Cutting machine for production and processing of fitness equipment

A fitness equipment and cutting machine technology, applied in metal processing equipment, shearing devices, manufacturing tools, etc., can solve the problems of low production efficiency, low efficiency, and high labor intensity, and achieve high production efficiency, high efficiency, and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

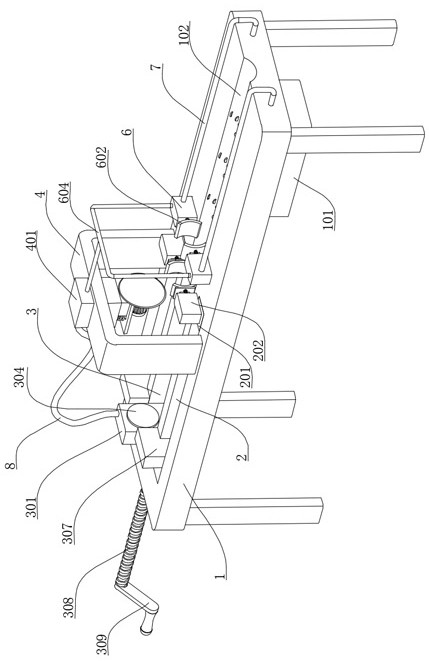

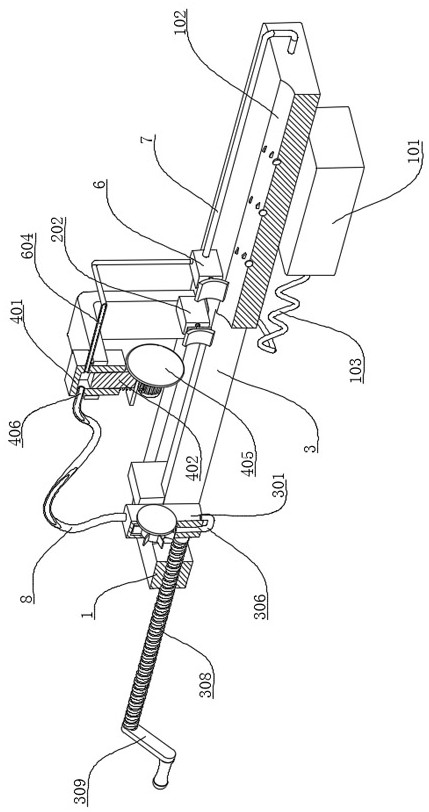

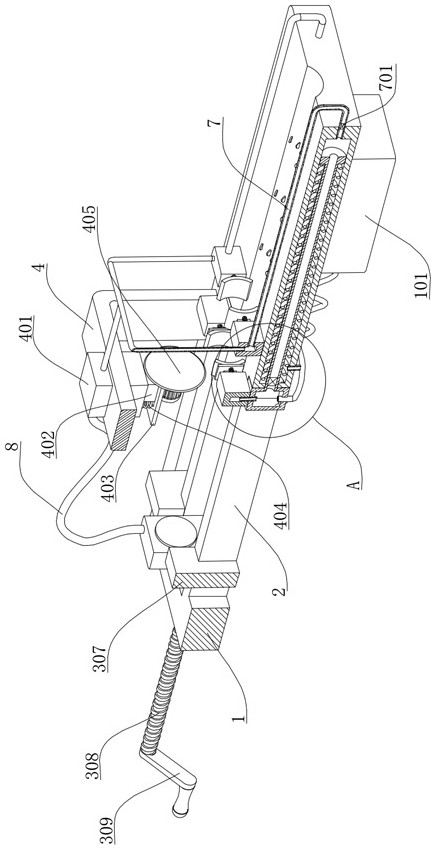

[0032] refer to Figure 1-8 , a cutting machine for the production and processing of fitness equipment, comprising an operating table 1, two mounting grooves 2 and a positioning groove 3 are provided in the operating table 1, a groove 102 is provided on the top wall of the operating table 1, and a groove 102 is provided in the groove 102 A number of pulleys ensure the smooth sliding of the pipe. The bottom wall of the console 1 is fixedly connected with an air pump 101, which can provide compressed air. The installation groove 2 is slidingly connected with an extension mechanism;

[0033] The extension mechanism is used to extend the pipe, and the extension mechanism also includes a mounting block 201, an air intake pipe 204, a first hose 103, a piston rod 5, an air storage chamber 501, a return spring 503, and a first pressure relief valve 505, the installation block 201 is slidingly socketed in the corresponding installation groove 2 and is a hollow structure, the upper surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com