Processing method of high-compactness concrete precast slab capable of preventing surface cracking

A processing method and concrete technology, which is applied in the field of concrete prefabricated slabs, can solve the problems of prefabricated slabs such as insufficient strength, surface water seepage, surface shedding, etc., and achieve the effects of improving molding strength and compactness, improving overall bearing capacity, and preventing water seepage and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

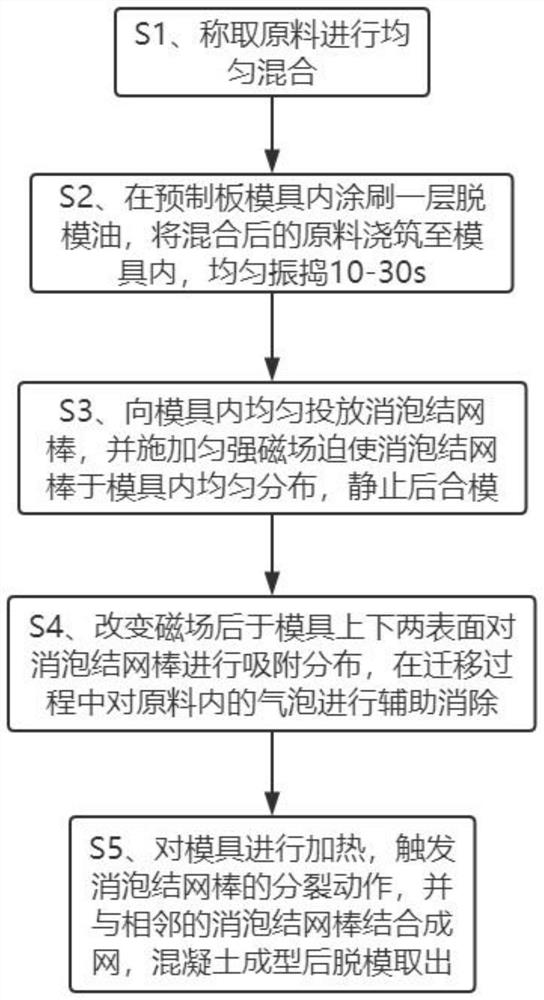

[0044] see Figure 1-4 , a method for processing a high-density concrete prefabricated panel that prevents surface cracking, comprising the following steps:

[0045] S1. Weigh the raw materials and mix them evenly. The raw materials include the following ingredients in parts by weight: 265 parts of Portland cement, 165 parts of water, 725 parts of fine sand, 1000 parts of gravel, 75 parts of mineral powder, and 75 parts of fly ash , 10 parts of polycarboxylate superplasticizer, 5 parts of composite early strength agent, 2 parts of defoamer;

[0046] S2. Apply a layer of release oil to the prefabricated board mold, pour the mixed raw materials into the mold, and vibrate evenly for 10 seconds;

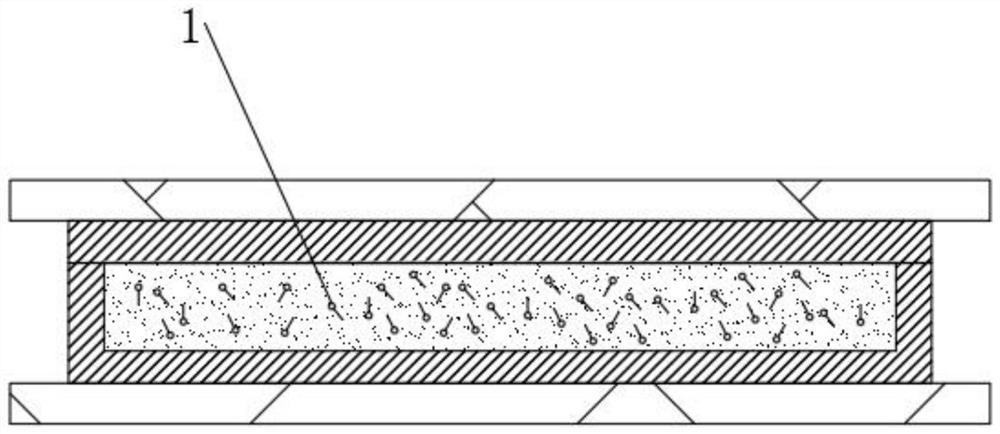

[0047] S3. Evenly put defoaming netting rods 1 into the mold, and apply a uniform magnetic field to force the defoaming netting rods 1 to be evenly distributed in the mold, and close the mold after resting;

