Patents

Literature

40results about How to "Effective contraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

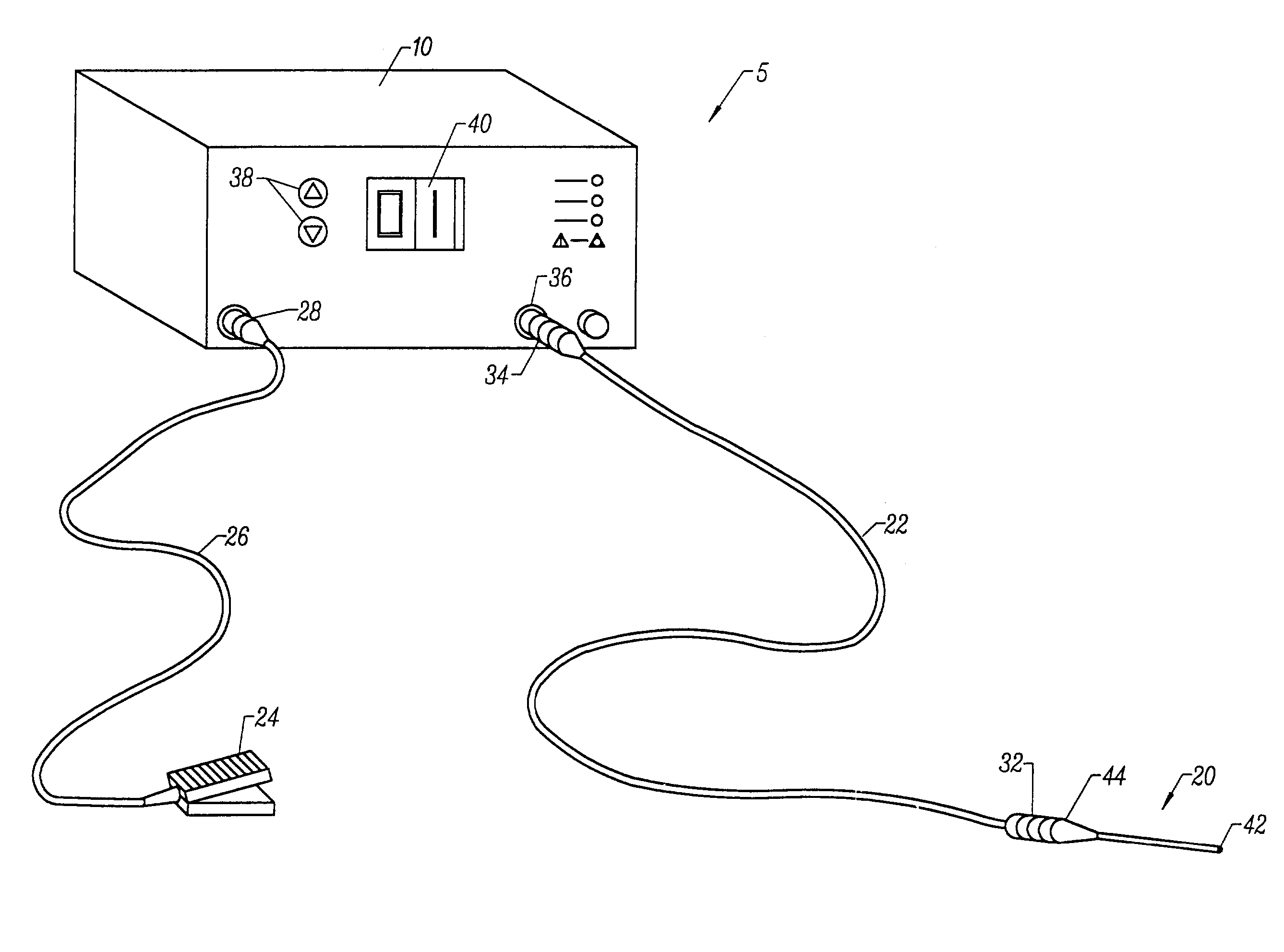

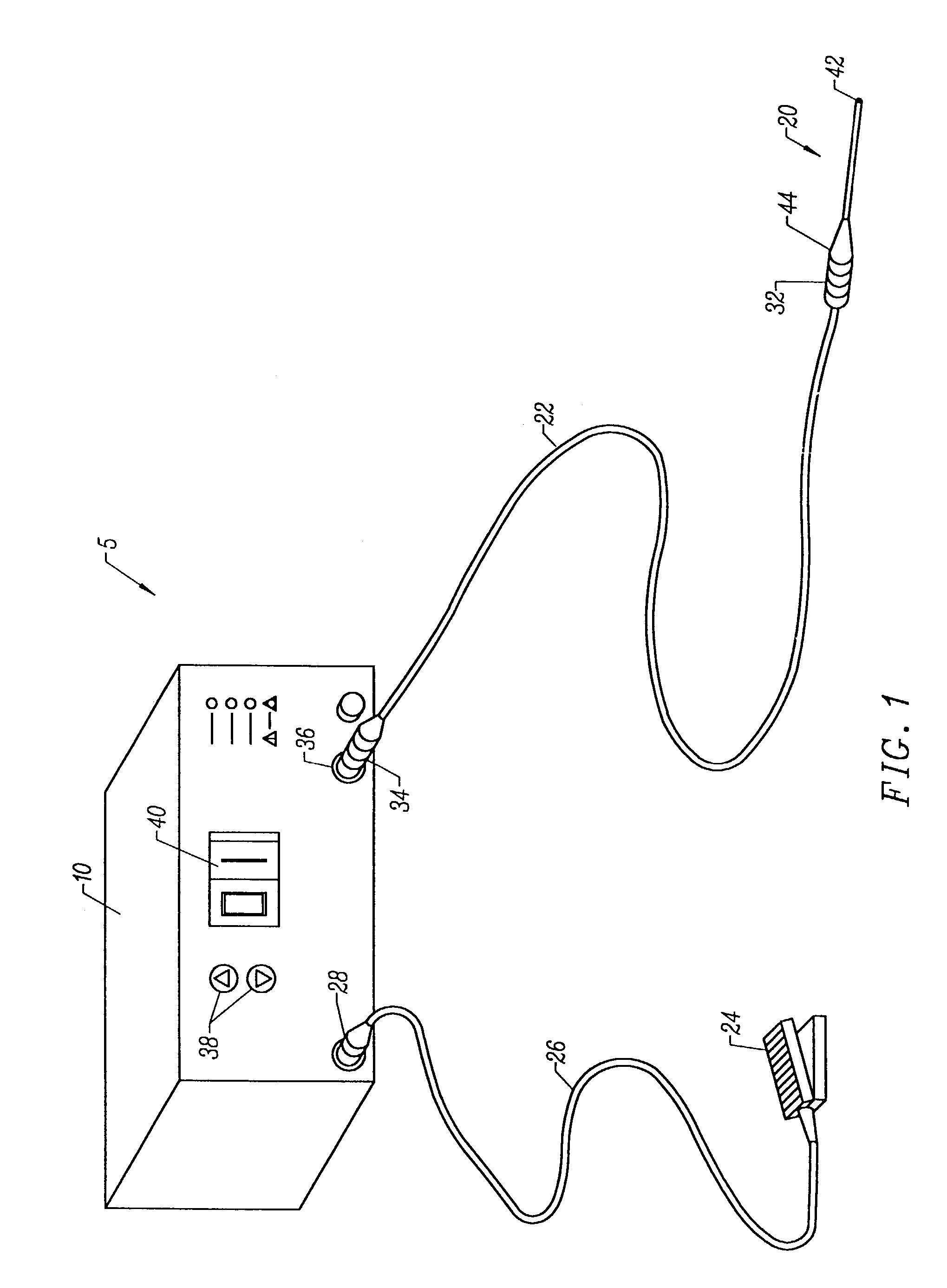

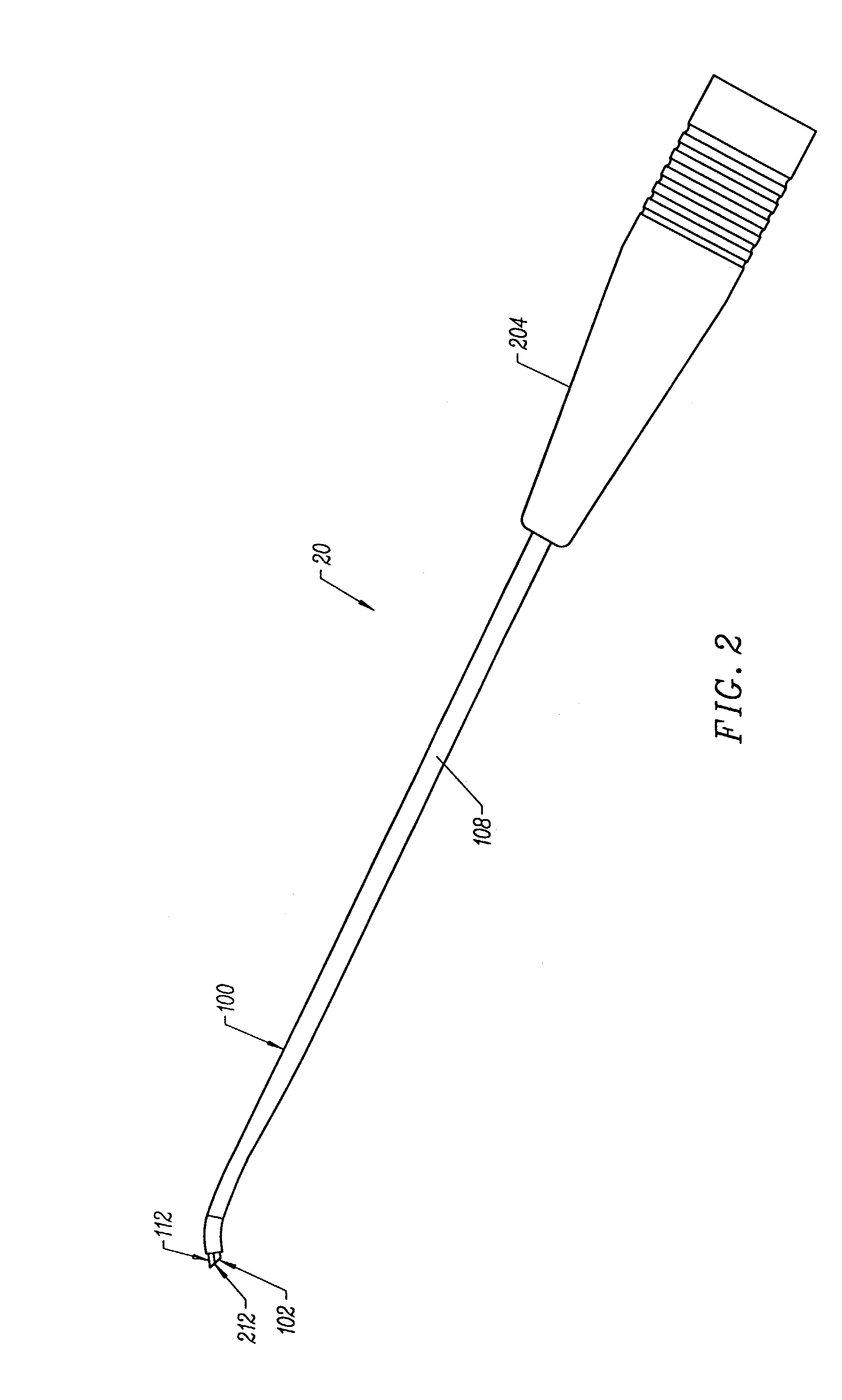

Systems and methods for electrosurgical tissue contraction

InactiveUS7094215B2Limiting thermal damage and dissociationSuppress thermal damageEye treatmentSurgical instruments for heatingSacroiliac jointSurgical department

Systems and methods are provided for performing electrosurgical interventions, such as selectively contracting soft collagen tissue and other body structures, while limiting thermal damage or molecular dissociation of such tissue and limiting the thermal damage to tissue adjacent to and underlying the treatment site. The systems and methods of the present invention are particularly useful for surgical procedures in electrically conducting environments, such as arthroscopic procedures in the joints, e.g., shoulder, knee, hip, hand, foot, elbow or the like. The present invention is also useful in relatively dry environments, such as treating and shaping the cornea, and dermatological procedures involving surface tissue contraction of tissue underlying the surface of the skin for tissue rejuvenation, wrinkle removal and the like.

Owner:ARTHROCARE

Active agent for titanium alloy tungsten electrode argon arc welding

InactiveCN102626839AEffective contractionStrong penetrating powerArc welding apparatusWelding/cutting media/materialsPorosityMetallurgy

The invention discloses an active agent for titanium alloy tungsten electrode argon arc welding, which aims to increase the weld penetration, reduce the input of welding heat, thin a weld structure and reduce the weld porosity. In percent by weight, the active agent comprises the following components: 20-30% of CaF2, 10-20% of CrCl3, 10-20% of KF and 40-50% of Te.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

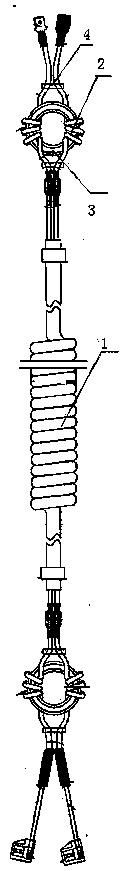

Anti-electromagnetic interference high-elasticity spiral cable connecting line

InactiveCN104319582AProtection lifeGuaranteed not to deformLine/current collector detailsCoupling device detailsElectrical conductorCopper wire

The invention relates to an anti-electromagnetic interference high-elasticity spiral cable connecting line. A manufacturing process of the connecting line comprises the following steps that firstly, a copper wire conductor is adopted for carrying out stranding, and a cable internal core wire is manufactured; secondly, a cable material is manufactured; thirdly, a cable is manufactured; fourthly, a cable wire is formed through rolling of a rolling bar, the cable wire formed through rolling is shaped through the high temperature of an oven to form a spiral cable, the temperature of the oven ranges from 160 DEG C to 180 DEG C, and time ranges from 5 minutes to 15 minutes; fifthly, the shaped spiral cable is cooled through cooling water; sixthly, after cable cores at the two ends of the spiral cable obtained in the fifth step wind around a magnetic ring by three circles, the cable cores are fixed through buckles, and then the spiral cable connecting line can be obtained. The anti-electromagnetic interference and a spiral spring are organically combined, and the service life of a motor is effectively protected while the working range of a connecting rod of an electric tool is enlarged.

Owner:ZHENJIANG ZHONGJIA ELECTRICAL CO LTD

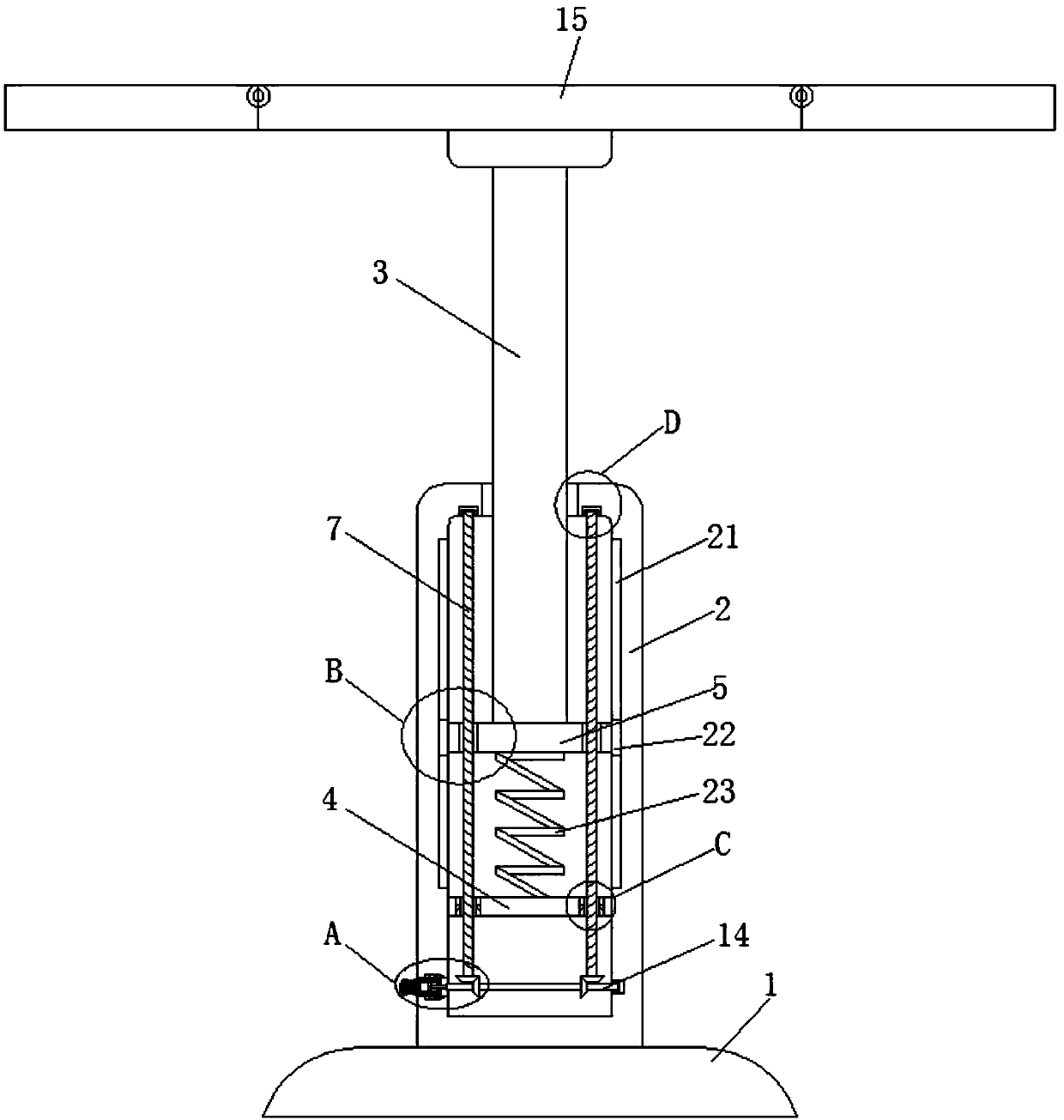

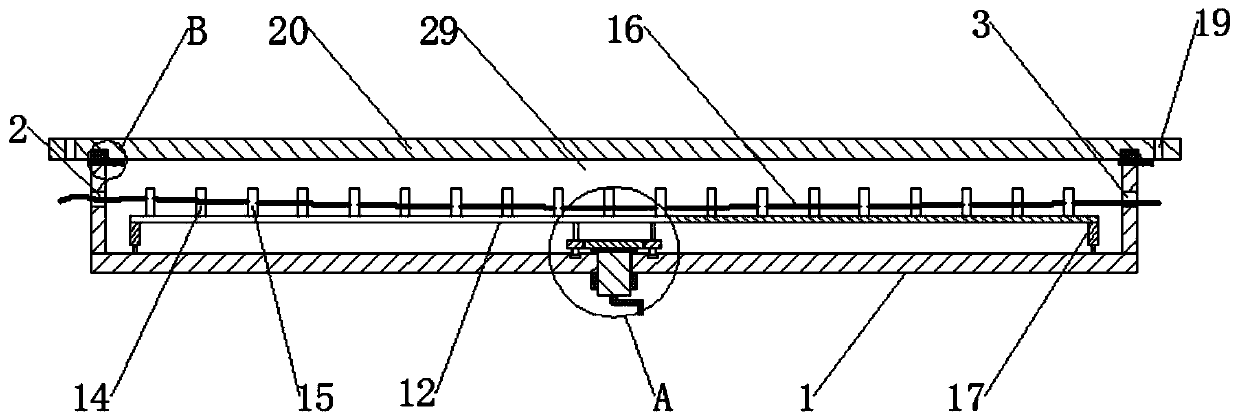

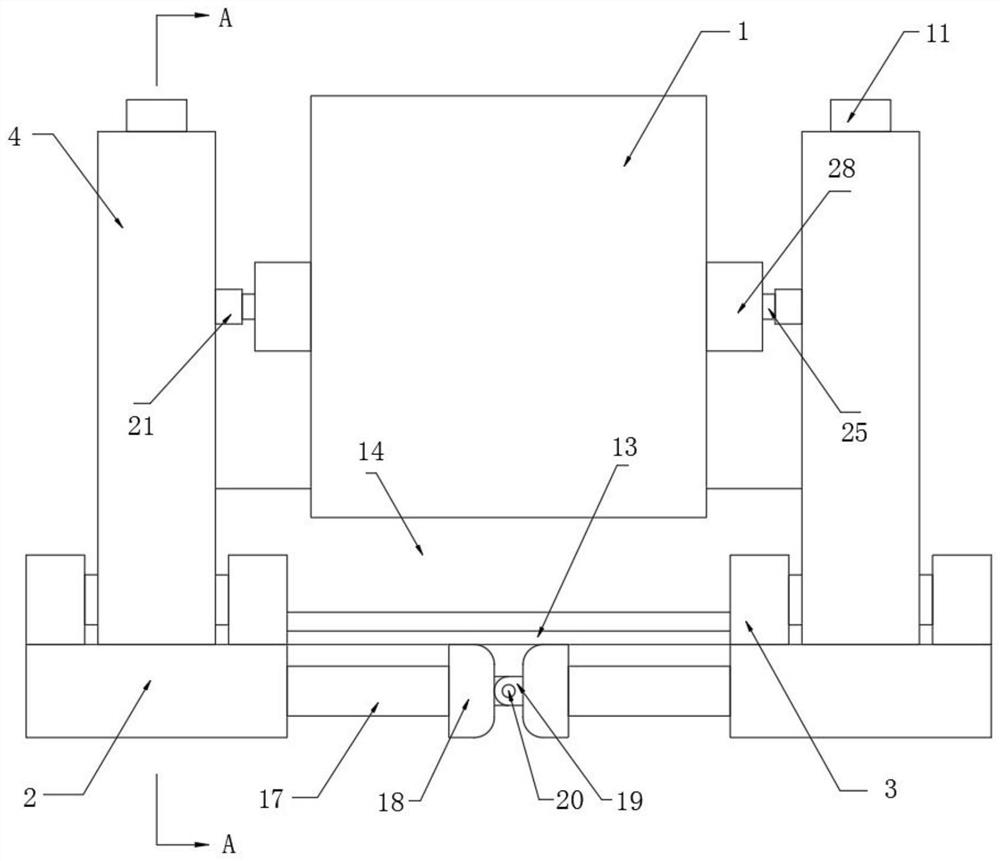

Supporting equipment for software development display screen

InactiveCN109668026AEffective contractionReduce volumeStands/trestlesSoftware engineeringSoftware development

