Machining cutting device for machine manufacturing

A cutting device and machining technology, applied in the direction of shearing devices, manufacturing tools, metal processing equipment, etc., can solve problems such as inability to perform firm positioning and fixing, fail to meet people's use needs, and affect the cutting accuracy of workpieces, etc., to achieve a compact structure , Strong practicability, and the effect of ensuring cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

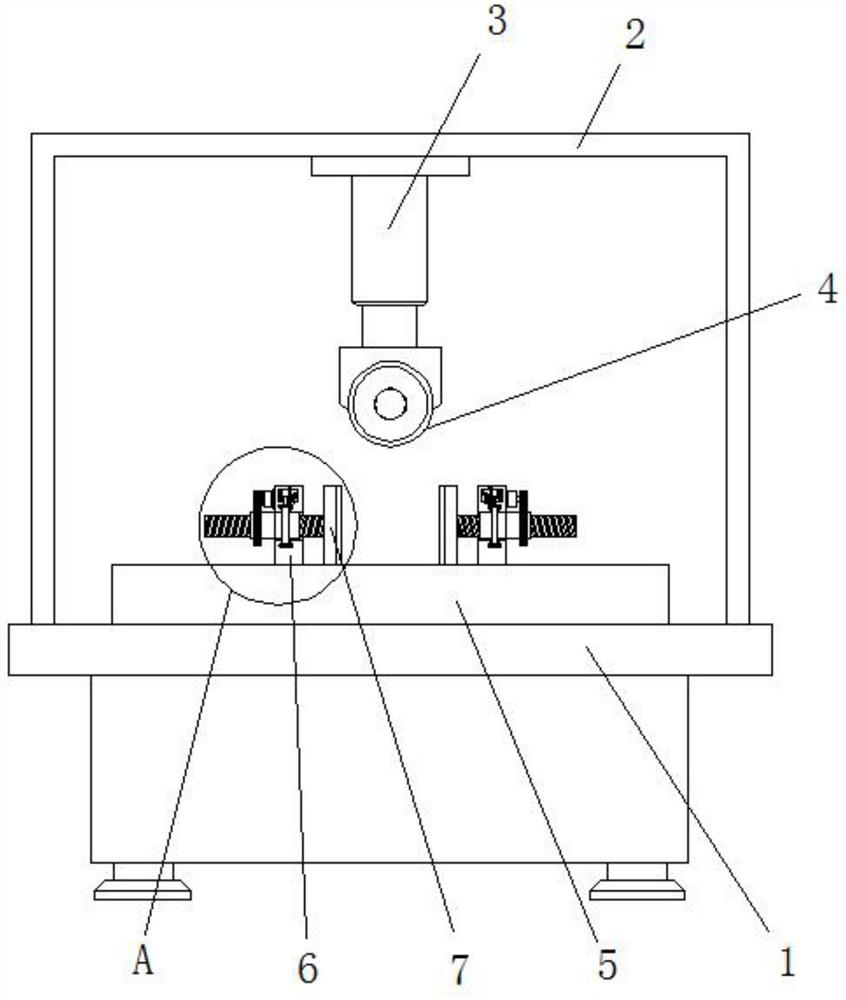

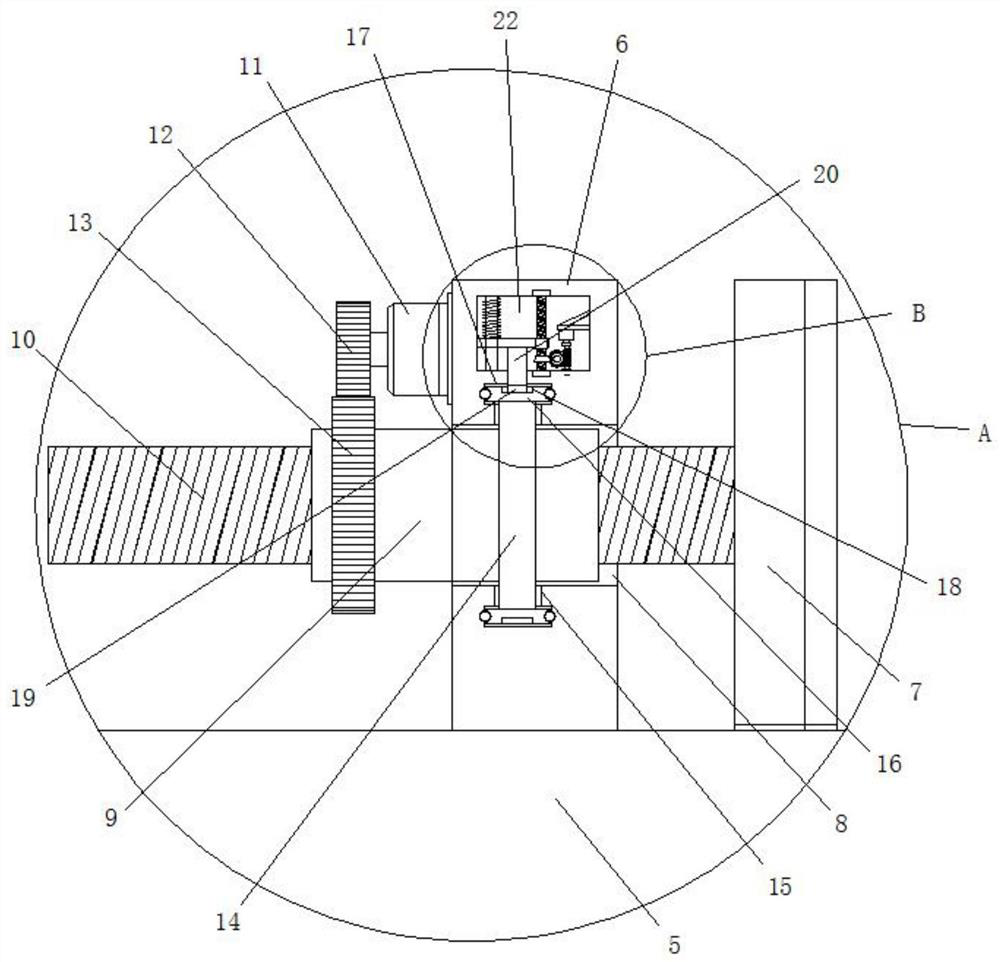

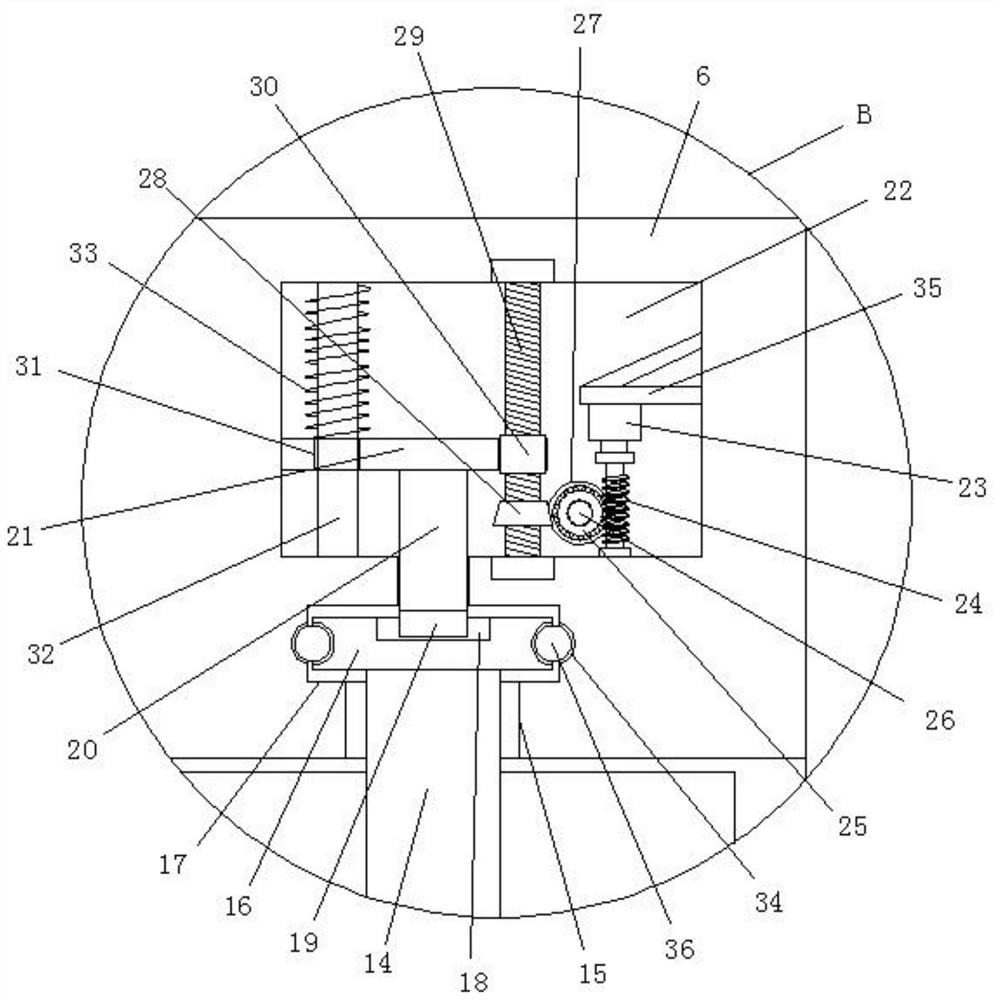

[0028] refer to Figure 1-6 In this embodiment, a kind of mechanical processing and cutting device for mechanical manufacturing is proposed, including a machine platform 1 and a gantry frame 2 fixedly arranged on the machine platform 1, a lifting motor 3 is installed on the top inner wall of the gantry frame 2, and a lifting motor 3 The output end of the cutting device is equipped with a cutting device main body 4, a cutting table 5 is arranged below the cutting device main body 4, and a positioning and fixing mechanism is arranged on the cutting table 5, and the positioning and fixing mechanism includes two fixing frames fixedly installed on the top of the cutting table 5 6. Positioning blocks 7 are movable on the sides where the two fixing frames 6 are close to each other, and threaded rods 10 are fixedly connected on the sides where the two positioning blocks 7 are far away from each other. Both fixing frames 6 are provided with rotation holes 8 , and the rotation hole 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com