Foam cutting machine

A cutting machine and foam technology, applied in metal processing and other directions, can solve the problems of low cutting precision and slow cutting efficiency, and achieve the effect of high-efficiency foam cutting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

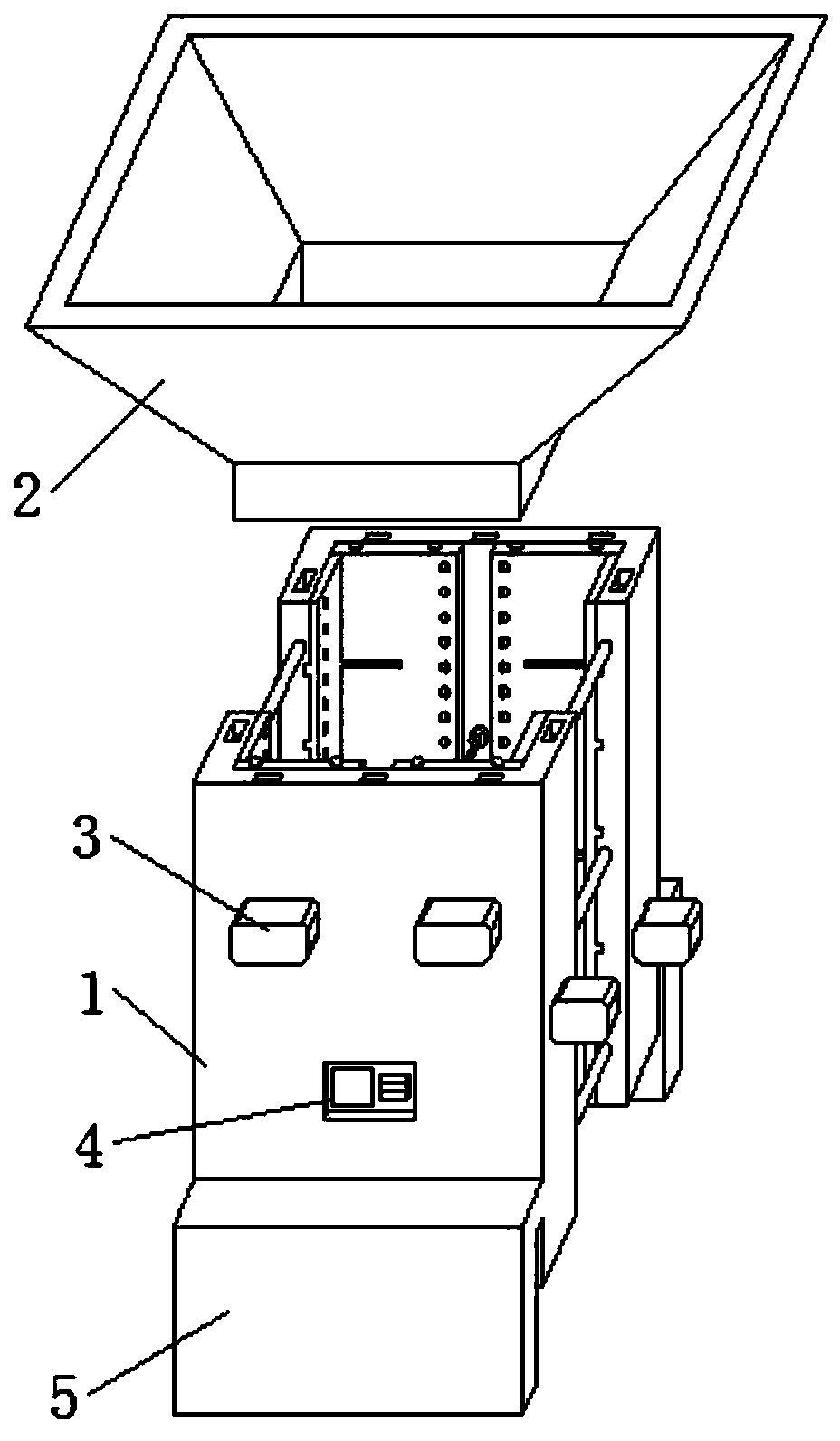

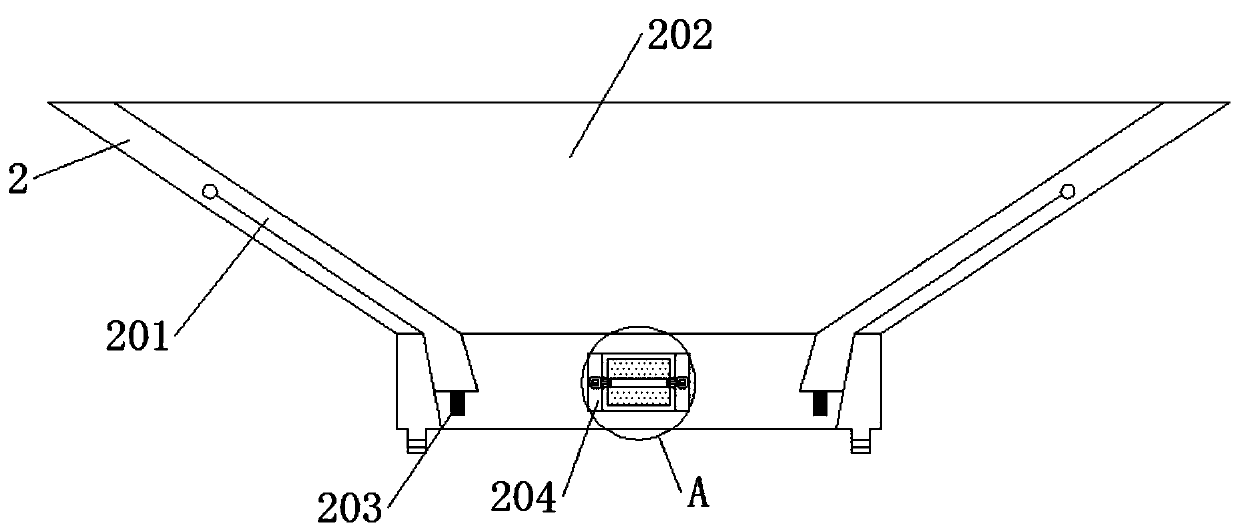

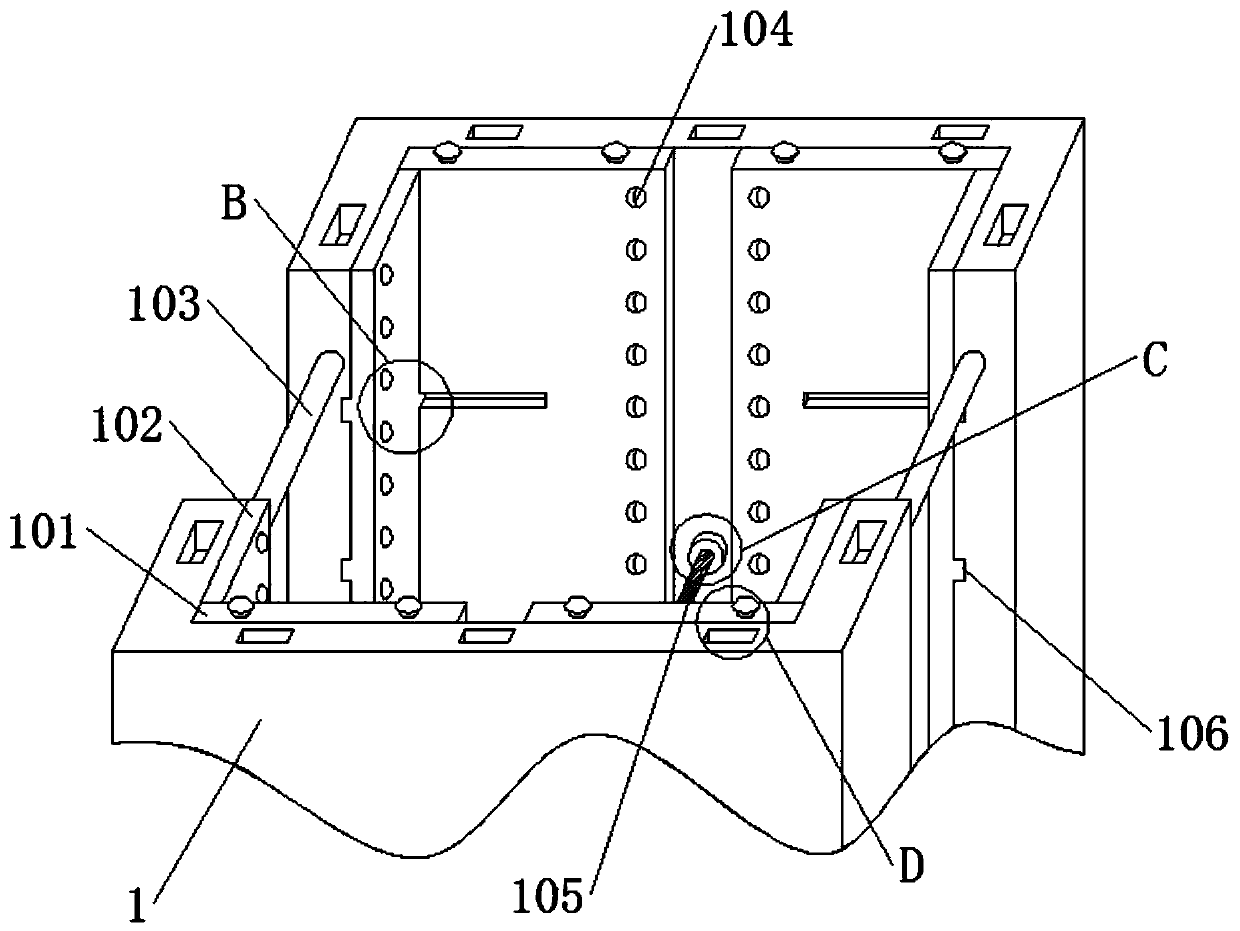

[0028] See attached figure 1 To attach Figure 8 , a foam cutting machine, including: a shell 1, a horizontal limit plate 101, an outer slide rail 1011, a connecting button 1012, a vertical limit plate 102, an anti-off slide plate 1021, a ball 1022, a connecting column 103, a guide plate bead 104, Electric heating wire 105, inner slide rail 106, socket groove 107, funnel 2, movable inner plate 201, top groove 202, elastic traction rope 203, correction wheel 204, small motor 2041, rotating shaft 2042, friction wheel body 2043, hydraulic pump 3. The controller 4 and the support plate 5, the top of the housing 1 is fixedly connected with the funnel 2 through the socket groove 107, the middle parts of the front and rear ends of the housing 1 are fixedly connected with the hydraulic pump 3, and the middle part of the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com