The invention discloses supporting equipment for a software development display screen, and belongs to the field of software development. The supporting equipment for the software development displayscreen comprises a base, a mounting cylinder is fixedly connected to the top of the base, a lifter is arranged at the top of the mounting cylinder, the bottom end of the lifter penetrates through themounting cylinder and extends into the interior of the mounting cylinder, and a fixed plate which is fixedly connected to the inner wall of the mounting cylinder is arranged inside the mounting cylinder. With the rotating force applied to a rotating device, a rotating rod can be driven to rotate; through the cooperation among second conical gears, first conical gears, second bearings, first bearings and threaded rods, a movable block can be effectively driven to move downwards in the mounting cylinder, and the lifter can be quickly and effectively retracted into the mounting cylinder; and a folding supporting plate is folded, so that the size of the supporting equipment for the software development display screen is further reduced and the storage is more convenient.

Owner:池州市普丰科技服务有限公司

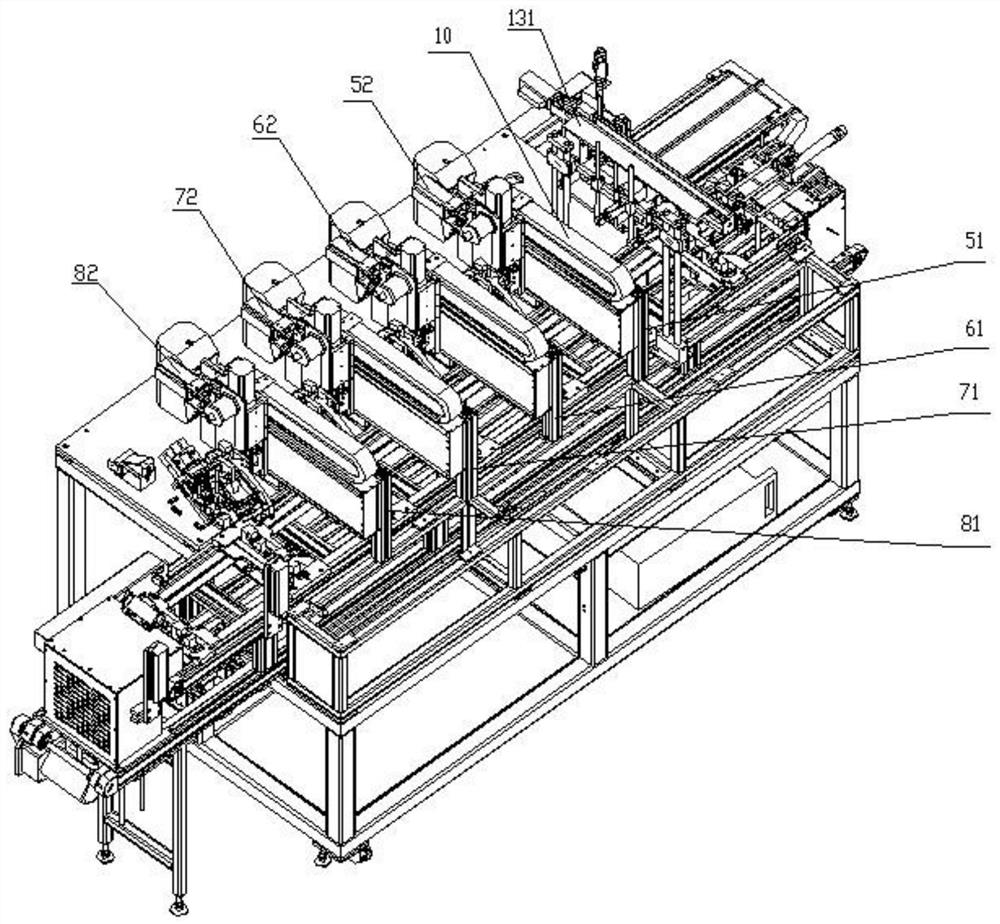

High performance WPU superfine fiber synthetic leather and clean production method thereof

ActiveCN106939517AShorten the lengthReduce widthFibre treatmentProduction lineWater vapor permeability

Provided are a high performance WPU superfine fiber synthetic leather and a clean production method thereof; superfine fiber synthetic leather base cloth is impregnated through an impregnating tank filled with a shrinkage and rubbing liquid and then enters a continuous graining machine, and the superfine fiber synthetic leather base cloth is dried to obtain shrinkage-rubbed base cloth; a synthetic leather dry-process production line provided with a PUR scraping device is adopted, a WPU coating is scraped on release paper and is dried, a WPU film is formed on the release paper, then the WPU film is coated with PUR, then the coated WPU film is fitted with the shrinkage-rubbed base cloth, and the obtained productt is cooled and coiled and is placed and cured; after the release paper is stripped, the high performance WPU superfine fiber synthetic leather is obtained. With adoption of the shrinkage rubbing technology, the softness, air permeability and water vapor permeability of the superfine fiber synthetic leather base cloth are greatly improved; then through the composite technology of coating layer transferring with release paper and PUR scrapping, the WPU coating layer is composited on the superfine fiber synthetic leather substrate, and the WPU superfine fiber synthetic leather with soft hand feeling and good mechanical properties and use performance is obtained.

Owner:JIANGSU KEMEI NEW MATERIALS

Suede simulation type superfine fiber synthetic leather and clean production method thereof

ActiveCN107177989AShorten the lengthReduce widthMechanical cleaningPressure cleaningProduction lineWater vapor permeability

The invention relates to suede simulation type superfine fiber synthetic leather and a clean production method thereof. The method comprises the steps of impregnating superfine fiber synthetic leather base cloth through an impregnating tank full of shrinking and kneading liquid, entering a continuous graining machine, drying the superfine fiber synthetic leather base cloth, and obtaining shrinking and kneading base cloth; adopting a flocking production line provided with PUR lattice roller coating equipment, coating PUR on the shrinking and kneading base cloth, sprinkling collagen fiber, adhering on the shrinking and kneading base cloth, cooling and winding, and placing to obtain flocking base cloth; adopting a brushing machine for removing the collagen fiber which is not firmly adhered onto the flocking base cloth, and obtaining the suede simulation type superfine fiber synthetic leather. According to the suede simulation type superfine fiber synthetic leather and the clean production method thereof provided by the invention, a shrinking and kneading technology is adopted, so that the softness, the air permeability and the water vapor permeability of the superfine fiber synthetic leather base cloth are greatly improved; a PUR lattice roller coating composite technology is adopted, so that the collagen fiber is compounded onto the superfine fiber synthetic leather base cloth, and the suede simulation type superfine fiber synthetic leather with the appearance being similar to the appearance of natural suede leather, and the mechanical property and the hygiene property being superior to the mechanical property and the hygiene property of the natural suede leather is obtained.

Owner:JIANGSU KEMEI NEW MATERIALS

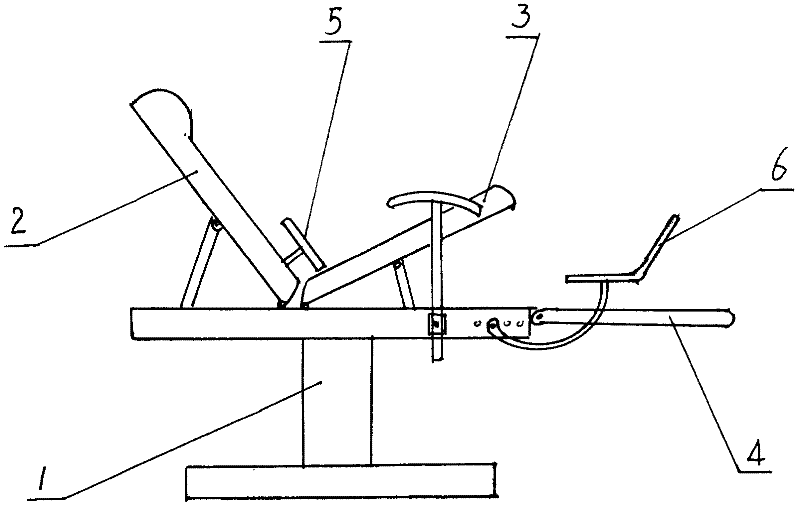

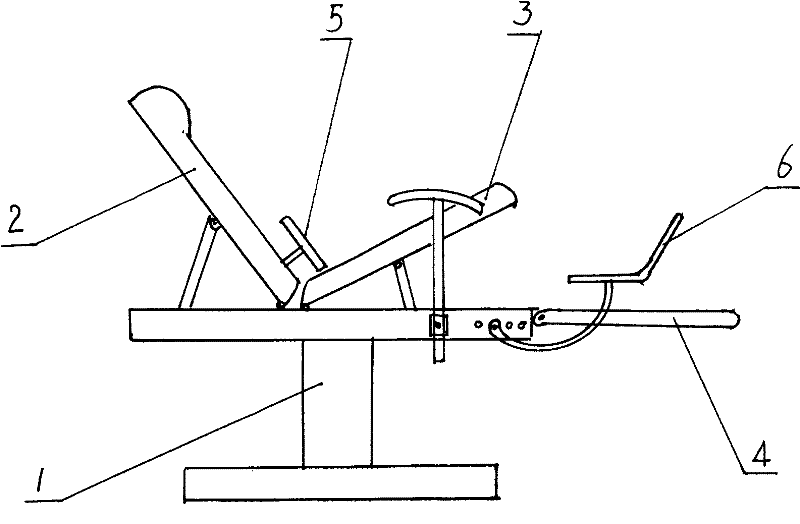

Pedal type gynecological obstetric bed

The invention discloses a pedal type gynecological obstetric bed. The pedal type gynecological obstetric bed has a bending bed structure consisting of a bed frame and a bed board, wherein the bed board consists of a head board, a waist board and a leg board; two sides of the bed board are provided with handrails; and pedal frames are movably connected with the positions of the bed board which correspond to two feet. When a pregnant woman gives birth to a child, a fulcrum is added for each foot of the pregnant woman, muscle body of legs and a lower body of the pregnant woman can be effectively shrunk at the moment, and the large effect can be achieved with smaller force by the physical strength of the pregnant woman, so that the childbearing process is promoted; and in addition, the pedal frames are movably connected to the bed board, so the pedal frames can be adjusted from front to back according to the heights of pregnant women to meet the requirements of the pregnant women of different heights.

