Patents

Literature

56results about How to "Avoid manual cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

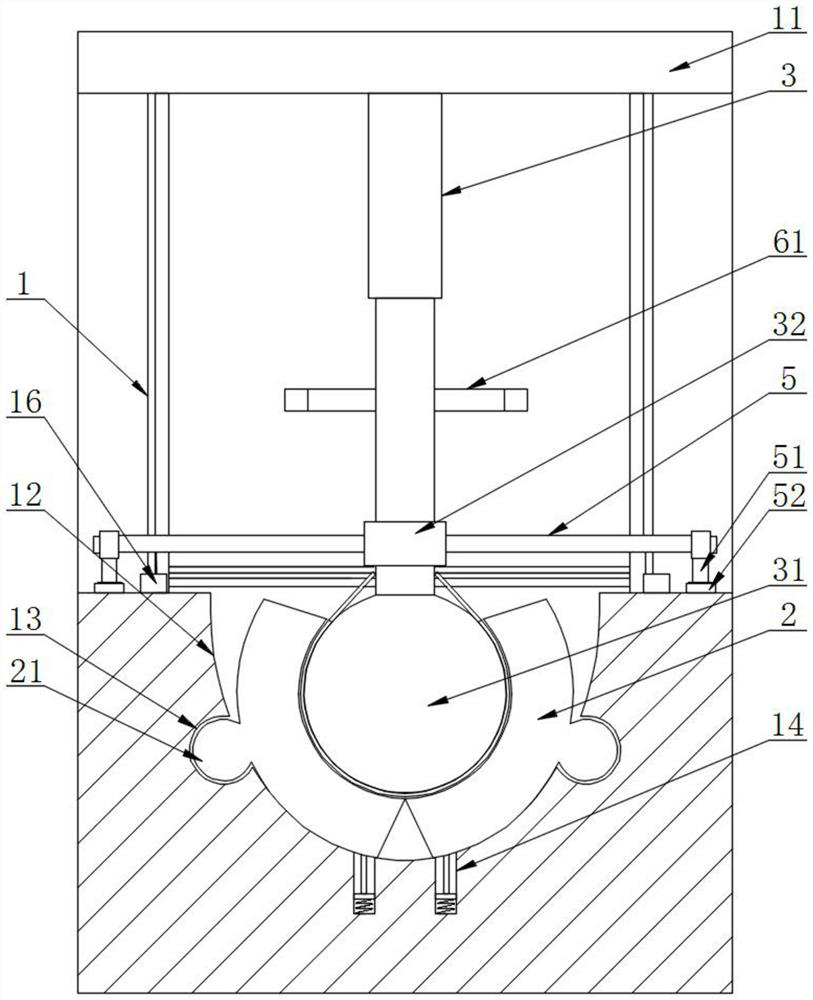

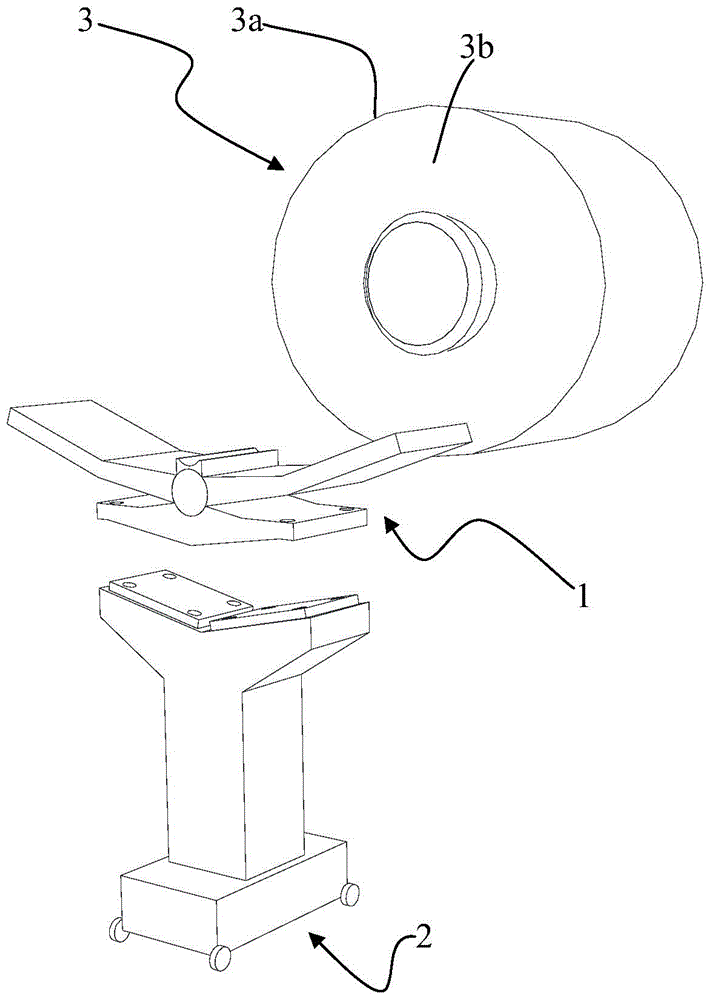

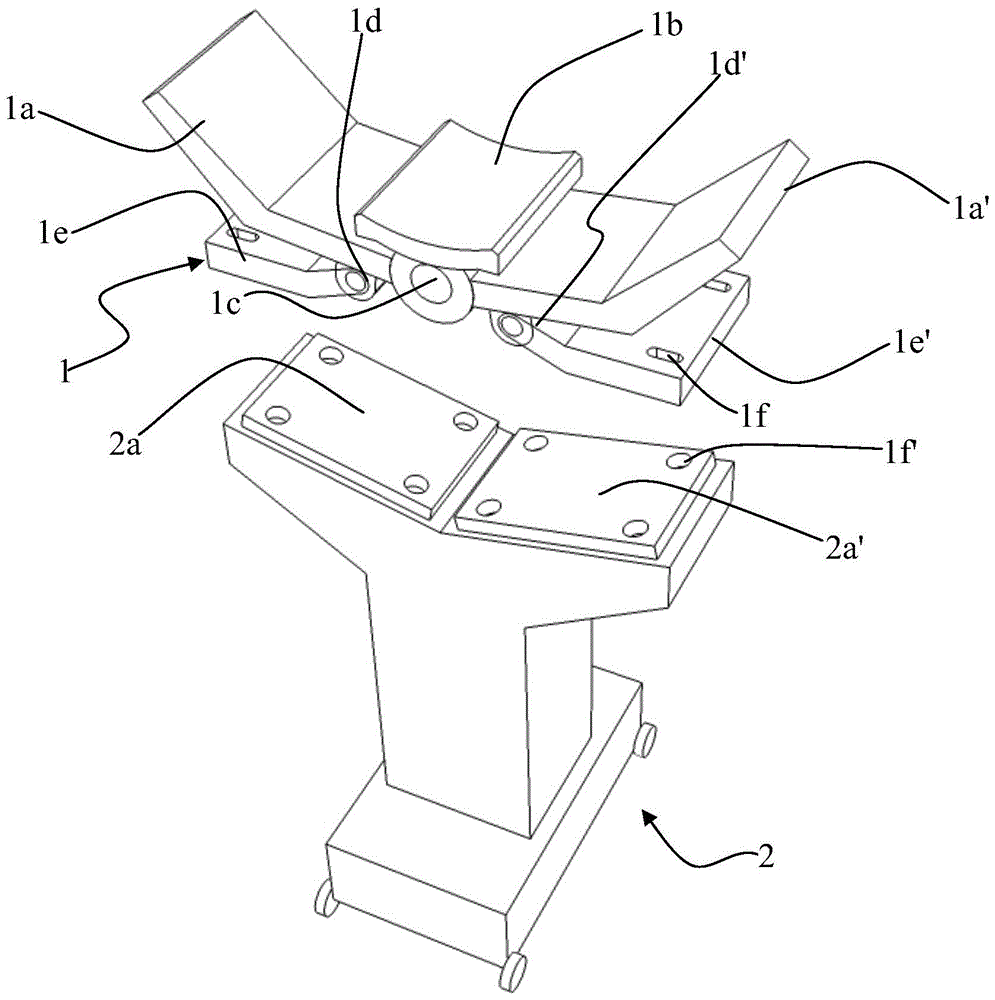

Rapid treatment method for coiler unwinding

The present invention relates to a rapid treatment method for coiler unwinding. The rapid treatment method comprises: providing a steel coil support frame with a movable hinge joint and an adjustment mechanism, and a steel coil trolley; lifting the steel coil support frame onto the steel coil trolley, and fixing; driving the steel coil trolley to the position below the unwinding steel coil, and lifting so as to bear against the steel coil and support the steel coil through the left support arm and the right support arm of the support frame; contracting the drum, and making the outlet pressing roller arranged above the drum press the outer ring of the steel coil, such that a gap is formed between the drum outer wall and the steel coil inner ring of the unwinding coil; adopting a penetrating belt rod to penetrate from the gap, and making the bundle belt penetrate into the inner ring gap; inching the drum to rotate to make the steel coil rotate 180 DEG, binding the bundle belt on the position opposite to the inner ring with the bundle belt, and tightening; making the drum maintain the contracting state, lifting the outlet pressing roller, and making the steel coil trolley descend, such that the loose part is tightened with the bundle belt; and inching steel coil trolley to move toward the outer side, and lifting away the steel coil. With the rapid treatment method of the present invention, the steel coil unwinding can be rapidly and conveniently treated.

Owner:BAOSHAN IRON & STEEL CO LTD

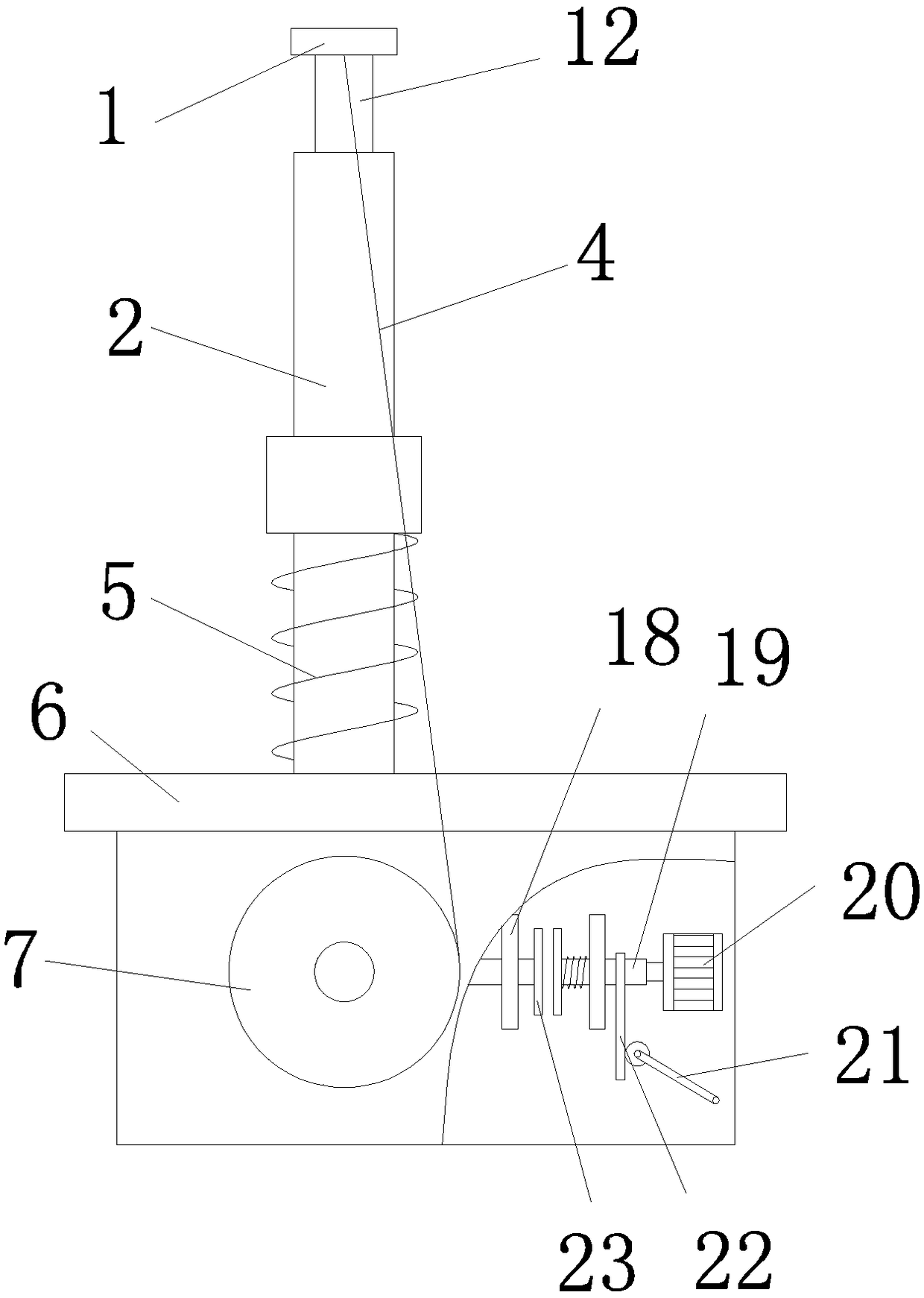

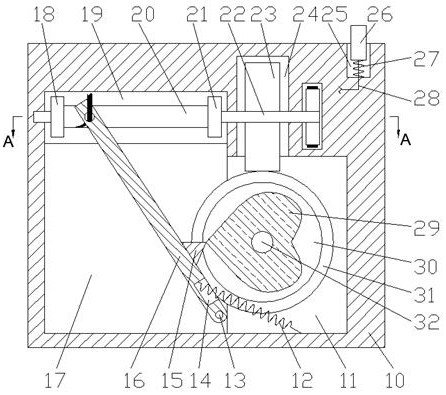

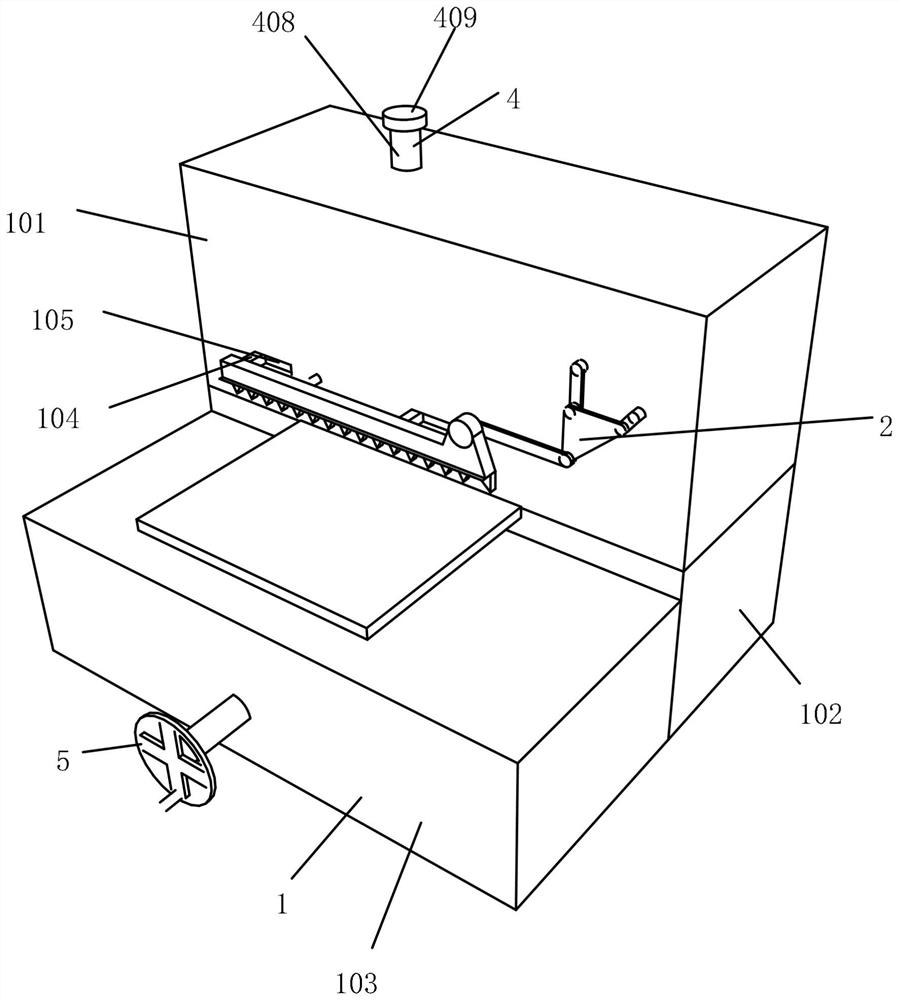

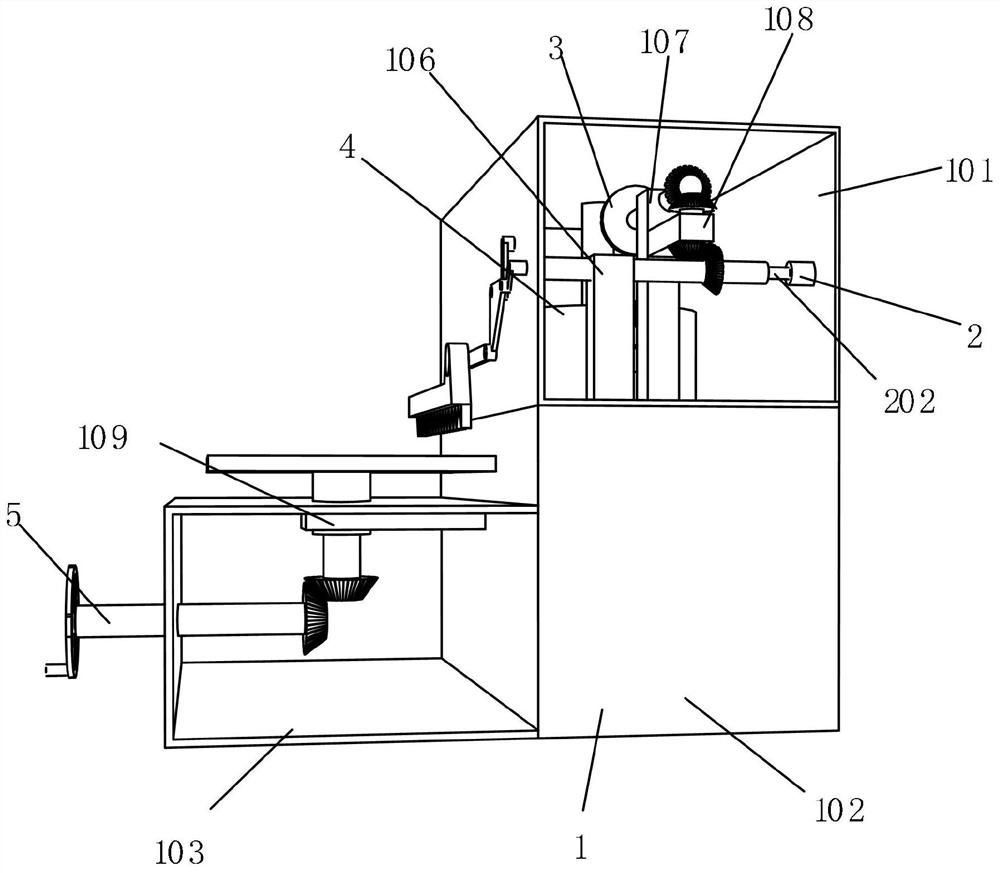

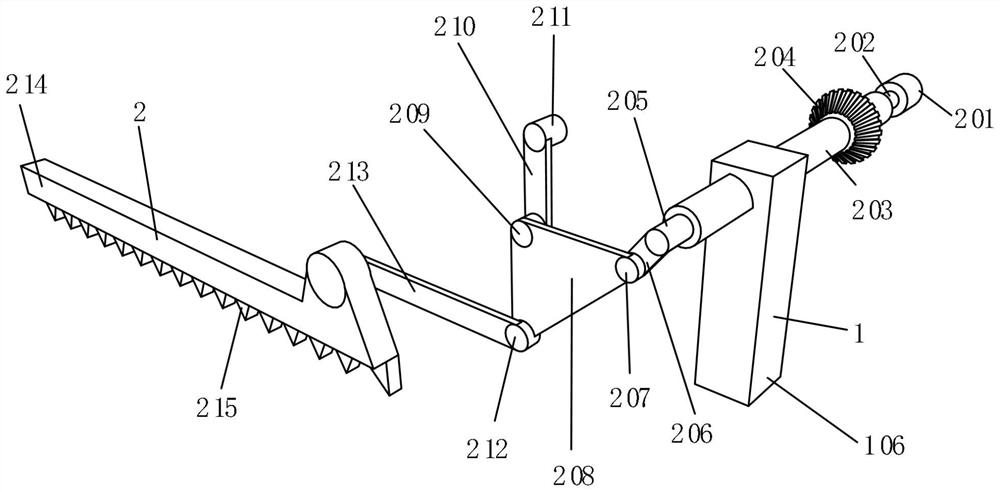

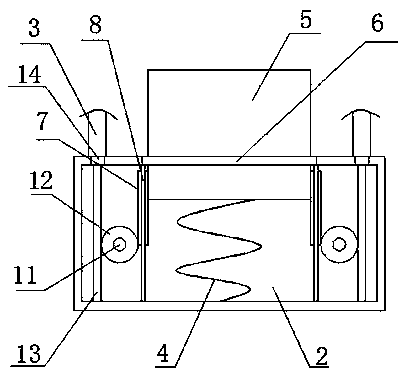

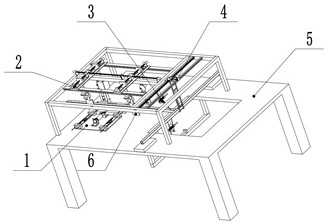

Medicine cutting device

The invention discloses a medicine cutting device comprising a work table and support legs symmetrically connected to the bottom of the work table. According to the medicine cutting device, the structure is simple, a motor drives a shaft sleeve and clutch discs connected with the shaft sleeve to rotate, a pedal is stepped, a sliding plate is rotatably connected with the shaft sleeve, the pedal drives the sliding plate to horizontally slide to achieve contact of the two clutch discs, and the clutch discs drive a second bevel gear to rotate; the second bevel gear is engaged with a first bevel gear to drive a winding disc to rotate, a connecting line and a horizontal rod drive a double-face rack to move downward, and the double-face rack and a straight gear are engaged; the straight gear is engaged with a single-face rack, and a blade is driven to move downwards through a triangular connecting plate to cut medicine; and the pedal is loosened, under the effect of a first spring and a second spring, the blade moves upwards, the steps are conducted in this way, thus continuous cutting can be conducted, simple and practical effects are achieved, manual cutting is avoided, and the workerlabor intensity is reduced.

