Ceramic-tile cutting machine

A technology for cutting machines and ceramic tiles, which is applied in the field of mechanical equipment and ceramic tile cutting. It can solve the problems of affecting cutting accuracy, easy movement, and affecting the later stage of ceramic tiles, so as to improve the freedom of movement, avoid mutual separation, and improve coping ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

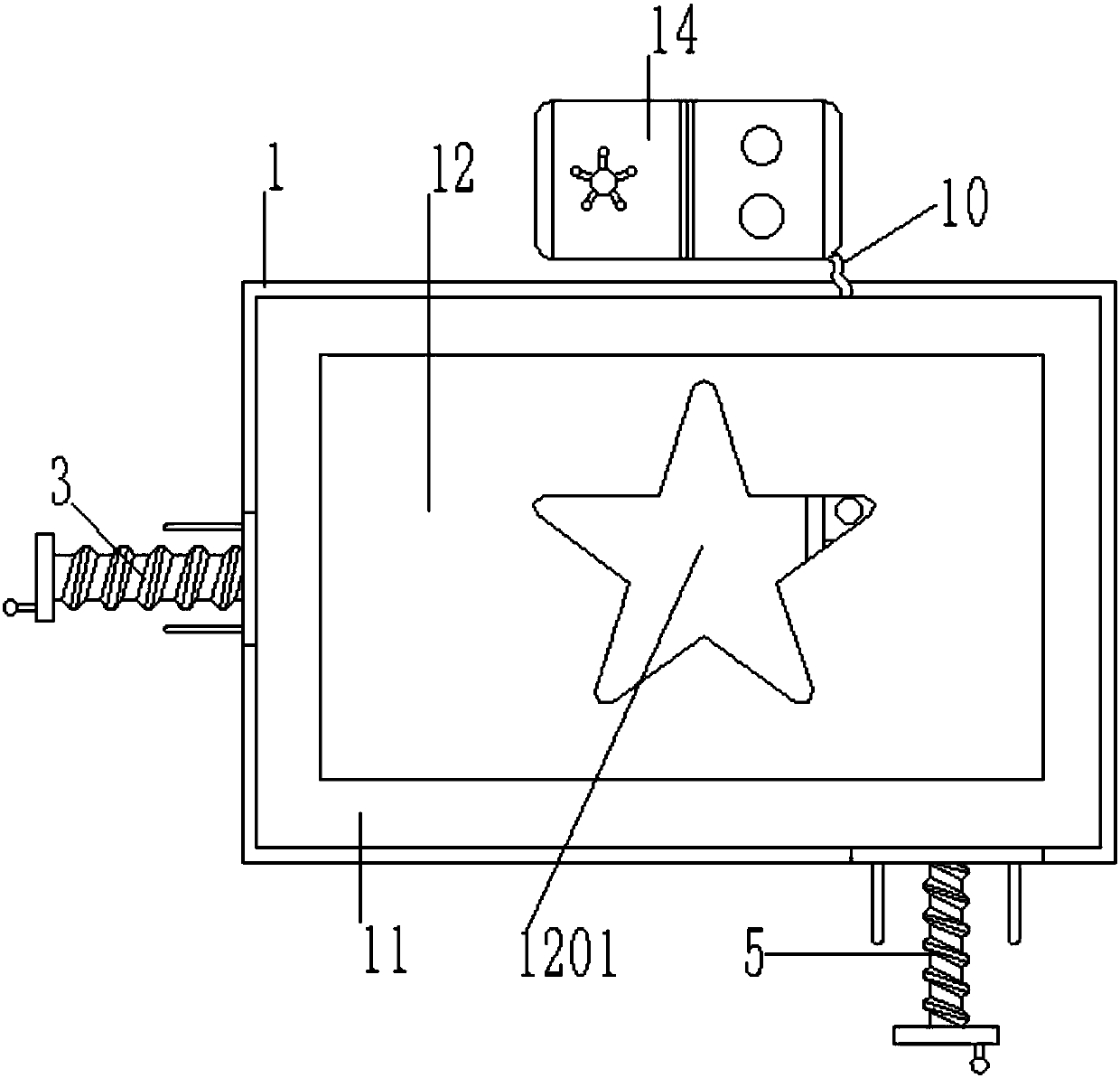

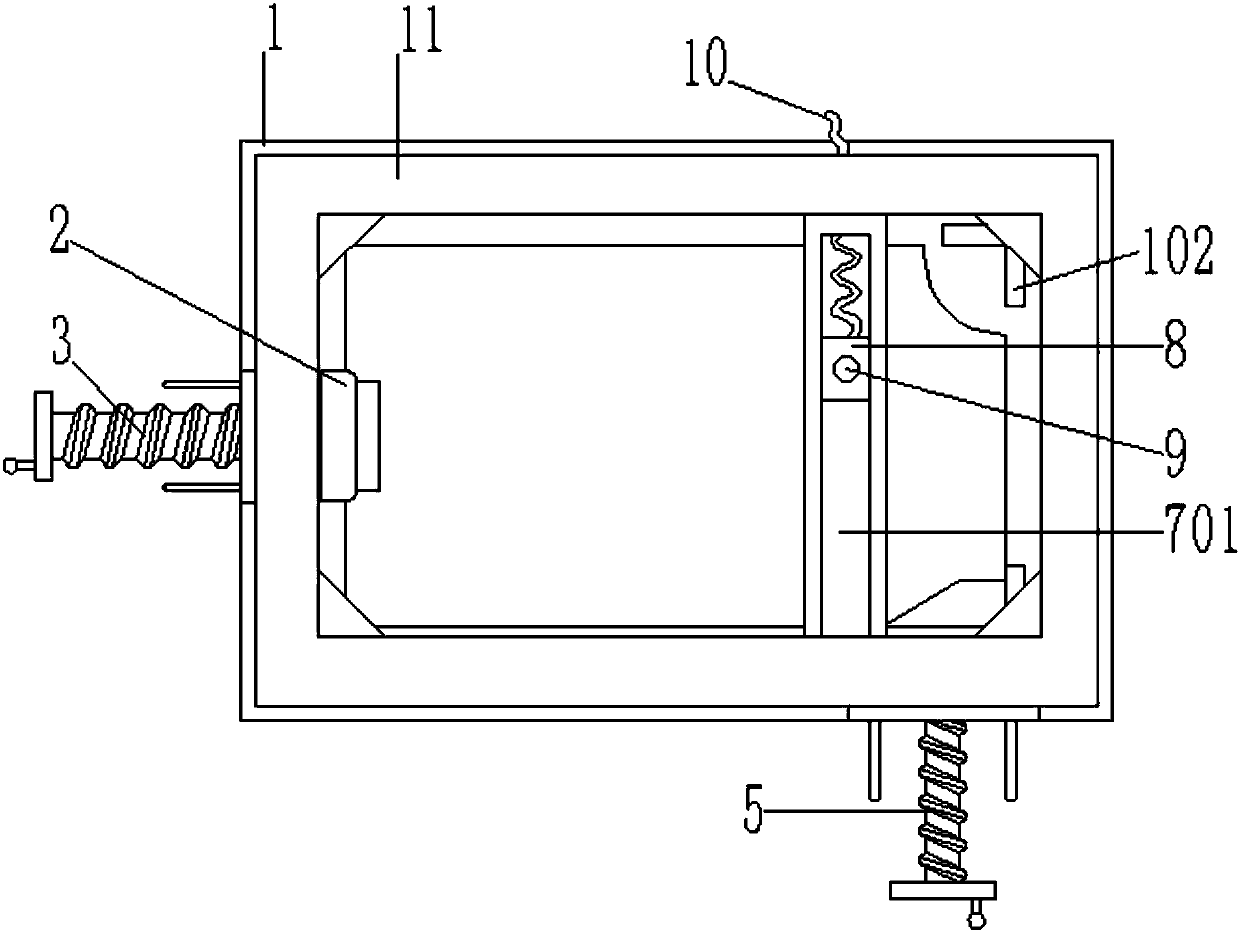