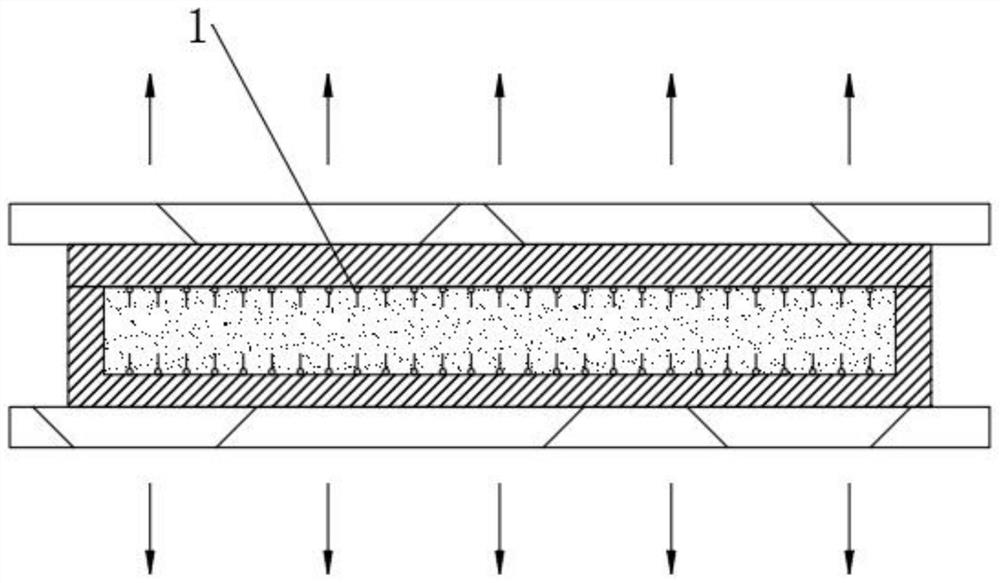

[0048] S4. After changing the magnetic field, adsorb and distribute the defoa...

Embodiment 2

[0060] see Figure 1-4 , a method for processing a high-density concrete prefabricated panel that prevents surface cracking, comprising the following steps:

[0061] S1. Weigh the raw materials and mix them evenly. The raw materials include the following components in parts by weight: 268 parts of Portland cement, 168 parts of water, 728 parts of fine sand, 1025 parts of gravel, 80 parts of mineral powder, and 78 parts of fly ash , 15 parts of polycarboxylate superplasticizer, 8 parts of composite early strength agent, 3 parts of defoamer;

[0062] S2. Apply a layer of release oil to the prefabricated board mold, pour the mixed raw materials into the mold, and vibrate evenly for 20 seconds;

[0063] S3. Evenly put defoaming netting rods 1 into the mold, and apply a uniform magnetic field to force the defoaming netting rods 1 to be evenly distributed in the mold, and close the mold after resting;

[0064] S4. After changing the magnetic field, adsorb and distribute the defoam...

Embodiment 3

[0069] see Figure 1-4 , a method for processing a high-density concrete prefabricated panel that prevents surface cracking, comprising the following steps:

[0070] S1. Weigh the raw materials and mix them evenly. The raw materials include the following components in parts by weight: 270 parts of Portland cement, 170 parts of water, 730 parts of fine sand, 1050 parts of gravel, 85 parts of mineral powder, and 80 parts of fly ash , 20 parts of polycarboxylate superplasticizer, 10 parts of composite early strength agent, 5 parts of defoamer;

[0071] S2. Apply a layer of release oil to the prefabricated board mold, pour the mixed raw materials into the mold, and vibrate evenly for 30 seconds;

[0072] S3. Evenly put defoaming netting rods 1 into the mold, and apply a uniform magnetic field to force the defoaming netting rods 1 to be evenly distributed in the mold, and close the mold after resting;

[0073] S4. After changing the magnetic field, adsorb and distribute the defoa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com