Owner:JINAN SUNNYPHARMACY

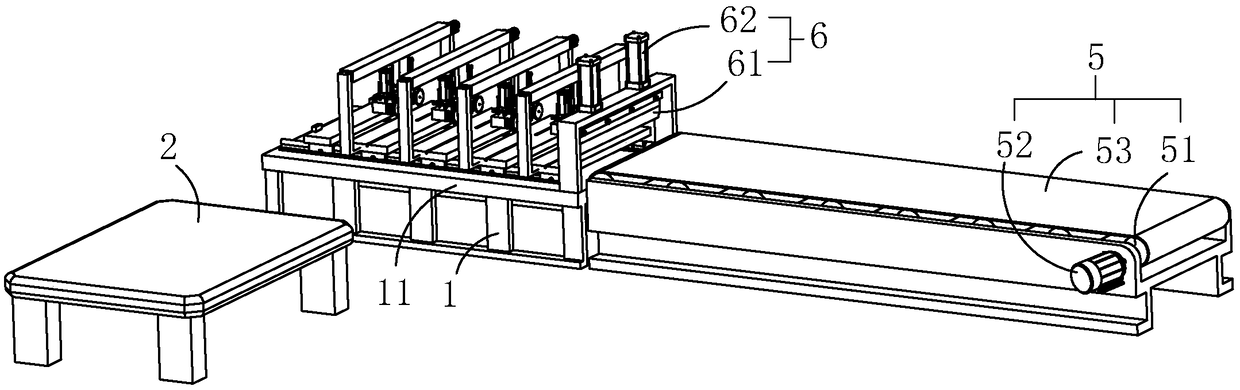

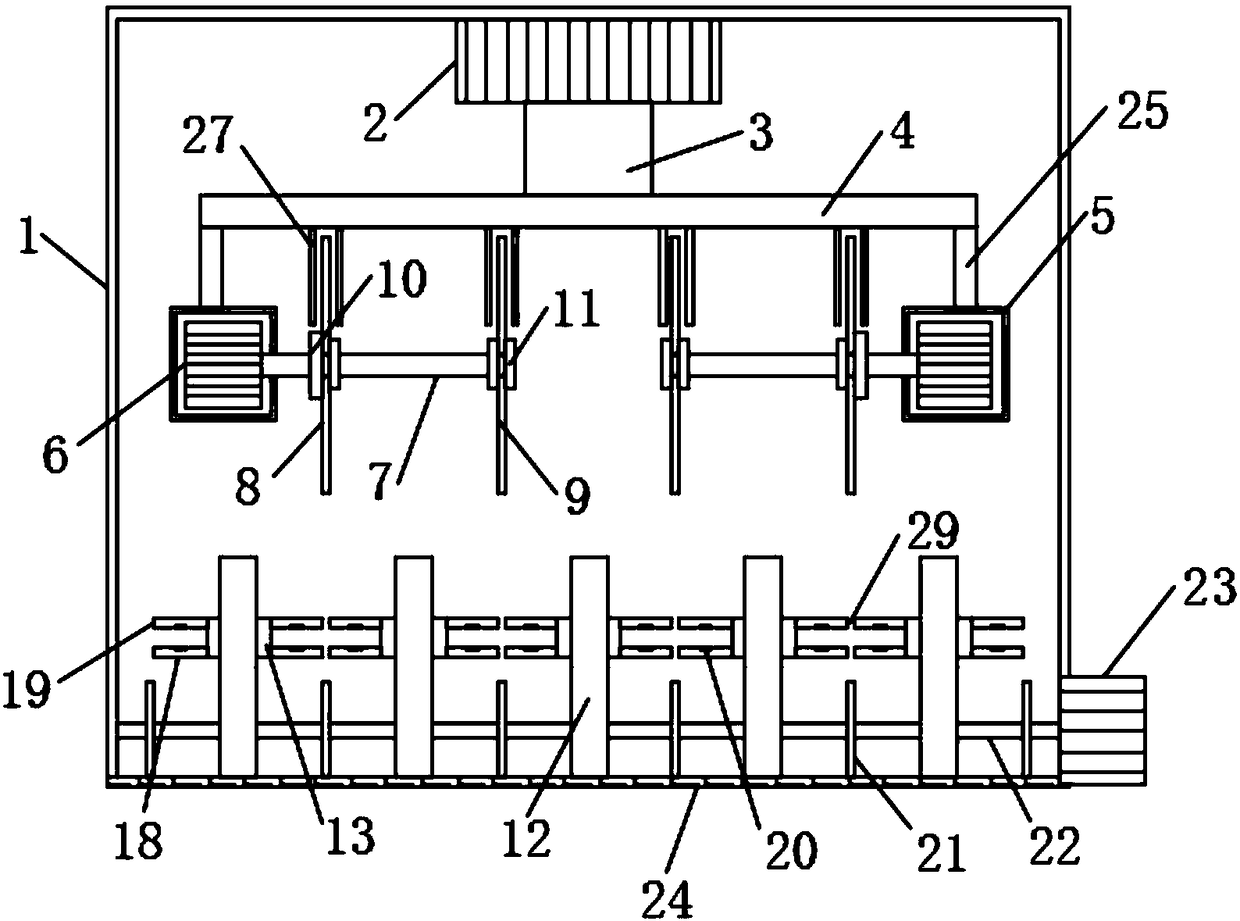

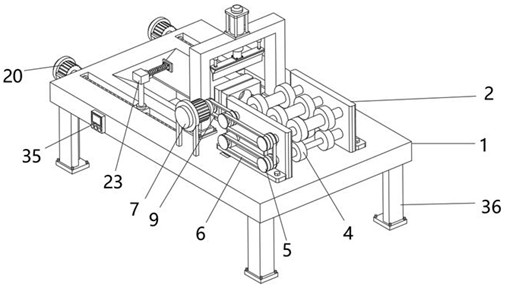

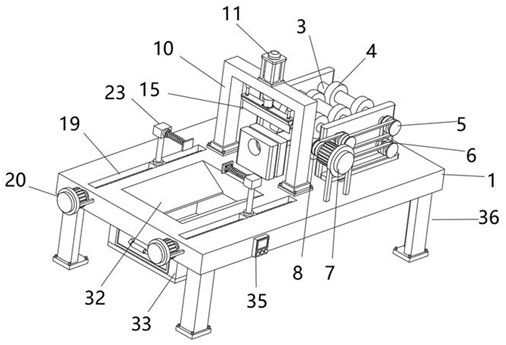

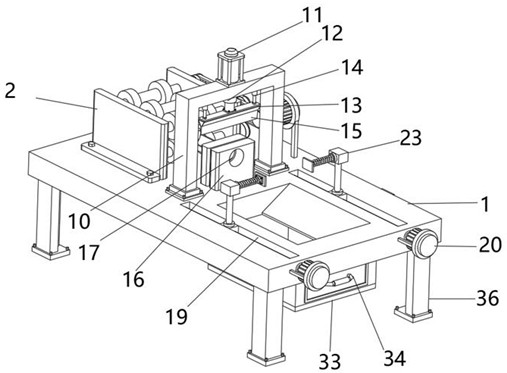

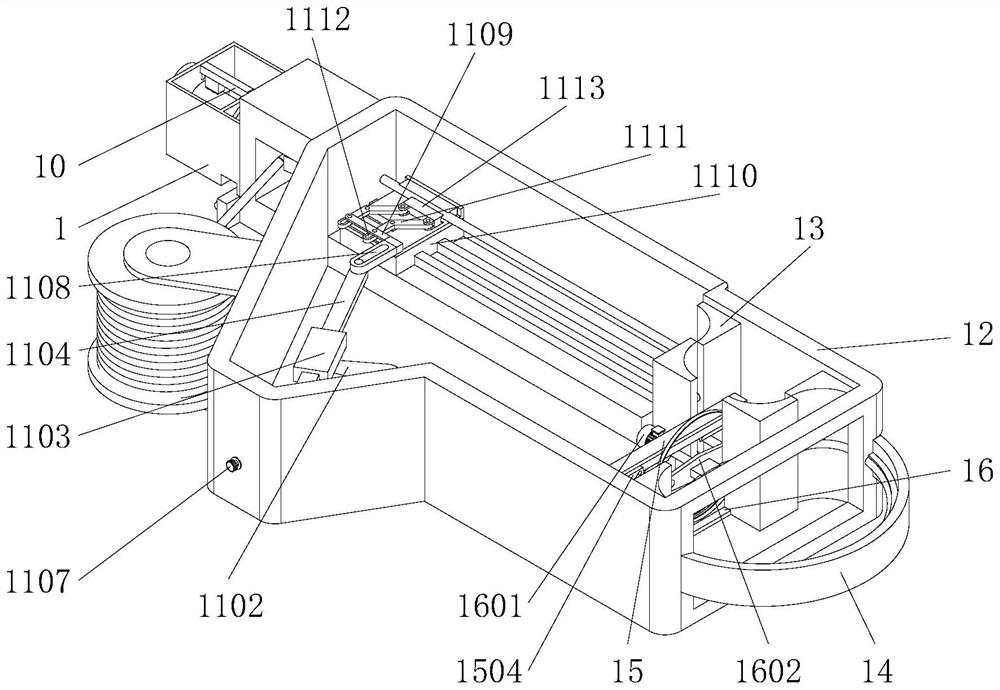

Door sheet packing equipment and packing method thereof

InactiveCN109229636ASimplify the operation processImprove packaging efficiencyPackagingCardboardEngineering

The invention relates to door sheet packing equipment and a packing method thereof, and belongs to the technical field of furniture package. The equipment comprises a rack and a workbench arranged atone side of the rack, wherein the rack is fixedly provided with a fixing platform, the fixing platform is provided with working blocks, the working blocks are provided with cutting grooves, each working blocks is fixedly provided with a fixing frame, each fixing frame is provided with a cutting device, and each fixing frame is provided with a driving mechanism; the rack is also provided with a belt conveyor used for conveying a paperboard onto the working blocks, and the rack is provided with severing devices located between the belt conveyor and the working blocks and used for severing the paperboard. The cutting devices and the driving mechanisms are started, the cutting devices are driven to cut the paperboard in the direction of the cutting grooves, finally eight parallel cracks are formed in the paperboard, and the two sides in the paperboard movement direction are provided with four cracks respectively, thereby avoiding the situation that a worker manually cuts and tears the paperboard, simplifying the manual operation procedures of the worker and improving the packing efficiency.

Owner:杭州顾家定制家居有限公司

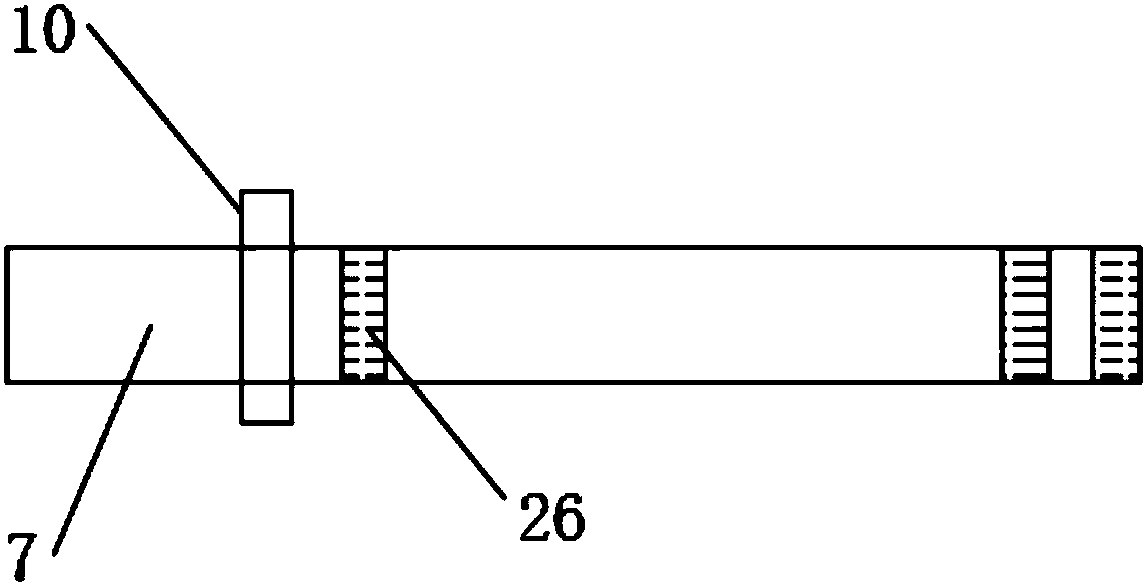

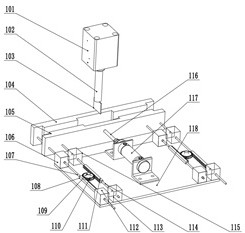

Cutting machine for production and processing of fitness equipment

ActiveCN113042806AImprove performanceAvoid manual cuttingOther manufacturing equipments/toolsTube shearing machinesGrindingEngineering

The invention discloses a cutting machine for production and processing of fitness equipment. The cutting machine comprises an operation table and a stretching mechanism; two mounting grooves and a positioning groove are formed in the operation table, a groove is formed in the top wall of the operation table, an air pump is fixedly connected to the bottom wall of the operation table, and extending mechanisms are slidably connected into the mounting grooves; the stretching mechanism is used for stretching out a pipe, the stretching mechanism further comprises mounting blocks, air inlet pipes, a first hose, a piston column, an air storage cavity, a return spring and a first pressure release valve, the mounting blocks are slidably connected into the corresponding mounting grooves in a sleeved manner and are of a hollow structure, and clamping mechanisms are fixedly connected to the upper surfaces of the mounting blocks; and the air inlet pipes are fixedly connected with the bottom walls of the corresponding mounting blocks in a penetrating manner. Compared with the prior art, the cutting machine has the advantages that the efficiency is higher, the use is convenient, the automation degree is high, the production efficiency is higher, automatic grinding can be carried out while cutting is carried out, manual grinding is avoided, and the labor intensity is reduced.