Owner:许圣菊

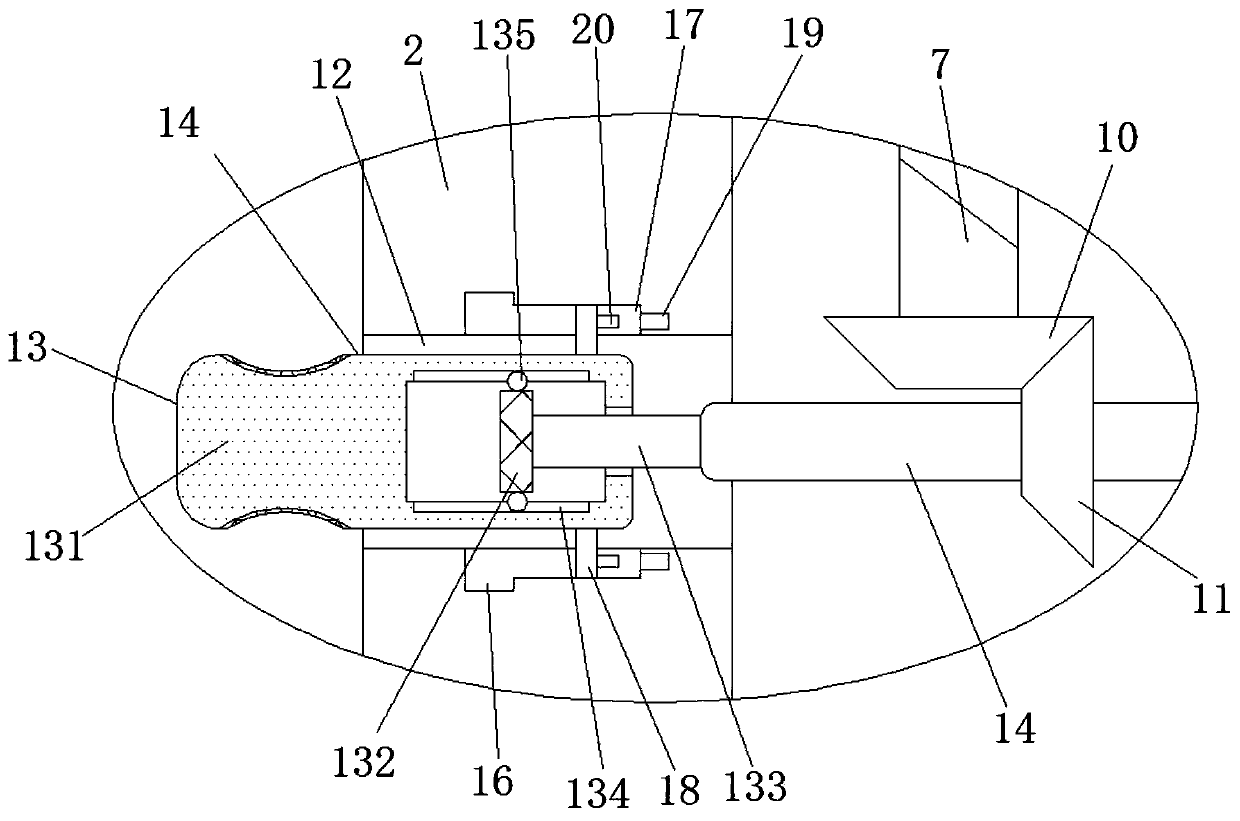

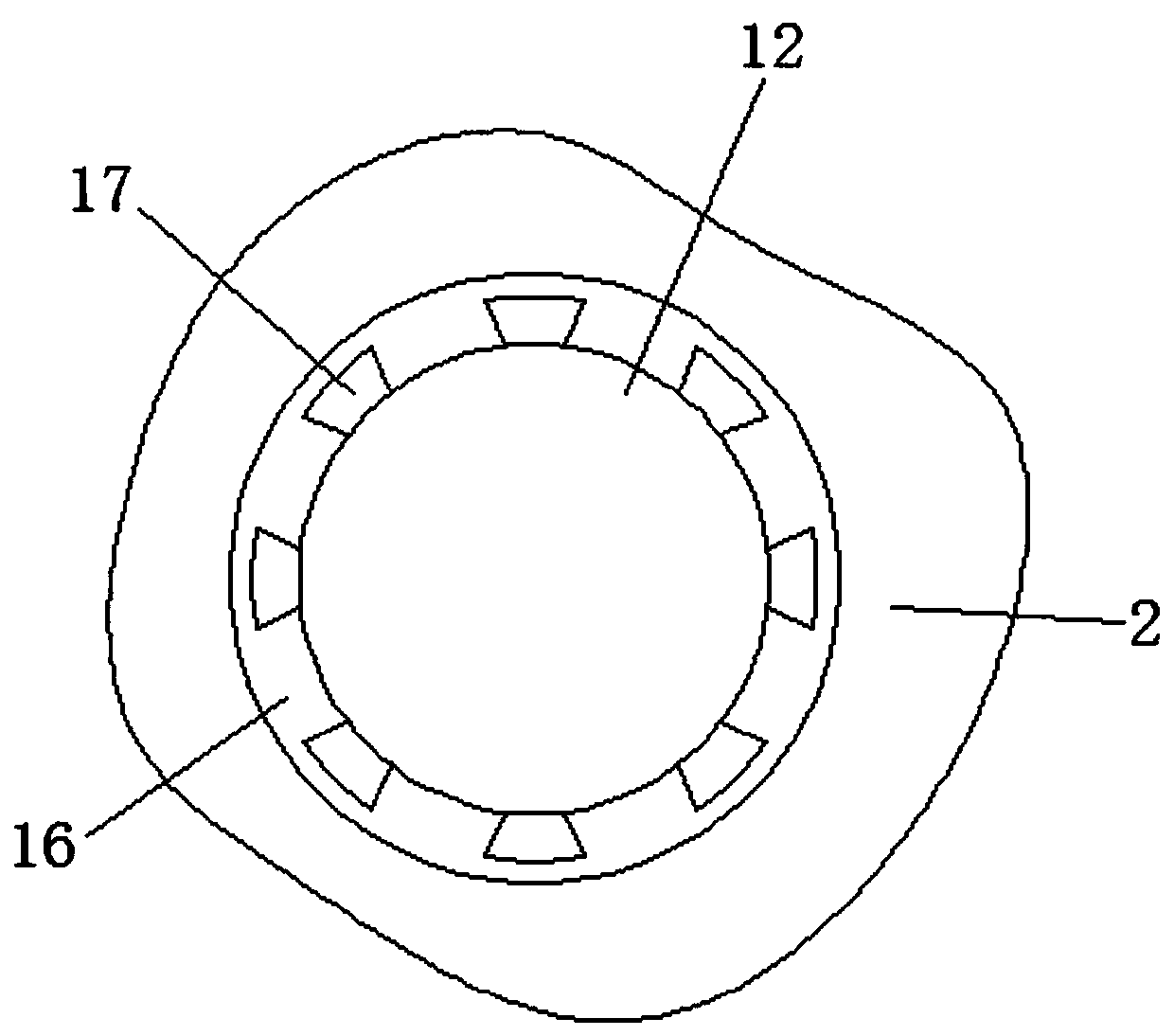

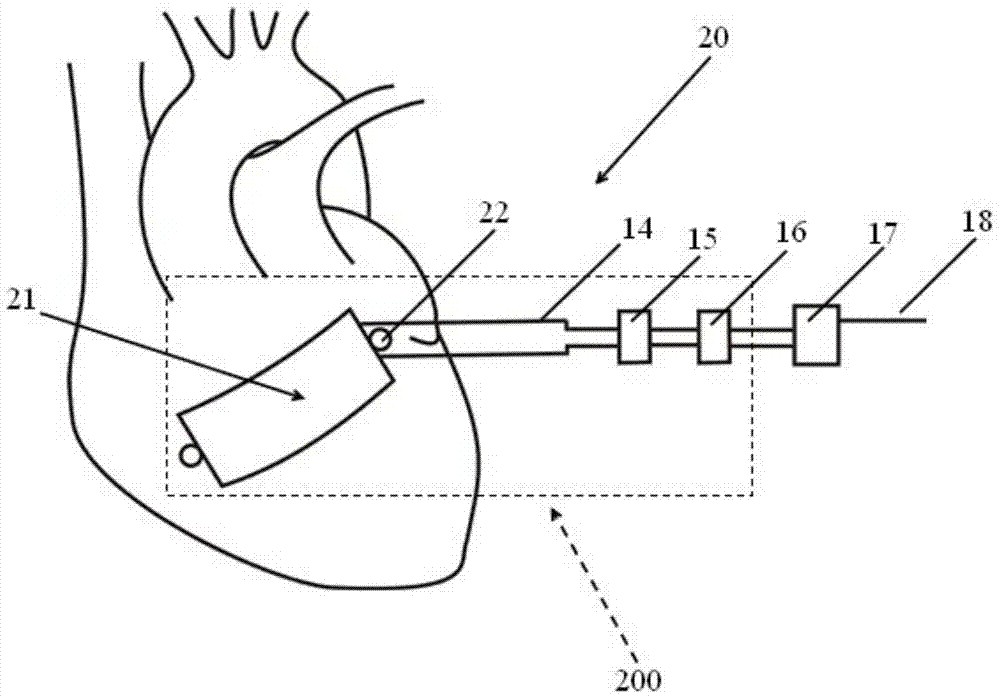

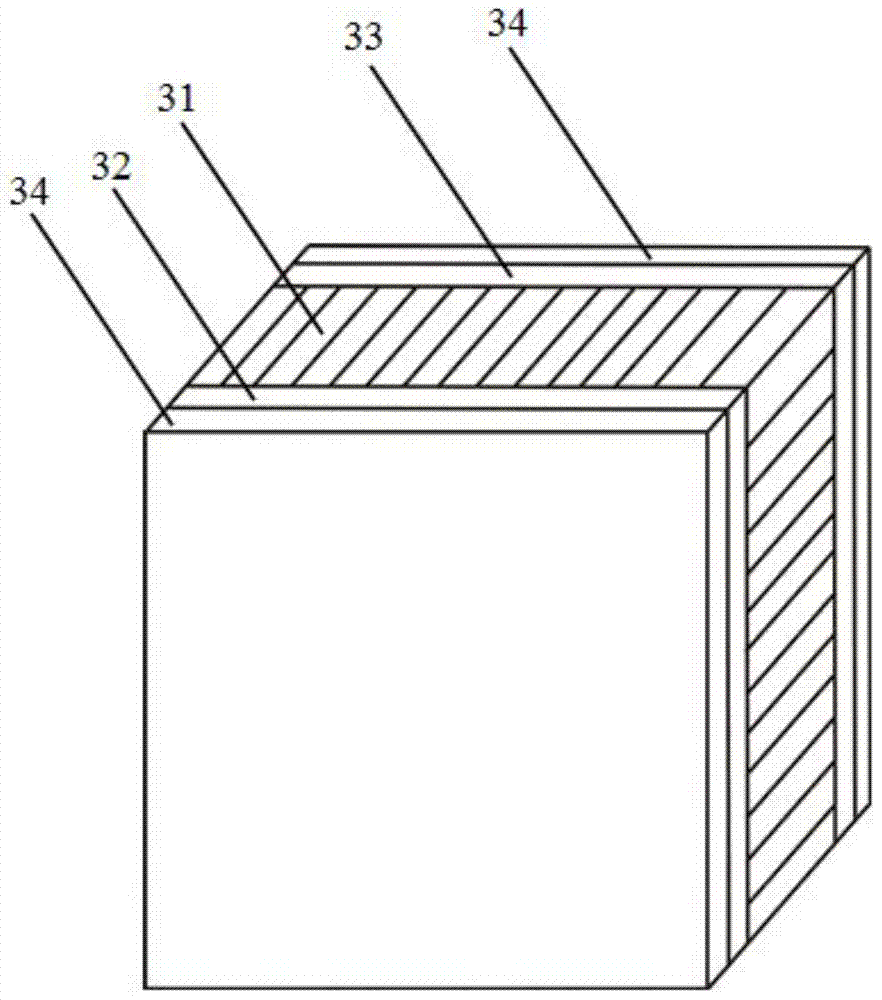

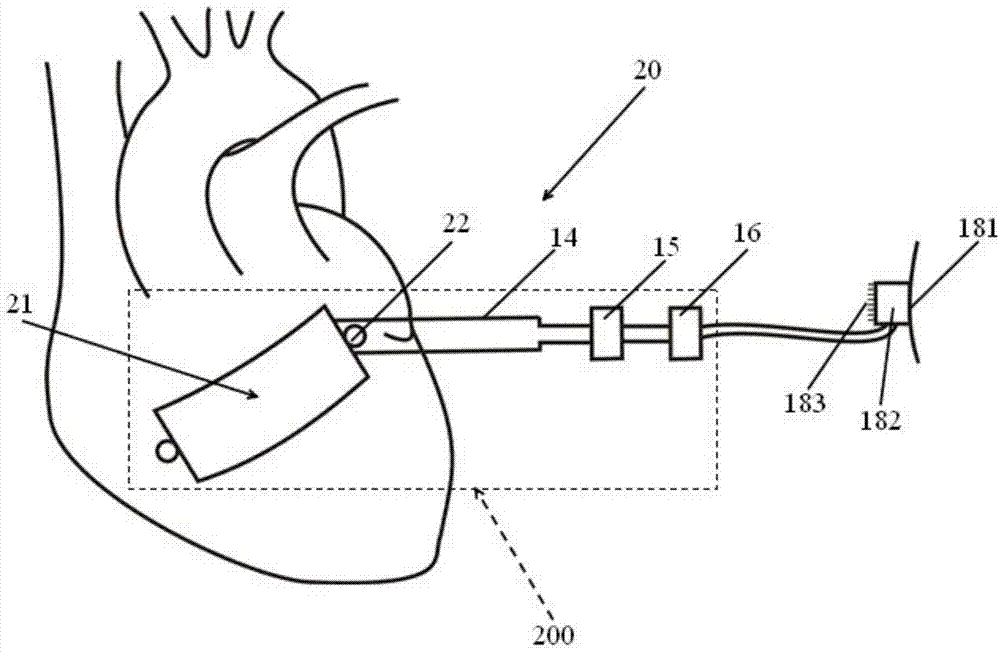

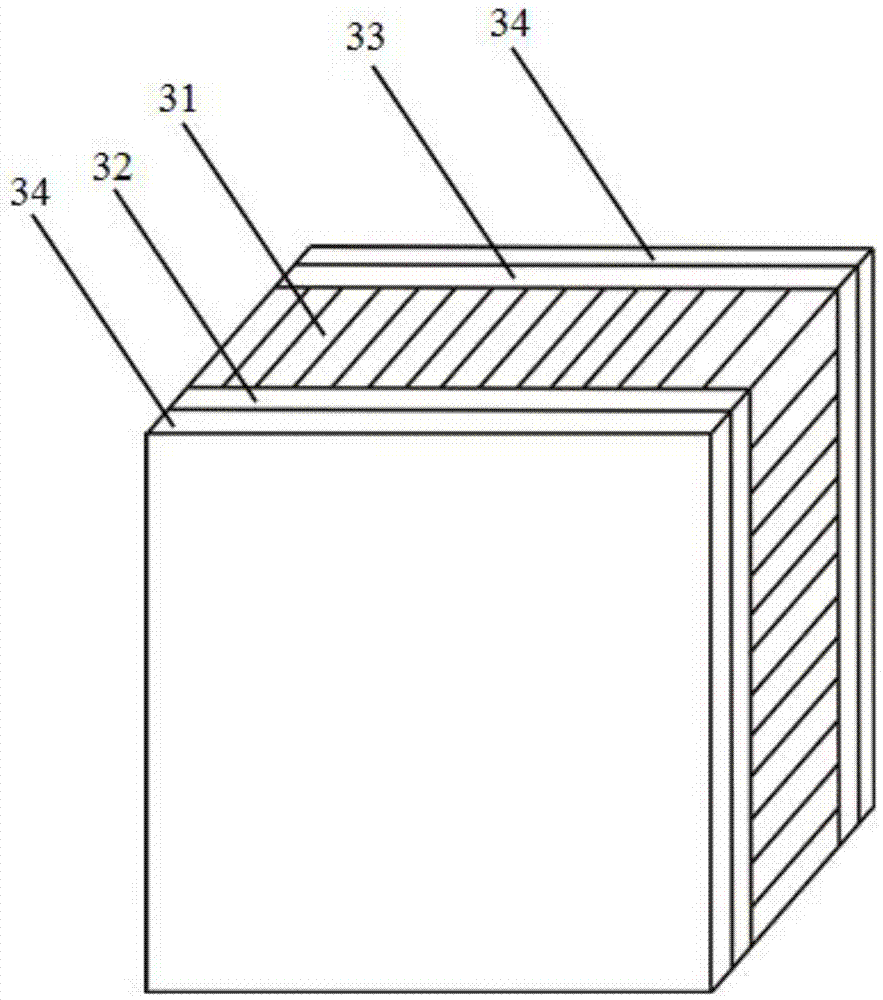

Self-energized bladder pacemaker

InactiveCN104740763AEffective contractionEffective relaxationPiezoelectric/electrostriction/magnetostriction machinesArtificial respirationElectricityPower flow

The invention provides a self-energized bladder pacemaker, which is characterized by comprising a pulse generator, an exciting electrode, and a power generation portion. The power generation portion comprises a power generation main body, an output unit, an electric energy storage unit, a fixing unit, and a packaged layer. The power generation main body is in a multilayered film structure, comprising a piezoelectric material layer on the center of the power generation main body and electrode layers on two sides of the piezoelectric material layer. The power generation main body is adhered to the surface of a heart to acquire energy of the heart to generate electric energy. The output unit is connected with the electrode layers, and the output unit is used to output current generated by the power generation main body to the electric energy storage unit. The electric energy storage unit is used to store electric energy and supply power for the pulse generator. The fixing unit is on the edge of the power generation main body, and is used to fix the power generation main body on the epicardium. The packaged layer covers the surfaces of the power generation main body, the output unit, the electric energy storage unit, and the fixing unit. The self-energized bladder pacemaker does not need to change batteries, and can be used for whole life.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

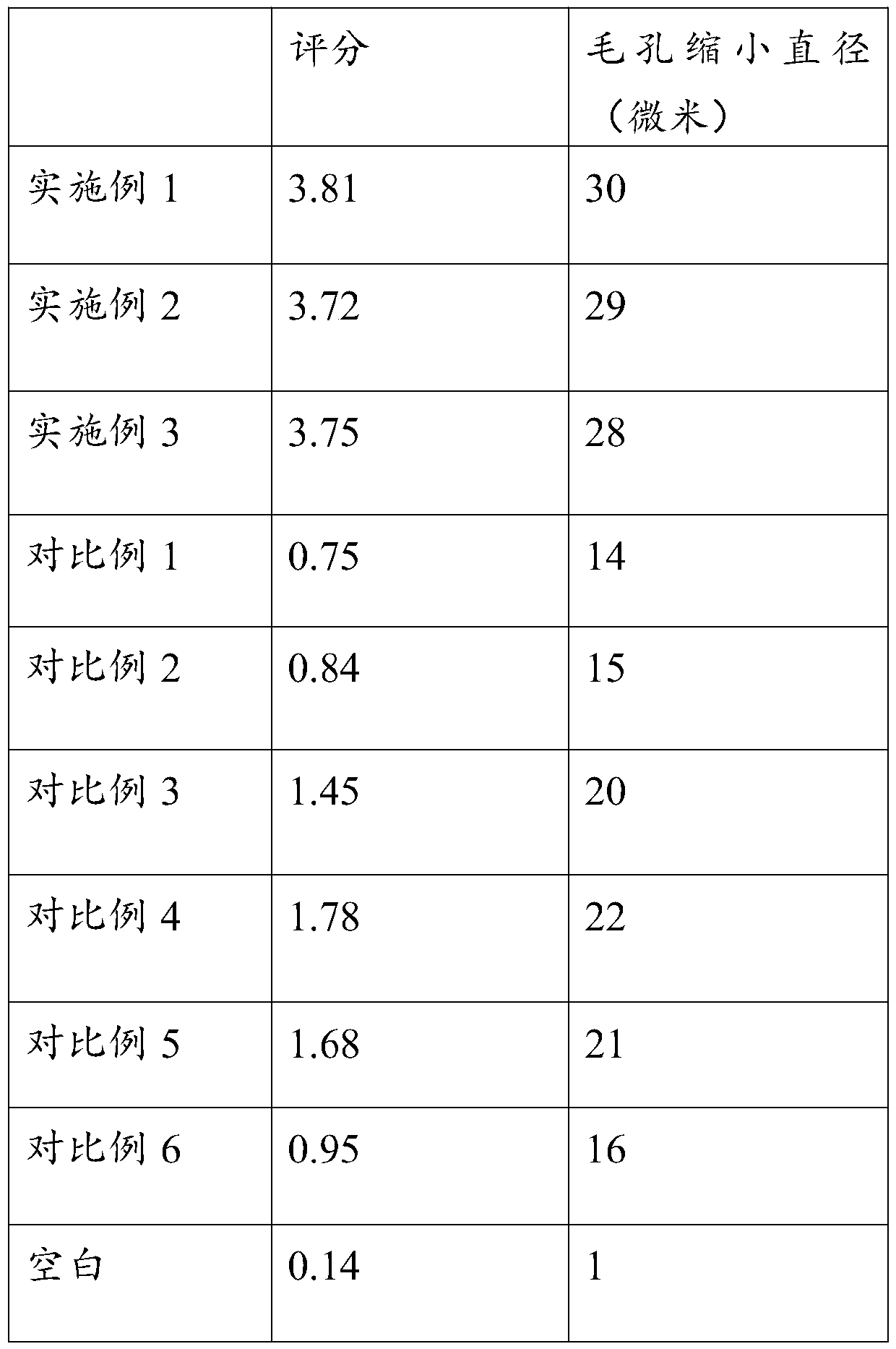

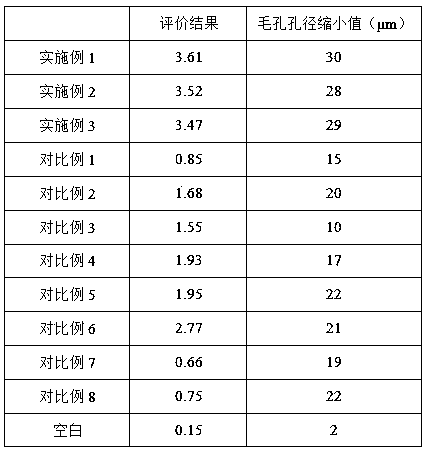

Formula for instantly shrinking pores in long-acting manner and application

InactiveCN111450000AInhibitionReduce generationCosmetic preparationsToilet preparationsEngineeringOfficinalis

The invention discloses a formula for instantly shrinking pores in a long-acting manner and application. The formula is characterized by comprising 10-20% of a Schinus extract, 20-30% of a fomes officinalis extract and 50-70% of nicotinamide. Compared with the prior art, the formula has the advantages that the Schinus extract, the fomes officinalis extract and the nicotinamide are compounded, so that the pores can be effectively shrunk, and the skin is smoother; the formula is combined with cosmetics with water as a basic solvent for use, so that effects of shrinking the pores, and tighteningand cleaning the skin can be fully achieved, and meanwhile, the resistance of the skin to air pollution PM2.5 can be enhanced.

Owner:深圳市大美仁生物科技有限公司

Production method of vegetarian sausage

InactiveCN109497168AImprove tasteRational use of resourcesCheese manufactureFood scienceSodium carbonateFlavor

The invention discloses a production method of a vegetarian sausage, and belongs to the field of processing techniques of soybean products. The production method of the vegetarian sausage comprises the following steps: preparing raw materials, soaking, soaking with sodium carbonate, squeezing, cutting into pieces, wrapping with cloth, binding, cooking for shaping and marinating. With adoption of the production method, the taste of the vegetarian sausage is effectively improved on a basis of ensuring the nutritive value of the vegetarian sausage; in addition, broken dried bean curds are taken as the raw materials in a production process, so that the produced vegetarian sausage contains the flavor of the soybean products, resources are reasonably utilized, and the broken dried bean curds cannot be wasted.

