Manual and automatic integrated engagement and disengagement type switching safe operation mechanism

A safe operation and clutch-type technology, applied in the direction of valve operation/release devices, mechanical equipment, engine components, etc., can solve problems such as safety hazards, inability to open and close valves, and poor real-time performance, so as to reduce safety hazards and structure Simple, real-time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

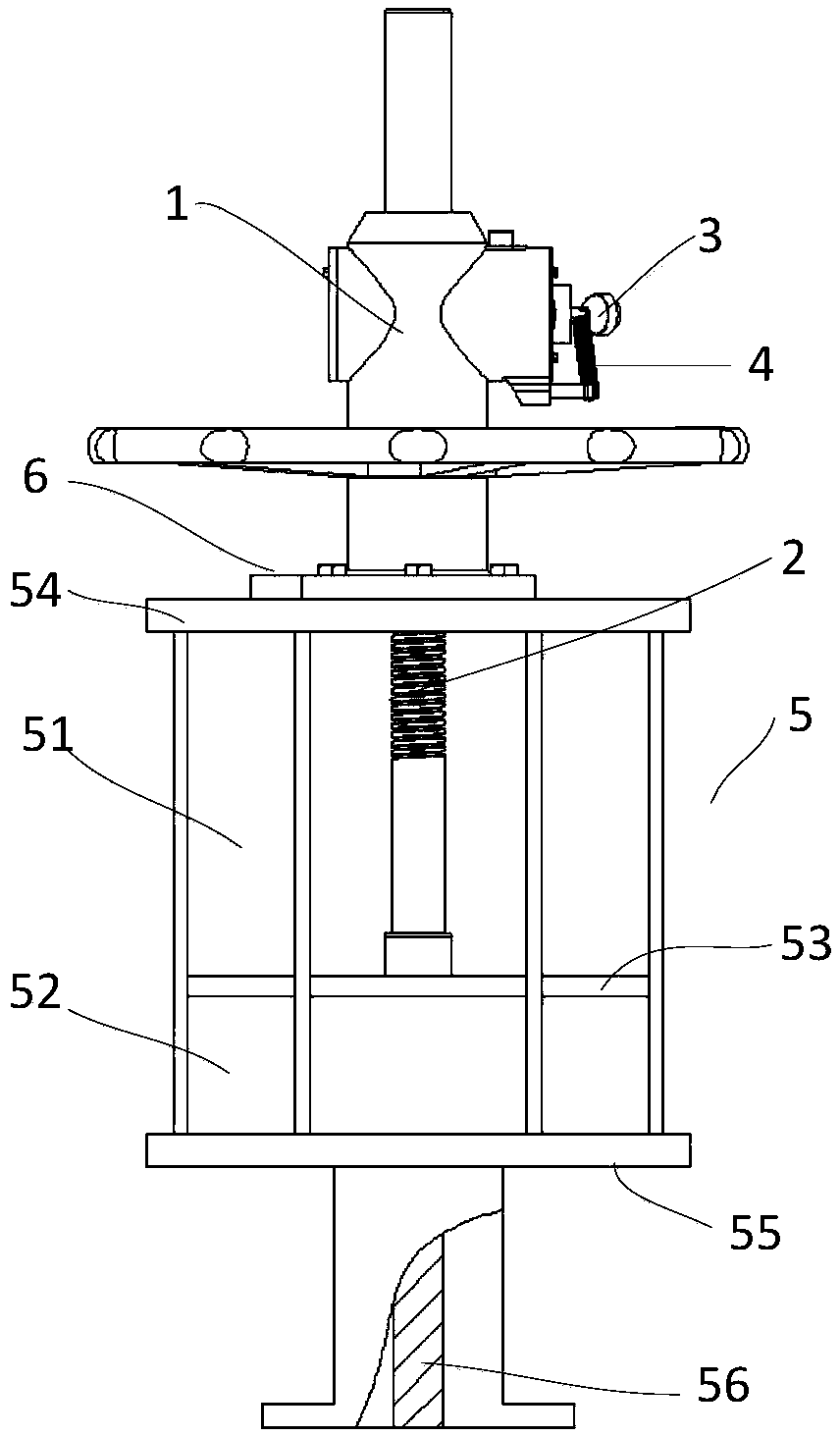

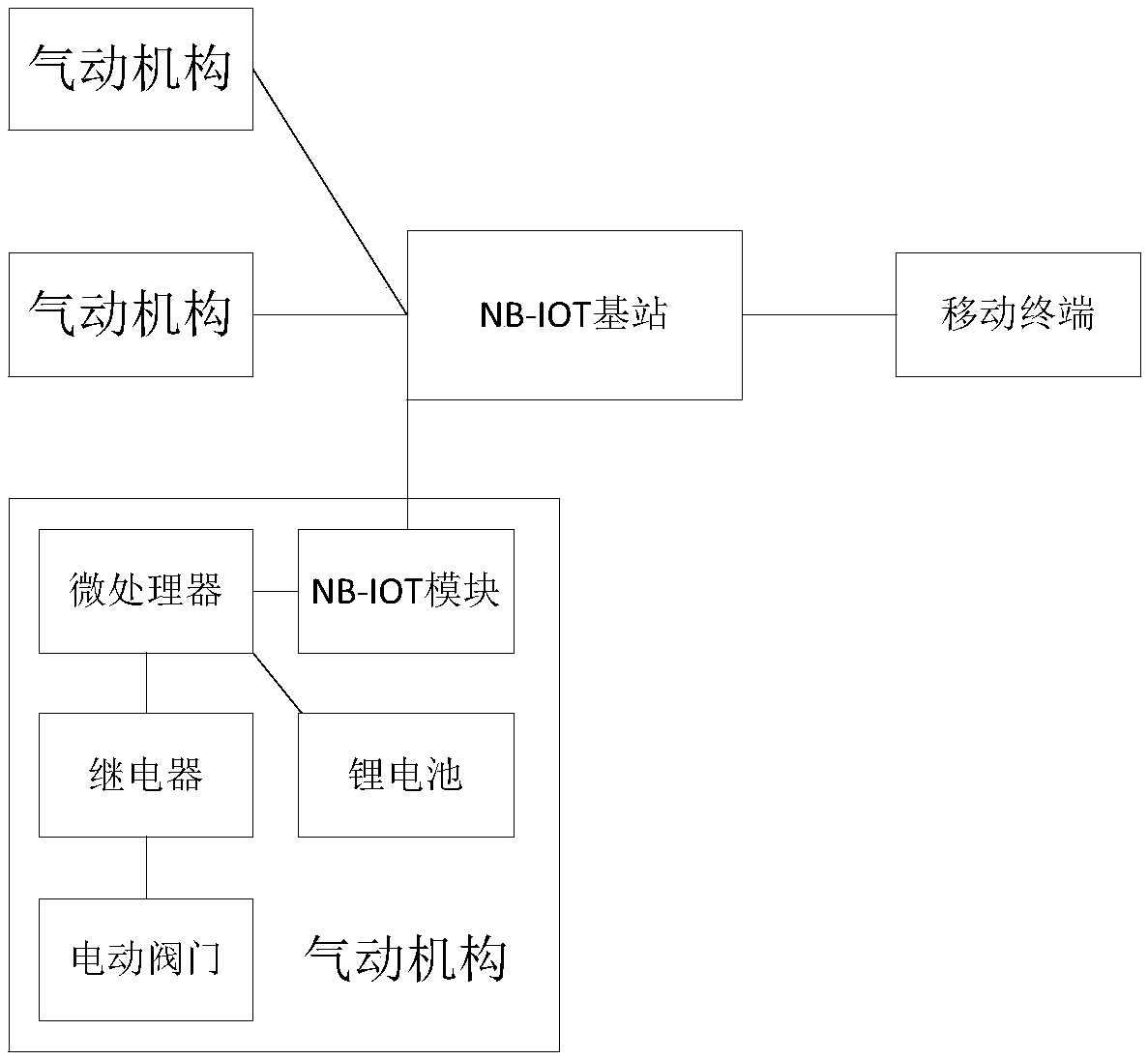

[0020] Such as Figure 1-2 As shown, a safety operating mechanism for manual and automatic clutch switching, including a split nut, a lead screw 2, a handle 3, a spring 4 and a pneumatic mechanism 5; the split nut is arranged horizontally and is provided with a tooth groove; 2. Set vertically to the split nut, the handle 3 is connected to the split nut, and the split nut moves closer to or away from the lead screw 2 in the horizontal direction under the rotation adjustment of the handle 3; the pneumatic mechanism 5 includes a microprocessor, which is connected to the Relay, NB-IOT module and lithium battery, NB-IOT module is externally connected to NB-IOT base station, and NB-IOT base station is connected to a mobile terminal through the Internet.

[0021] Such as Figure 1-2 As shown, one end of the spring 4 is connected to the handle 3, and the other end of the spring 4 is fixedly connected to the outer casing 1 of the split nut. The spring 4 expands and contracts with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com