Owner:南通力人健身器材有限公司

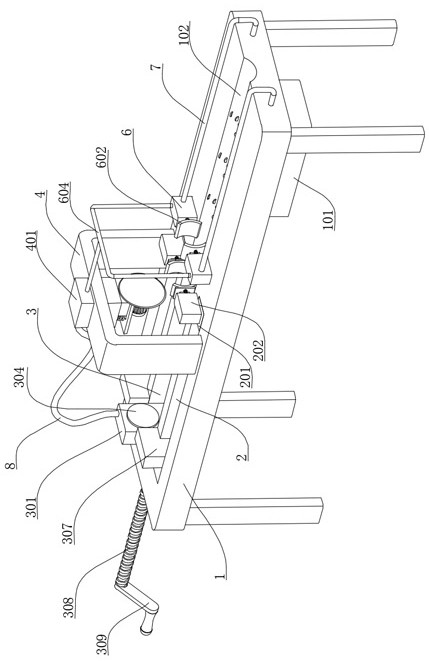

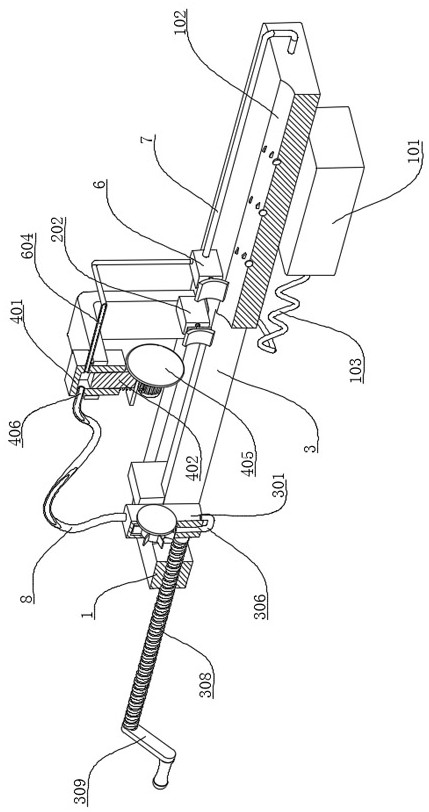

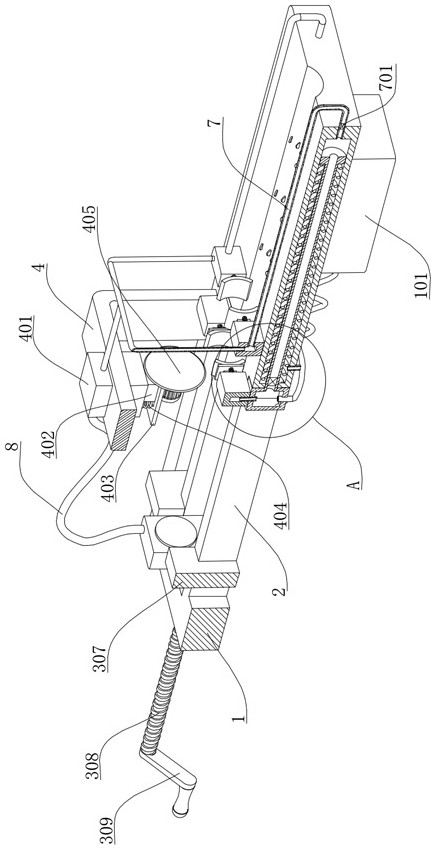

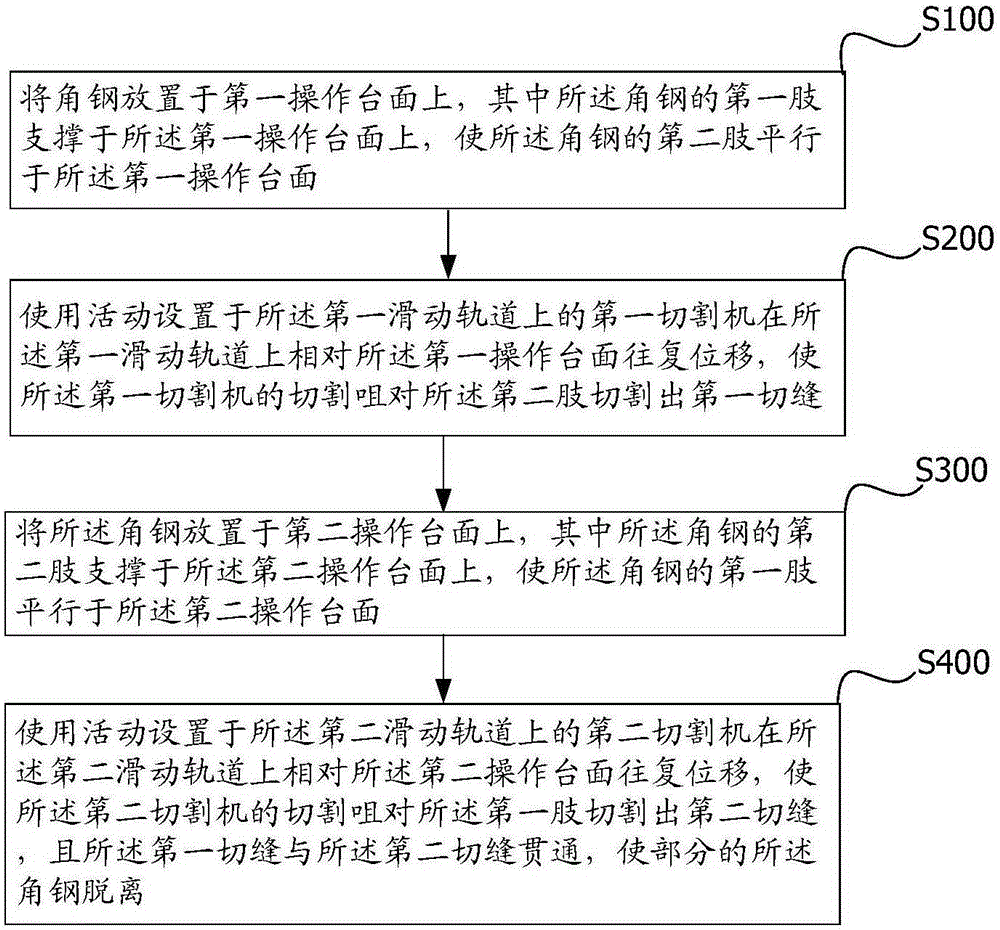

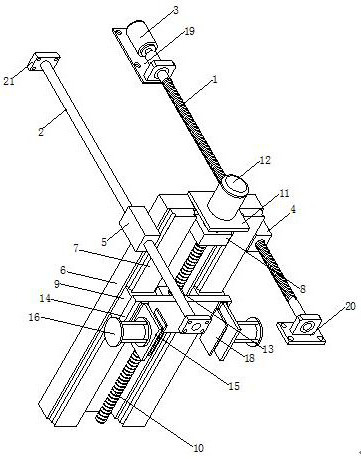

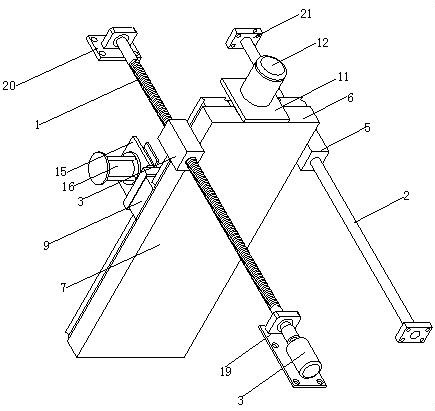

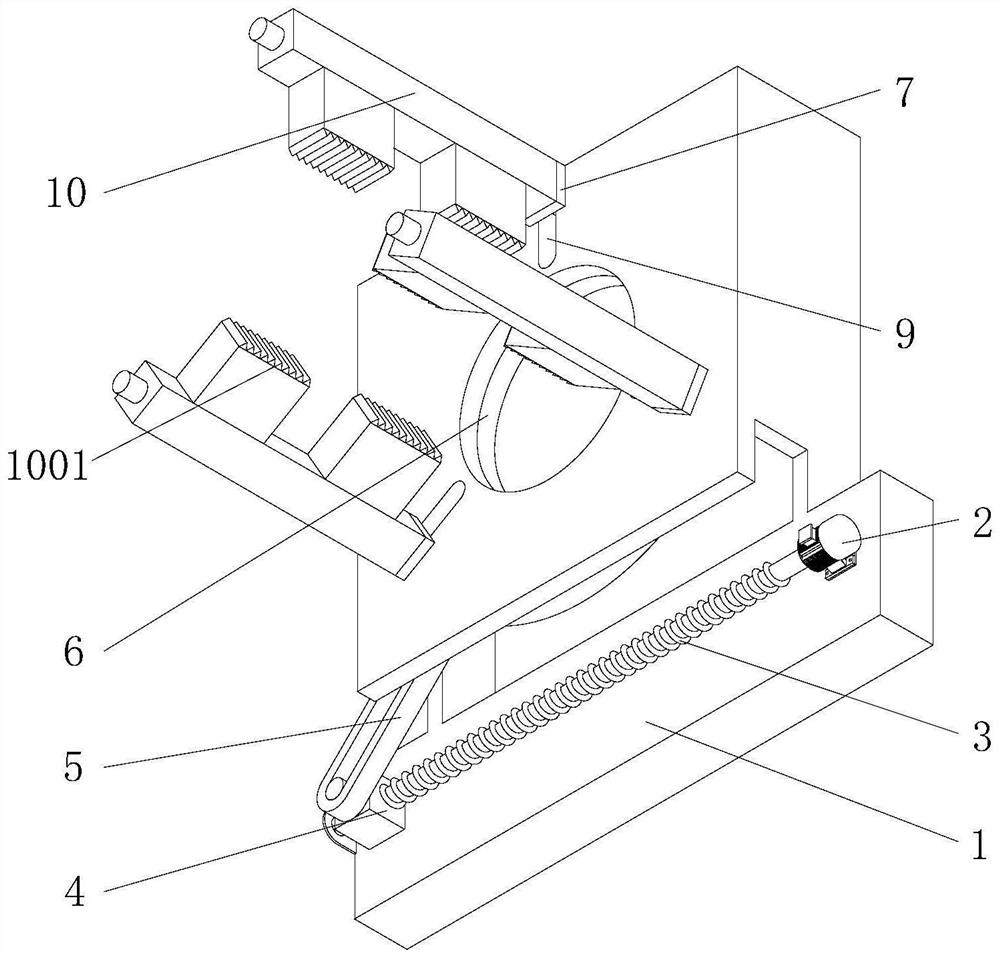

Device and method for cutting angle iron

ActiveCN105149724AImprove processing efficiencyReduce wasteGas flame welding apparatusEngineeringNozzle

The invention discloses a device and method for cutting angle iron. The device comprises a first cutting unit and a second cutting unit. The first cutting unit comprises a first operation tabletop, a first sliding rail, a limiting mechanism and a first cutting machine. The first cutting machine is movably arranged on the first sliding rail and moves in a reciprocating manner on the first sliding rail relative to the first operation table. The first cutting machine comprises a first cutting nozzle arranged on the first operation tabletop in a suspended manner, moves in a reciprocating manner along the first cutting machine and is used for cutting a first kerf on a second limb of the angle iron. The second cutting unit comprises a second operation tabletop, a second sliding rail, a positioning mechanism and a second cutting machine. The second cutting machine is used for cutting a second kerf on a first limb of the angle iron. The first kerf is communicated with the second kerf so that part of the angle iron can be disengaged. According to the device and method for cutting the angle iron, the problems that for steel machining in the current stage, processes are complex, so that the machining efficiency is low, and materials are wasted due to multiple times of cutting of steel are solved.

Owner:DUOWEI UNION GRP

Printed wiring board containing gold at different thicknesses and manufacturing method thereof

InactiveCN104470233ARealize thick gold processingRealize processingConductive pattern formationEtchingWire cutting

The invention discloses a printed wiring board containing gold at different thicknesses and a manufacturing method of the printed wiring board. An outer layer plate surface of the printed wiring board comprises a thin gold area and a thick gold area. The manufacturing method includes the following steps of pattern transferring for the first time, wet film printing, gold plating for the first time, pattern transferring for the second time, gold plating for the second time, film removing, pattern transferring for the third time and etching. According to the manufacturing method, manual wire cutting is not needed, and the efficiency of volume production is high; the requirement for machining with different gold thicknesses is satisfied; machining of the printed wiring board containing gold at two or more different thicknesses is achieved in the manner of protecting wires through wet films and protecting the thin gold area through dry films.

Owner:GCI SCI & TECH

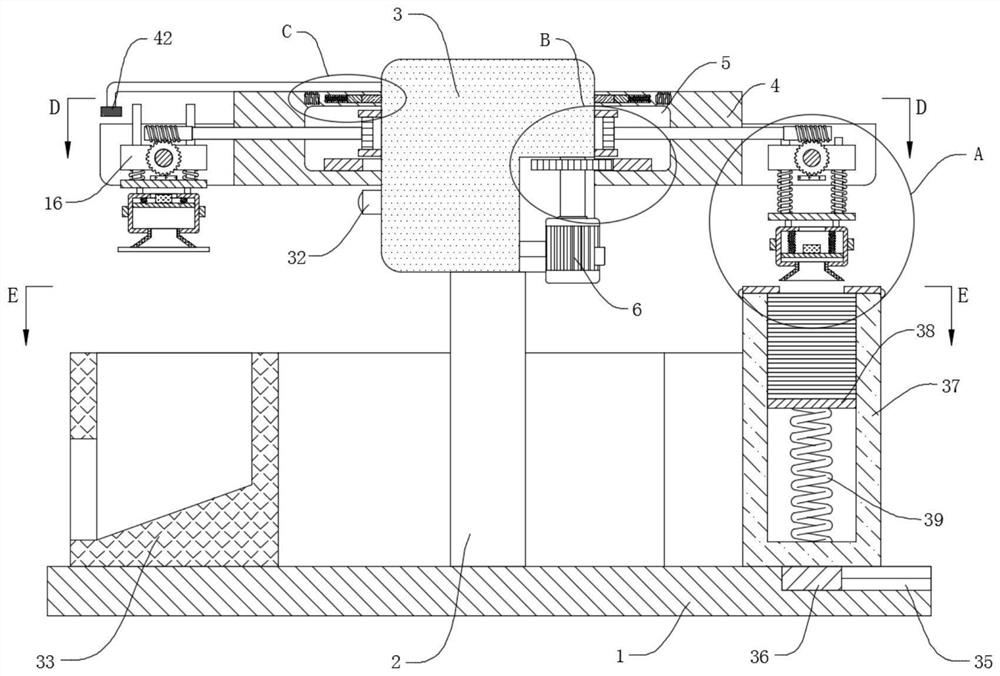

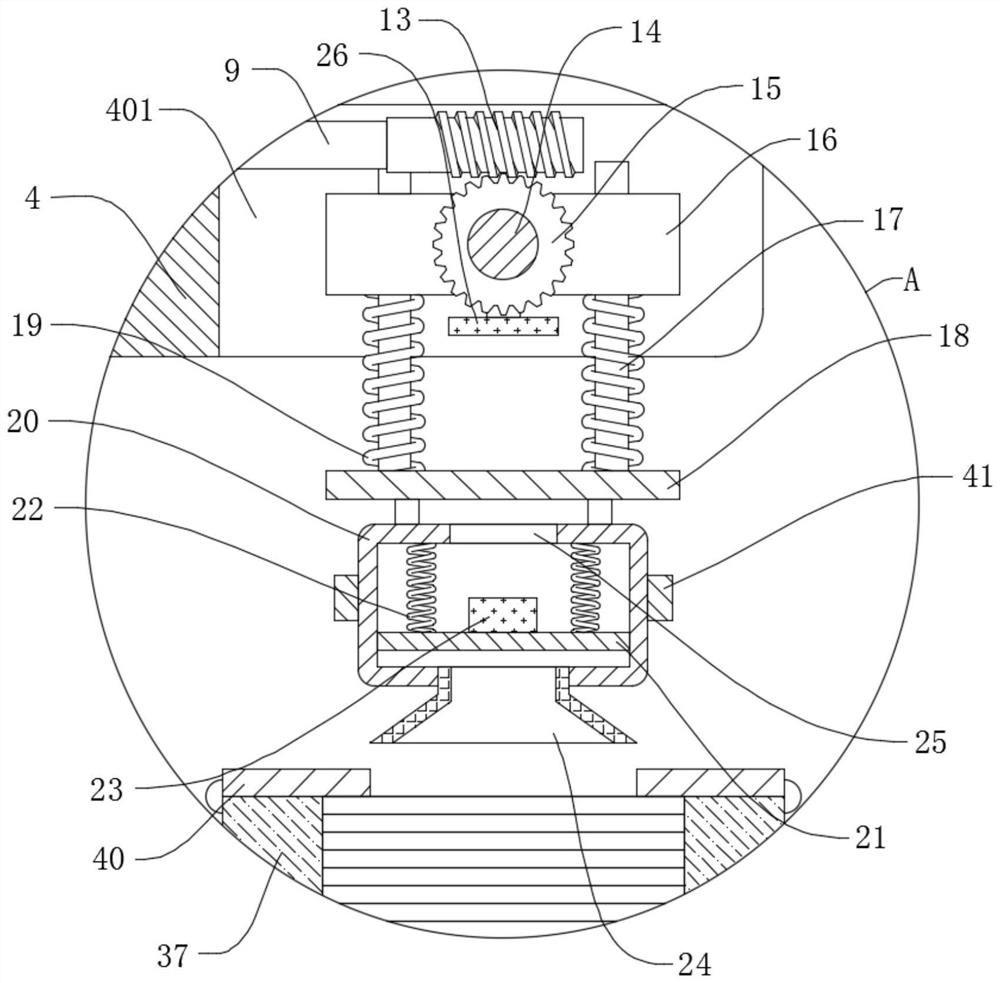

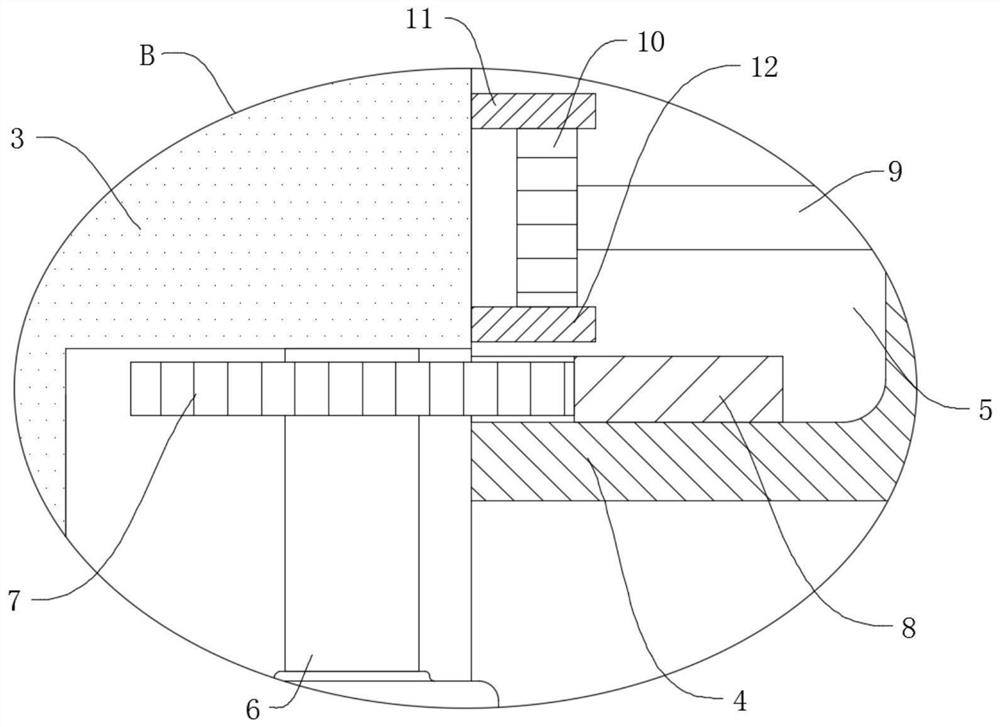

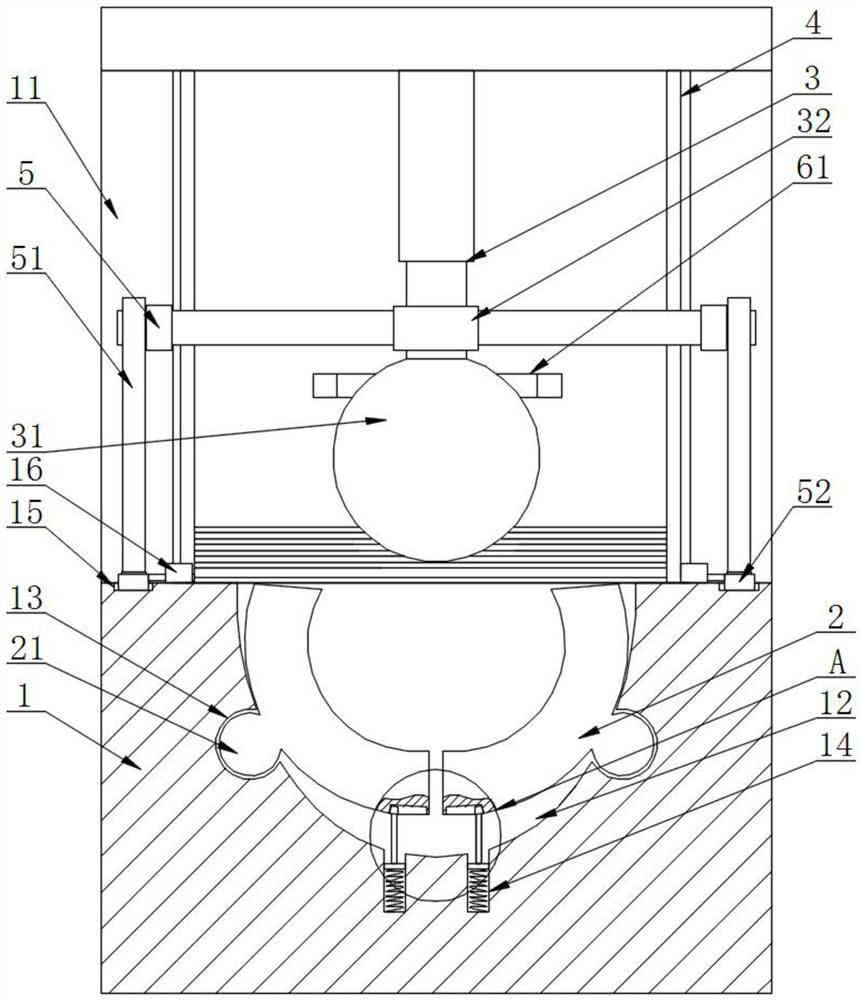

Integrated circuit chip flatness detection device and method

An integrated circuit chip flatness detection device disclosed by the present invention comprises a machine base, a stand column is welded on the upper surface of the machine base, the stand column is fixedly connected with a fixed block, the side wall of the fixed block is fixedly connected with a plurality of detectors, and the fixed block is rotatably connected with a rotating block through a bearing in a penetrating manner. A detection mechanism for flatness detection is arranged in the rotating block; the detection mechanism comprises a mounting groove formed in the inner side wall of the rotating block, the inner bottom wall of the mounting groove is fixedly connected with an inner gear ring, the inner side wall of the fixed block is fixedly connected with a servo motor through a support, an output shaft of the servo motor is in interference fit with a first gear, and the first gear is meshed with the inner gear ring; the rotating block is provided with eight functional grooves. Compared with the prior art, the chip detection device has the advantages that chips can be continuously and automatically detected, feeding, discharging and classification can be automatically carried out, and therefore the detection efficiency is greatly improved, and meanwhile the equipment cost and the labor cost are reduced.