Owner:JINCAIDI FOOD CO LTD

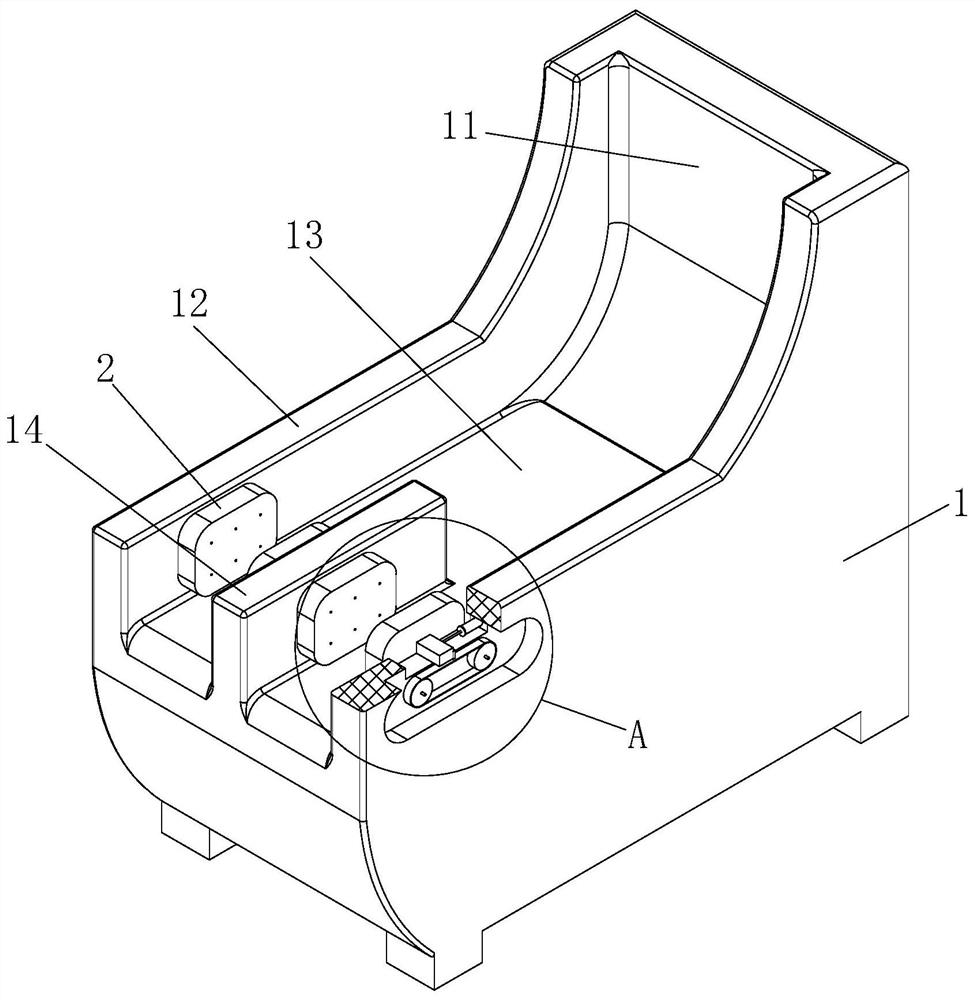

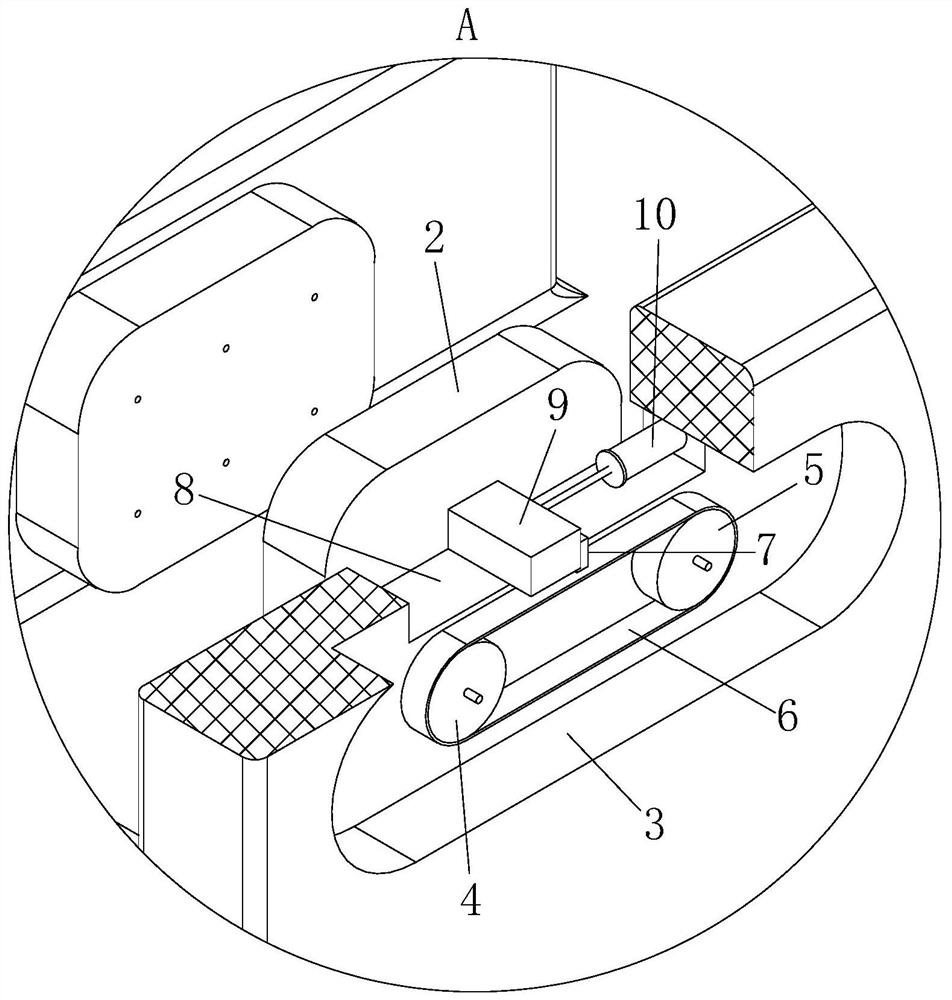

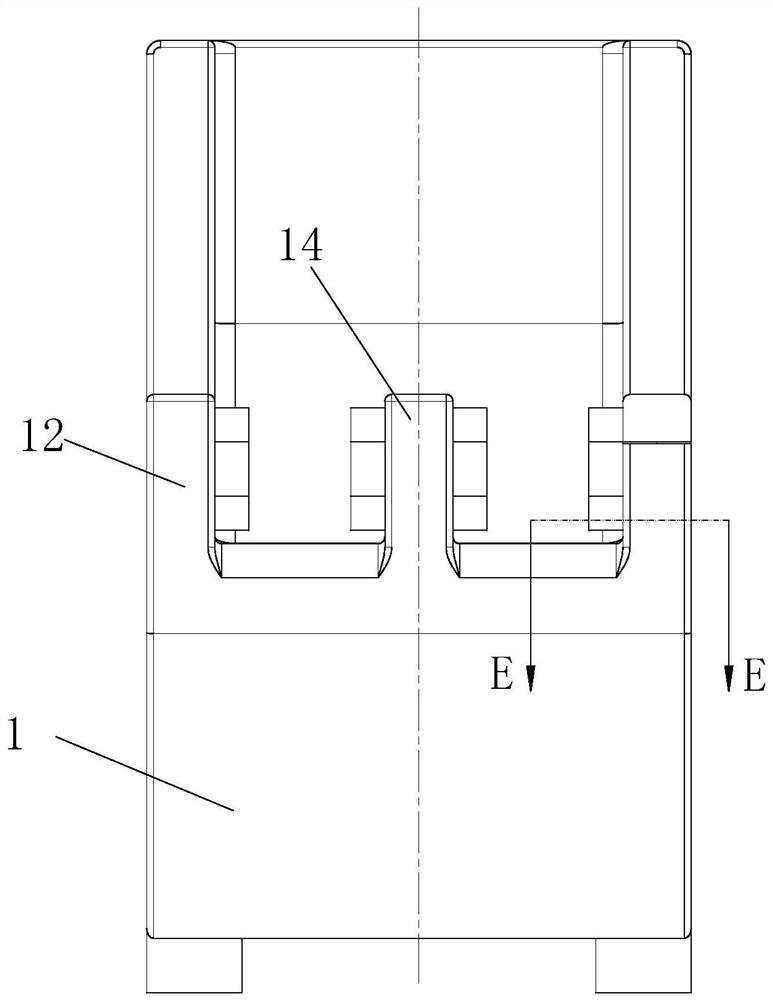

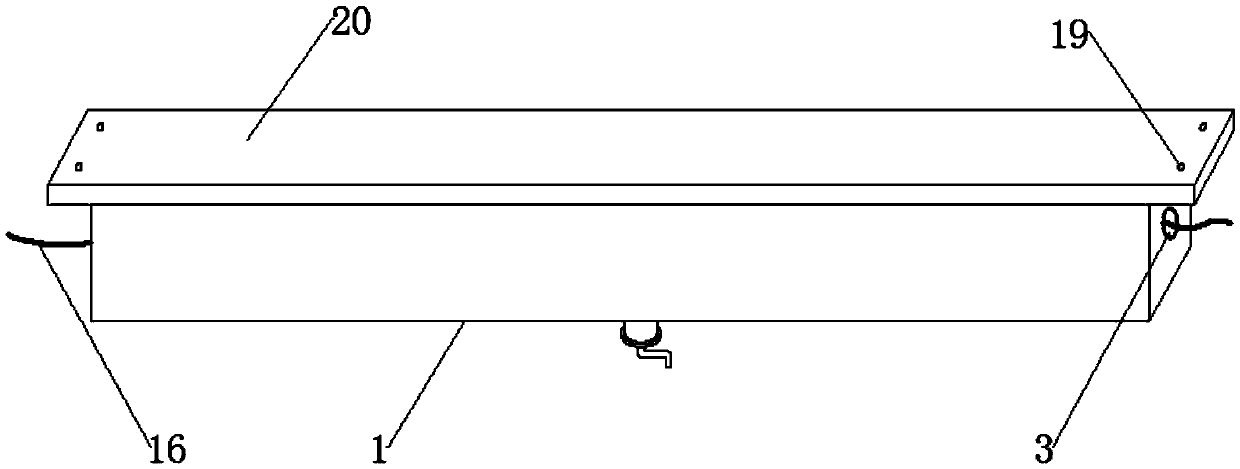

Guiding type semi-automatic massager

InactiveCN112515932AEasy to relaxEffective contractionSuction-kneading massageDrive wheelClassical mechanics

The invention belongs to the field of massagers, and particularly relates to a guiding type semi-automatic massager. The guiding type semi-automatic massager comprises a main body; a back cushion is arranged on the rear part of the main body; side plates are arranged on the left side and the right side of the main body; a sitting cavity is formed between the side plates; a middle plate is fixedlyconnected to the part, between the two side plates, of the main body; the length of the middle plate is smaller than that of the side plates; a pair of clamping bags is arranged between the side plates and the middle plate; the clamping bags are slidably connected with the side plates and the middle plate; the clamping bags communicate with air pumps through air pipes and control valves; side groove are formed in the sides, away from the clamping bags, of the side plates; driving wheels and driven wheels are rotationally connected with the side grooves; the driving wheels and the driven wheelsare sleeved with conveying belts; and baffles are fixedly connected to the outer sides of the conveying belts. By inflating the clamping bags and controlling sliding blocks to drive the clamping bagsto slide at the same time, the clamping bags clamp a leg and then drag the leg, muscles of the leg are effectively contracted and relaxed, and meanwhile the flexibility of the clamping bags can improve the leg relaxing effect, eliminate fatigue and improve comfort.

Owner:杭州黎桂电子商务有限公司

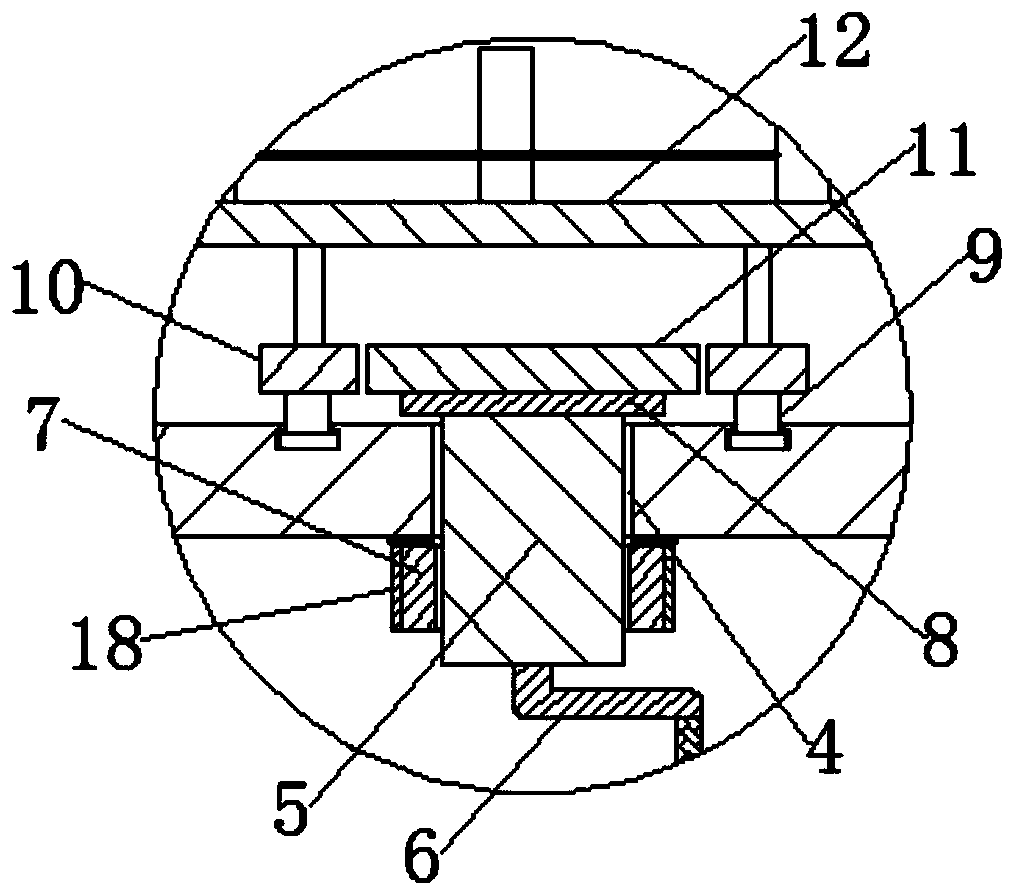

Novel cable retracting device

ActiveCN109534105AEffective contractionControl lengthArrangements using extensible carrierScrew threadGeotechnical engineering

The invention relates to the field of cables, and discloses a novel cable retracting device. The novel cable retracting device comprises a cable placement box body, the cable placement box body comprises a bottom plate, front and rear side plates and left and right side plates, a cable is placed inside the cable placement box body, a wire supplying hole is formed in the left side plate of the cable placement box body, a wire outlet hole is formed in the right side plate of the cable placement box body, a rotary through hole is formed in the bottom plate of the cable placement box body, an external thread rotary rod is inserted in the rotary through hole, the outer end of the external thread rotary rod is connected with an inner thread screw sleeve in a threaded mode, the inner thread screwsleeve is located on the lower side of the bottom plate of the cable placement box body, a handle is fixedly connected to the lower end of the external thread rotary rod, a limiting plate is fixedlyconnected to the upper end of the external thread rotary rod, the limiting plate is located in the cable placement box body, a gear is fixedly connected to the upper end of the limiting plate, and racks are connected to the left end and the right end of the gear in an engaged mode correspondingly. The cable can be effectively retracted, the required length of the cable when in use is effectively controlled, and the phenomenon of cable winding or knotting is decreased.

Owner:迅立达电梯有限公司

Pure plant edible freckle-removing mask and use method thereof

InactiveCN109431952ASolve allergiesSolve the easy-to-growth bacteriaCosmetic preparationsToilet preparationsVitamin CAllergy

The invention discloses a pure plant edible freckle-removing mask and a use method thereof, relating to the technical field of skincare. The mask is prepared from the following raw materials: sticky rice flour, vitamin C, coix seed flour, milk powder, edible gypsum powder, oat powder, vitamin E, honey, lemon juice, edible vinegar and egg yolk. Mask components are regulated according to use time. During one to seven days of use, a basic preparation job is made for removing freckles and inhibiting melanin generated in dermis in following days; during 8-15 days, the melanin is reduced; during 16-18 days, cell metabolism is promoted; and during 19-20 days, the mask has effects of smoothing skin and inhibiting sensitivity, so as to keep the skin vibrant. All raw materials of the mask are food level, thereby being purely natural, containing no additives and causing no allergy, therefore, the mask solves the problems that existing mask is easy to cause allergy and grow bacterium, makes the skin more transparent effectively, reduces the melanin, and has good effects in removing the freckles, moisturizing and whitening.

