Cutting fluid for cutting large-size silicon wafer by diamond wire and preparation process of cutting fluid

A diamond wire cutting, large-size technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of rising, cutting fluid can not effectively disperse cutting efficiency, low abnormal rate and contamination rate, etc., to avoid cutting accuracy , Improve lubricity and penetration, reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

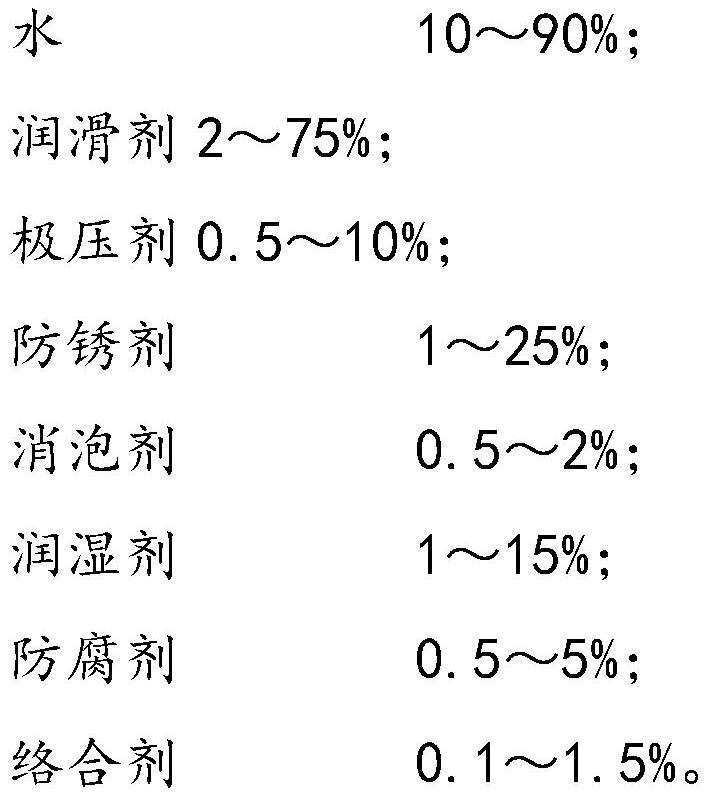

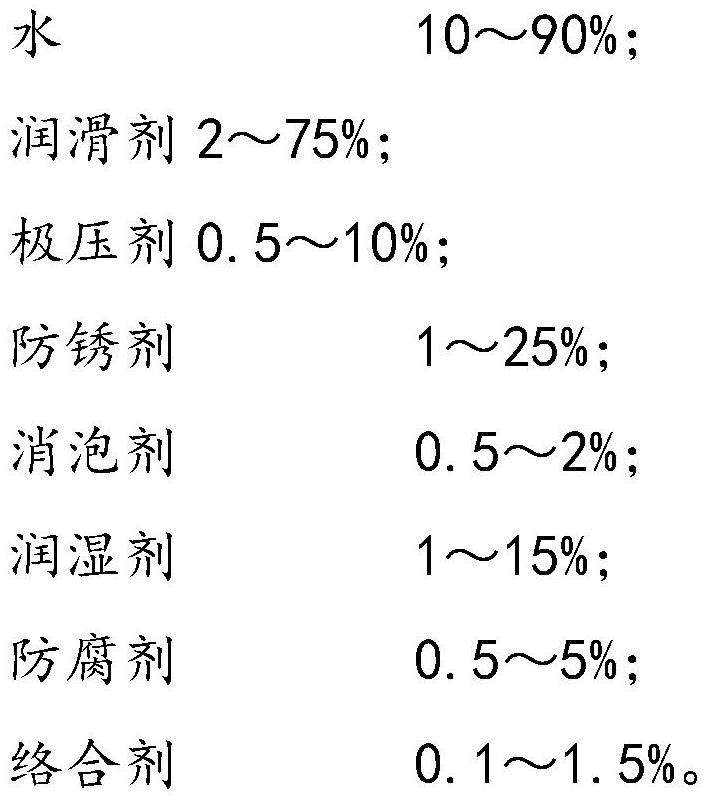

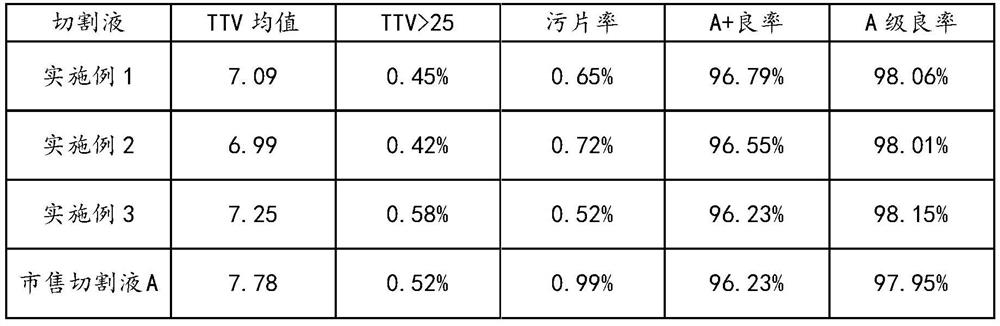

[0024] Embodiment 1: A cutting fluid for diamond wire cutting large-size silicon wafers in the preferred embodiment of the present embodiment, in terms of mass fraction, includes: 4.35 kg of triethanolamine oleate, 1.73 kg of tributyl oleate, polyethylene glycol 8.70kg, oleic acid 0.87kg, borax 2.61kg, triethanolamine borate 13.04kg, sodium benzoate 0.87kg, fatty alcohol polyoxyethylene ether 2.61kg, lauryl ether phosphate 1.74kg, propylene glycol block polyether 1.74kg, Nitrilotriacetic acid 0.87kg, deionized water 60kg.

Embodiment 2

[0025] Embodiment 2: A kind of cutting fluid for diamond wire cutting large-size silicon wafers in the preferred embodiment of the present embodiment, in mass fraction, includes: 2.33 kg of triethanolamine oleate, 0.93 kg of tributyl oleate, polyethylene glycol 7.76kg, oleic acid 0.66kg, borax 0.52kg, triethanolamine borate 9.31kg, sodium benzoate 0.62kg, fatty alcohol polyoxyethylene ether 2.33kg, lauryl ether phosphate 1.65kg, propylene glycol block polyether 2.12kg, Nitrilotriacetic acid 0.57kg, deionized water 71.2kg.

Embodiment 3

[0026] Embodiment 3: A kind of cutting fluid for diamond wire cutting large-size silicon wafers in the preferred embodiment of the present embodiment, in terms of mass fraction, includes: 2.49 kg of triethanolamine oleate, 1.58 kg of tributyl oleate, polyethylene glycol 12.88kg, oleic acid 0.74kg, borax 0.96kg, triethanolamine borate 8.39kg, sodium benzoate 0.73kg, fatty alcohol polyoxyethylene ether 4.94kg, propylene glycol block polyether 0.90kg, nitrilotriacetic acid 1.00kg, deionized 65.40kg of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com