Owner:深圳市通恒伟创科技有限公司

Cutting-polishing dual-purpose device for metal machining

InactiveCN108356540AAchieve the purpose of exerciseEasy to moveOther manufacturing equipments/toolsMetal machiningEngineering

The invention discloses a cutting-polishing dual-purpose device for metal machining. The device comprises a device body. An air cylinder is installed inside the device body, the lower portion of the air cylinder is provided with a support through a push rod, a base is fixedly connected to the lower portion of the support, one side of the base is provide with a first motor, one side of the first motor is rotationally connected with a first rotating shaft, the outer side of the first rotating shaft is sleeved with a first cutting blade and a second cutting blade, the inner side of the first cutting blade is provided with a baffle, the lower portion of the device body is provided with a telescopic rod, the upper end of the telescopic rod is connected with a connection block through a bearing,a first clamping arm is fixedly connected to the side portion of a first sliding block, a second clamping arm is fixedly connected to the side portion of a second sliding block, and the lower side ofthe device body is provided with a through hole. By means of the cutting-polishing dual-purpose device for metal machining, metal can be easily and conveniently cut and polished, energy consumption needed by transfer is reduced, and labor is saved.

Owner:郑伟杰

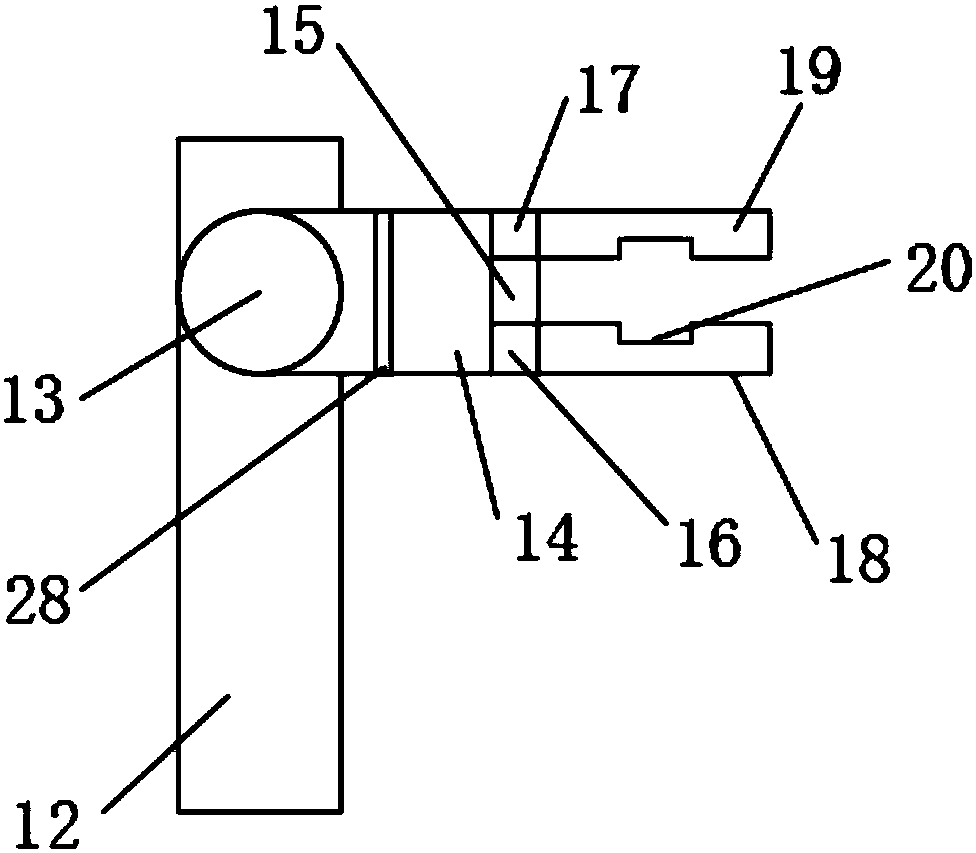

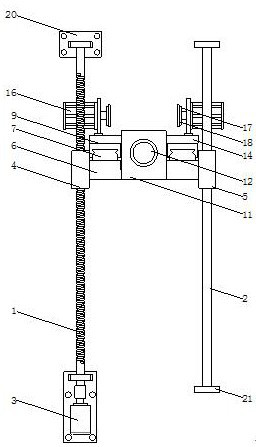

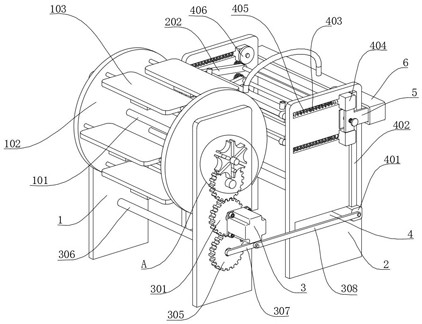

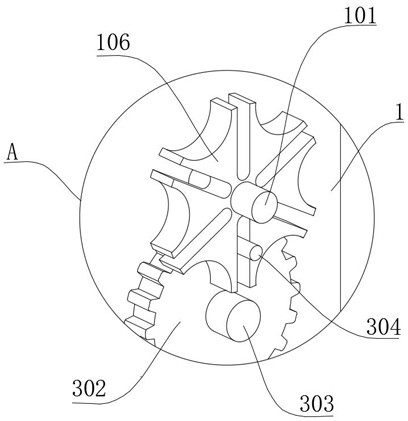

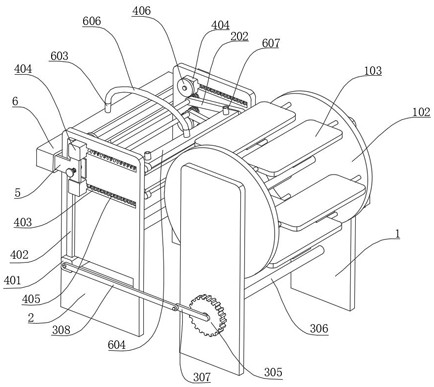

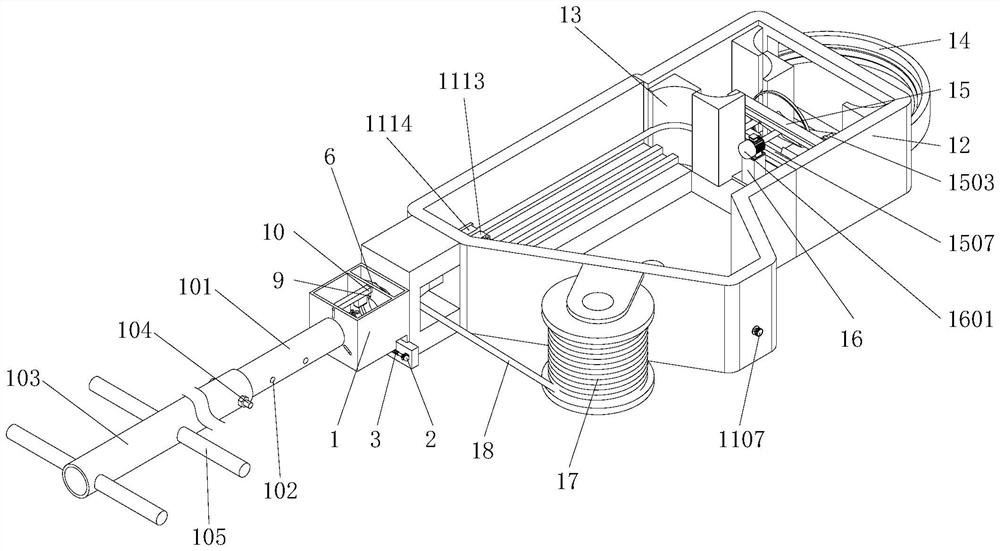

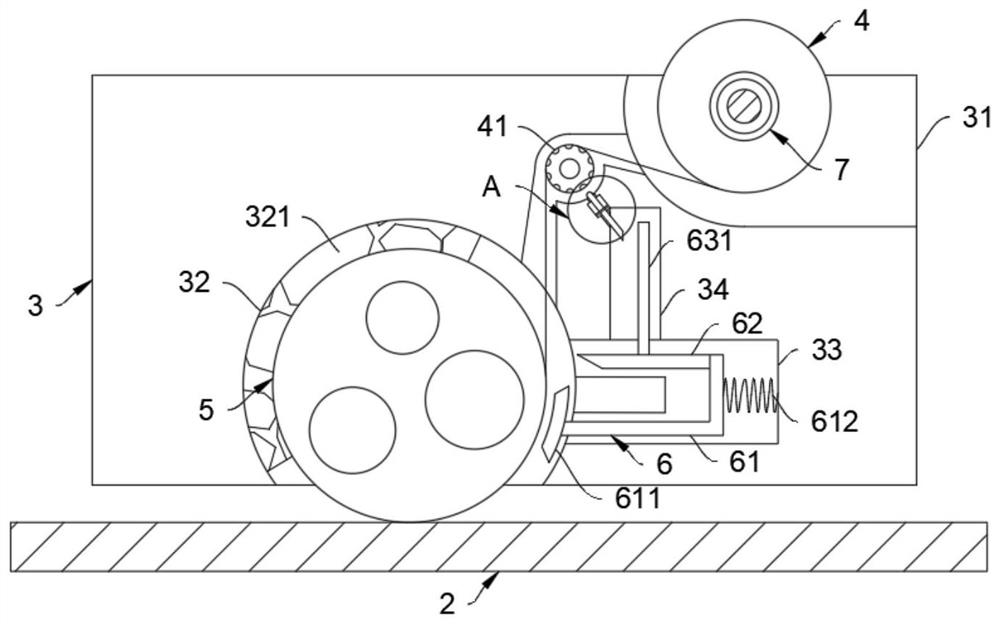

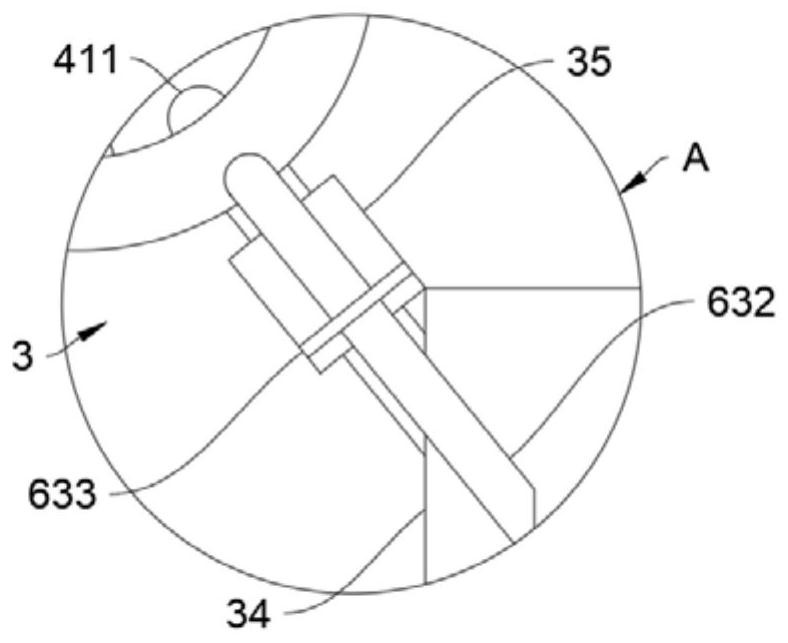

Anti-dislocation cable take-up and pay-off device with cutting function

The invention relates to the related field of power grids, and discloses an anti-dislocation cable take-up and pay-off device with a cutting function. The anti-dislocation cable take-up and pay-off device with the cutting function comprises a main box body, wherein a swing rod cavity is formed in the main box body; a cam cavity is communicated with the right end wall of the swing rod cavity; a cable reel cavity is communicated with the upper end wall of the swing rod cavity; the upper end wall of the cam cavity is provided with an upper bevel gear cavity located on the right side of the cablereel cavity in a communicating mode; a cam shaft is connected between the front end wall and the rear end wall of the cam cavity in a rotating fit mode; cables can be wound and pulled out neatly and evenly in the mode of adjusting the take-up and pay-off positions while take-up and pay-off are conducted, so that the problems that the cables are staggered during winding and are knotted easily during pulling out are solved, and the take-up and pay-off efficiency and the quality are improved; and meanwhile, when the cables are pulled out, the cables can be cut off according to actual requirements, so that the cables are prevented from being cut off manually, the workload of operators is reduced, the working efficiency and the notch quality are improved, and the waste of the cables is reduced.

Owner:SHAOXING SUODON ELECTRONICS TECH CO LTD

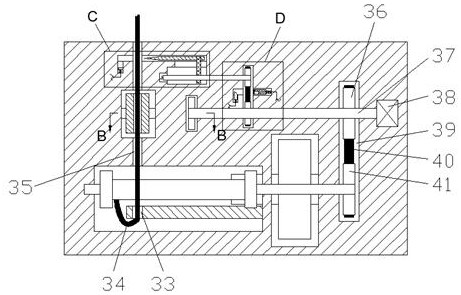

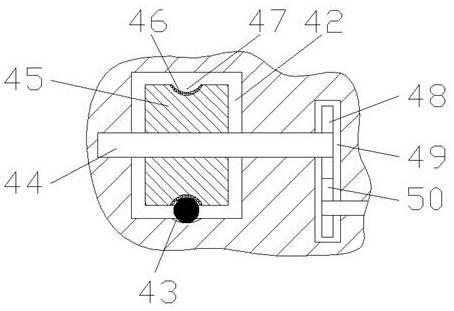

Silica gel sealing gasket production cutting device and using method thereof

PendingCN114131672AReduce labor intensityAvoid manual cuttingMetal working apparatusGear wheelSilica gel

The silica gel sealing gasket production cutting device comprises an operation table, one side of the top of the operation table is connected with an L-shaped plate, a sliding groove is formed in the top of the L-shaped plate, and a cutting mechanism is arranged in the sliding groove. Through continuous rotation of the incomplete gear, under the interaction of the front rack and the rear rack, automatic cutting and resetting of the cutter are achieved, manual cutting is avoided, the cutting efficiency is high, the clamping plate and the racks are integrally formed, installation and positioning of the incomplete gear are completed through the locking nut, and the cutting efficiency is high. The two racks are connected with the upper plate body and the lower plate body through the inner hexagon bolts, parts of the whole mechanism are fully exposed, observation is convenient, replacement is easy, the actual length of the silica gel on the left side is larger than the length of the silica gel when the silica gel is laid flatly through the arrangement of the protrusions, and therefore the length of the silica gel shrunk in the demolding process is compensated to a certain degree, and the service life of the silica gel is prolonged. And the length error after cutting is reduced.

