Stainless steel band cutting device

A technology for cutting devices and stainless steel strips, which is applied in the direction of shearing devices, accessories for shearing machines, maintenance and safety accessories, etc. It can solve problems such as poor cutting accuracy, easy damage, and steel strips are prone to force deviation, etc. Achieve the effect of avoiding deviation and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

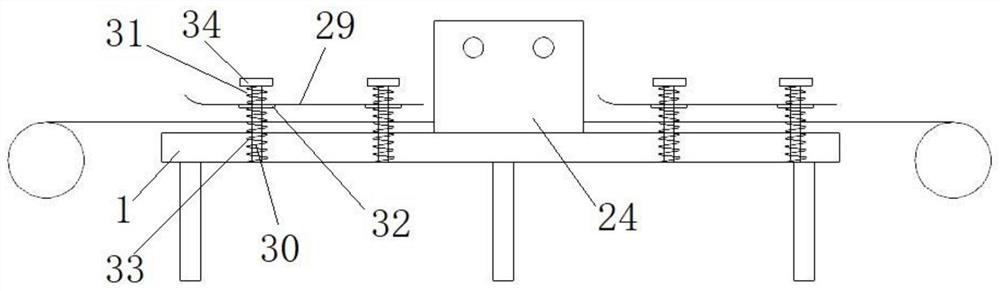

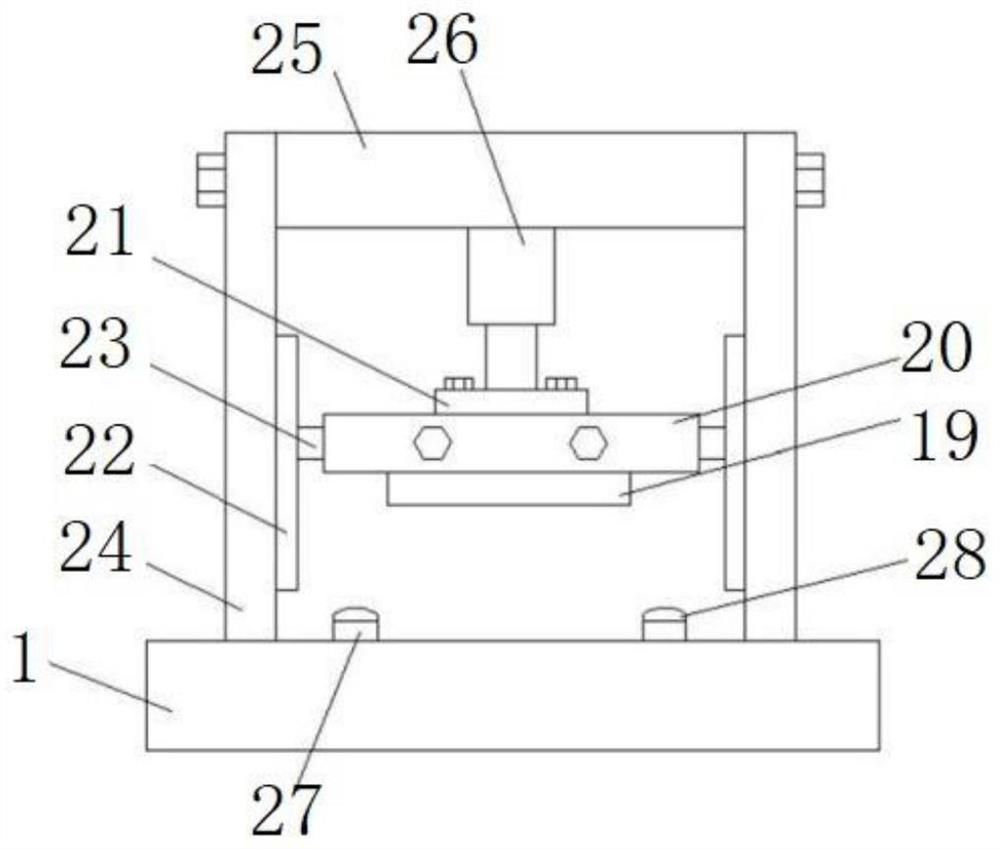

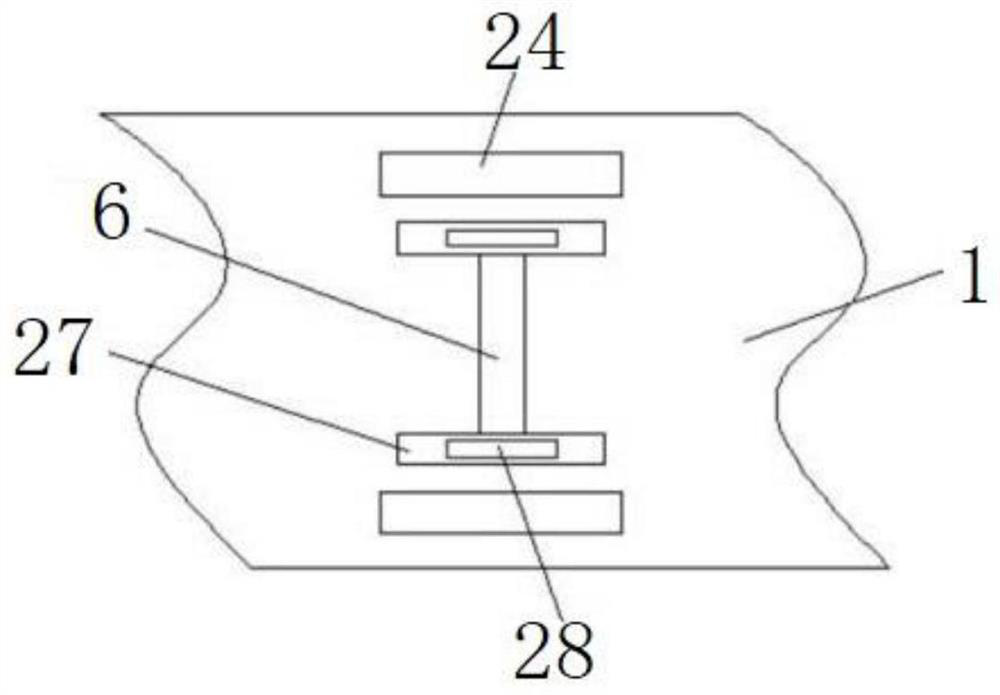

[0031] Such as Figure 1 to Figure 3 As shown, in this embodiment, the steel strip cutting mechanism includes a mounting frame on the working platform, a shearing knife assembly located in the mounting frame, and a lifting mechanism for driving the shearing knife assembly to move up and down to cut the steel strip.

[0032] The shearing knife assembly comprises shearing knife 19 and the knife seat 20 that fixed shearing knife 19 is installed, and described elevating mechanism comprises lifting power part, fixed plate 21, the first chute 22 that is symmetrically arranged on the two sidewalls of the mounting frame and the device For the first sliding block 23 in the first chute 22 , the two ends of the fixing plate 21 are respectively connected to the two first sliding blocks 23 , and the tool holder 20 is connected to the lifting power component through the fixing plate 21 . The lifting power components can be hydraulic cylinders, air cylinders or electric push rods, and this e...

Embodiment 2

[0041] Such as Figure 4 with Figure 5As shown, the difference between this embodiment and Embodiment 1 is that a recovery box is provided below the cutting groove on the working platform, and the inlet of the recovery box is located directly below the cutting groove. One side of the upper surface of the recovery box is provided with a fixed door 3, and the two relative side walls of the front side wall and the rear side wall in the recovery box 2 are all provided with a limit guide rail 16, and the limit guide rail 16 is arranged in parallel with the fixed door 3, and the position limit Guide rail 16 is arranged below fixed door 3, and the other side of recovery box 2 upper surface is provided with movable door 4, and the width of movable door 4 is less than the width of described fixed door 3, and described movable door 4 and described recovery box 2 pass through The limit guide rail 16 is slidingly connected, the upper end of the fixed door 3 is hinged with a spring plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com