Owner:曹秀琴

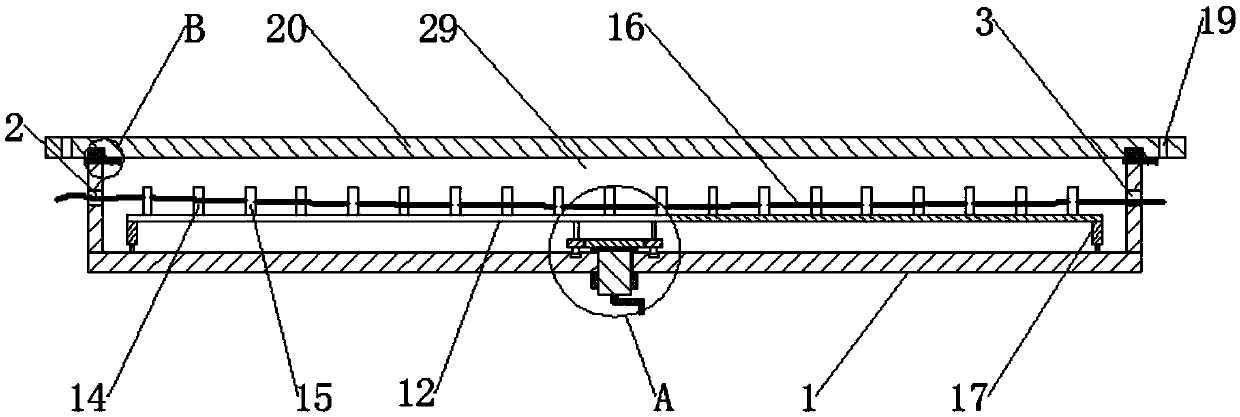

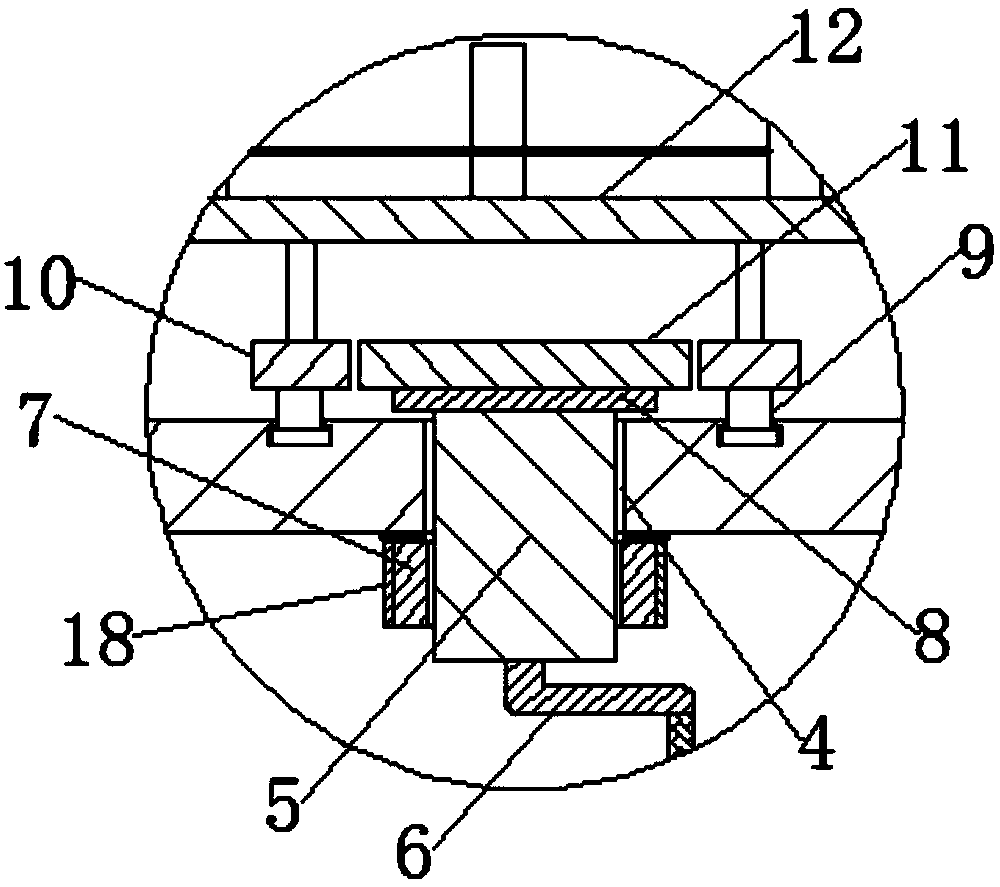

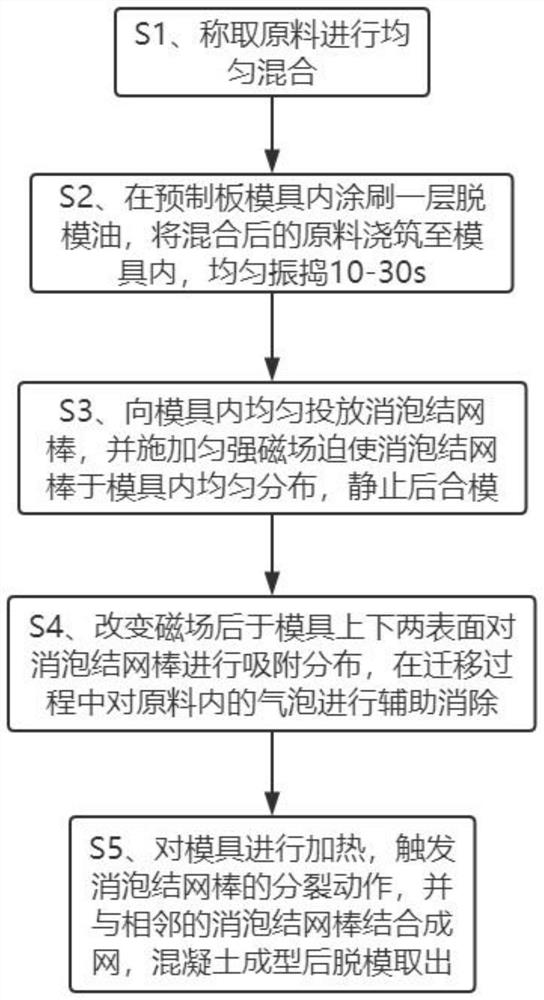

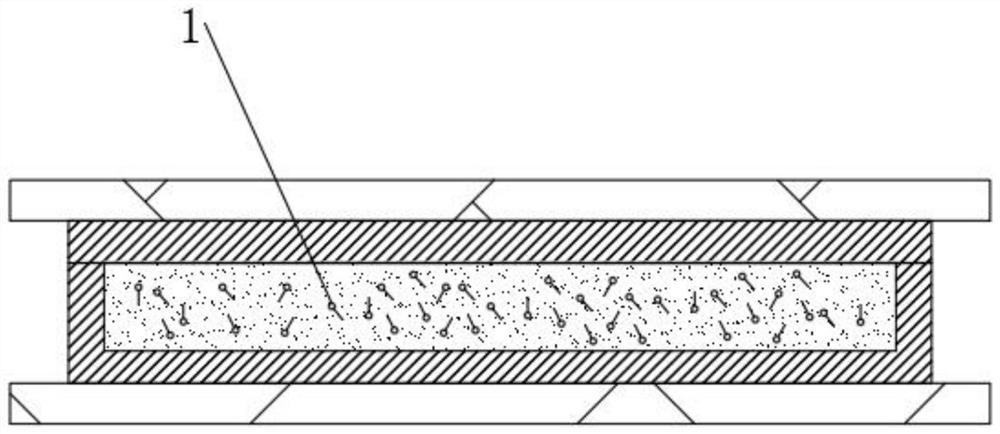

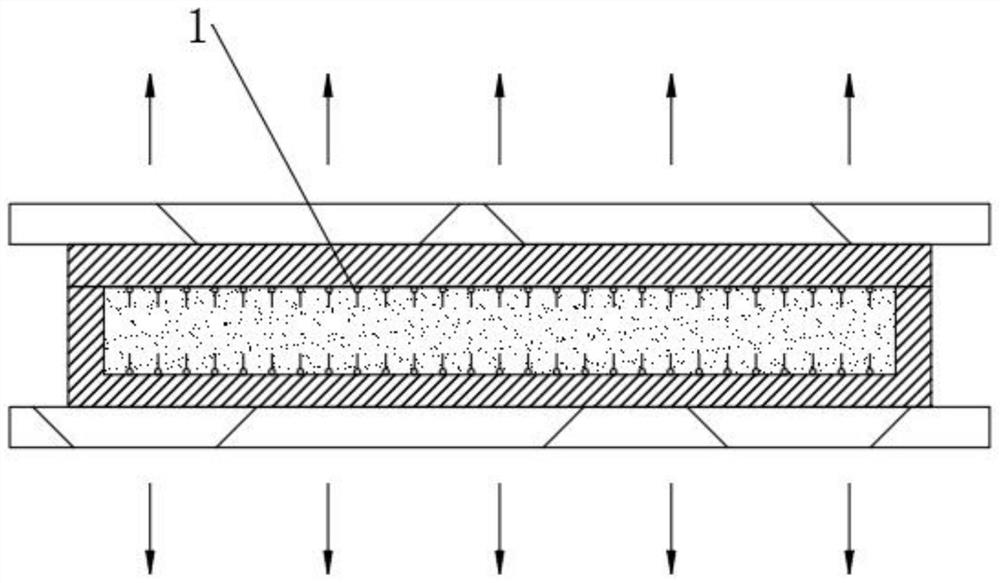

Processing method of high-compactness concrete precast slab capable of preventing surface cracking

InactiveCN112025968AImprove densification performanceHigh molding strengthCeramic shaping apparatusStructural engineeringUltimate tensile strength

The invention discloses a processing method of a high-compactness concrete precast slab capable of preventing surface cracking, and belongs to the technical field of concrete precast slabs. Accordingto the processing method, defoaming net-forming rods can be innovatively introduced and are uniformly distributed through a uniform magnetic field before being solidified, then the defoaming net-forming rods are forced to move from the middle of concrete to the surfaces of the two sides, bubbles in the concrete can be effectively eliminated, so that the compactness of the formed concrete is improved, and the air hole defect is greatly improved; after the defoaming net-forming rods are migrated to the surface of the concrete, the splitting action of the defoaming net-forming rods is triggered in a heating mode, so that the defoaming net-forming rods are in contact with the adjacent defoaming net-forming rods and are combined to form a net; and through melting and re-curing of phase change nodes, a high-strength connecting surface is formed, a net-shaped reinforcing structure is formed on the surface of the concrete, and the contraction force is triggered when the temperature is reduced,so that the phenomena of water seepage and cracking of the surface of the concrete are prevented, and the forming strength and the compactness of the concrete are effectively improved.

Owner:郭冰晨

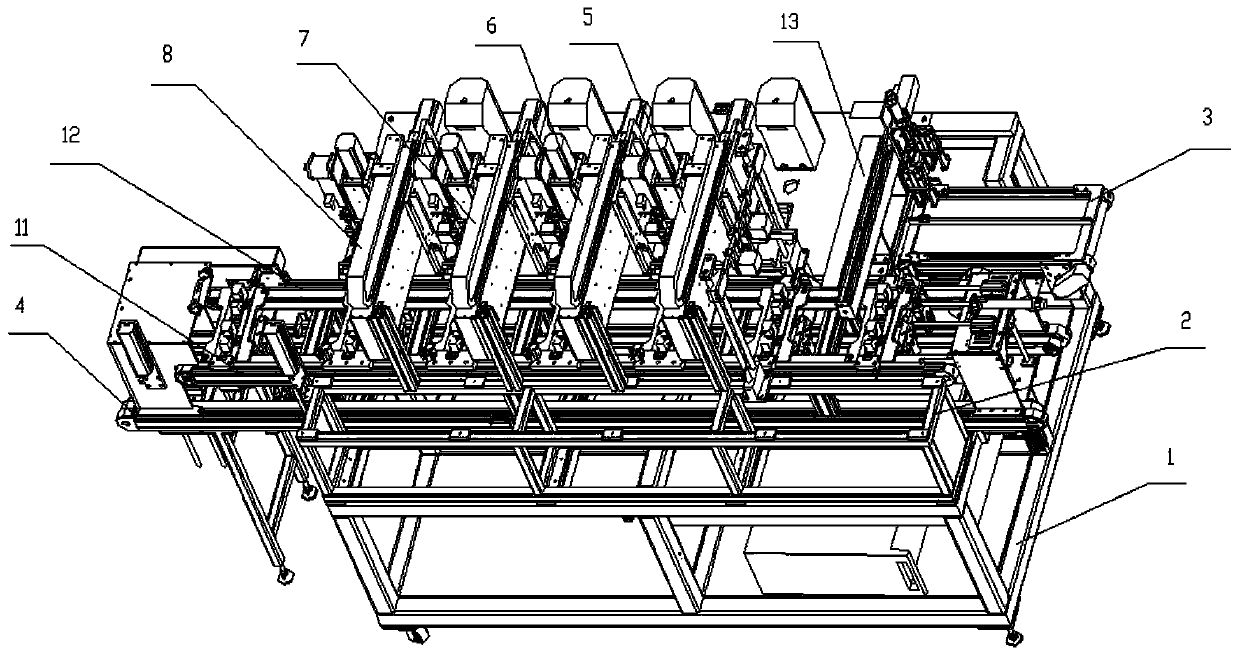

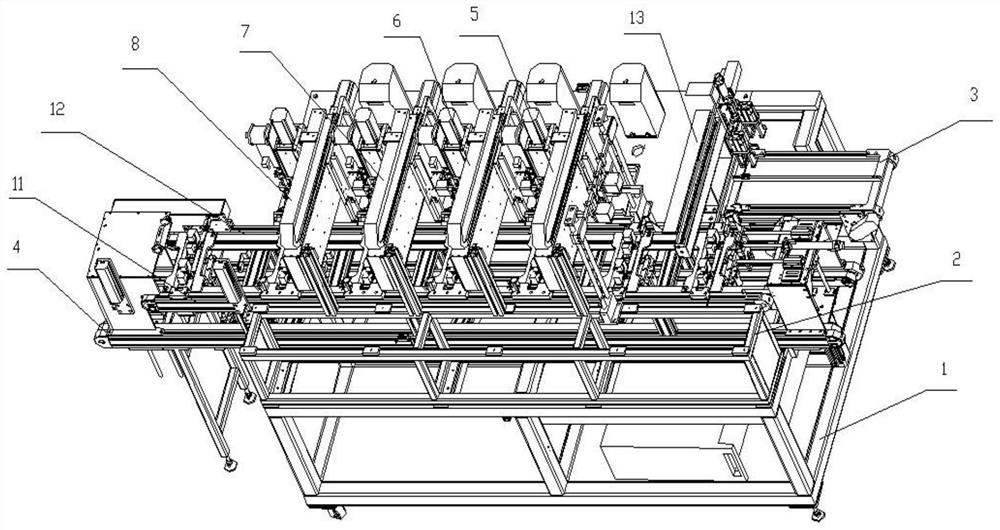

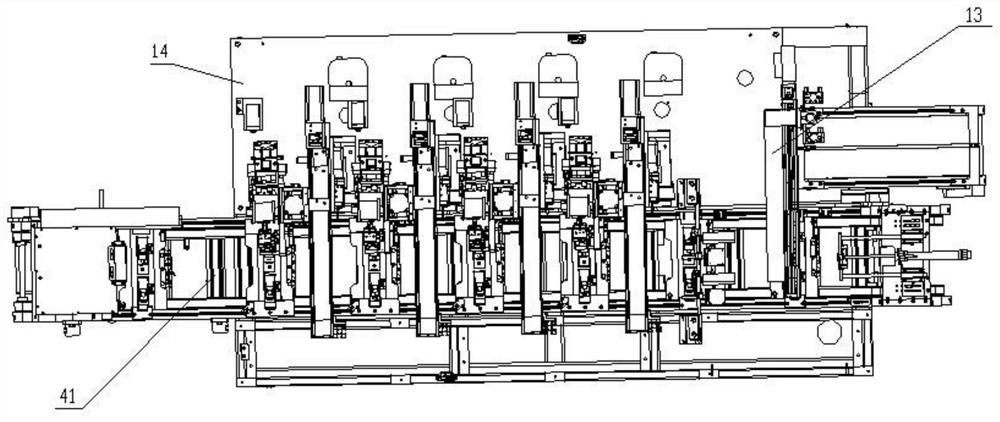

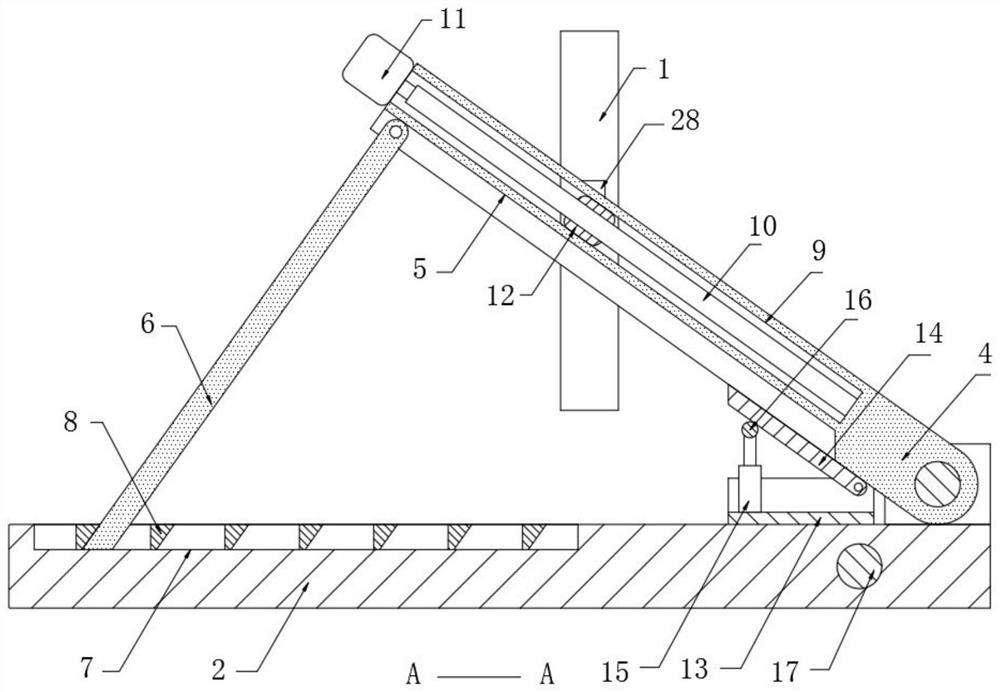

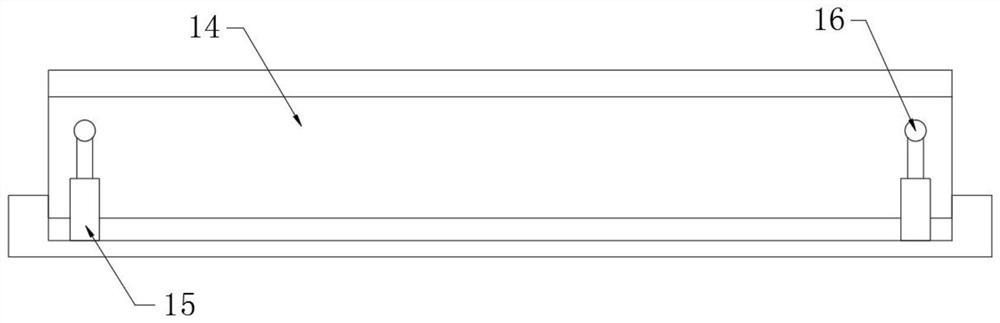

Multi-layer circuit board welding device convenient to adjust

ActiveCN109702288ALive UpdateGood lifting effectMultilayer circuit manufactureSoldering auxillary devicesEngineeringPetroleum engineering

The invention discloses a multi-layer circuit board electric welding device convenient to adjust. The multi-layer circuit board electric welding device convenient to adjust comprises a supporting frame, a fixed frame and a linkage mechanism. The linkage mechanism is installed at one end of the supporting frame, the linkage mechanism is arranged under a circuit board outlet, a circuit board inlet is formed in the other end of the supporting frame, and a first welding station, a second welding station, a third welding station and a fourth welding station are installed sequentially between the circuit board inlet and the circuit board outlet. According to the multi-layer circuit board welding device convenient to adjust, the width between conveyor belts is adjusted by ball screws, the heightof a welding structure is adjusted by a swinging arm, the position of a motor is adjusted by a telescopic rod to drive the transmission of the moving conveyor belt and the fixed conveyor belt, the welding device is effectively adjusted from width and thickness to enable the welding device to be suitable for welding of various multi-layer circuit boards, and the equipment cost and production cost are saved.

Owner:安徽米兰电子科技有限公司

A kind of high-performance tpu superfine fiber synthetic leather and its clean production method

The invention provides high performance TPU superfine fiber synthetic leather and a cleaner production method thereof. The method comprises the following steps: a piece of superfine fiber synthetic leather base cloth is dipped by a dipping tank which contains shrinking and boarding liquid, the synthetic leather base cloth enters a continuous type boarding machine, and a piece of boarding base cloth is obtained; a calendering production line is used, calendering materials are thrown into a high speed kneader for mixing, after mixing, plastication and calendering of the materials, the materials and a piece of release paper are laminated, in order to obtain a release paper laminated TPU film; a synthetic leather dry method production line with a piece of PUR scraping equipment is used, PUR is scraped on the release paper laminated TPU film, the boarding base cloth is attached, the release paper is peeled, and the product is obtained. Shrinking and boarding technology is used, in order to greatly improve flexibility, permeability and moisture permeability of the superfine fiber synthetic leather base cloth; the scraping and lamination technology of release paper transferred coating and reaction type polyurethane hot melt adhesive is used, the thermoplastic polyurethane calendering film is laminated on the superfine fiber synthetic leather base material in order to obtain the TPU superfine fiber synthetic leather with soft hand feeling, mechanical properties and good usage performance.