Owner:镇江润众新能源科技有限公司

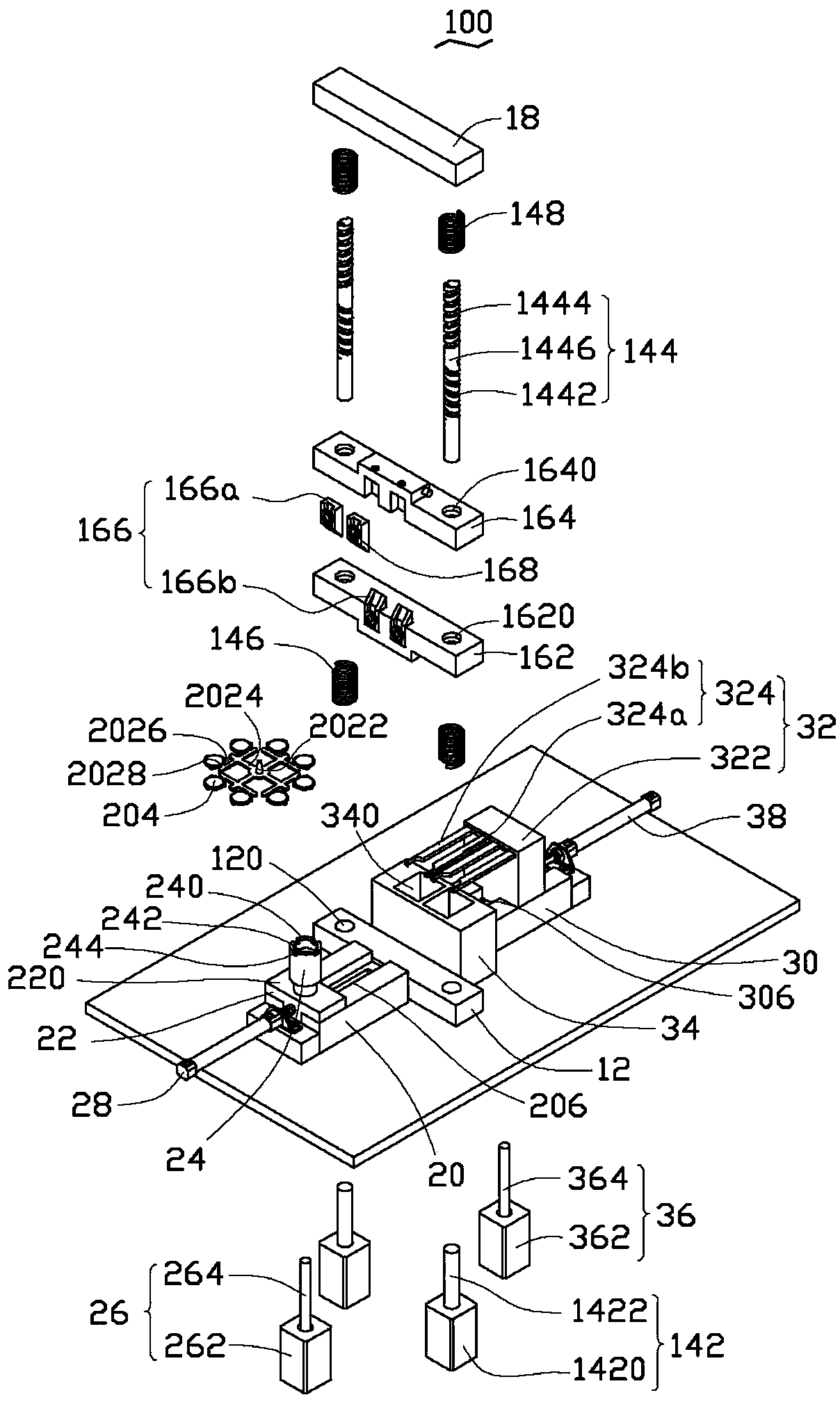

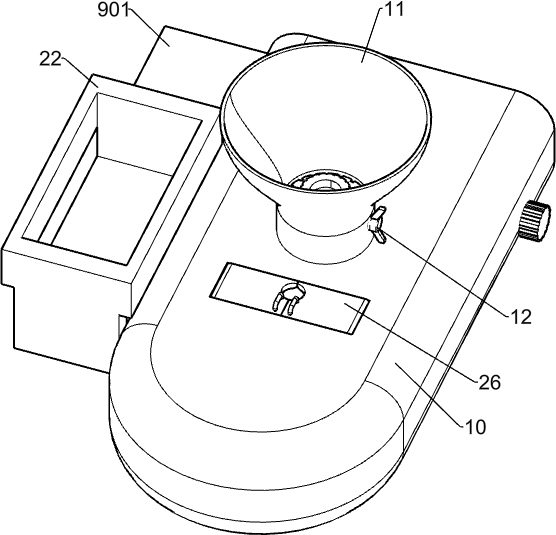

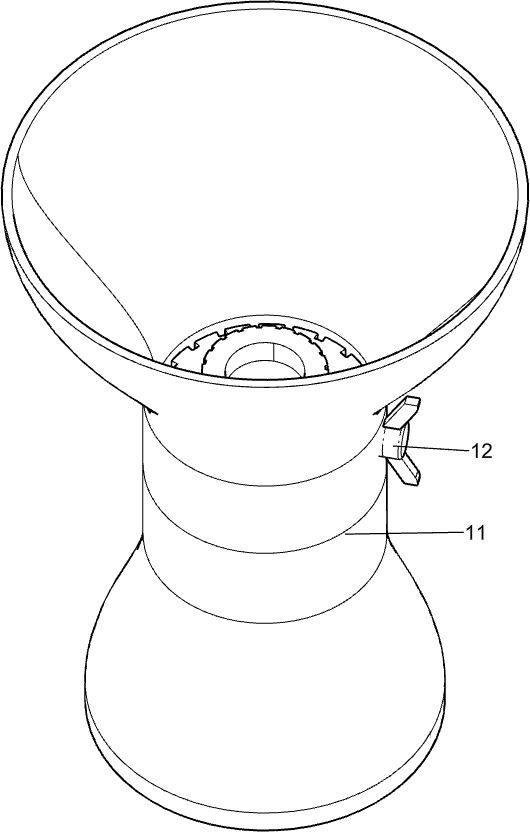

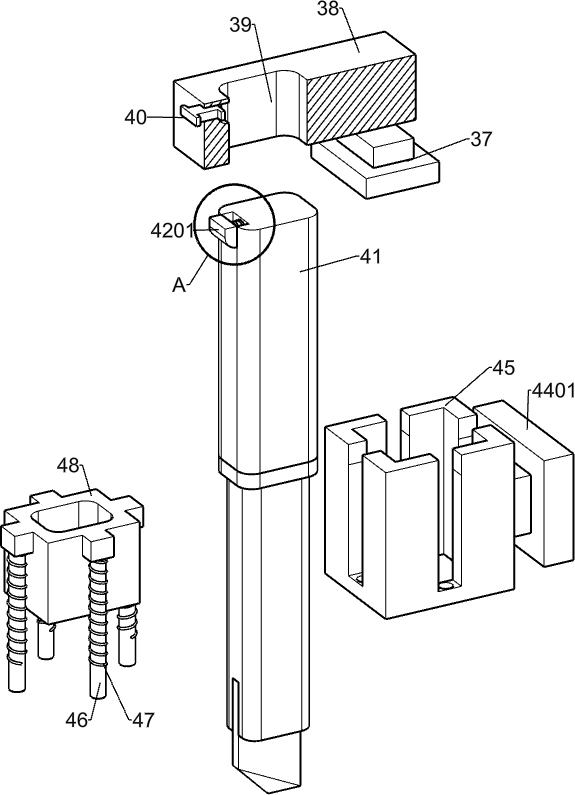

Intra-mould automatic material cutting head device

The invention provides an intra-mould automatic material cutting head device. The device comprises a material cutting component, a transmission component and a power component, wherein the material cutting component comprises a large water gap pumping tip, a bearing and a gear, the large water gap pumping tip is provided with an injection molding channel, the large water gap pumping tip is sleeved with the bearing and the gear, and the gear can drive the large water gap pumping tip to move; the transmission component comprises a body and a straight gear arranged on the body, the straight gear is meshed with the gear, the power component comprises a hydraulic cylinder, the hydraulic cylinder is arranged on a hydraulic cylinder fixed plate, and the power component is in transmission connection with the body through a transmission rod. According to the intra-mould automatic material cutting head device, in the process of producing a plastic part, a generated material head is automatically cut, manual material cutting or manual side material head tearing is avoided, the production efficiency is improved, and burden of production personnel is relieved.

Owner:NINGBO XINGLI AUTOMOBILE MOLD

Injection molding discharging equipment convenient to use

The invention discloses injection molding discharging equipment convenient to use. The equipment comprises a linear lead screw and a linear sliding rod, one end of the linear lead screw is fixedly connected with a linear servo motor through a coupler, the linear lead screw is in threaded connection with a horizontal threaded block, and the linear sliding rod is in sliding connection with a horizontal sliding block; a fixing base is fixedly installed between the opposite sides of the horizontal threaded block and the horizontal sliding block, and a linear sliding rail and a first bearing seat are fixedly installed on the front face of the fixing base. The linear servo motor is used for driving the fixing base to move in the horizontal direction, a vertical servo motor is used for driving abottom plate to move in the vertical direction, an air cylinder push rod pushes clamping plates to complete clamping and taking of an injection molding part, therefore, the injection molding part is driven to leave an injection mold, discharging work of the injection molding part is achieved, the equipment is suitable for a production line, manual discharging is avoided, potential safety hazards are reduced, the labor intensity of workers is relieved, and the production efficiency is improved.

Owner:宝应县嘉永电器有限公司

Air conditioner air pipe tail end hose production device

PendingCN114211533AImprove practicalityImprove cutting productivityMetal working apparatusDrive wheelElectric machinery

The invention belongs to the technical field of air conditioner hose machining, and relates to an air conditioner air pipe tail end hose production device which comprises a workbench, a first belt and a second belt, a pair of supporting plates are installed on the workbench, three pairs of rotating columns are rotationally connected between the two supporting plates, extrusion wheels are installed on the rotating columns, and driven wheels are installed on the rotating columns. A first driving motor is installed on the workbench, a cutting knife is installed on the bottom face of the knife rest, a limiting plate is installed on the workbench and located below the cutting knife, a fixing rod is fixedly connected to the sliding block, a fixing plate is installed at the end, away from the bottom block, of the spring, and an extrusion plate is installed on the fixing plate. A material leakage groove is formed in the workbench and located between the two sliding blocks, a material storage box is installed on the bottom face of the workbench and located below the material leakage groove, and a controller is installed on one side of the workbench. Materials are effectively fixed, and the situation that the cutting face is uneven during cutting, and production and machining of the materials are affected is prevented.

Owner:江苏盈达机电科技有限公司

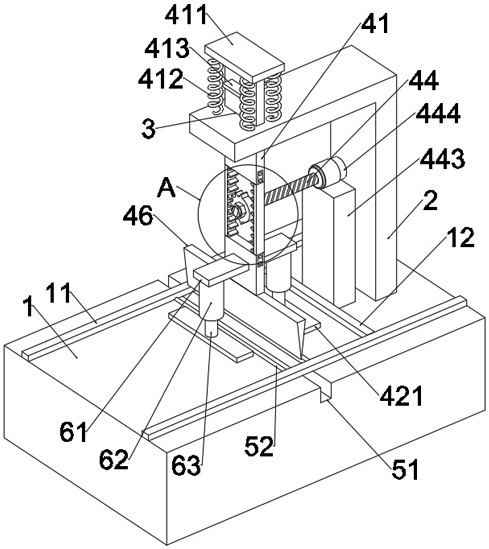

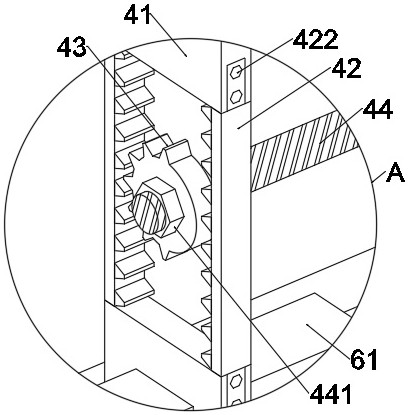

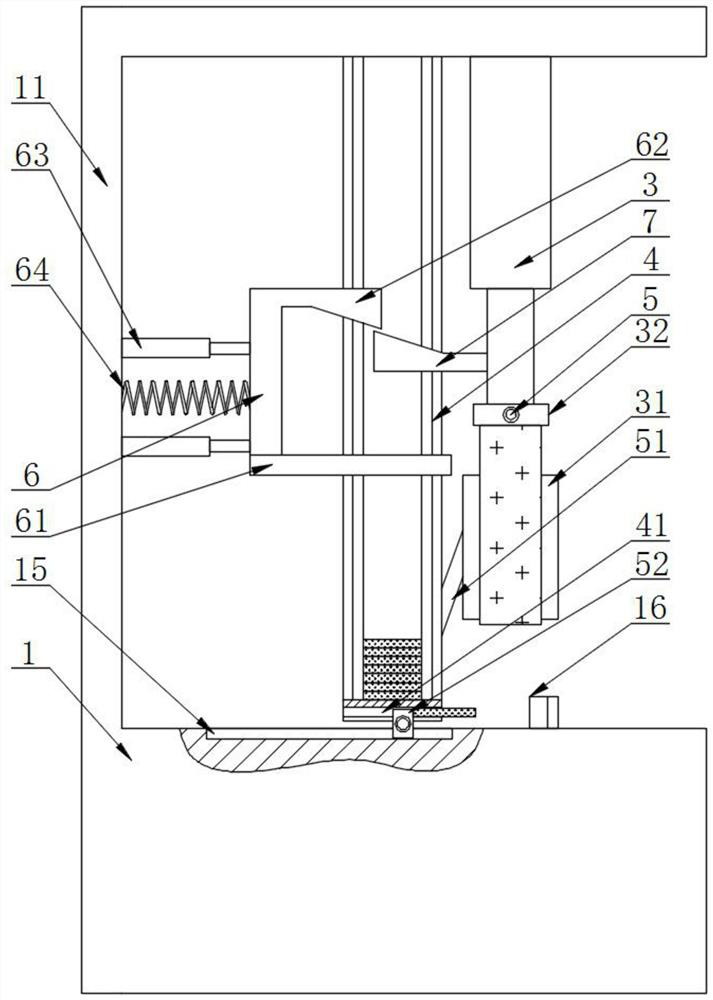

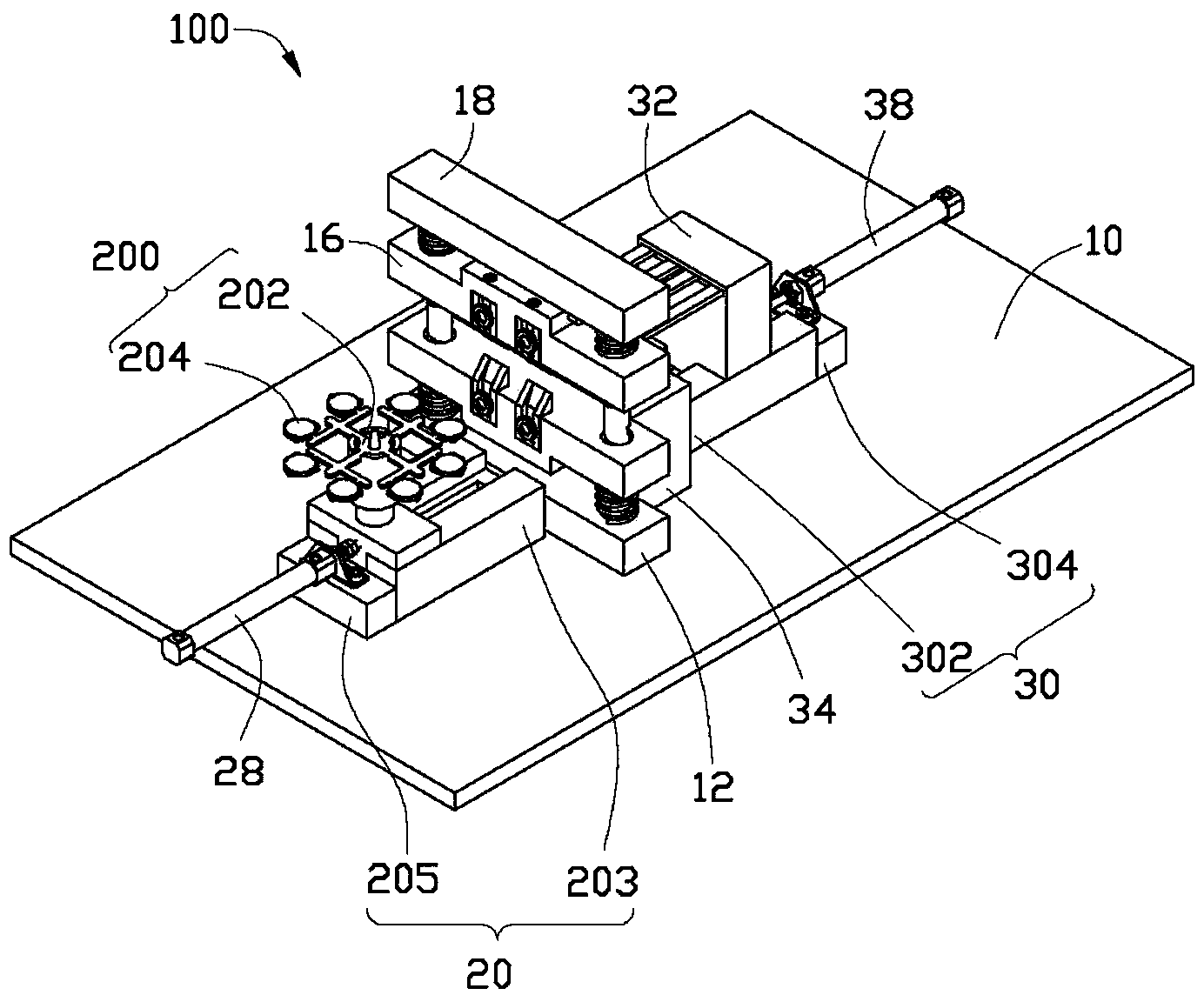

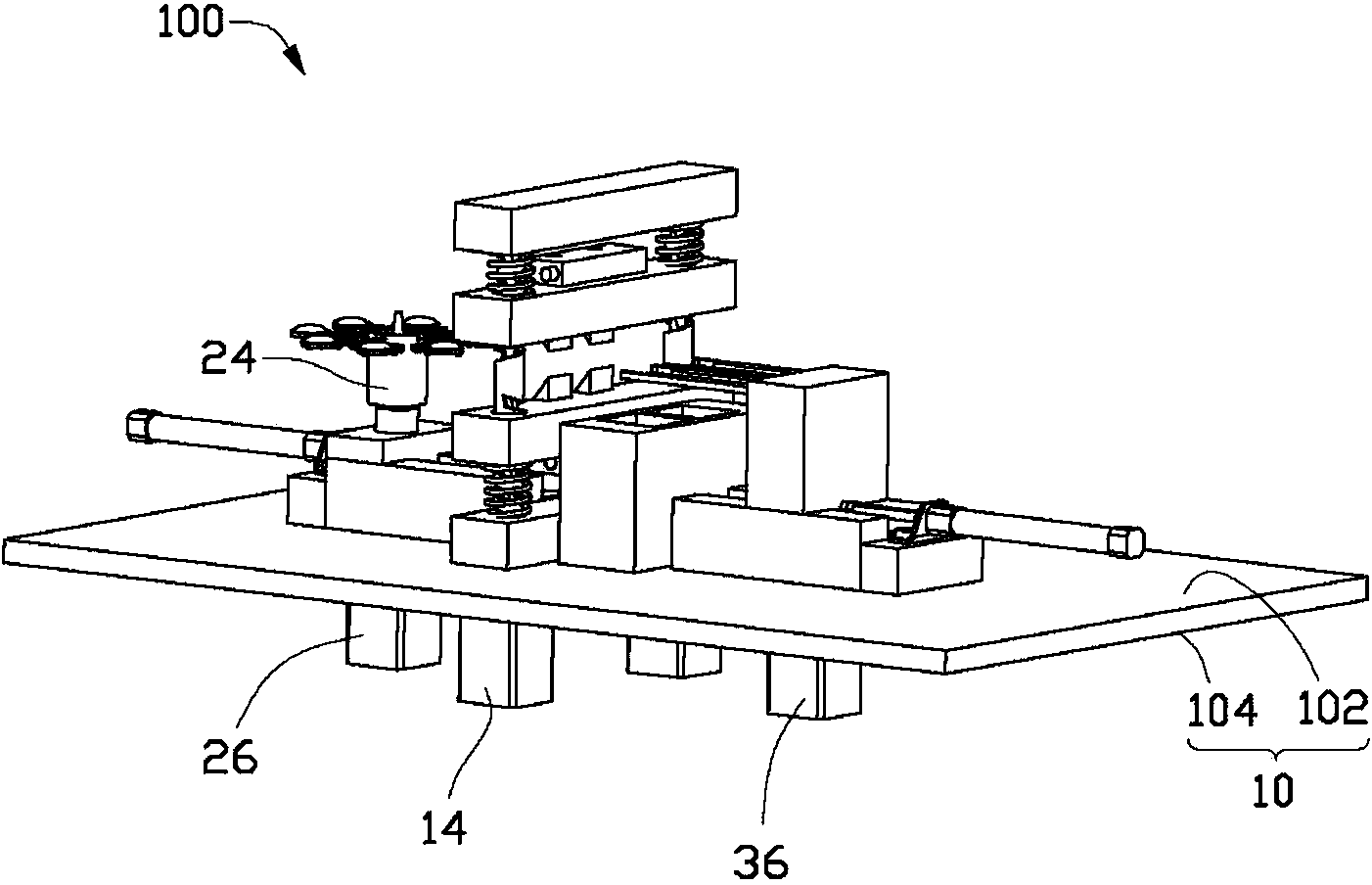

Circular ring workpiece machining equipment

InactiveCN112935045AAvoid manual cuttingImprove processing efficiencyMetal-working feeding devicesPositioning devicesStampingEngineering

The invention discloses circular ring workpiece machining equipment, and particularly relates to the field of circular ring machining. The circular ring workpiece machining equipment comprises a workbench, a top plate is fixedly mounted on one side of the top of the workbench, a hydraulic telescopic rod is fixedly mounted on the lower surface of the top of the top plate, and a stamping cylinder is fixedly mounted at the bottom end of the hydraulic telescopic rod. A stamping groove is formed in the top of the workbench, arc-shaped blocks are arranged on the two sides of the interior of the stamping groove, and a circular groove is formed in the groove side of the stamping groove. A matched circular block is integrally formed on the side, close to the stamping groove, of each arc-shaped block, and the matched circular blocks are movably arranged in the circular groove. According to the circular ring workpiece machining equipment, a wedge block is arranged to be subjected to upward pressure of a matched wedge block, a pushing plate is driven to move rightwards, a circular ring workpiece arranged on the stamping cylinder in a sleeving mode is pushed out, and when the stamping cylinder moves downwards, the function that a flat-plate workpiece is stamped into the circular ring workpiece is achieved. And when the stamping cylinder moves upwards, the function that the device can automatically push out the stamped and formed circular ring workpiece is achieved.

