Knife collision prevention device used on knife rest of numerical control machine tool

A technology of CNC machine tools and knife devices, applied in the field of CNC machine tools, can solve problems such as troubles, tool collisions, and endangering the safety of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

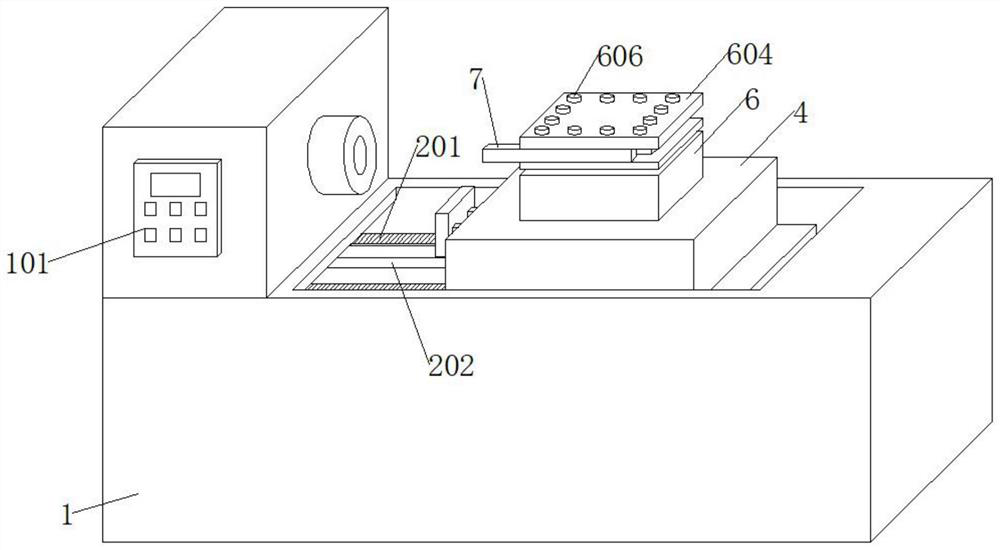

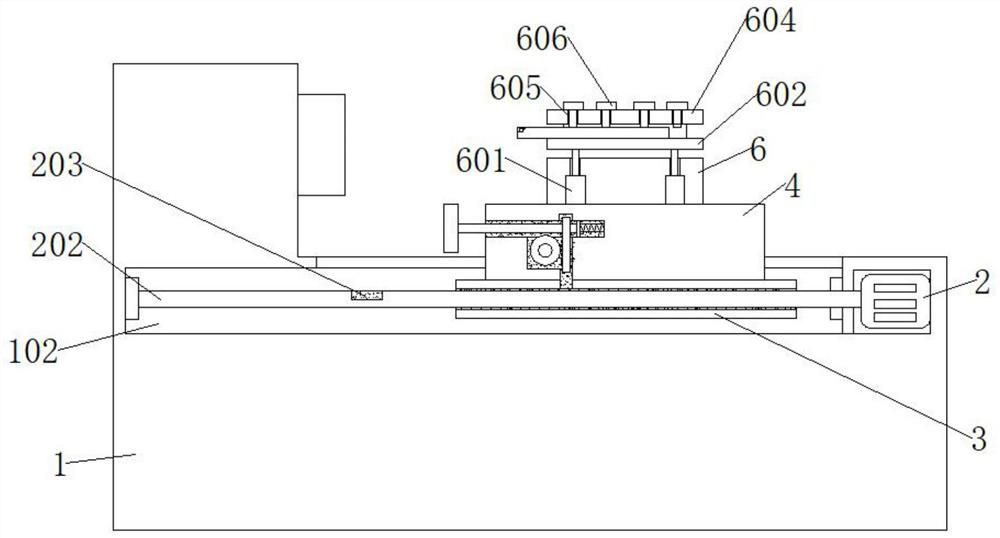

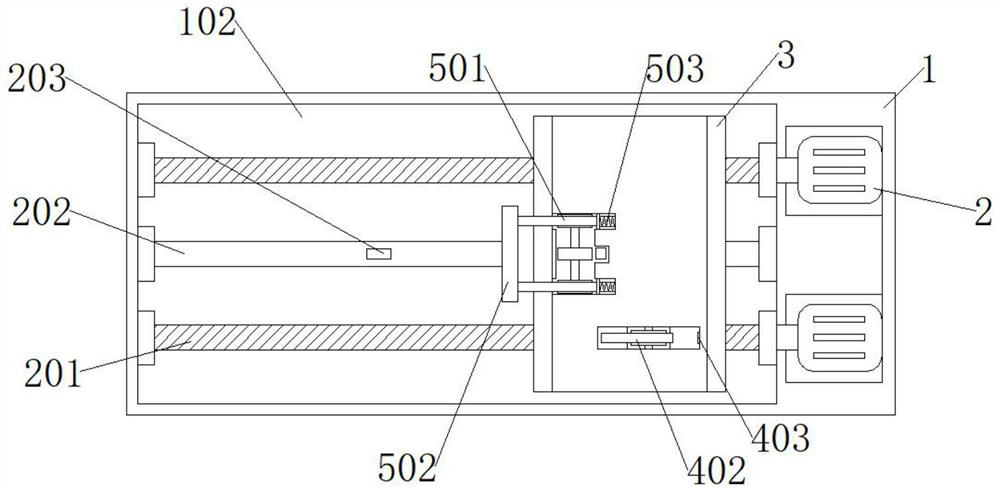

[0033] see Figure 1-9 middle,

[0034] This embodiment provides an anti-collision tool device for a CNC machine tool holder, including a machine tool body 1, a slide plate 3, a tool holder 6 and an engaging assembly;

[0035] An equipment box is fixedly installed on the top of the machine tool main body 1, an operation panel 101 is fixedly installed on the front of the equipment box, a moving cavity 102 is opened inside the machine tool main body 1, a slide bar 202 is fixedly installed inside the moving cavity 102, and a slide plate 3 is arranged outside the slide bar 202, An equipment block 4 is fixedly installed on the top of the slide plate 3, and the tool holder 6 is fixedly connected to the top of the equipment block 4;

[0036] An engaging assembly is provided between the sliding bar 202 and the sliding plate 3 for engaging and fixing the sliding plate 3 .

[0037] The main body of the machine tool 1 is made of cast carbon steel, which has high strength and toughness,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com