Owner:JIANGSU KEMEI NEW MATERIALS

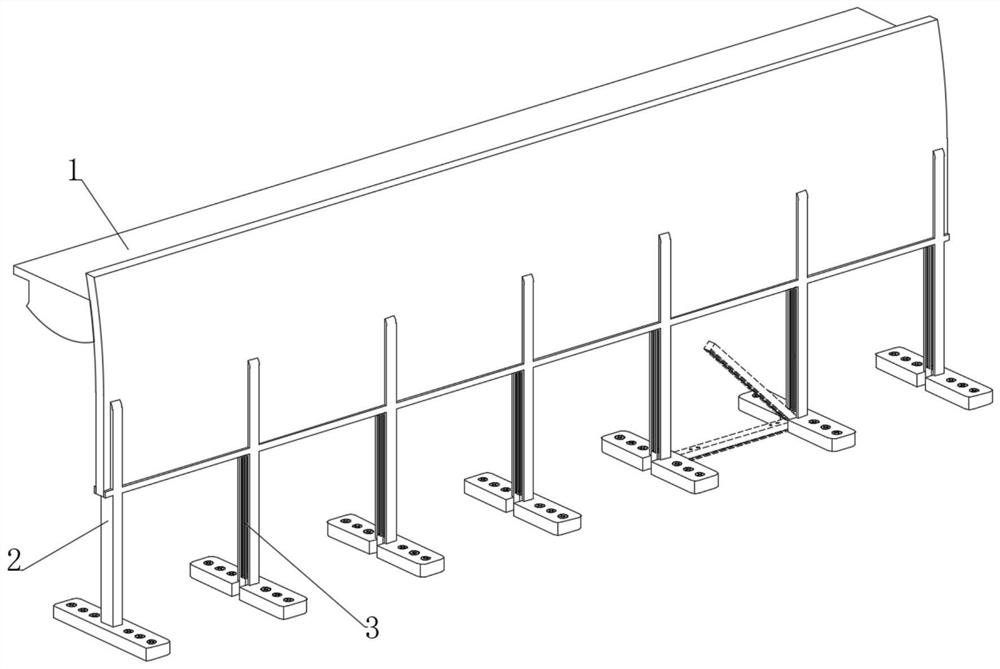

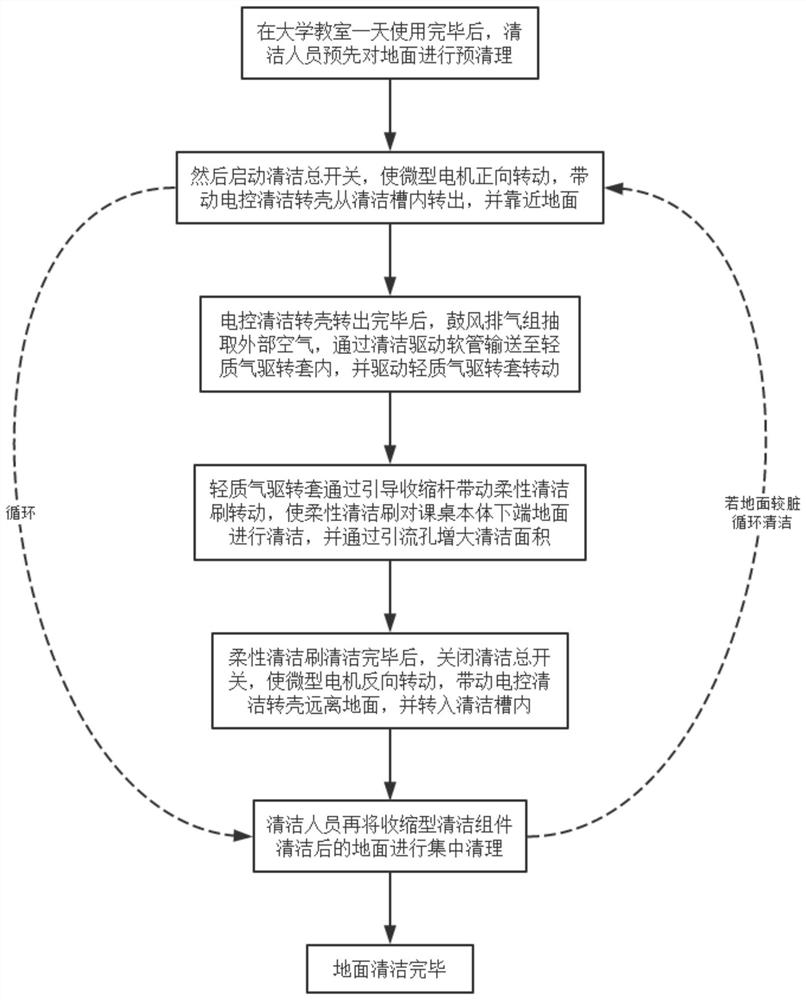

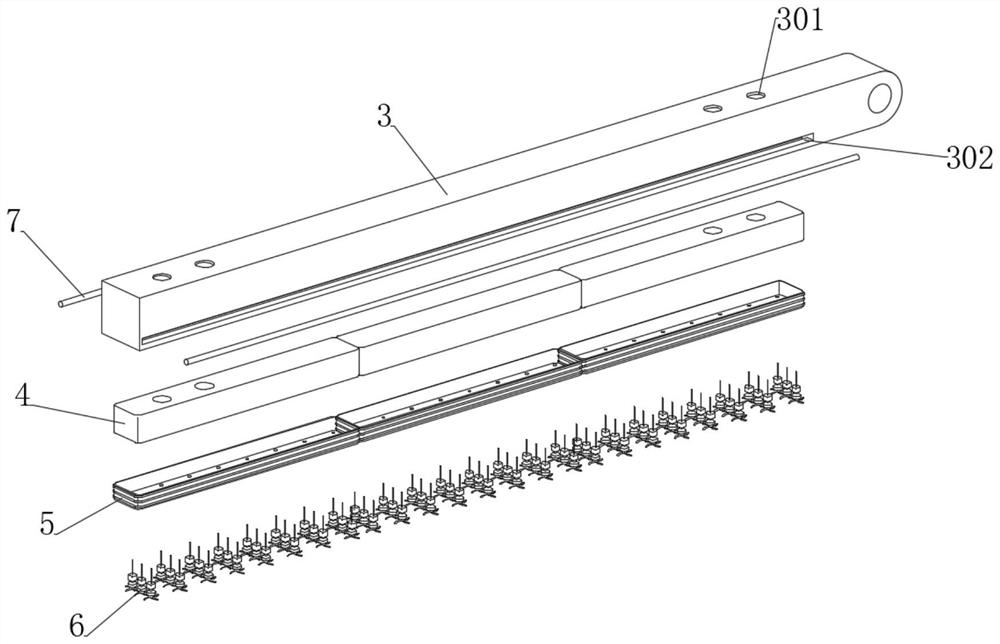

Desk with ground cleaning structure and use method thereof

The invention discloses a desk with a ground cleaning structure and a use method thereof, and belongs to the field of desks. The desk with the ground cleaning structure comprises combined desk legs fixedly connected to the lower end of a desk body, and cleaning grooves are formed in the inner side surfaces of the combined desk legs; and through mutual cooperation of an air blowing exhaust set and a retractable cleaning assembly, when the ground is cleaned, the retractable cleaning assembly continuously rotates and sweeps, so that dust and bacteria accumulated at the lower end of the desk body are quickly discharged, cleaning workers can conveniently clean the ground after use, the cleaning efficiency is improved, and the labor intensity of the cleaning workers is relieved, and meanwhile, the cleaning effect is greatly improved, accumulation and breeding of dust and bacteria at the lower end of the desk body are reduced, the body health of college students in class is effectively guaranteed, an electrically-controlled cleaning rotating shell can be stored, the occupied area is effectively reduced, and normal class of the students is not hindered.

Owner:詹睿

Composition for shrinking pores as well as preparation method and application thereof

InactiveCN110169935AEffective contractionCosmetic preparationsToilet preparationsMedicineOfficinalis

The invention relates to the field of cosmetics, provides a composition for shrinking pores as well as a preparation method and application thereof, and is used for solving the problem of rough poresof skin. The composition for shrinking the pores provided by the invention is prepared from 2-40% of a herba portulacae extract, 2-40% of a fomes officinalis extract and 2-40% of a salix nigra bark extract. Through compounding herba portulacae, fomes officinalis and salix nigra bark, the pores can be effectively shrunk, and the skin can be smoother.

Owner:广东科盈科技有限公司

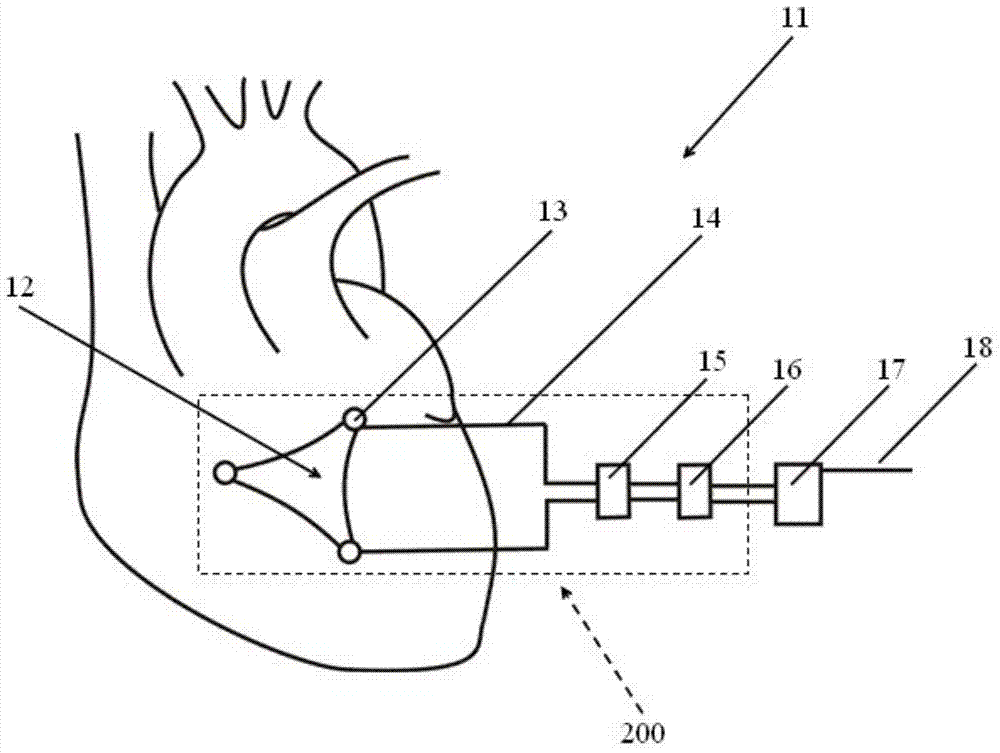

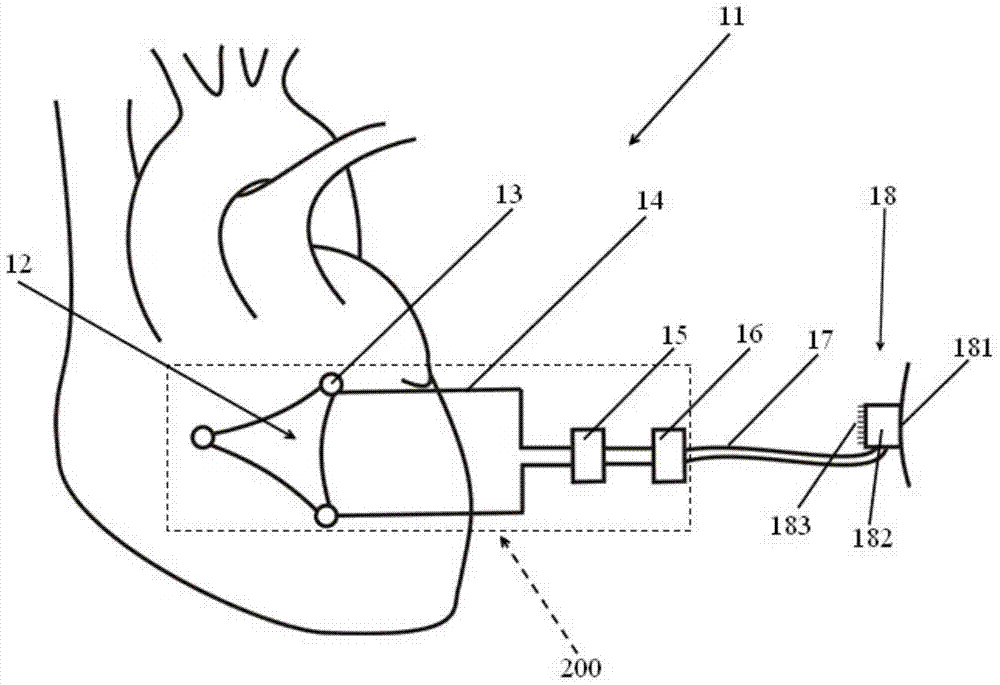

Self-powered electronic retina

The invention provides a self-powered electronic retina. The self-powered electronic retina is characterized by comprising a photosensitive unit, a signal processing unit, a stimulating electrode and a power generation unit. The power generation unit comprises a power generation body, an output unit, an electrical energy storage unit, a fixing unit and an encapsulation layer. The power generation body is of a multilayer film structure and comprises a piezoelectric material layer arranged on the center of the power generation body and electrode layers arranged on both sides of the piezoelectric material layer. The output unit is connected to the electrode layers to output the current generated by the power generation body to the electrical energy storage unit. The electrical energy storage unit is used for storing electrical energy and supplying the signal processing unit and the stimulating electrode with power. The fixing unit is arranged on the edge of the power generation body and used for fixing the power generation body to the epicardium. The encapsulation layer covers the surfaces of the power generation body, the output unit, the electrical energy storage unit and the fixing unit. The self-powered electronic retina needs no battery replacement and can achieve lifetime use.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

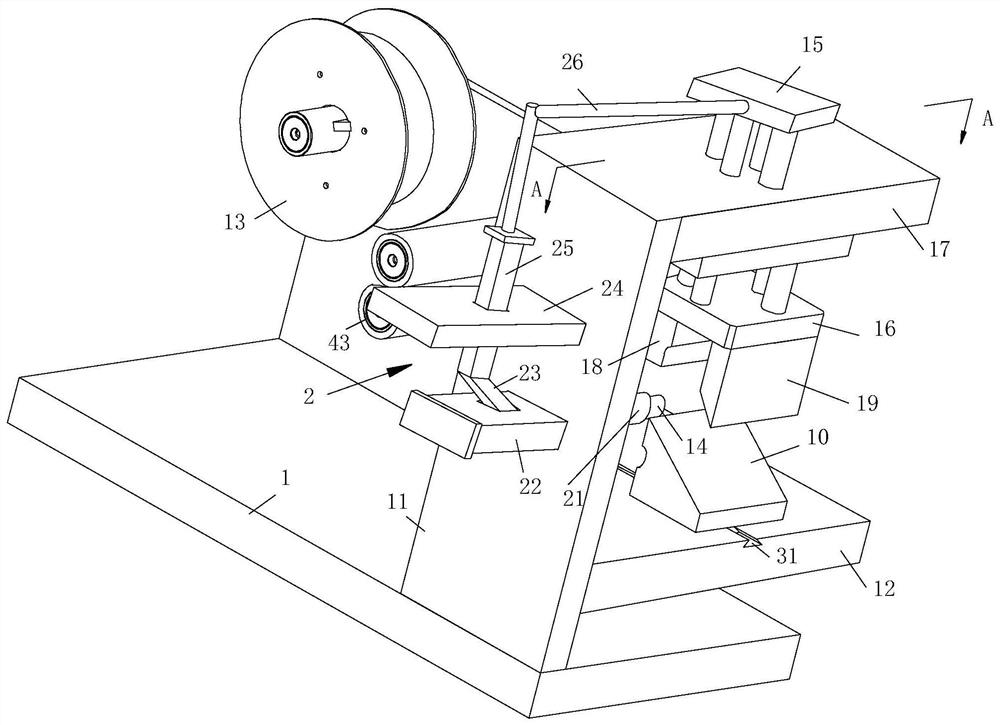

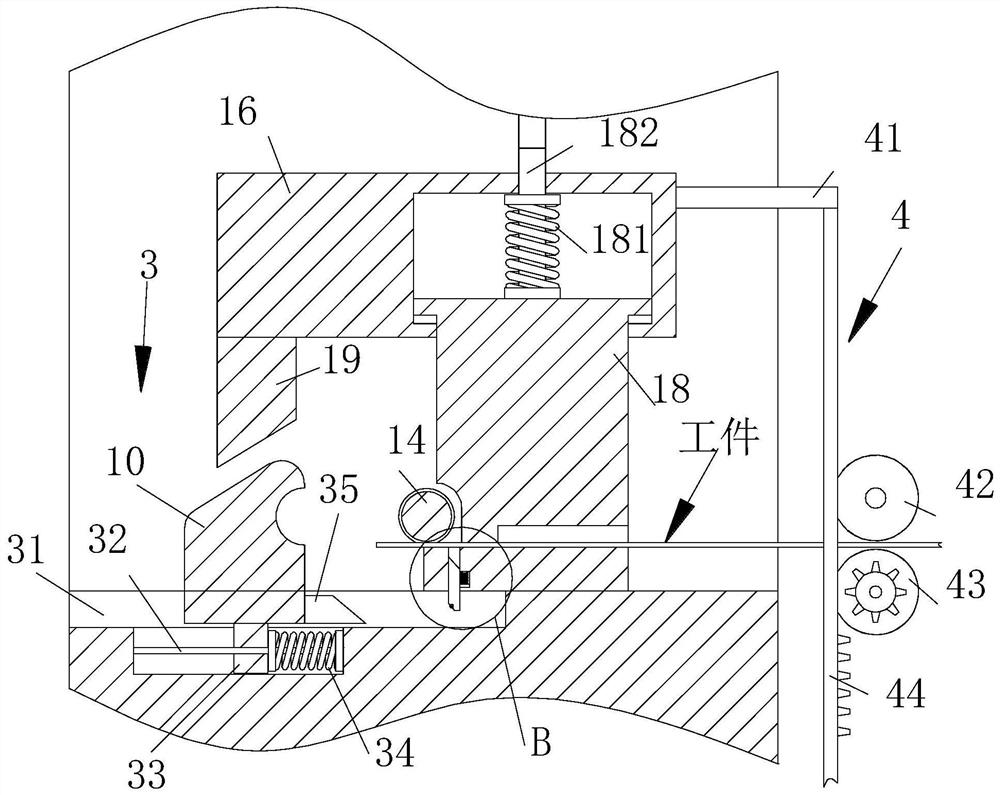

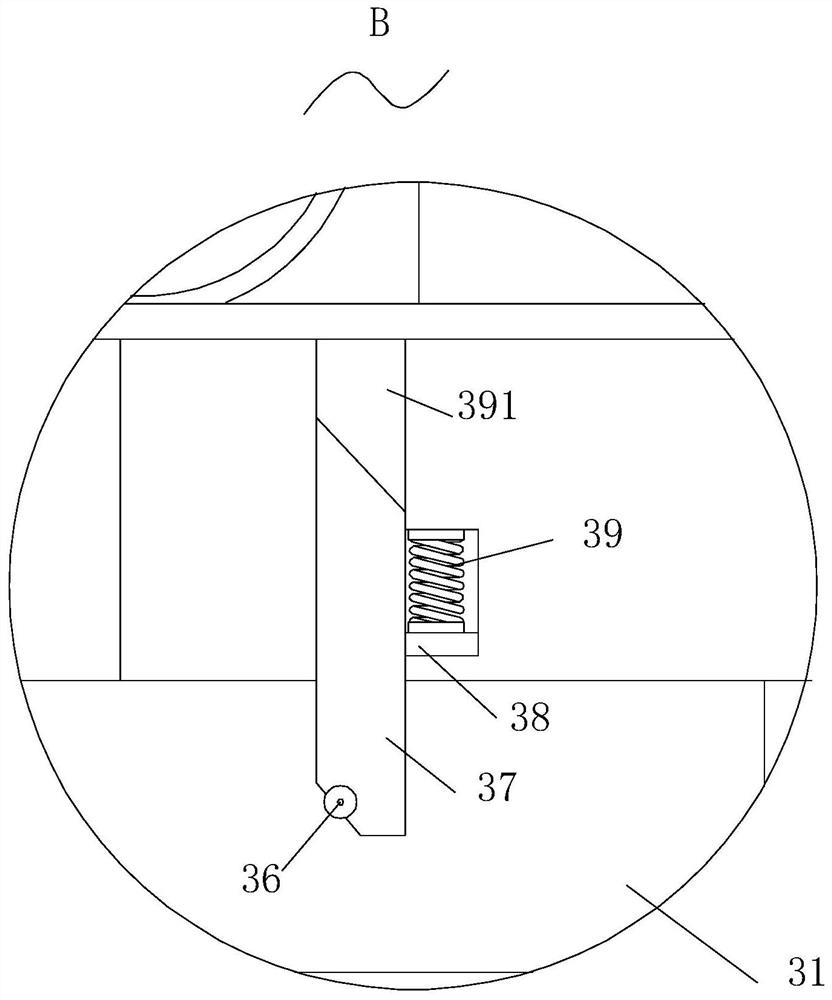

Arc-shaped sheet metal workpiece stamping mold

PendingCN113953384AReduce resource consumptionStamping and demoulding are orderly and efficientShaping toolsMetal-working feeding devicesPhysicsEngineering

The invention relates to the field of molds, in particular to an arc-shaped sheet metal workpiece stamping mold which comprises a bottom plate, wherein a side plate is fixedly connected to the side edge of one end of the bottom plate, a transverse plate is fixedly connected to the center of one side of the side plate, the transverse plate and the bottom plate are located on the same side of the side plate, a sliding seat is slidably connected to the top of the transverse plate, a cutting assembly is arranged at the joint of the sliding seat and the transverse plate, and a top plate is fixedly connected to one side of the top of the side plate. The stamping mold is used for overcoming the defect exists under the special condition that an existing stamping mold for the arc-shaped metal plate workpiece is inconvenient for technicians to demold manually, the existing stamping mold used in the environment has the defect of low machining efficiency, on one hand, due to the fact that the procedures of feeding, cutting and demolding are carried out separately, the machining efficiency is reduced, and on the other hand, the workpiece is processed into the sleeve and then sleeved on the mold, so that the demolding is very inconvenient, and the sleeve is easily clamped on the mold.