Owner:蔡德银

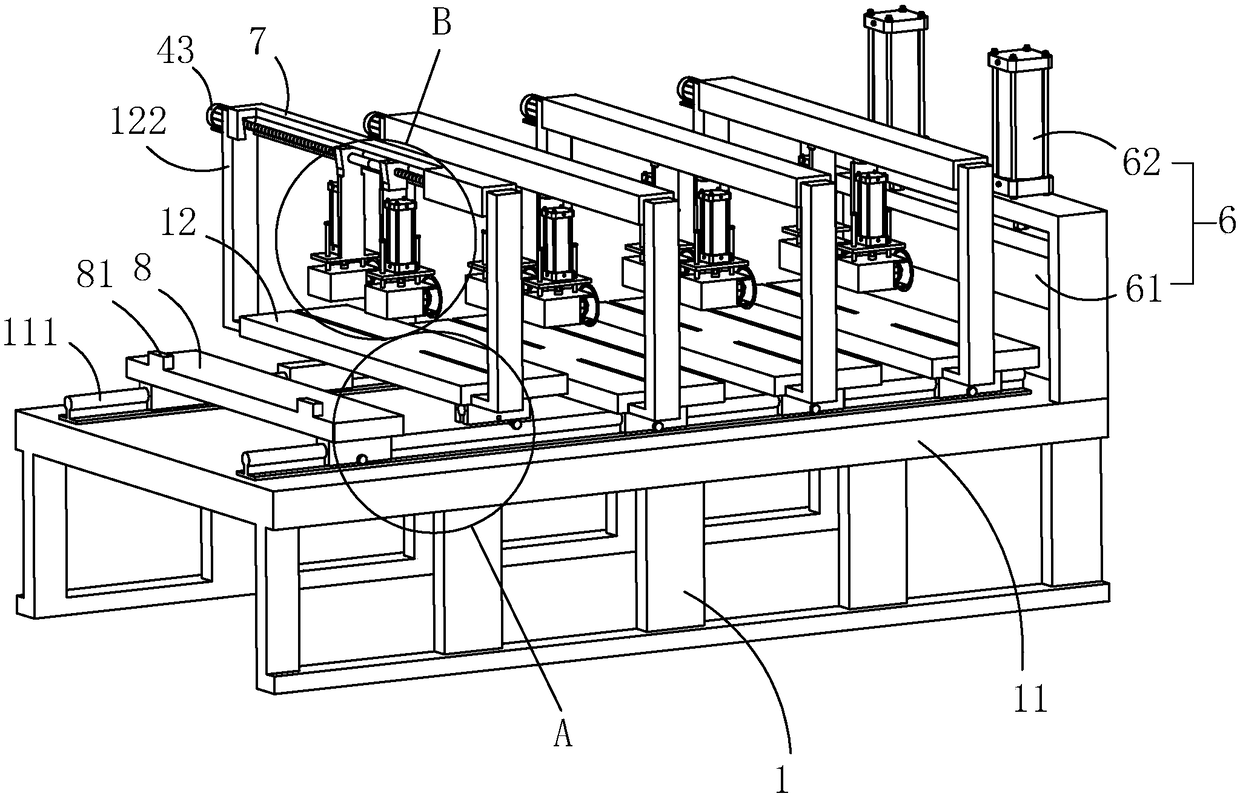

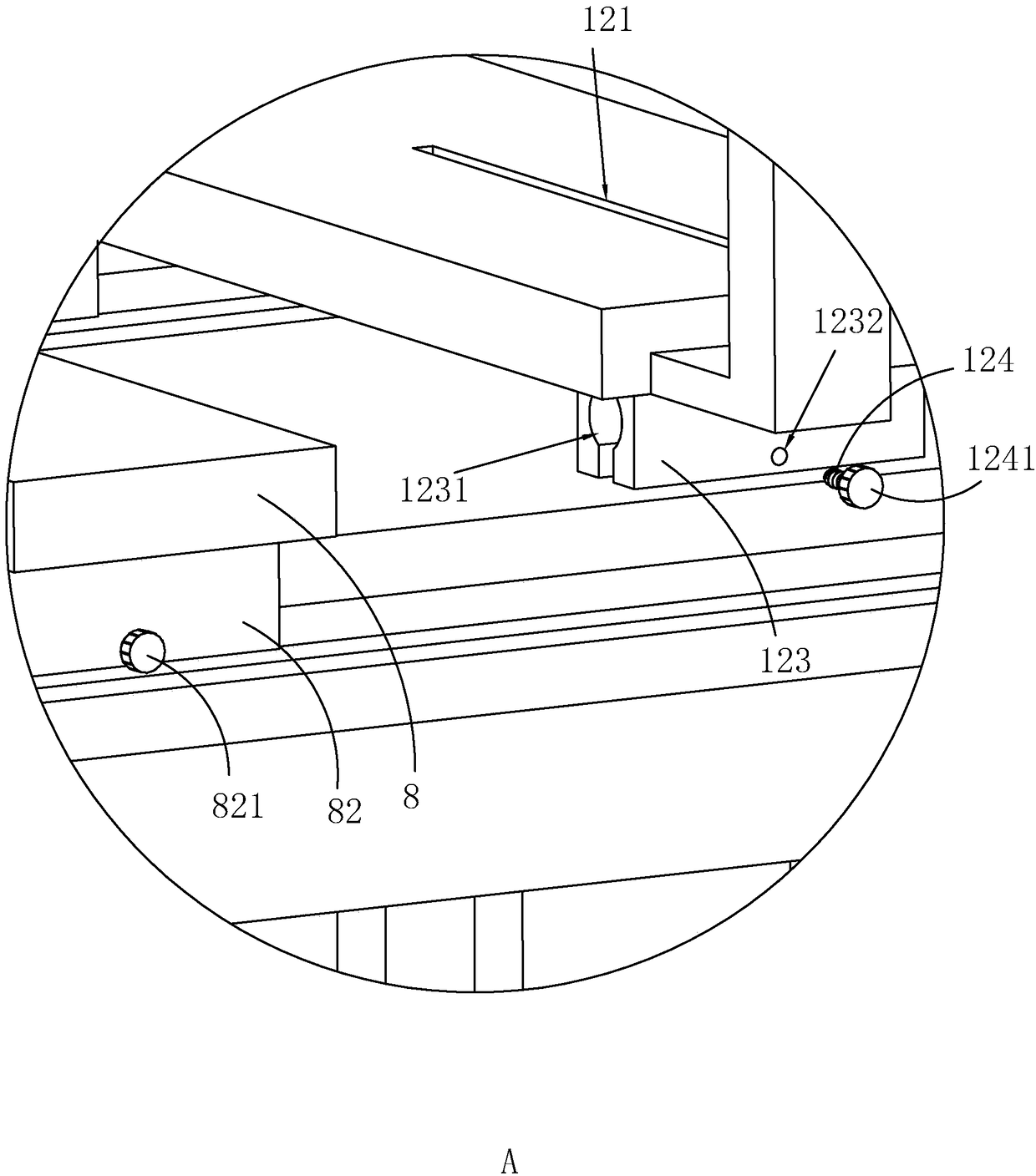

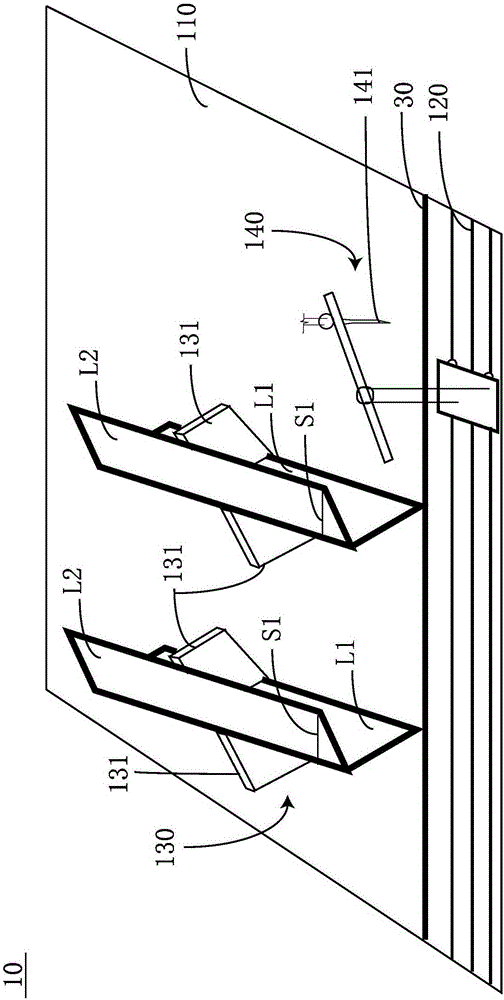

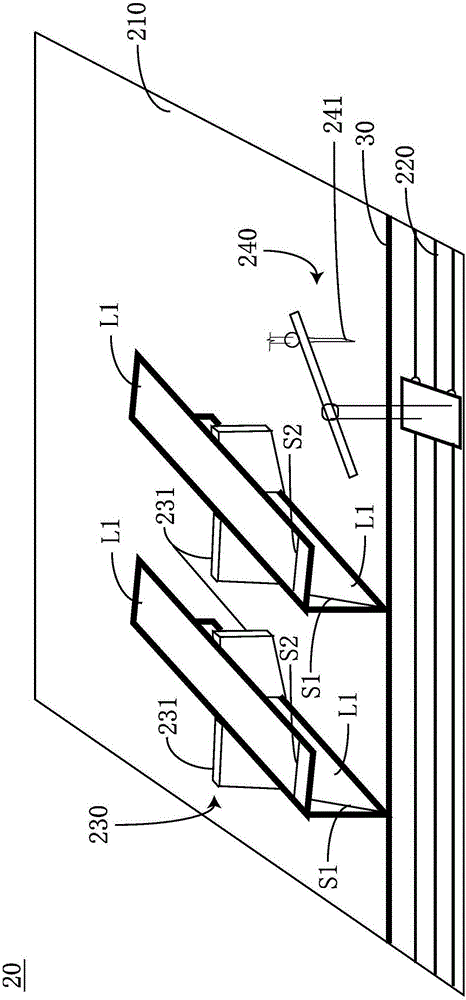

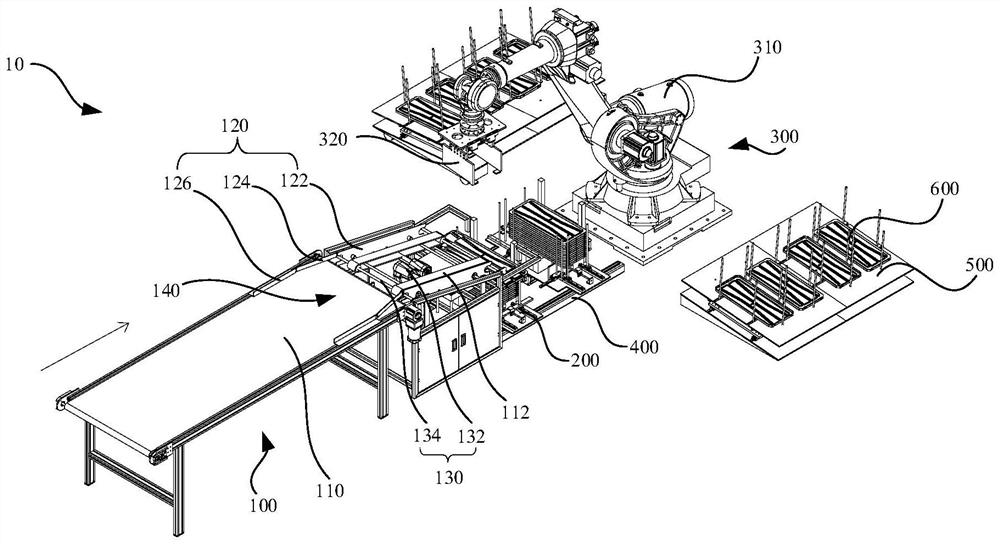

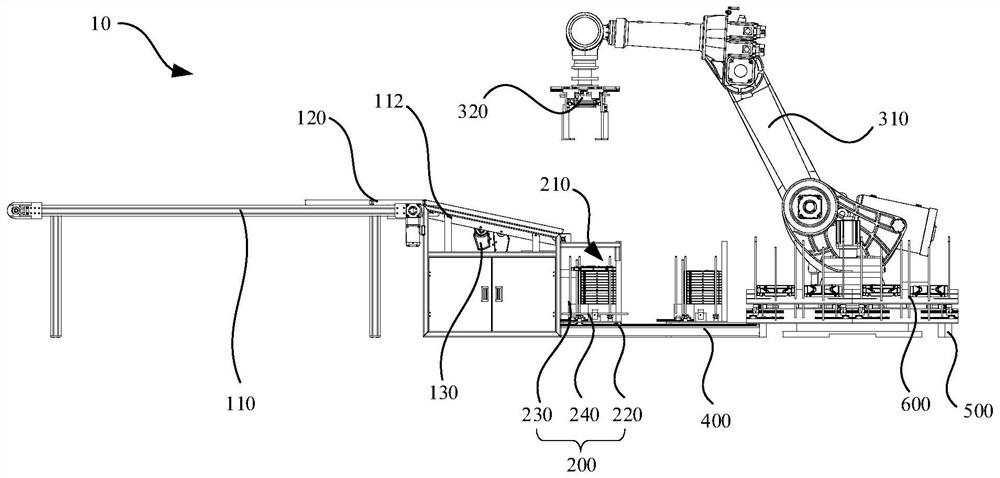

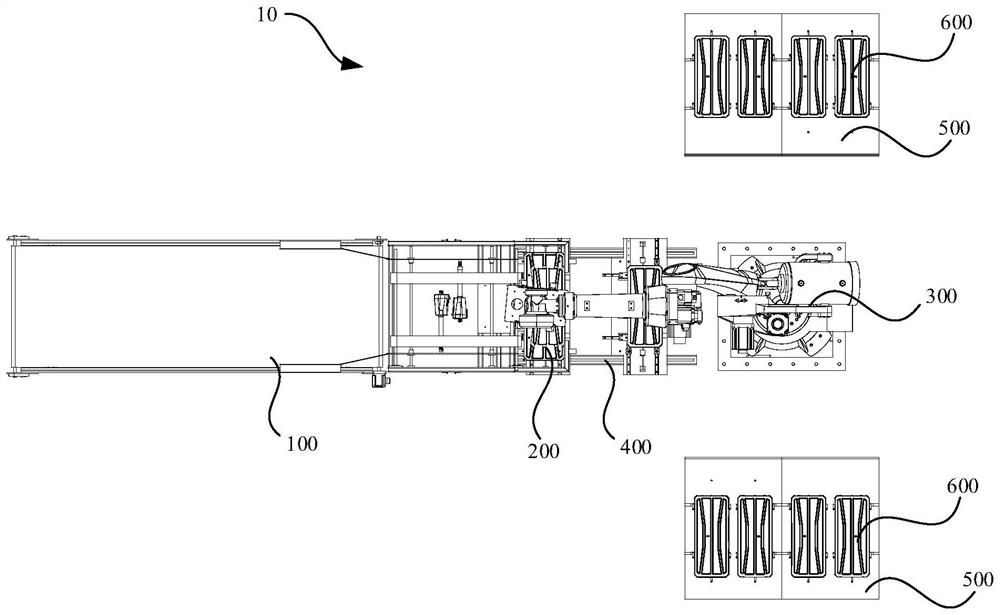

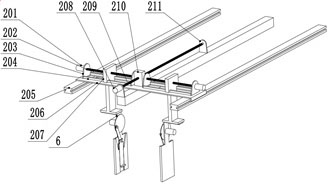

Stacking equipment and stacking transportation method

PendingCN114104745AEasy to transportAvoid manual cuttingStacking articlesConveyor partsEngineeringTransfer line

The stacking equipment comprises a conveying device, a stacking container and a conveying device, the conveying device comprises a conveying line, a limiting piece and a variable-pitch assembly, a conveying channel is defined by the limiting piece and the conveying line, the limiting piece is used for limiting the position of a workpiece, and the variable-pitch assembly is connected with the limiting piece; the variable-pitch assembly drives the limiting piece to move so as to adjust the width of the conveying channel. The stacking container is provided with a storage space, and the stacking container is arranged at the output end of the conveying line, so that the workpieces can be stacked and stored in the storage space; the conveying device is used for transferring all the workpieces located in the storage space. According to the stacking equipment, the situation that the workpieces need to be continuously and manually discharged is avoided, the workpieces are automatically stacked after being discharged through the conveying device, the stacking equipment is matched with the conveying device to transfer the stacked workpieces, the working efficiency is improved, and the cost is reduced. According to the stacking and transporting method, the working process is simple and convenient, the workpiece discharging and transferring process is rapid, and the stacking precision is high.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Automatic heat sealing packaging machine used for bagged products

ActiveCN113387013AEasy to operateRealize automatic feeding processWrapper twisting/gatheringThermodynamicsHeat sealer

The invention discloses an automatic heat sealing packaging machine used for bagged products. The automatic heat sealing packaging machine used for the bagged products comprises first machine frames and second machine frames, a feeding mechanism is arranged between the first machine frames, a heat sealing mechanism is arranged between the second machine frames, the heat sealing mechanism comprises two fixed rods fixedly connected between the second machine frames, each fixed rod is rotationally connected with two rotating plates in a penetrating mode through bearings, torsion springs are fixedly connected to positions between the rotating plates and the second machine frames, the lower surfaces of the two corresponding rotating plates are jointly and fixedly connected with a heat sealing plate, and four function holes are formed in the second machine frames. The automatic heat sealing packaging machine used for the bagged products has the advantages that automatic continuous heat sealing packaging can be achieved, compared with the prior art, the packaging efficiency is greatly improved, meanwhile, the labor intensity is reduced, the automatic heat sealing packaging machine used for the bagged products is suitable for packaging of packaging bags of different materials and thicknesses, practicability is higher, meanwhile, cooling can be continuously carried out on the heat sealing plate, and the packaging bags are effectively prevented from being burnt through due to too high temperature after long-time use.

Owner:南通市通州区茂润包装制品有限公司

A steel plate cutting device for interior design and decoration

The invention discloses a steel plate cutting device for indoor design and decoration, comprising a steel plate cutting machine, the steel plate cutting machine includes a shell one, the lower surface of the shell is fixedly connected with a support base, the back side of the support base is fixedly connected with a shell two, and the shell one is equipped with The fixed base 1 and the fixed base 2, the lower surfaces of the fixed base 1 and the fixed base 2 are fixedly connected with the inner lower surface of the shell 1, the fixed rod 1 is fixedly connected to the right side of the fixed base 2, and the steel plate cutting machine is equipped with a cutting device. The cutting device includes a motor, the motor is provided with a motor rotation shaft, the back side of the motor rotation shaft is fixedly connected with a transmission shaft 1, the outer side of the transmission shaft 1 is fixedly connected with a bevel gear 1, and the outer side of the transmission shaft 1 is connected with the fixed base 1 front and rear sides Through the rotational connection, a circular fixed block 1 is fixedly connected to the back side of the transmission shaft, and the outer side of the circular fixed block 1 is connected to the outer shell through rotational connection.

