Hole saw assembly

a technology of hole saw and assembly, which is applied in the direction of sleeve/socket joint, sawing apparatus, fastening means, etc., can solve the problems of tight plug jamming, difficult plug removal, and considerable force to be used to remove the plug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The following detailed description of the invention refers to the accompanying drawings. Although the description includes exemplary embodiments, other embodiments are possible, and changes may be made to the embodiments described without departing from the spirit and scope of the invention. Wherever possible, the same reference numbers will be used throughout the drawings and the following description to refer to the same and like parts.

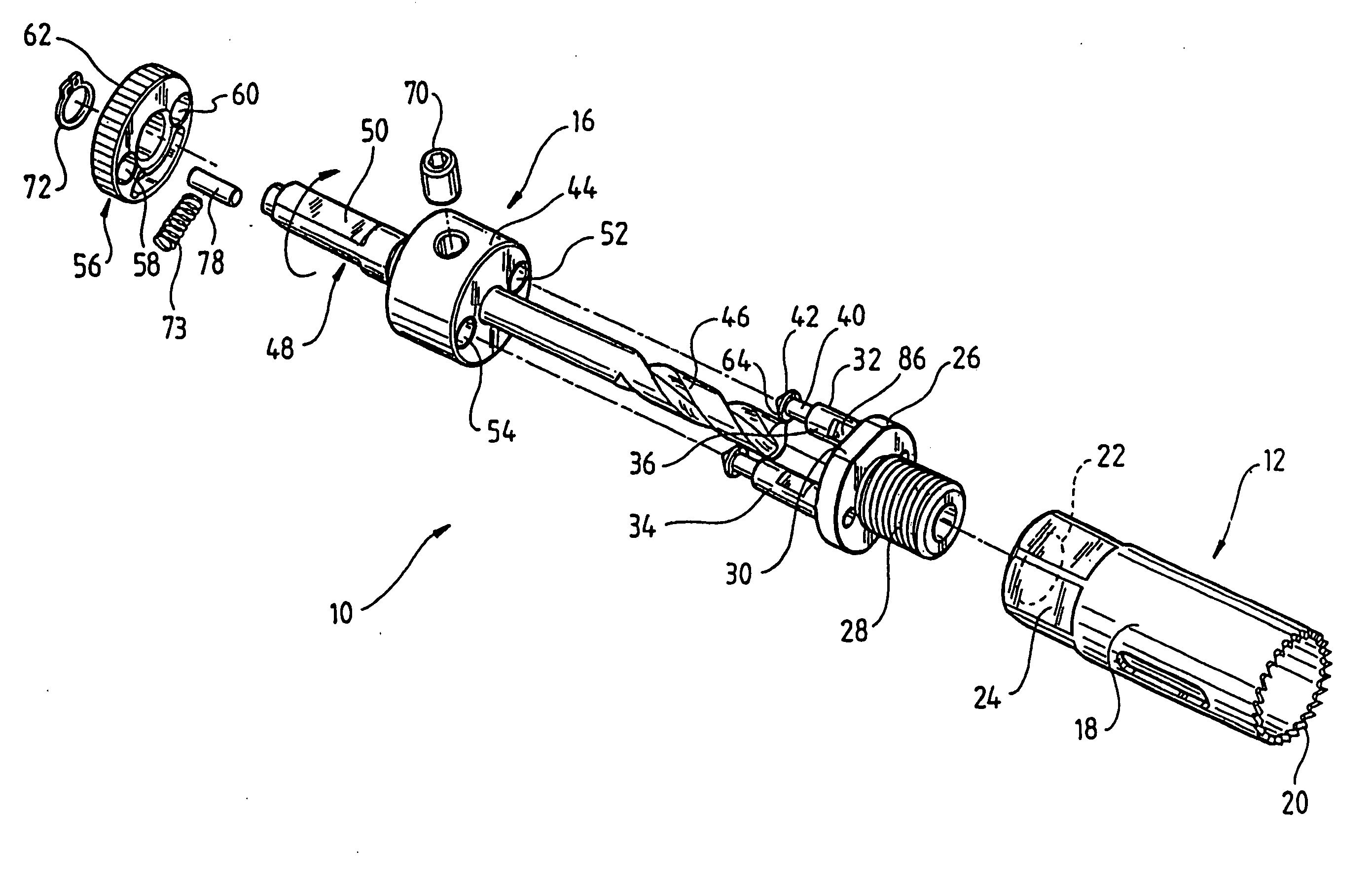

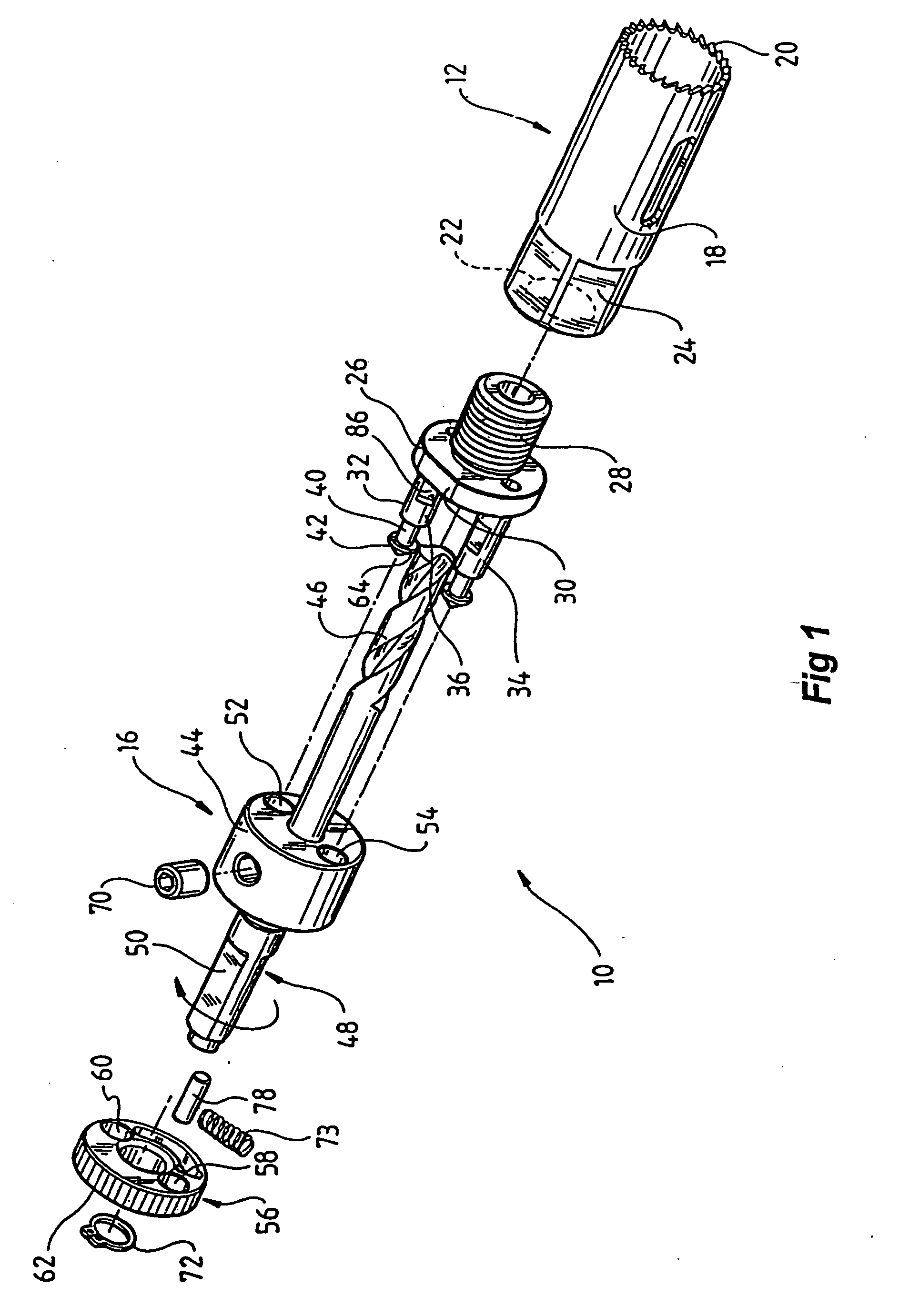

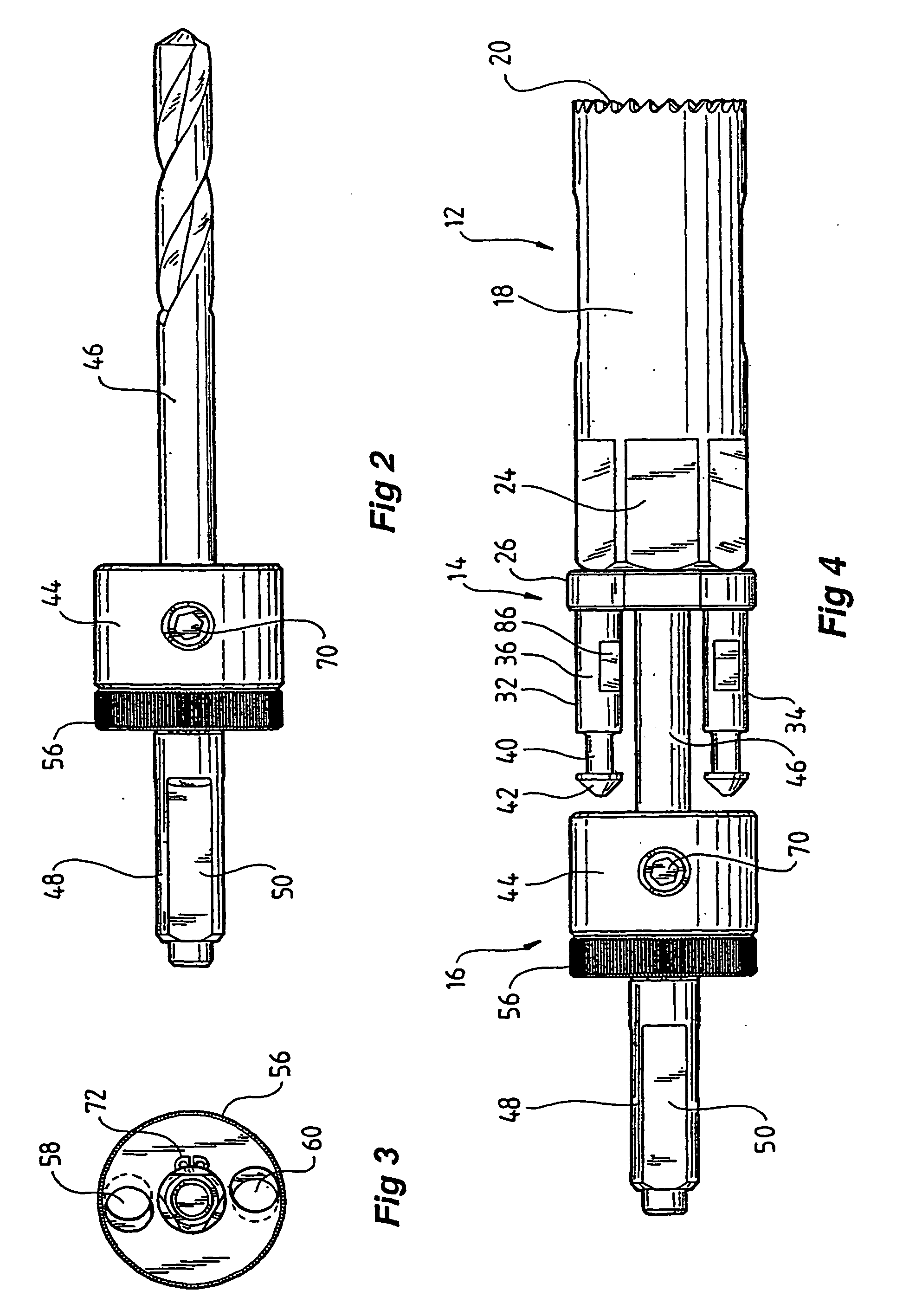

[0065] Referring to FIGS. 1 to 5 there is shown a hole-saw assembly 10 including a hole-saw 12, base 14, and mandrel 16.

[0066] The hole-saw 12 includes a cylindrical body 18 having cutting teeth 20 at one end thereof. At the opposite end the hole-saw 12 includes a threaded bore 22 (with inner threads), the outer surface of the hole-saw body 18 adjacent the bore 22 including circumferentially disposed shoulders 24 to enable a tool (not shown) such as a wrench to engage the hole-saw 12 for rotational movement thereof.

[0067] The base 14 inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com