Owner:周于昊

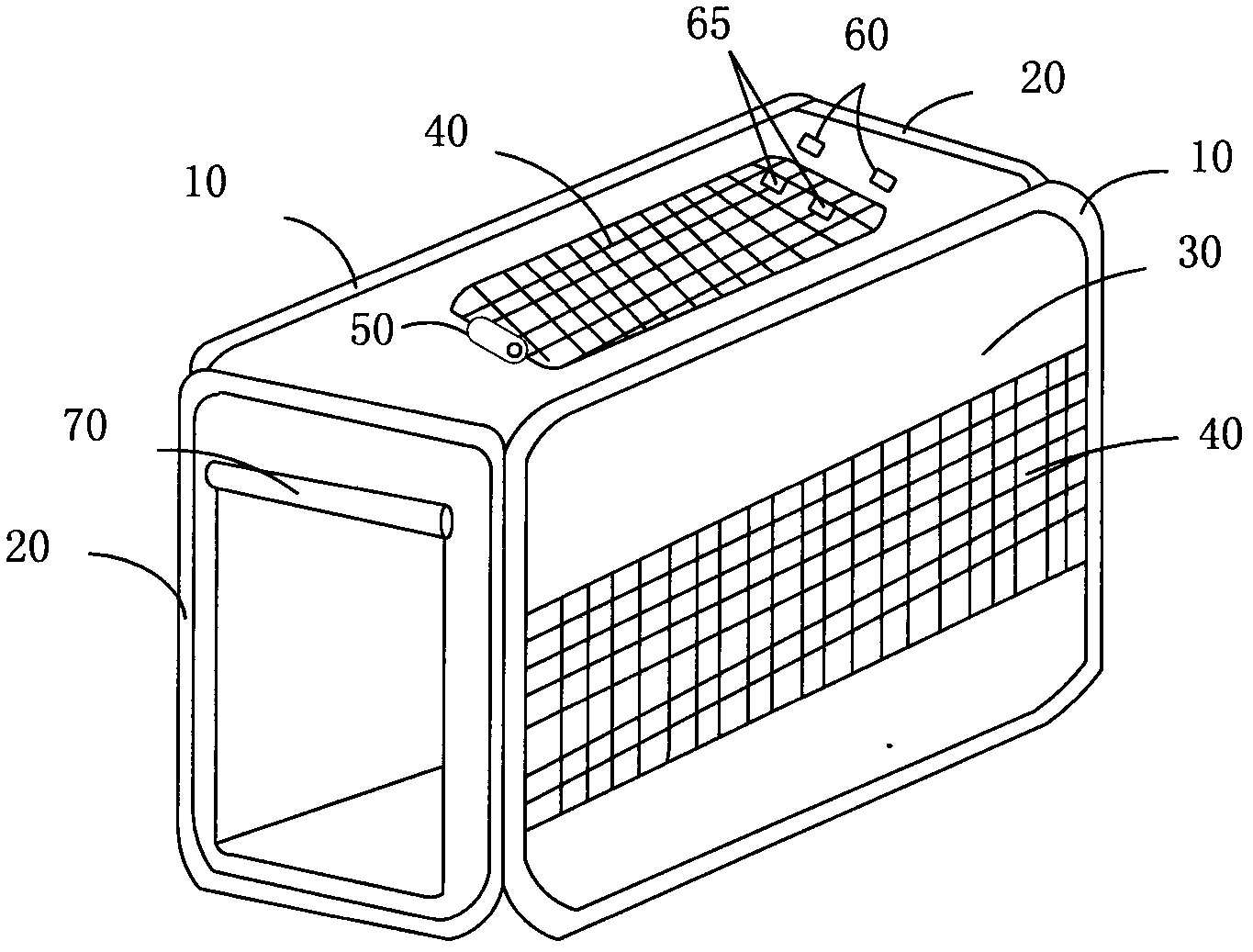

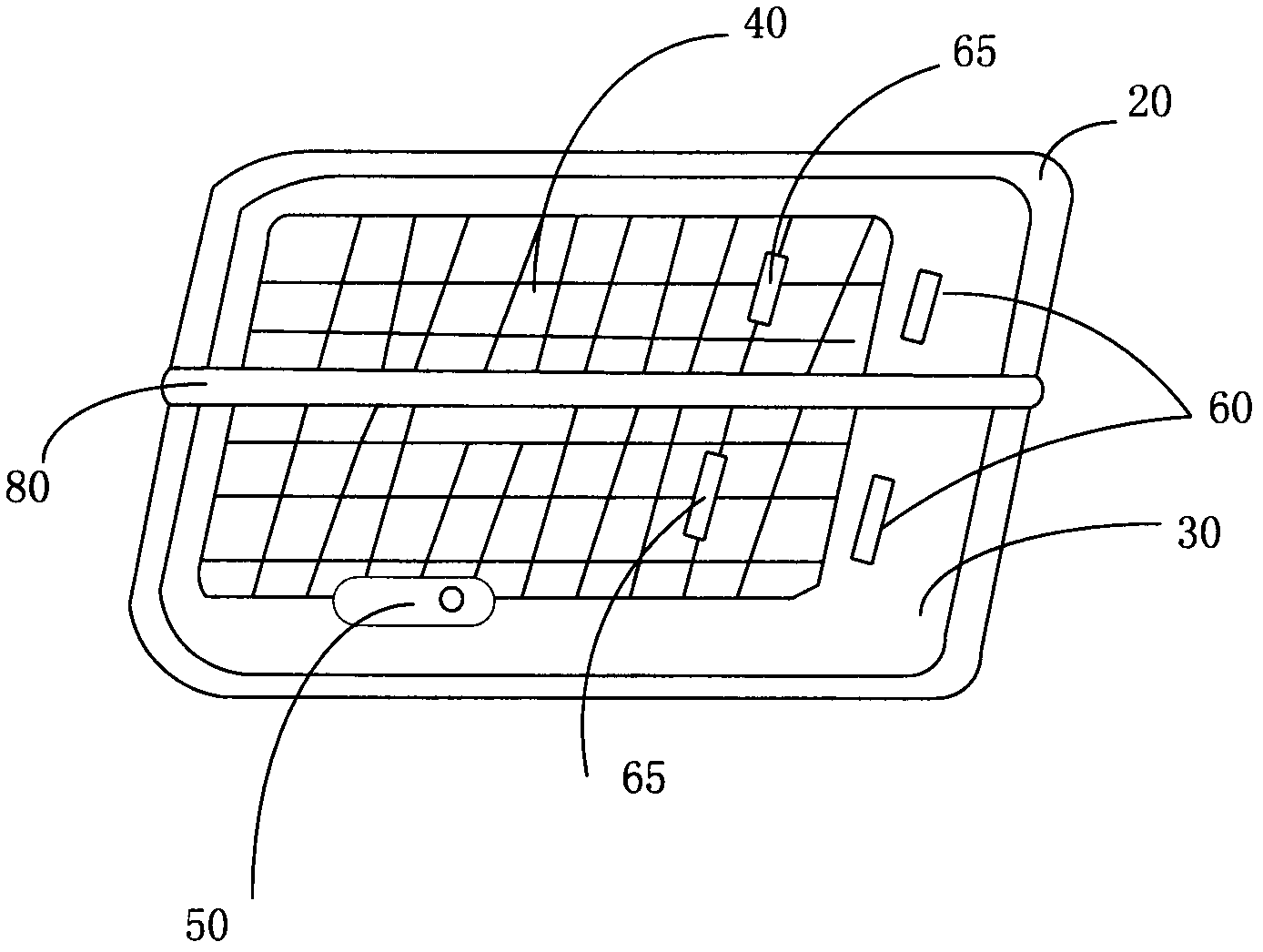

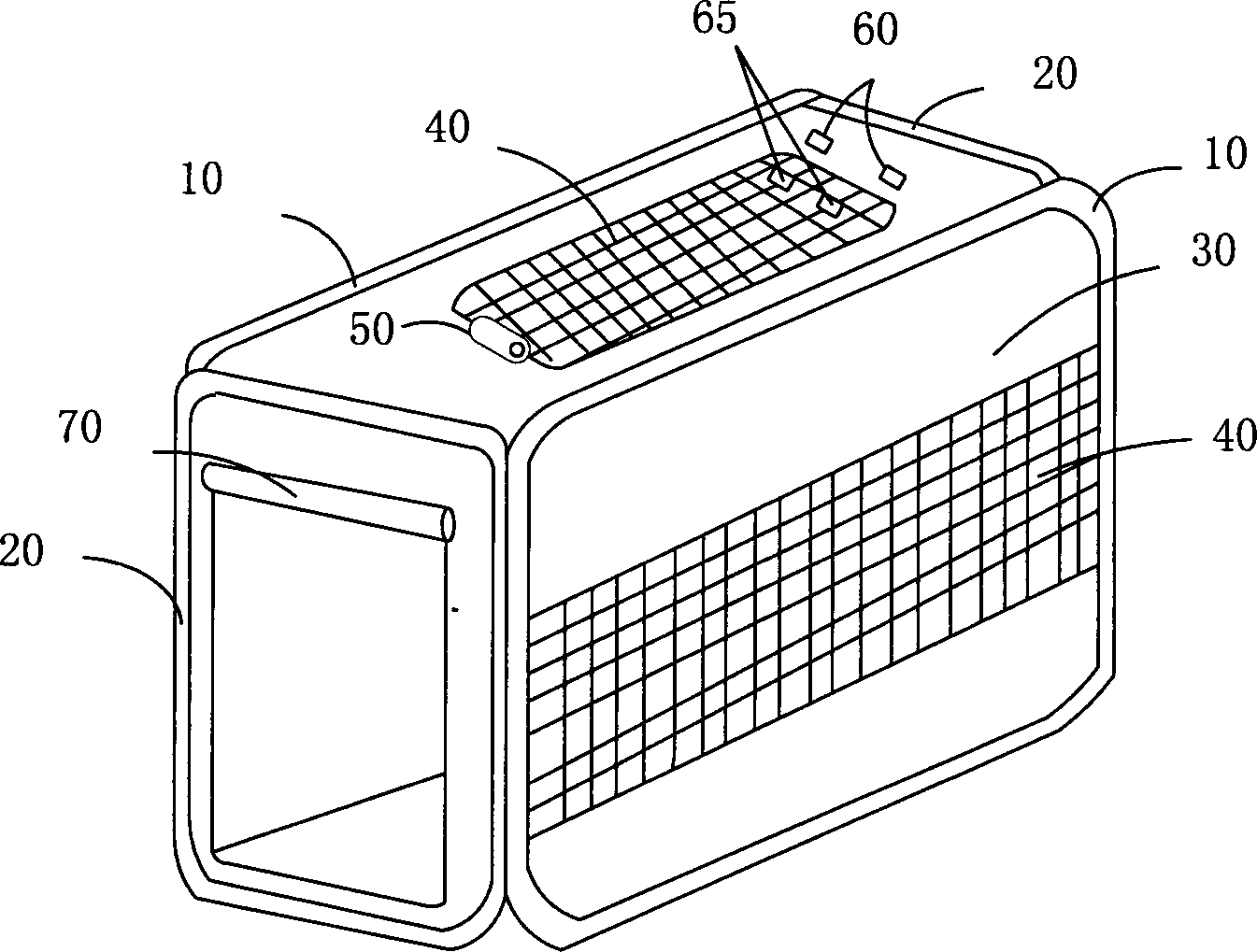

Storage box

The invention discloses a storage box, which comprises a box body, a plurality of cloth side faces for closing the box body and a plurality of metal frames for supporting the box body, wherein at least one cloth side face is provided with a movable open moving part; each metal frame is sleeved in an outer edge ring of each cloth side face; a first metal frame which can randomly bend is formed in a first outer edge ring; a second metal frame which cannot randomly bend is formed in a second outer edge ring adjacent to the first outer edge ring; and the same metal frame is formed in the outer edge ring of each opposite side face of the box body. The storage box can be used for effectively storing objects when stretched and can be effectively shrunk when folded, so that storage and carrying are facilitated.

Owner:深圳市五洲行户外用品有限公司

Chinese patent medicine ointment for treating rhinitis and nasosinusitis

InactiveCN113384611AStrong stimulationRapid contractionAnthropod material medical ingredientsOintment deliverySinusitisDrug ointment

The invention discloses a Chinese patent medicine ointment for treating rhinitis and nasosinusitis. The Chinese patent medicine ointment is prepared from the following raw materials by weight: 0.5-1.5 g of mustard, 3-7 g of bee venom, 0.01-0.03 g of medicinal sodium benzoate and 40-50 g of medicinal vaseline. The formula is simple, the bee venom and the mustard are innovatively prepared into the ointment according to the monarch, minister, assistant and guide, so that the bee venom and the mustard interact to form the functions of stronger and more effective nasal mucosa contraction, snot stopping and blocked nostrils, and gradually recovery of self-expansion and contraction of the mucosa of the nasal cavity, and the allergic rhinitis and the nasosinusitis are radically treated.

Owner:王天高

High performance TPU superfine fiber synthetic leather and cleaner production method thereof

The invention provides high performance TPU superfine fiber synthetic leather and a cleaner production method thereof. The method comprises the following steps: a piece of superfine fiber synthetic leather base cloth is dipped by a dipping tank which contains shrinking and boarding liquid, the synthetic leather base cloth enters a continuous type boarding machine, and a piece of boarding base cloth is obtained; a calendering production line is used, calendering materials are thrown into a high speed kneader for mixing, after mixing, plastication and calendering of the materials, the materials and a piece of release paper are laminated, in order to obtain a release paper laminated TPU film; a synthetic leather dry method production line with a piece of PUR scraping equipment is used, PUR is scraped on the release paper laminated TPU film, the boarding base cloth is attached, the release paper is peeled, and the product is obtained. Shrinking and boarding technology is used, in order to greatly improve flexibility, permeability and moisture permeability of the superfine fiber synthetic leather base cloth; the scraping and lamination technology of release paper transferred coating and reaction type polyurethane hot melt adhesive is used, the thermoplastic polyurethane calendering film is laminated on the superfine fiber synthetic leather base material in order to obtain the TPU superfine fiber synthetic leather with soft hand feeling, mechanical properties and good usage performance.

Owner:JIANGSU KEMEI NEW MATERIALS

An easily adjustable multi-layer circuit board electric welding device

ActiveCN109702288BGood lifting effectEffective rotationMultilayer circuit manufactureSoldering auxillary devicesElectric machineryConveyor belt

The invention discloses an adjustable multi-layer circuit board electric welding device, which includes a support frame and a fixed frame, and also includes a linkage mechanism. The linkage mechanism is installed at one end of the support frame, and the linkage mechanism is arranged below the circuit board outlet. The other end of the circuit board is provided with a circuit board inlet, and the first welding station, the second welding station, the third welding station and the fourth welding station are sequentially installed between the circuit board inlet and the circuit board outlet; Adjust the width between the conveyor belts, adjust the height of the welding structure through the swing arm, adjust the position of the motor through the telescopic rod to drive the transmission of the movable conveyor belt and the fixed conveyor belt, and effectively adjust the welding device from the width and thickness to make it suitable for multiple applications. The welding of multi-layer circuit boards saves equipment costs and production costs.

