Irregular blank workpiece clamping table for vertical milling machine

A workpiece clamping and vertical milling machine technology, which is applied in the direction of metal processing machinery parts, clamping, positioning devices, etc., can solve the problems of small clamping force, low gripping degree of workpieces, and inability to use large-weight workpieces. Large holding force, good effect, and the effect of improving friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

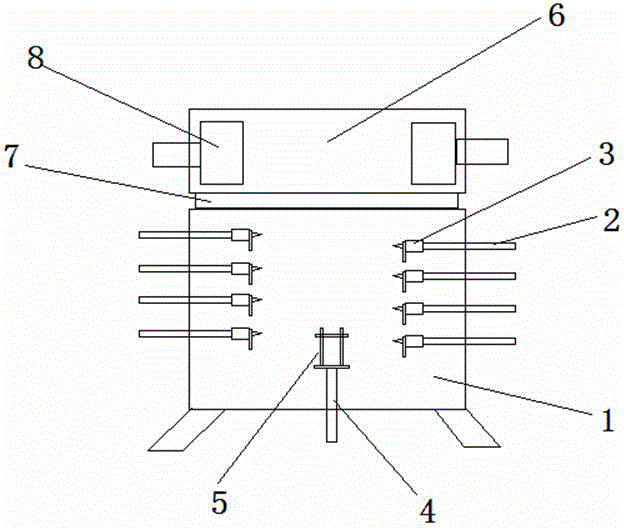

[0037] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

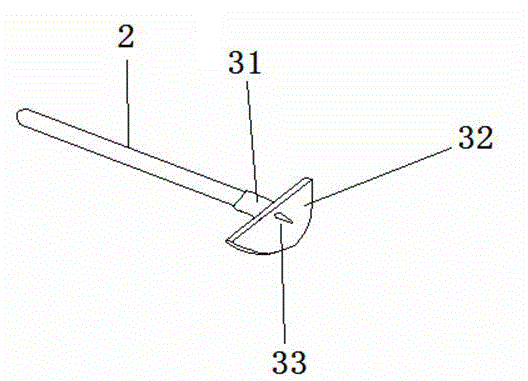

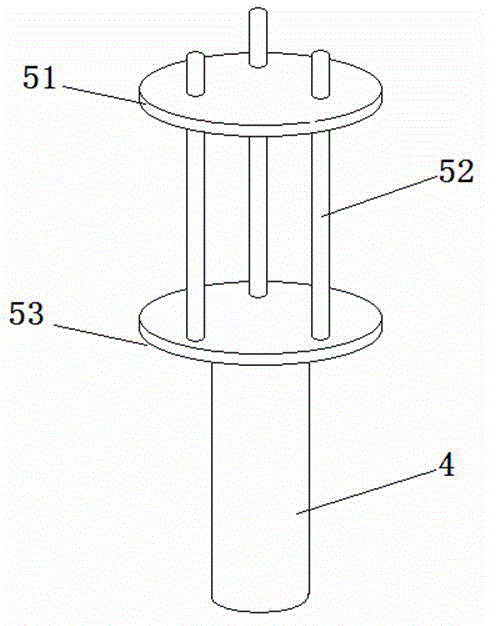

[0038] As shown in the figure, an irregular blank workpiece clamping platform for a vertical milling machine of the present invention includes a workpiece groove 1 with an upward opening. Generally, the workpiece groove 1 is a vertical column structure, and the side of the workpiece groove 1 A number of screw holes are arranged on the wall, and a fixed rod 2 is arranged horizontally through the screw holes. According to the shape of the long-term processed parts, the fixed rod 2 with an inclined angle can also be selected to be set. One end of the fixed rod 2 located in the workpiece groove 1 is provided with a Fastener 3;

[0039] The fastener 3 further includes a sleeve structure 31 radially movably connected to the fixed rod 2, and the end of the sleeve structure 31 away from the fixed rod 2 is provided with a clamping piece 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com