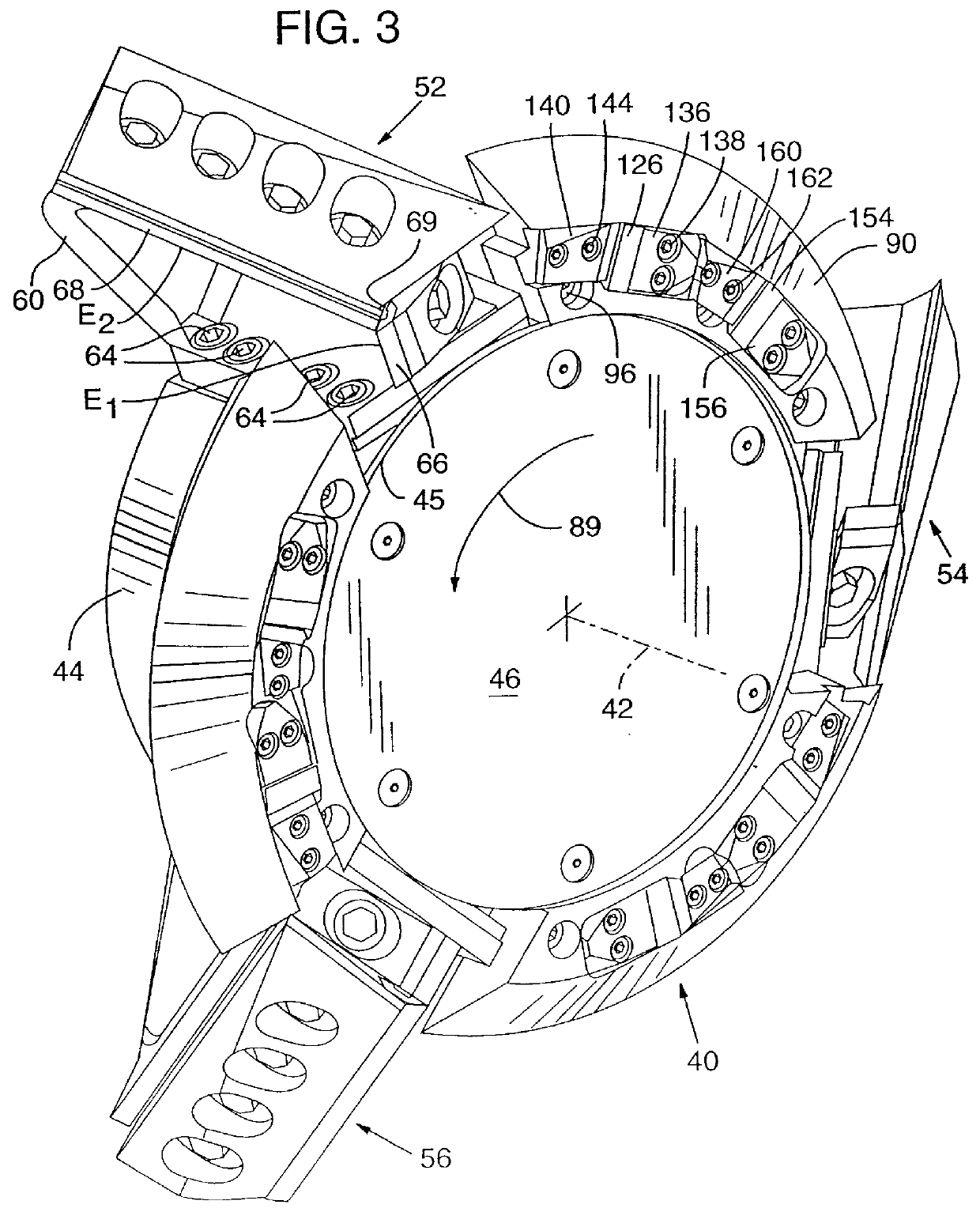

Referring now to the drawings, a log-slabbing chipper is illustrated in simplified form in FIG. 1 at 10. The chipper or woodworking machine includes a carriage 12 or log-supporting means, which mounts a log 14, with the log and carriage being movable in a direction extending longitudinally of the log (or toward and away from the viewer as the log and carriage are illustrated in FIG. 1).

Supported to one side of the carriage, on a frame 16 suitably mounted on the ground, is a stand 20. The stand is mounted for movement in the lineal path along the frame toward and away from the log, or in the direction indicated by the arrow 22 in FIG. 1.

Rotatably supported on stand 20 is a power-driven chipping head 26. The chipping head is rotated under power, about an axis 30, by suitable means, such as belts, or a motor connected to shaft 28.

Distributed about axis 30 on the chipping head are multiple knife structures given the reference numeral 36. With the chipping head rotated under power, and w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

| Perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com