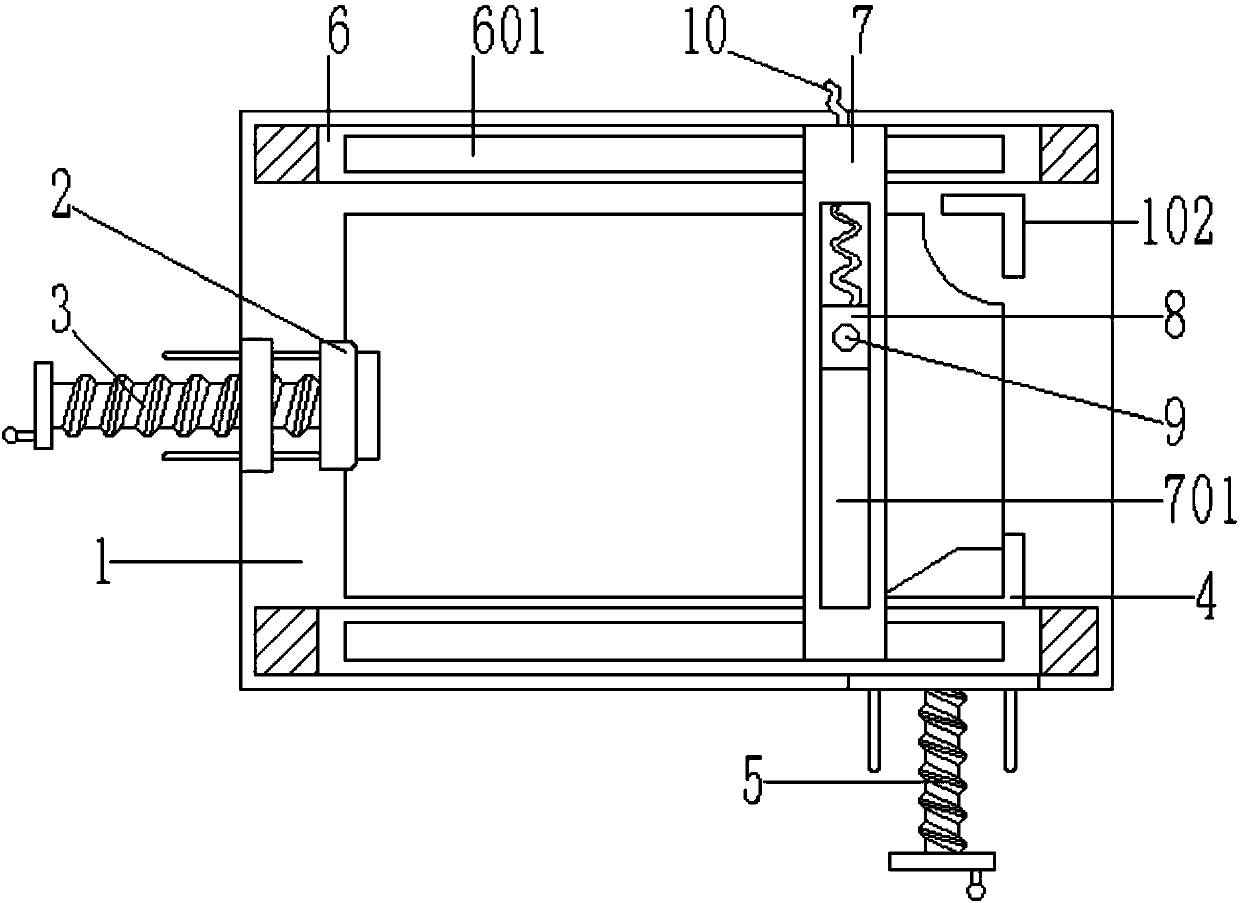

[0033] as attached figure 1 To attach Figure 8 Shown:

[0034] The present invention provides a ceramic tile cutting machine, comprising a cutting table 1, a cutting hole 101, a T-shaped fixing block 102, a left and right top block 2, a left and right spiral propulsion column 3, a front and rear top block 4, a front and rear spiral propulsion column 5, a support column 6, Chute 601, sliding column 7, rectangular opening 701, working block 8, manual control shaft 9, high-pressure pipe 10, template storage frame 11, template 12, polygonal opening 1201, water jet cutting head 13, water cutting machine 14, Drawer 15, blocking net 16, elastic line 17, filter plate 18, filter screen 19 and water flow valve 20, described cutting table 1 is a hollow structure, and the top of cutting table 1 is provided with a cutting hole 101, and the top end surface of cutting table 1 A T-shaped fixed block 102 is installed, the left and right top blocks 2 are installed on the top end surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com