Cutting machine

A technology for cutting machines and cutting parts, which is applied in the direction of sawing equipment, sawing components, and machine tools suitable for grinding the edge of workpieces, etc. It can solve the problems of high work intensity, low processing efficiency, and high requirements, and achieve reduced work intensity. The effect of improving processing efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

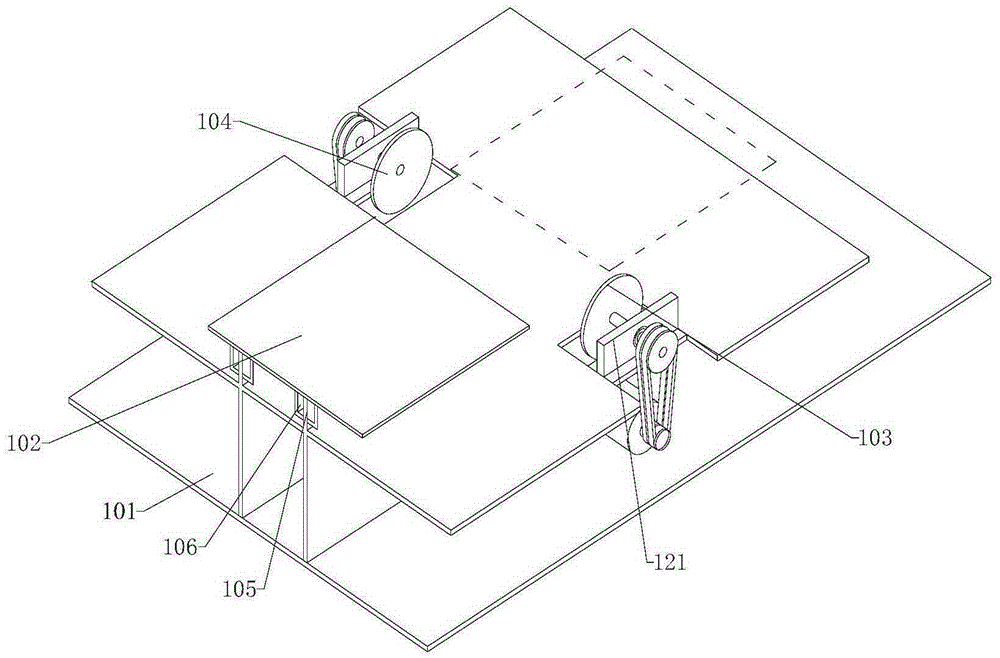

[0065] A cutting machine includes a frame body 101, a work table 102, a driving device, and a cutting member. The frame body is provided with a first guide rail 105, and the work table 102 is slidably connected to the first guide rail 105. The driving device is respectively connected with the worktable 102 and the cutting member, and the cutting member includes a first longitudinal cutting member 103 and a second longitudinal cutting member 104 that are symmetrically arranged. The first longitudinal cutting member 103 and the second longitudinal cutting member 104 Two longitudinal cutting members 104 are respectively connected to the frame body 101, the first longitudinal cutting member 103 is located at one side of the worktable 102 along the direction of the first guide rail 105, and the second longitudinal cutting member 104 is located at the The side of the worktable 102 away from the first longitudinal cutting member 103.

[0066] The workbench 102 is provided with a sliding...

