Guide correcting device of sponge cutting machine

A sponge cutting machine and guiding technology, applied in metal processing and other directions, can solve problems such as position deviation, affecting cutting accuracy, and inability to ensure sponge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

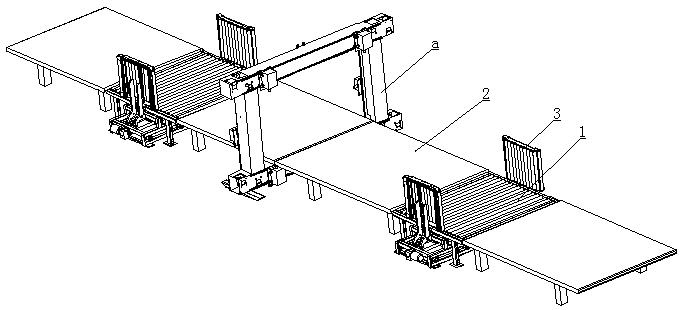

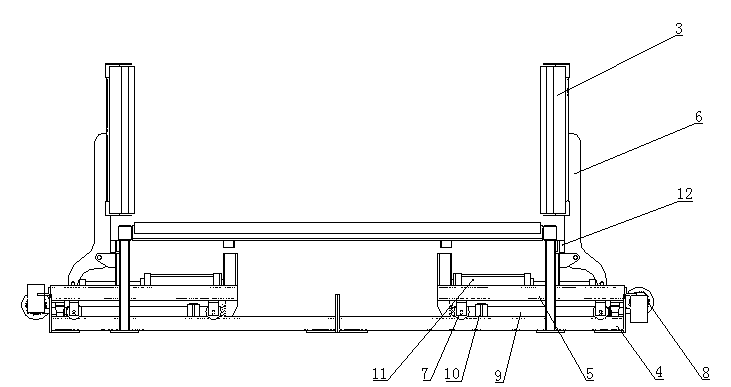

[0020] like figure 1 , 2 , 3, and 4, including righting conveyor belt 1, sponge cutting machine conveyor belt 2, righting guide plate 3, base 4, movable frame 5, guide plate bracket 6, roller 7, motor 8, screw rod 9, nut 10. Overturn cylinder 11, mechanical limit block 12.

[0021] The above-mentioned righting conveyor belt 1 is an actively driven roller conveyor belt, which is arranged on the feed end and discharge end conveyor belt 2 of the sponge cutting machine a, or the conveyor belt arranged on the feed end and discharge end of the sponge cutting machine a on the extension. The moving speed of the straightening conveyor belt 1 is consistent with the moving speed of the conveyor belt 2 of the sponge cutting machine.

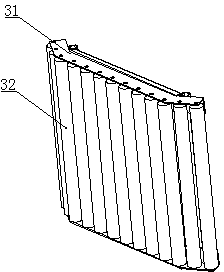

[0022] At least one straightening guide plate 3 for guiding and limiting the sponge passing through the straightening conveyor belt 1 . The righting guide plate 3 is arranged on one side or both sides of the upper surface of the righting conveyor belt 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com