Owner:深圳心品建设工程有限公司

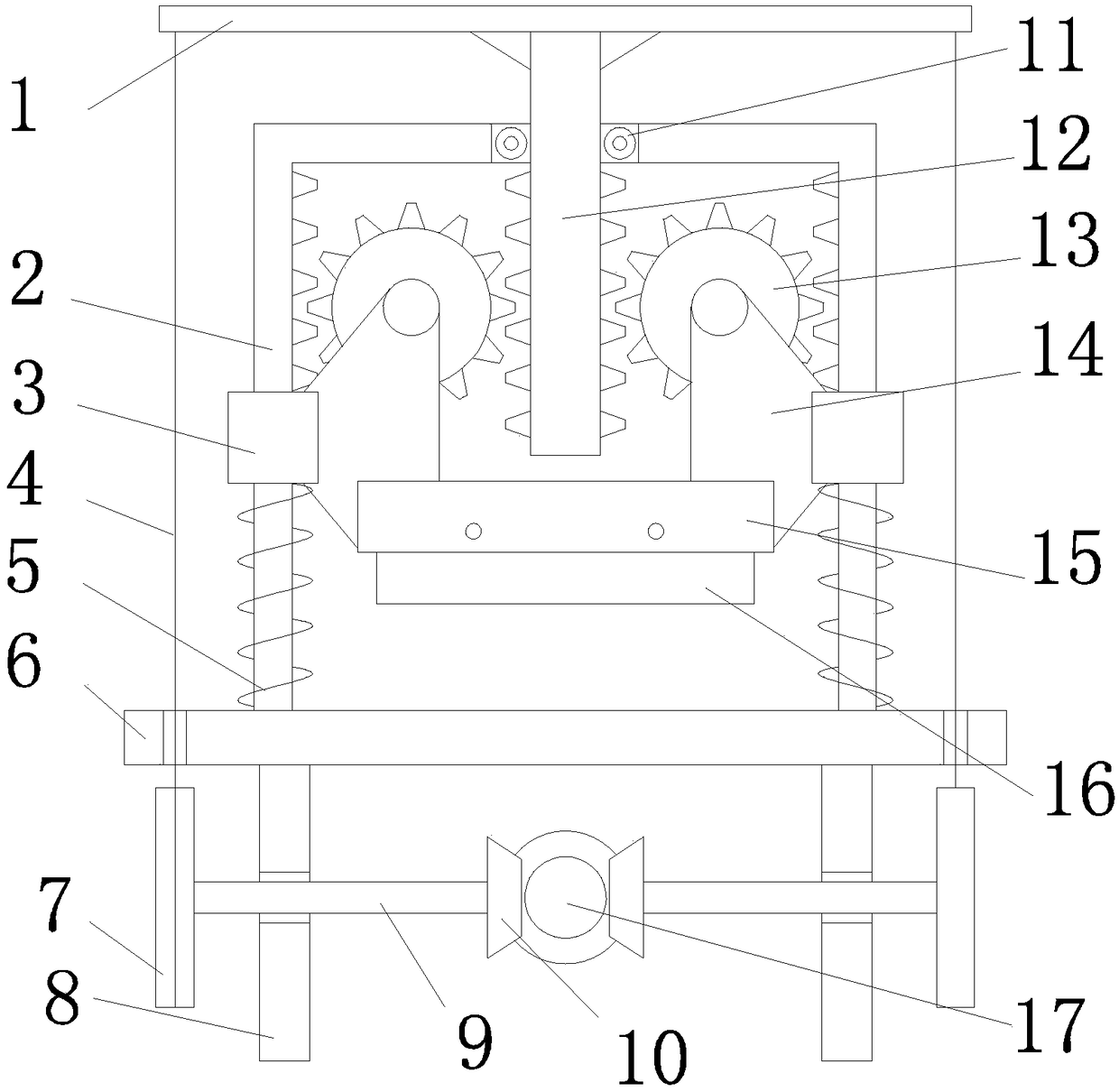

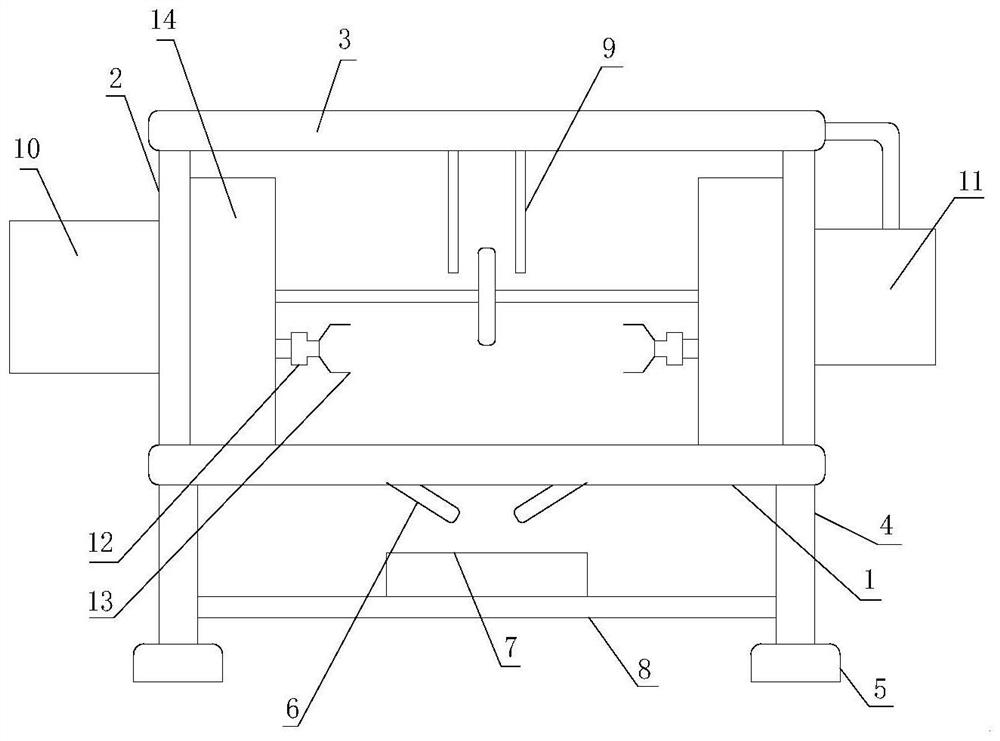

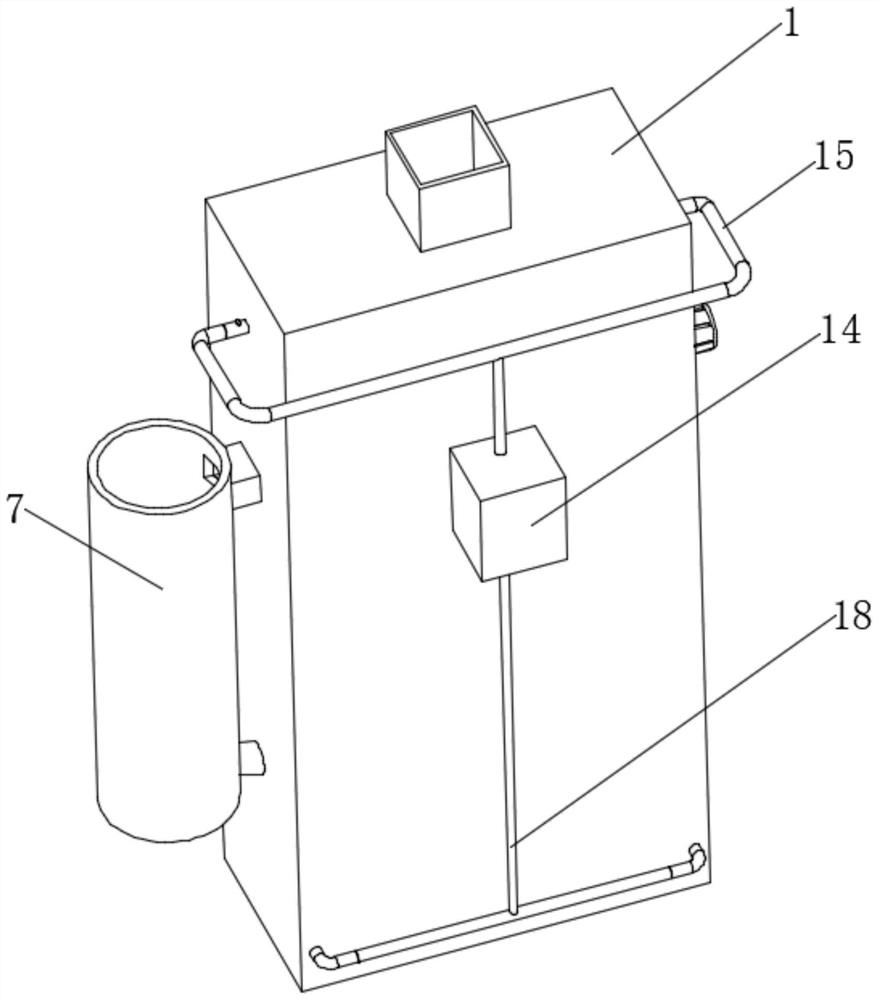

Biological organic fertilizer packaging machine

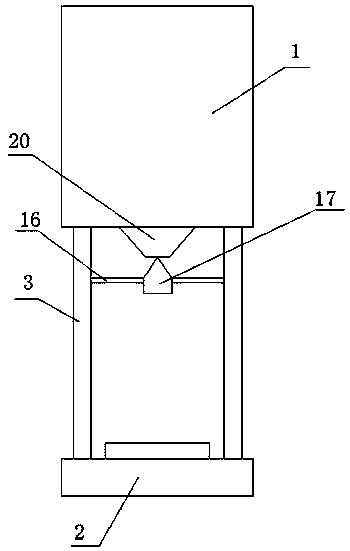

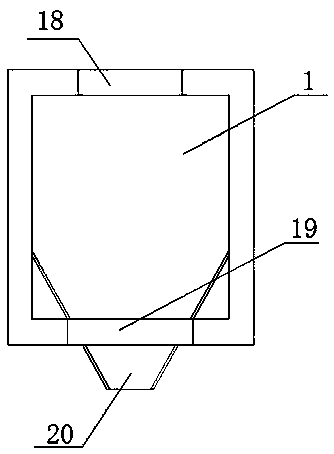

ActiveCN110745260AMove up and down normallyAvoid misalignmentLarge containersSolid materialAgricultural scienceAgricultural engineering

The invention belongs to the field of packaging, and particularly relates to a biological organic fertilizer packaging machine. Aiming at the problems that automatic feeding cutting-off cannot be generally achieved by an existing packing machine, feeding cutting-off needs to be completed manually after completion of feeding, the working efficiency is affected and the application demand cannot be satisfied, the following scheme is provided: the biological organic fertilizer packaging machine comprises a packaging machine body, wherein the packaging machine body is of a hollow structure, a baseis arranged below the packaging machine body, a connection support is arranged between the base and the packaging machine body, one end of the connection support is arranged on the base, and the otherend of the connection support is arranged on the packaging machine body. The biological organic fertilizer packaging machine is reasonable in structure, and automatic feeding cutting-off can be achieved, so that manual cutting-off is prevented, and the working efficiency is improved; and meanwhile, disengagement of a first rack from a gear is prevented by a positioning mechanism, so that the working stability of equipment is ensured, the working efficiency is improved, and the application demand is satisfied.

Owner:YANTAI JINHAI PHARMA

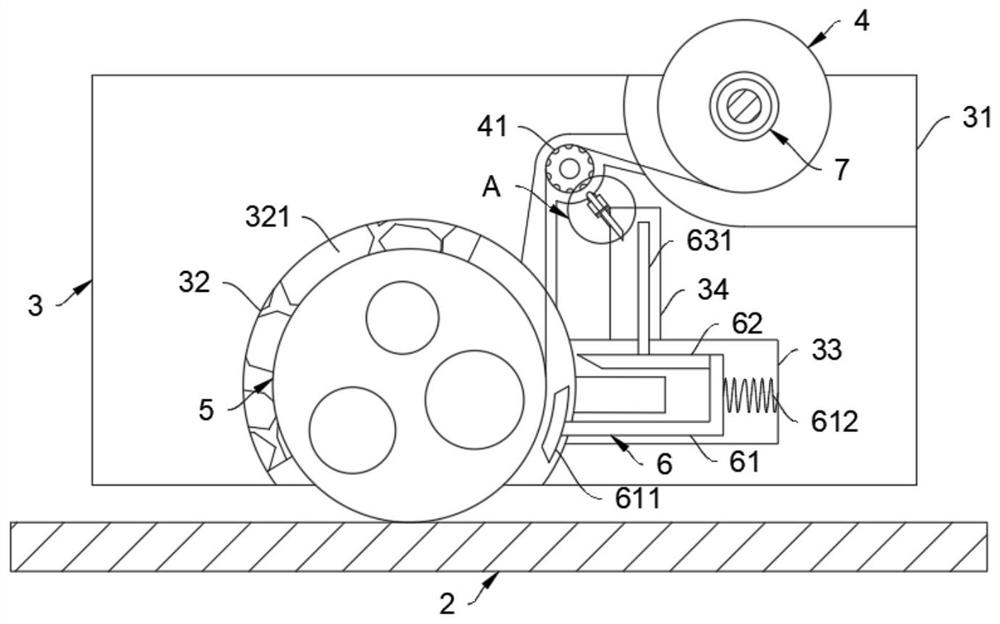

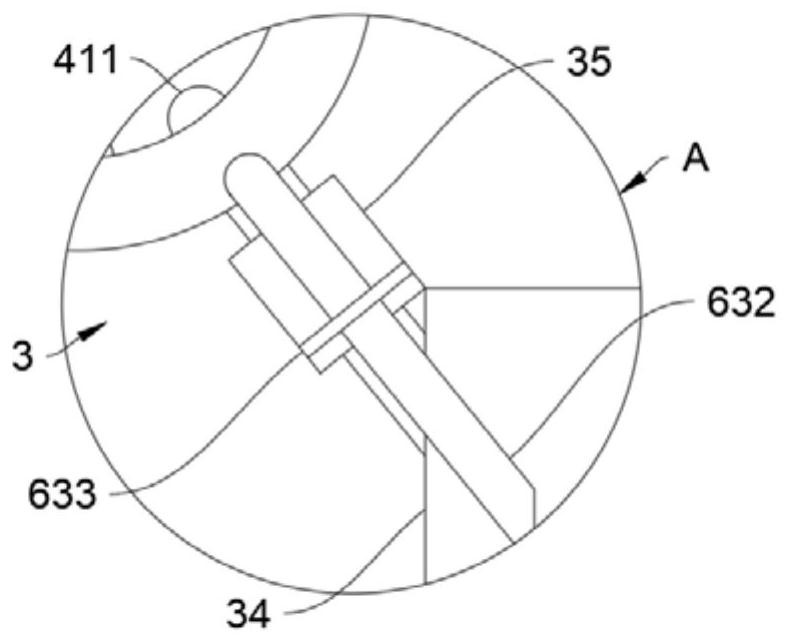

Automobile wire harness acetate cloth adhesive tape automatic winding device

ActiveCN111816376AReduce processing costsReduce stepsManufacturing wire harnessesAdhesive beltMachining process

The invention belongs to the field of automobile wire harness manufacturing, and especially relates to an automobile wire harness acetate cloth tape automatic winding device. The device comprises a workbench, the workbench is rotationally connected with a conveying belt, the workbench is obliquely provided with a winding plate, the winding plate is detachably connected with an adhesive tape, the adhesive tape is connected with a wire harness in a matched mode, the wire harness is connected with the conveying belt in a rolling mode, and the winding plate is connected with the wire harness in amatched mode through a shearing mechanism. According to the automobile wire harness acetate cloth adhesive tape automatic winding device, a worker is effectively prevented from operating in a manual winding mode in the wire harness machining process, the wire harness winding work efficiency is improved, the automobile wire harness winding machining cost is reduced, and the automobile wire harnessacetate cloth adhesive tape automatic winding device is suitable for being popularized in a wide range.