Owner:安徽米兰电子科技有限公司

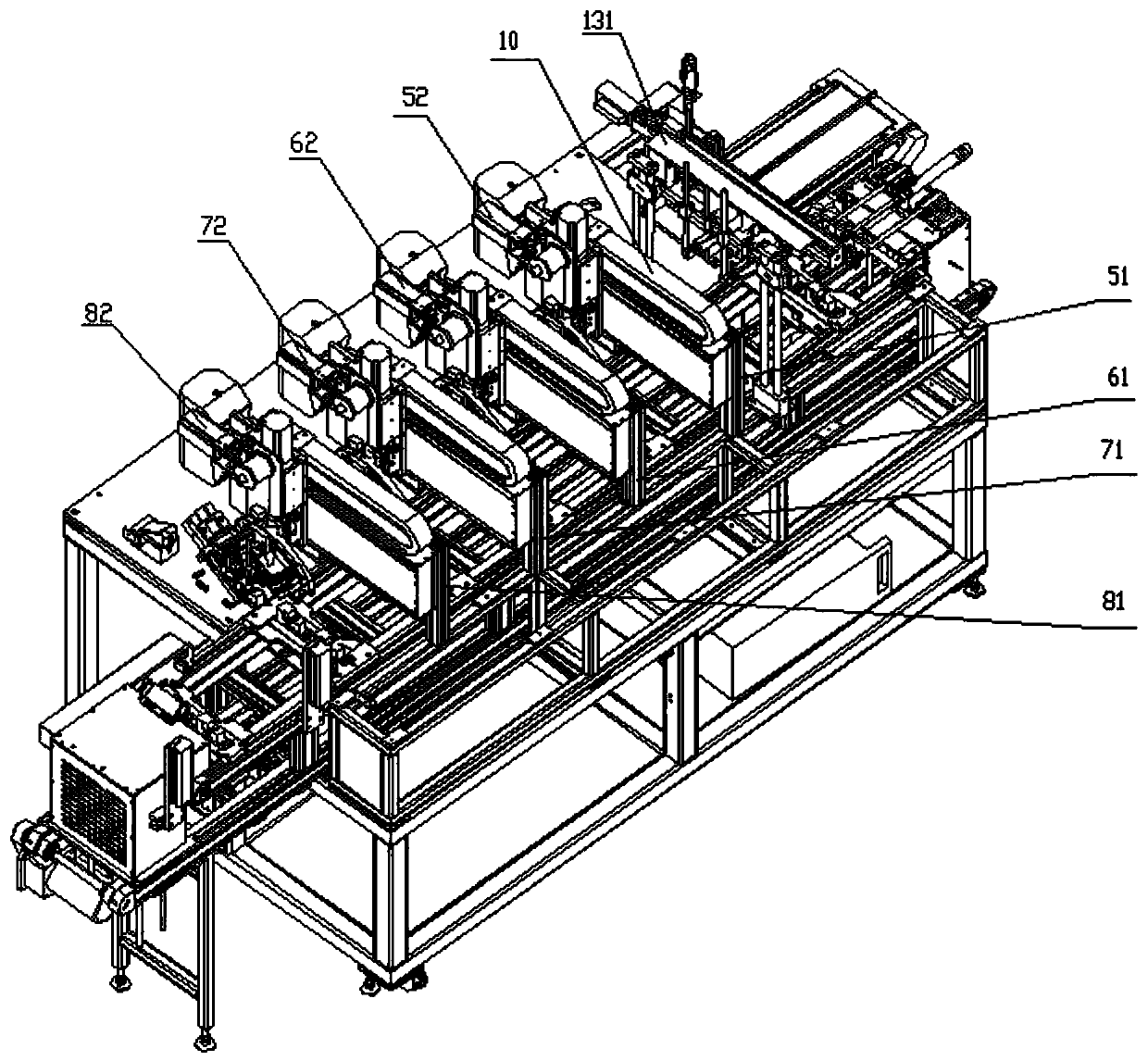

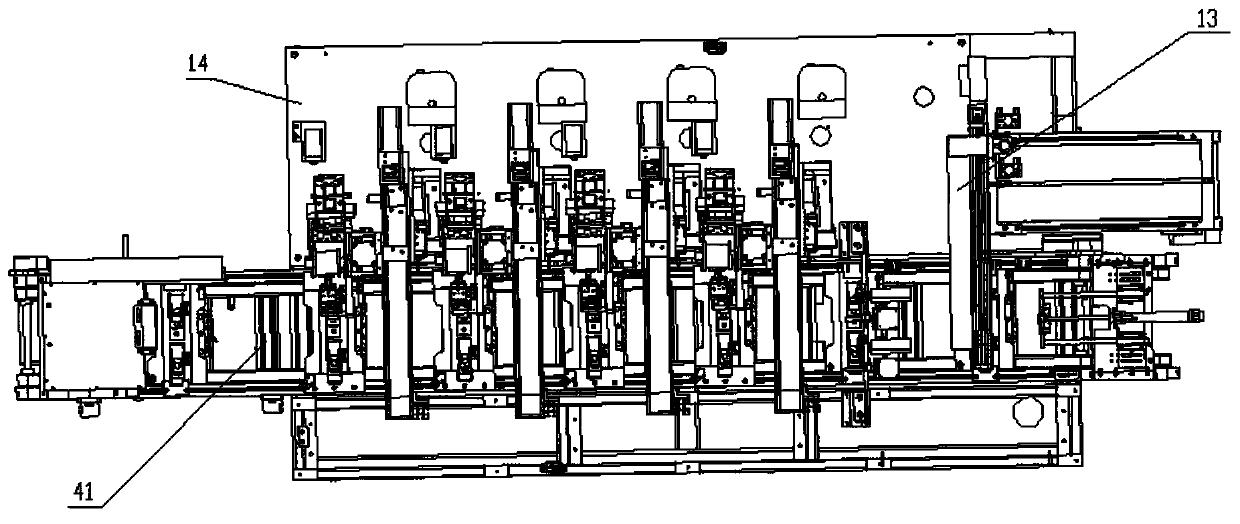

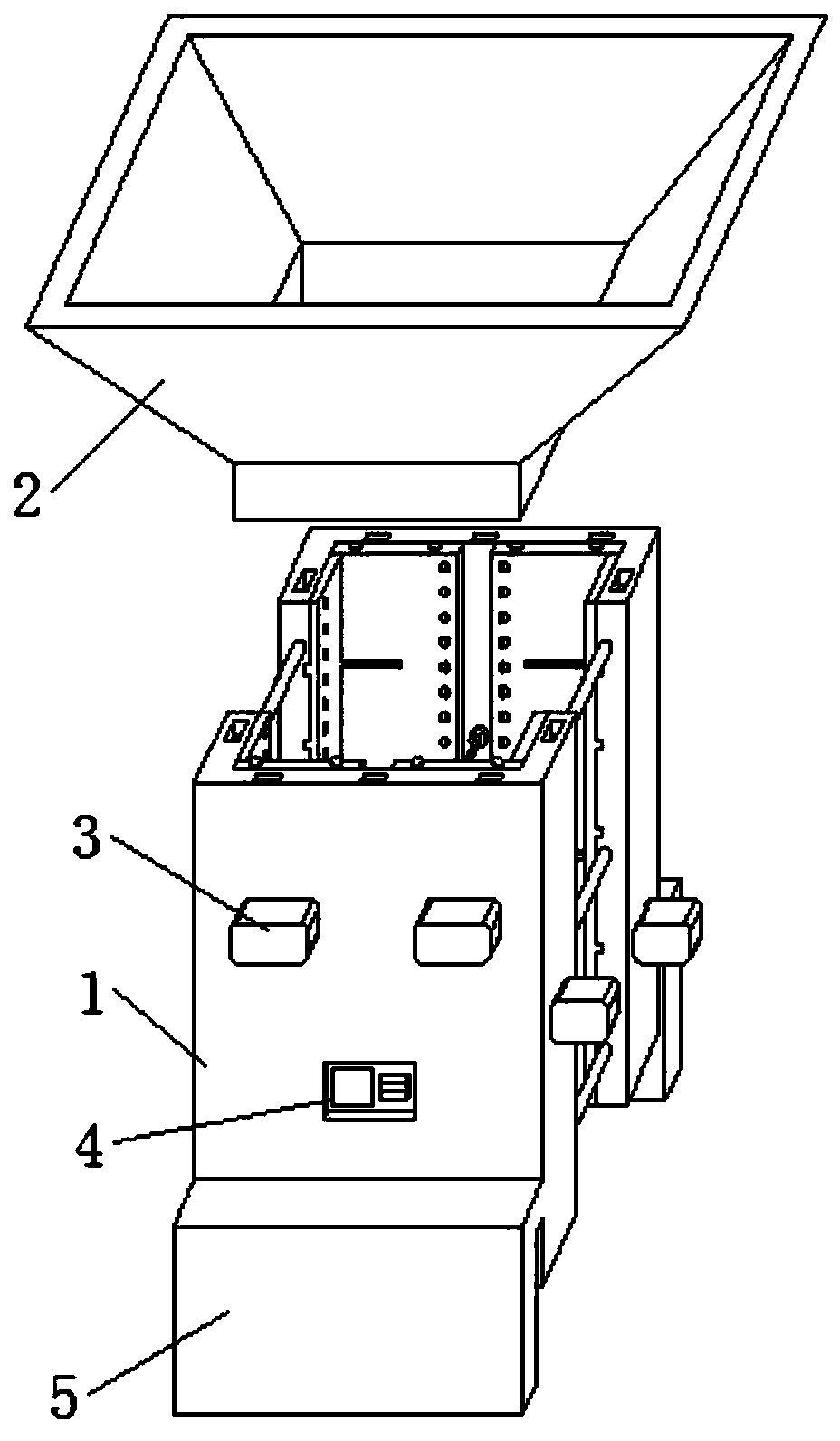

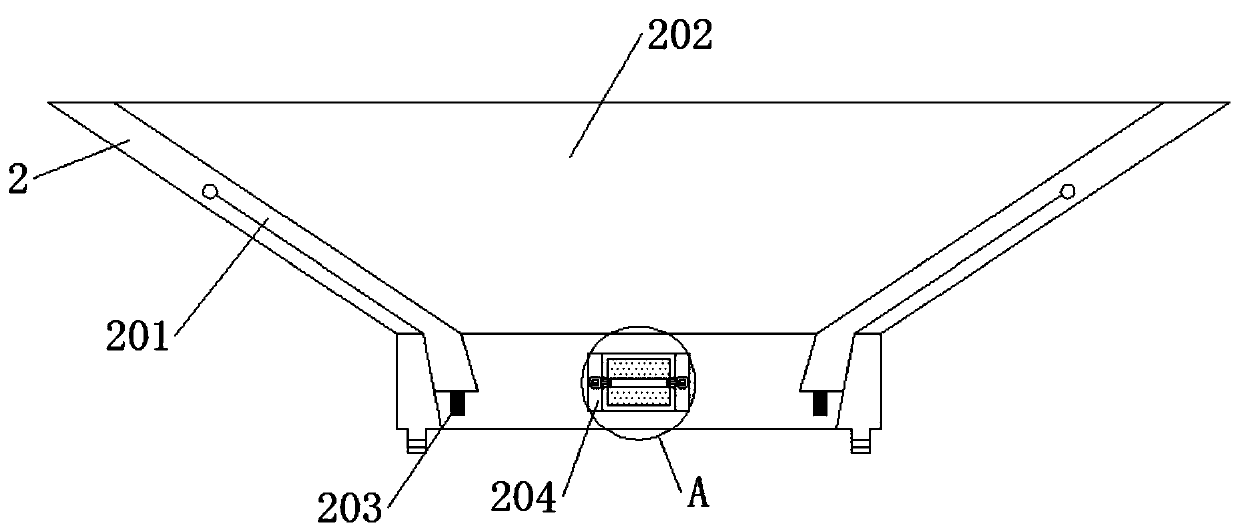

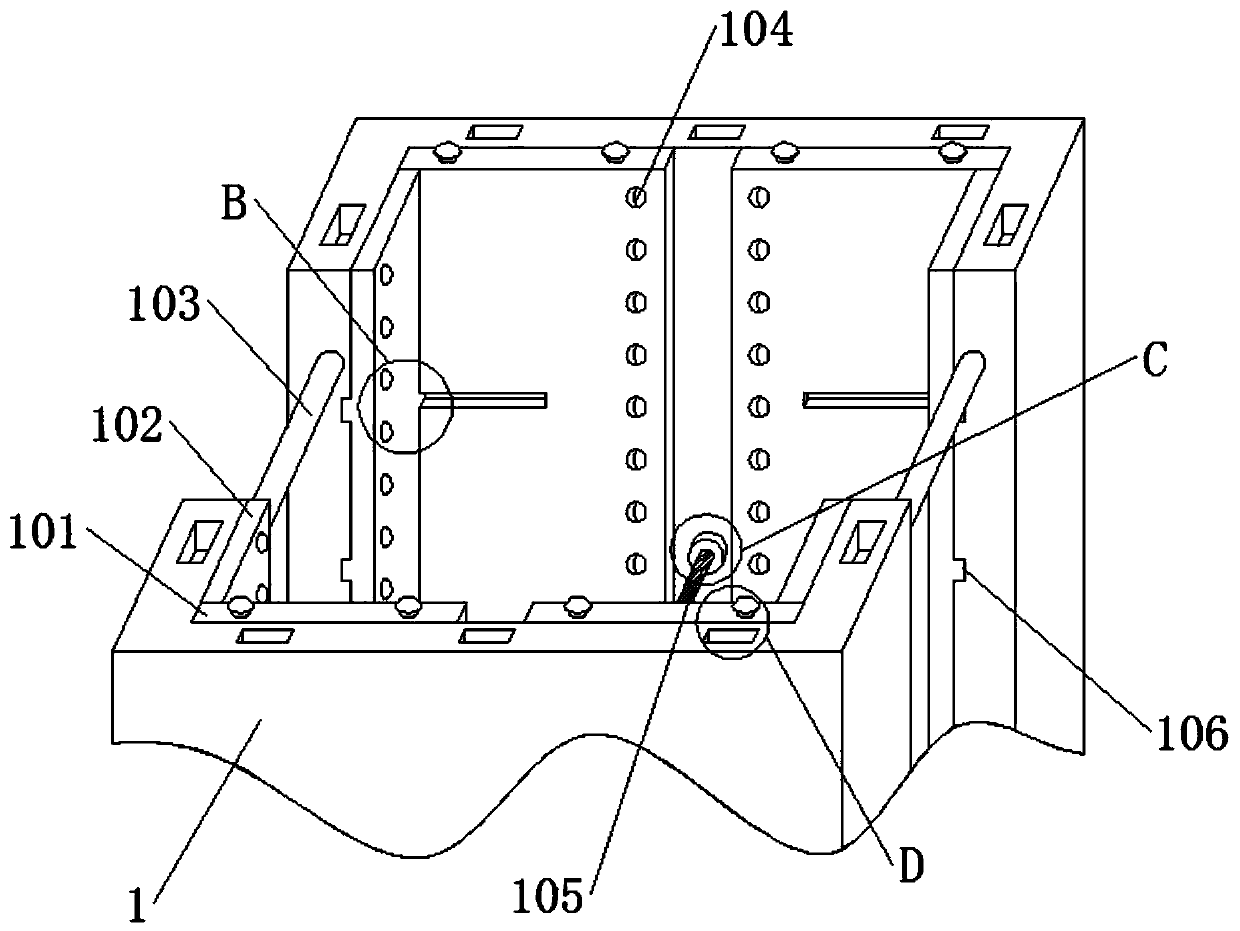

Foam cutting machine

ActiveCN110181603AAvoid shakingAffect cutting accuracyMetal working apparatusHydraulic pumpEngineering

The invention provides a foam cutting machine. The foam cutting machine comprises a shell, a funnel, a hydraulic pump and a controller, wherein the top end of the shell is fixedly connected with a funnel through a sleeving groove, and hydraulic pumps are separately fixedly connected to the middle parts of the front end and the rear end of the shell; the controller is embedded in the middle of thefront end of the shell; supporting plates are integrally arranged at the bottoms of the front end and the rear end of the shell; and a movable inner plate is integrally arranged on the inner wall of the funnel; an elastic traction rope is fixedly connected to the bottom end of the movable inner plate; a top groove is embedded in the middle of the top end of the funnel; correcting wheels are fixedly connected to the front side and the rear side of the bottom end of the inner wall of the funnel; small motors are embedded in the middles of the left end and the right end of the funnel respectively; a rotating shaft is movably connected to the middle of the inner wall of the correcting wheels; a friction wheel body is fixedly connected to the outer wall of the rotating shaft; transverse limiting plates are movably connected to the front end and the rear end of the inner wall of the outer shell separately; and a connecting button is connected to the top end of each transverse limiting platein a threaded mode. The whole device is stable in structure and convenient to use and operate; the cutting efficiency of a foam plate is high; the cutting precision is high; and the time and labor aresaved during cutting.

Owner:湖北世丰新材料有限公司

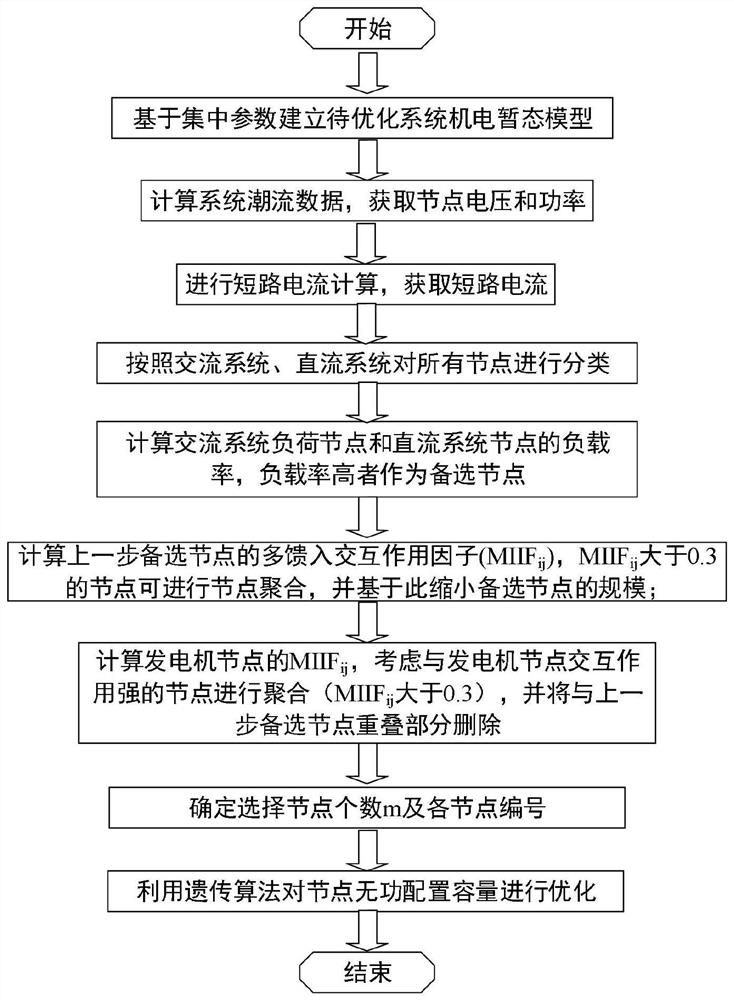

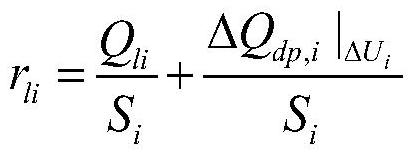

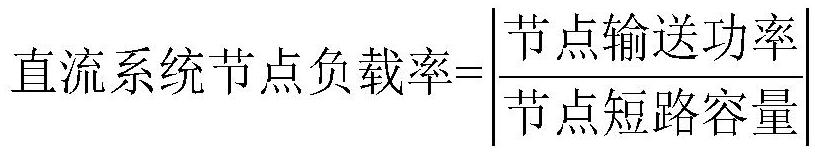

A configuration optimization method for reactive power compensation in power system

InactiveCN110492493BImprove selection efficiencyReduce the number of configurationsReactive power adjustment/elimination/compensationReactive power compensationPower compensationTransient state

The invention provides a reactive power compensation configuration optimization method for a power system, and belongs to the field of reactive power compensation configuration of the power system. The method comprises the following steps: firstly, establishing an electromechanical transient simulation model of a to-be-optimized power system, and acquiring power flow data and short-circuit currentof each node in the to-be-optimized power system; after the nodes are classified, with consideration of a node load rate, obtaining an initial alternative node configured with reactive compensation,and with consideration of the effect of a reactive voltage source and a multi-infeed interaction factor, performing aggregation to finally obtain a reactive compensation alternative node of the to-be-optimized power system; and optimizing the reactive power capacity required to be configured for each reactive power compensation alternative node by adopting a genetic algorithm to obtain a reactivepower capacity optimization compensation result of each reactive power compensation alternative node. The method is easy to implement and high in accuracy, and is a practical reactive compensation configuration optimization method for the power system.

Owner:TSINGHUA UNIV +2

A New Type of Cable Shrinking Device

ActiveCN109534105BEffective contractionControl lengthArrangements using extensible carrierEngineeringScrew thread

Owner:迅立达电梯有限公司

Self-made herba menthae pore-firming mask

InactiveCN108567588AEffective contractionPromote secretionCosmetic preparationsToilet preparationsMedicineSecretion

The invention relates to a self-made herba menthae pore-firming mask. The self-made herba menthae pore-firming mask is prepared from, by weight, 2-3 parts of herba menthae essential oil, 2-3 parts ofrosemary essential oil, 5-8 parts of edible soda powder and an appropriate amount of purified water. The self-made herba menthae pore-firming mask is capable of effectively shrinking pores to improveoil secretion fundamentally. Essential oil in the components is in pleasant faint scent and capable of soothing nerves, and better comfortable experience of skin can be achieved.

Owner:WUXI QIBAO CLEANING AGENT CO LTD

A kind of suede artificial superfine fiber synthetic leather and its clean production method

ActiveCN107177989BShorten the lengthReduce widthMechanical cleaningPressure cleaningPolymer scienceEngineering

The invention relates to suede simulation type superfine fiber synthetic leather and a clean production method thereof. The method comprises the steps of impregnating superfine fiber synthetic leather base cloth through an impregnating tank full of shrinking and kneading liquid, entering a continuous graining machine, drying the superfine fiber synthetic leather base cloth, and obtaining shrinking and kneading base cloth; adopting a flocking production line provided with PUR lattice roller coating equipment, coating PUR on the shrinking and kneading base cloth, sprinkling collagen fiber, adhering on the shrinking and kneading base cloth, cooling and winding, and placing to obtain flocking base cloth; adopting a brushing machine for removing the collagen fiber which is not firmly adhered onto the flocking base cloth, and obtaining the suede simulation type superfine fiber synthetic leather. According to the suede simulation type superfine fiber synthetic leather and the clean production method thereof provided by the invention, a shrinking and kneading technology is adopted, so that the softness, the air permeability and the water vapor permeability of the superfine fiber synthetic leather base cloth are greatly improved; a PUR lattice roller coating composite technology is adopted, so that the collagen fiber is compounded onto the superfine fiber synthetic leather base cloth, and the suede simulation type superfine fiber synthetic leather with the appearance being similar to the appearance of natural suede leather, and the mechanical property and the hygiene property being superior to the mechanical property and the hygiene property of the natural suede leather is obtained.

Owner:JIANGSU KEMEI NEW MATERIALS

Supporting anti-toppling device for film and television projection screen

PendingCN114087484AGuaranteed stabilityMeet the needs of useProjectorsStands/trestlesEngineeringProjection screen

The invention discloses a supporting anti-toppling device for film and television projection screen, wherein the device comprises a screen body and two bases; supporting mechanisms are arranged at the upper ends of the two bases, each supporting mechanism comprises a mounting frame fixed to the upper end of the corresponding base, the side wall of each mounting frame is rotationally connected with a supporting frame, and a storage groove is formed in the bottom of each supporting frame; and a supporting plate is rotationally connected to the inner walls of the storage grooves, a clamping groove is formed in the upper end of each base, a plurality of clamping blocks are fixed to the inner walls of the clamping grooves, one clamping block abuts against the supporting plate, and an adjusting groove is formed in the side wall of the supporting frame. The device has the advantages that the supporting frame, the supporting plate and the bases form a triangular structure, the acting force of the screen body is decomposed and acts on the supporting plate and the supporting frame, the triangular structure is kept stable, the bases are tightly attached to the ground, the situation of overall toppling is avoided, and thus the stability of equipment placement is guaranteed.

Owner:祝国利

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com