Embodiment approach 2

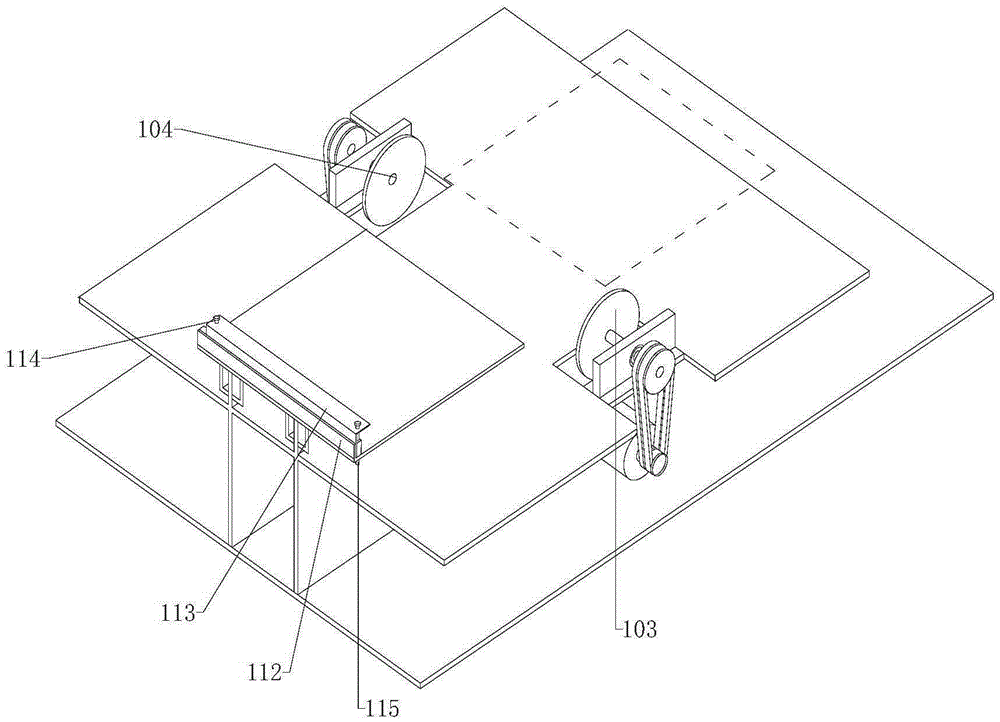

[0069] A cutting machine includes a frame body 101, a work table 102, a driving device, and a cutting member. The frame body is provided with a first guide rail 105, and the work table 102 is slidably connected to the first guide rail 105. The driving device is respectively connected with the worktable 102 and the cutting member, and the cutting member includes a first longitudinal cutting member 103 and a second longitudinal cutting member 104 that are symmetrically arranged. The first longitudinal cutting member 103 and the second longitudinal cutting member 104 Two longitudinal cutting members 104 are respectively connected to the frame body 101, the first longitudinal cutting member 103 is located at one side of the worktable 102 along the direction of the first guide rail 105, and the second longitudinal cutting member 104 is located at the The side of the worktable 102 away from the first longitudinal cutting member 103.

[0070] The workbench 102 is provided with a guiding...

Embodiment approach 3

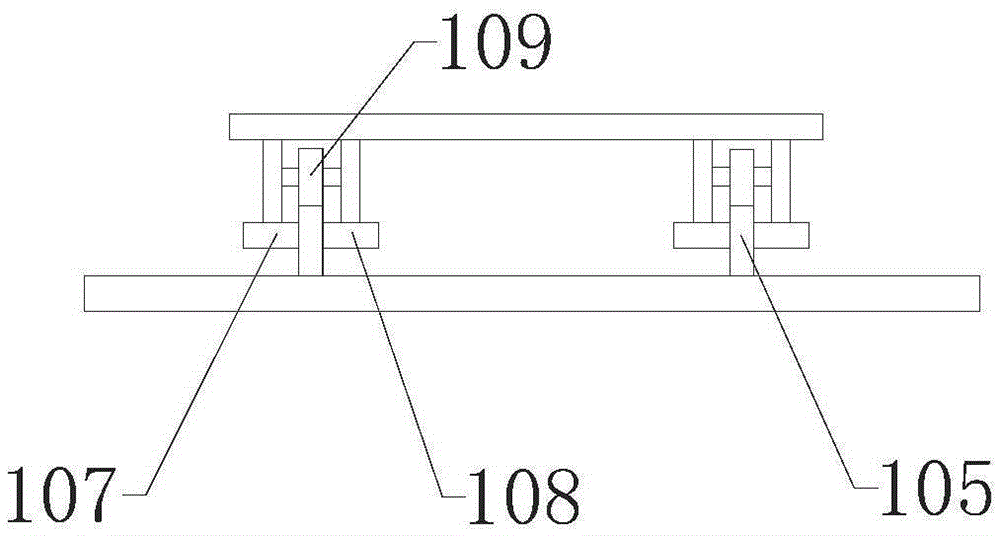

[0076] A cutting machine includes a frame body 101, a worktable 102, a driving device, and a cutting member. The frame body is provided with a first guide rail 105, and the worktable 102 is slidably connected to the first guide rail 105. The driving device is respectively connected with the worktable 102 and the cutting member, and the cutting member includes a first longitudinal cutting member 103 and a second longitudinal cutting member 104 which are symmetrically arranged. The first longitudinal cutting member 103 and the second longitudinal cutting member 103 Two longitudinal cutting members 104 are respectively connected to the frame body 101, the first longitudinal cutting member 103 is located on one side of the worktable 102 along the direction of the first guide rail 105, and the second longitudinal cutting member 104 is located at the The side of the worktable 102 away from the first longitudinal cutting member 103.

[0077] The workbench 102 is provided with a sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com