Owner:山东望声电子科技有限公司

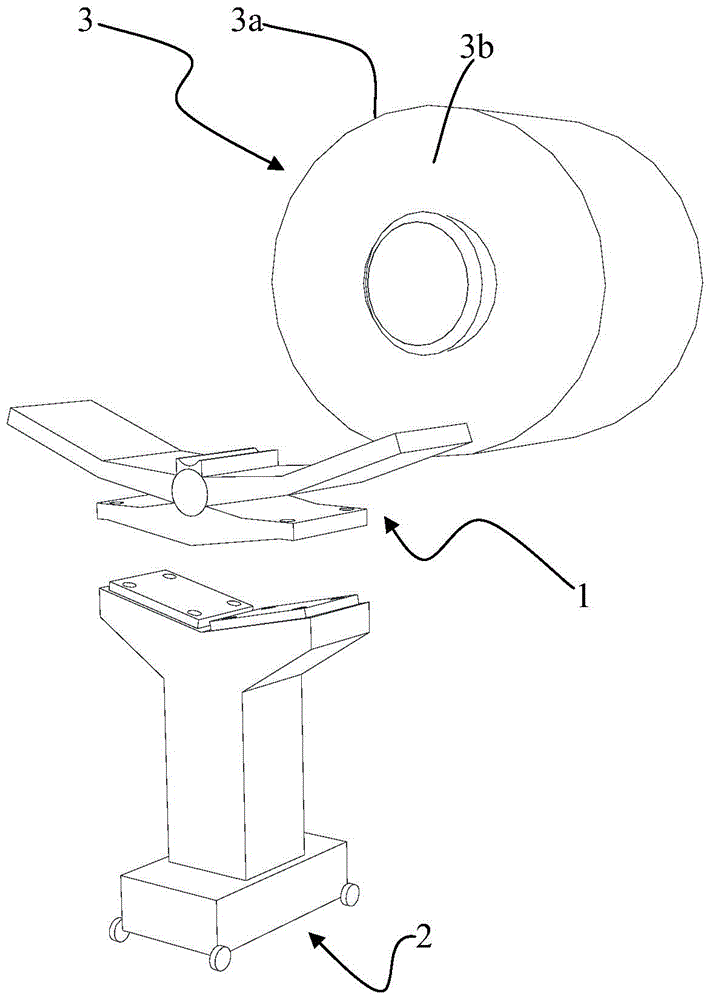

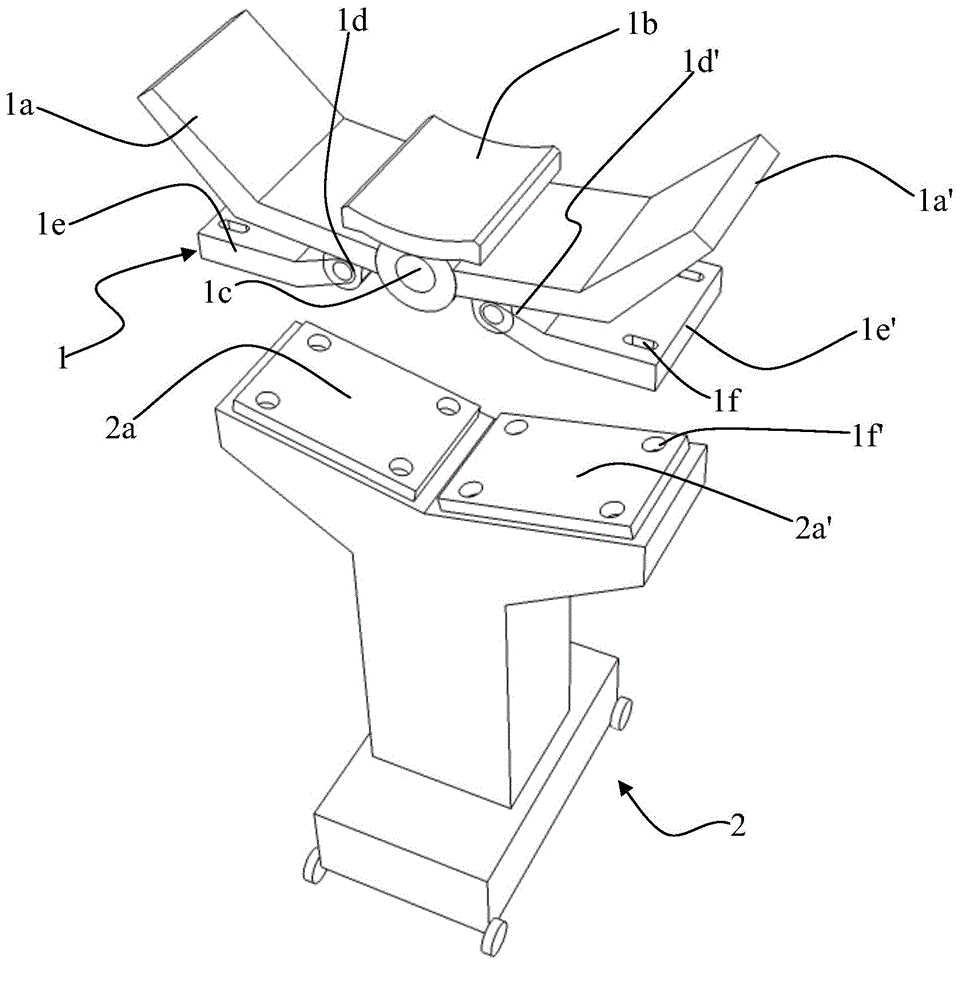

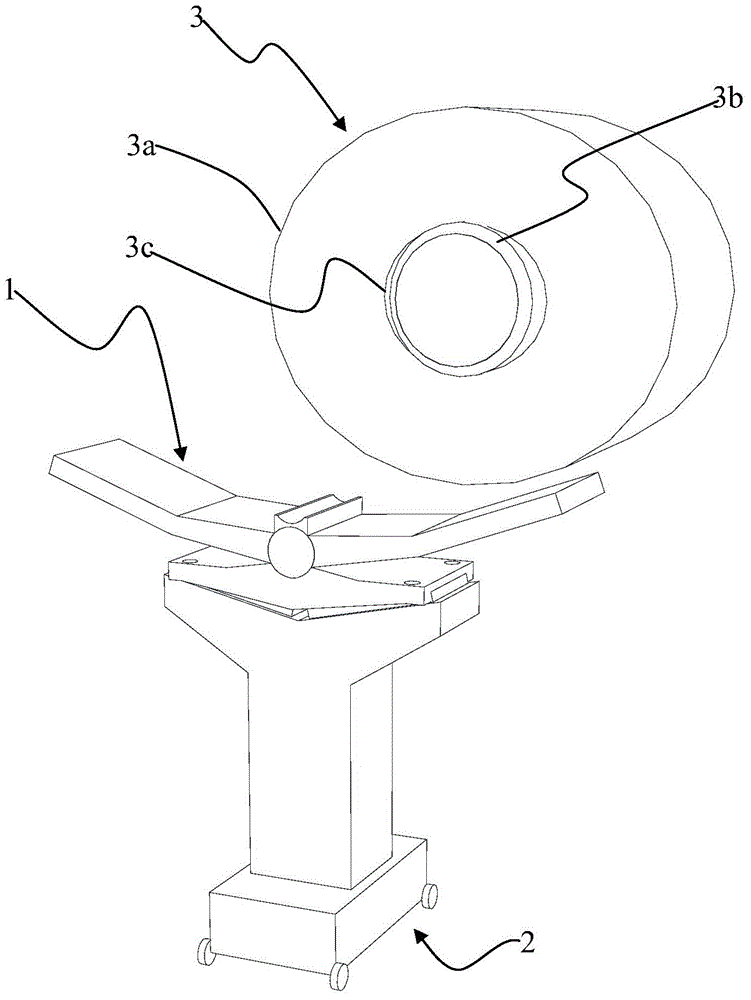

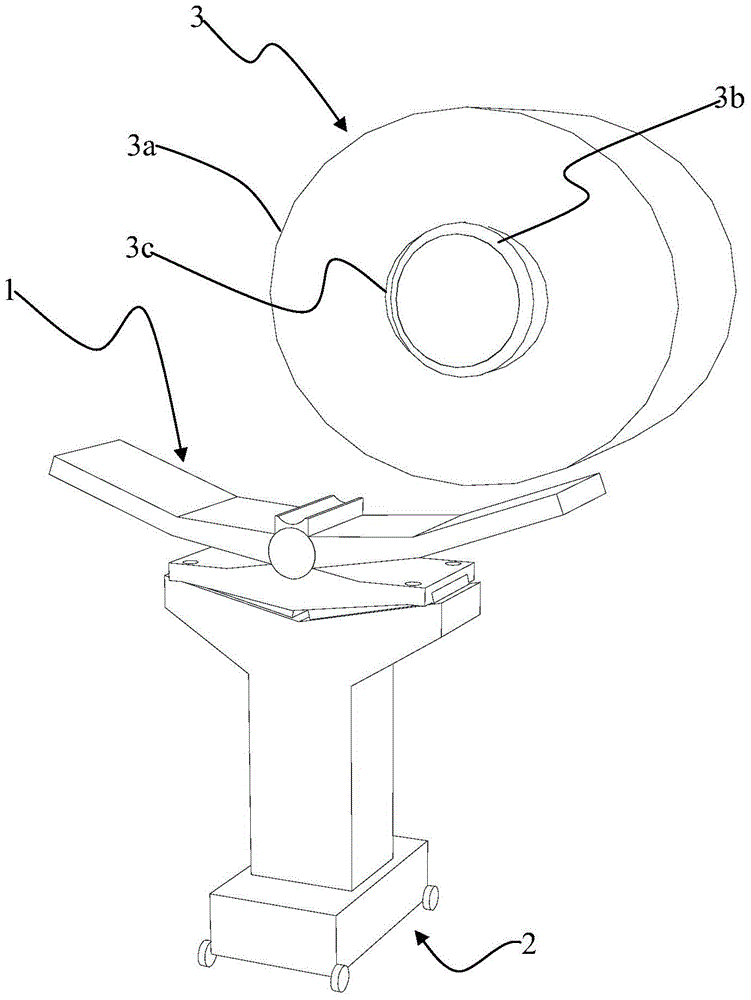

A Quick Handling Method for Coiler Unwinding

The present invention relates to a rapid treatment method for coiler unwinding. The rapid treatment method comprises: providing a steel coil support frame with a movable hinge joint and an adjustment mechanism, and a steel coil trolley; lifting the steel coil support frame onto the steel coil trolley, and fixing; driving the steel coil trolley to the position below the unwinding steel coil, and lifting so as to bear against the steel coil and support the steel coil through the left support arm and the right support arm of the support frame; contracting the drum, and making the outlet pressing roller arranged above the drum press the outer ring of the steel coil, such that a gap is formed between the drum outer wall and the steel coil inner ring of the unwinding coil; adopting a penetrating belt rod to penetrate from the gap, and making the bundle belt penetrate into the inner ring gap; inching the drum to rotate to make the steel coil rotate 180 DEG, binding the bundle belt on the position opposite to the inner ring with the bundle belt, and tightening; making the drum maintain the contracting state, lifting the outlet pressing roller, and making the steel coil trolley descend, such that the loose part is tightened with the bundle belt; and inching steel coil trolley to move toward the outer side, and lifting away the steel coil. With the rapid treatment method of the present invention, the steel coil unwinding can be rapidly and conveniently treated.

Owner:BAOSHAN IRON & STEEL CO LTD

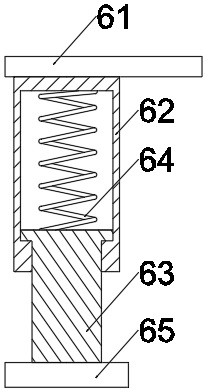

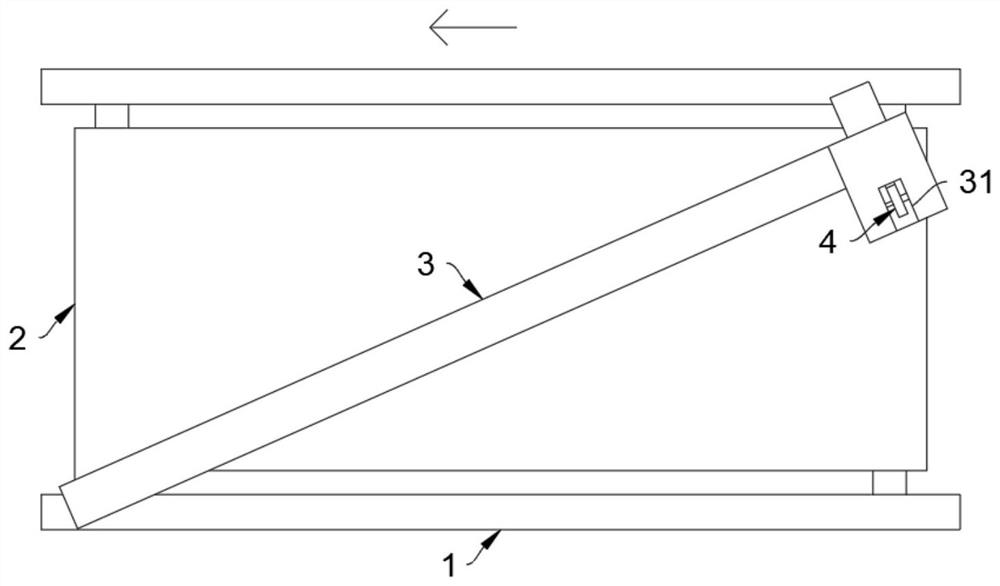

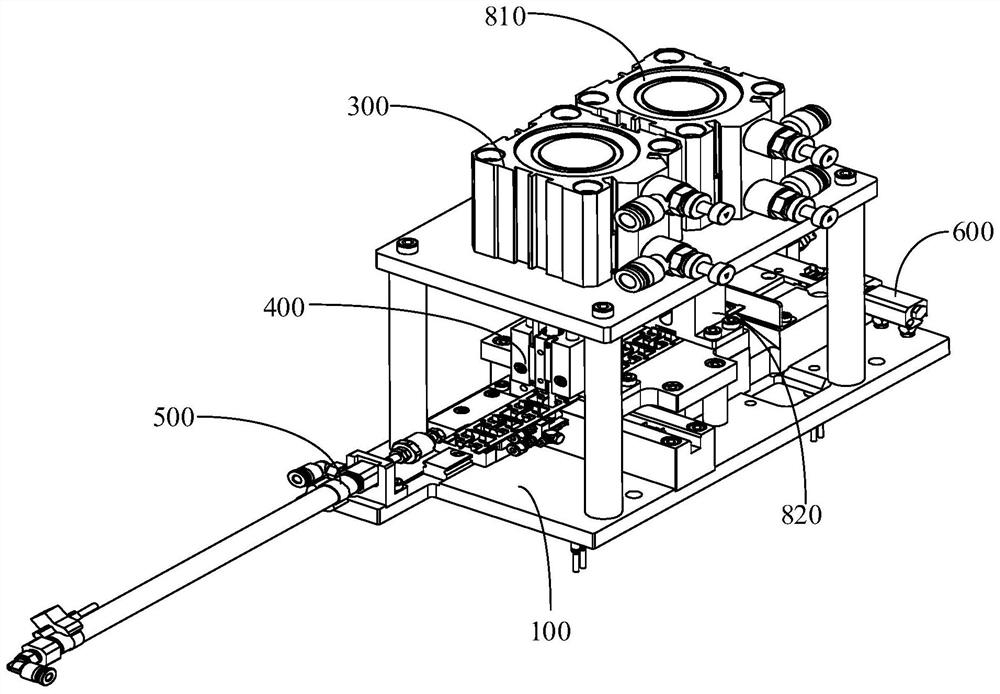

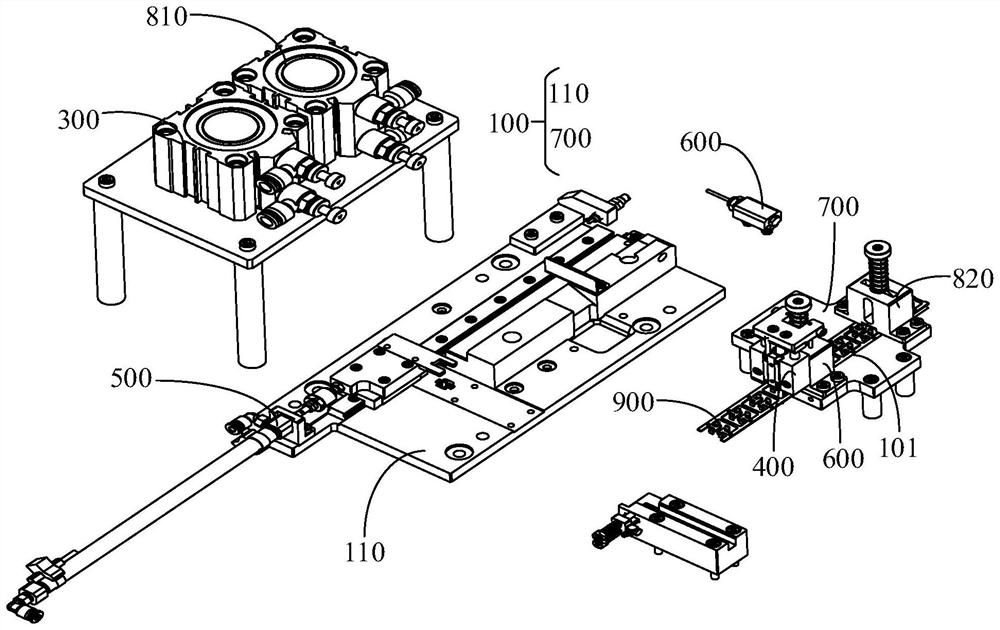

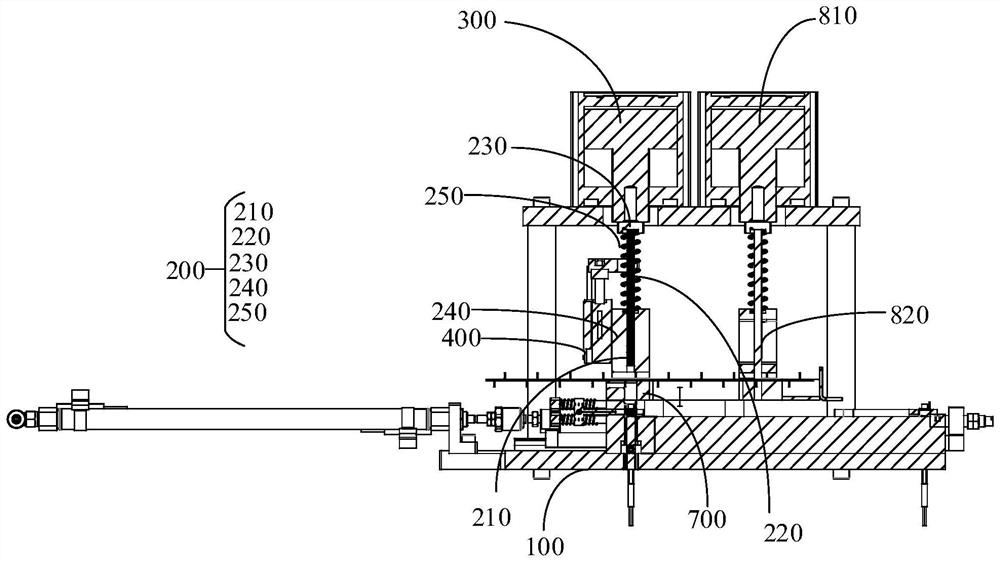

Blanking mechanism

PendingCN114178391AAvoid manual cuttingHigh degree of automationMetal-working feeding devicesPositioning devicesPhysicsEngineering

The blanking mechanism is used for blanking strip-shaped materials, the blanking mechanism comprises a mounting table, a cutting assembly and a first driving device, the mounting table is provided with a containing groove in the length direction of the mounting table, and the containing groove is used for containing the strip-shaped materials; the cutting assembly is mounted on the mounting table in a manner of moving up and down, and is used for cutting the convex part of the strip-shaped material; the first driving device is mounted on the mounting table and used for driving the cutting assembly to move up and down. According to the technical scheme, the production efficiency of shearing the strip-shaped materials is improved.

Owner:深圳市山柏智能设备有限公司

Square steel pipe vertical-welding robot

InactiveCN112338544AQuality assuranceEasy maintenanceOther manufacturing equipments/toolsHydraulic cylinderElectric machinery

The invention provides square steel pipe vertical-welding robot equipment which comprises a cutting device, a feeding device, a welding device, a moving device, a workbench and a lifting-clamping device, wherein the cutting device is fixedly mounted on the workbench; the feeding device and the workbench are fixedly mounted; the welding device and the workbench are fixedly mounted; the moving device and the workbench are fixedly mounted; and the lifting-clamping device and the feeding device are fixedly mounted. According to the square steel pipe vertical-welding robot equipment provided by theinvention, the cutting device is capable of clamping and cutting square steel pipes; the feeding device is capable of clamping as well as horizontally lifting and moving the square steel pipes; the welding device is capable of vertically welding the square steel pipes; the moving device is capable of intermittently moving the square steel pipes; hydraulic cylinders provide power for the cutting of the square steel pipes; and motors provide power for the feeding, welding and moving of the square steel pipes.

Owner:王鹏飞

Bundling and fixing device for multiple cable bundles

ActiveCN114313365ARealize cluster bundlingImprove bundling efficiencyBundling machine detailsStrappingElectric machinery

The invention discloses a multi-cable bundle bundling and fixing device which comprises a working frame, a cable feeding mechanism arranged in the working frame and a cable stranding mechanism arranged at the tail end of the working frame, one end of an output shaft of a cable feeding motor is connected with a rotating plate, and one end of the rotating plate is hinged to a swing sleeve. A swing rod is slidably connected into the swing sleeve, an adjusting sliding block is hinged to one end of the swing rod, and the other end of the swing rod is slidably connected with the sliding groove through a pin shaft. One end of the wire feeding sliding block is fixedly connected with a fixed clamping block, and the other end of the bending connecting rod is hinged to a movable clamping block. And the output end of the stranding motor is connected with a stranding pore plate through a rotating shaft. A strapping tape enters from the wire inlet hole of the wire stranding hole plate and extends out from the wire outlet hole of the wire stranding hole plate under the guiding action of the arc-shaped guide block and the wire leading arc plate, and then the strapping tape is stranded by utilizing the wire stranding motor, so that bundling and strapping of a plurality of cables are realized, the labor intensity of an operator is reduced, and the cable strapping efficiency is improved.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO PINGYUAN POWER SUPPLY CO +1

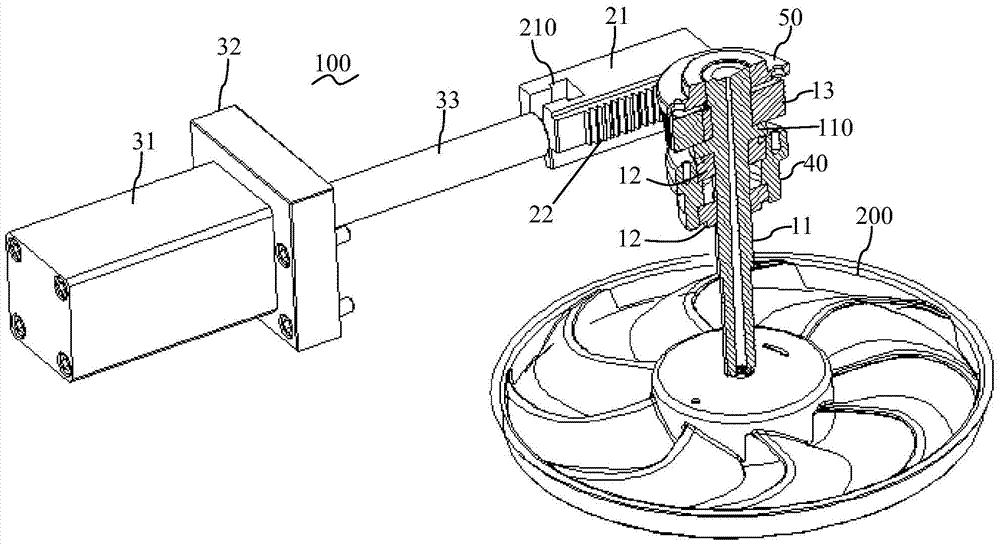

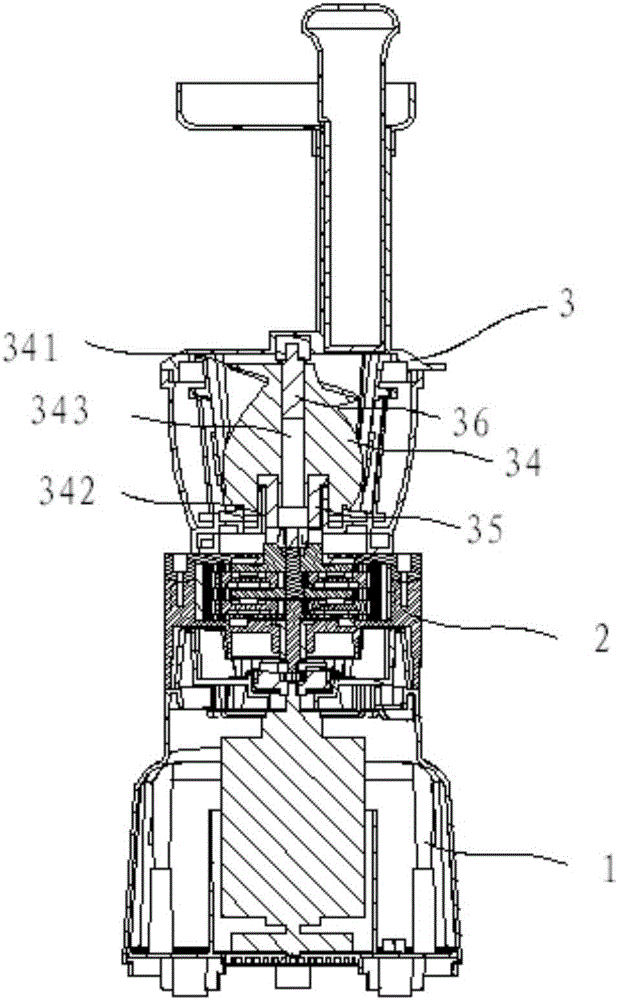

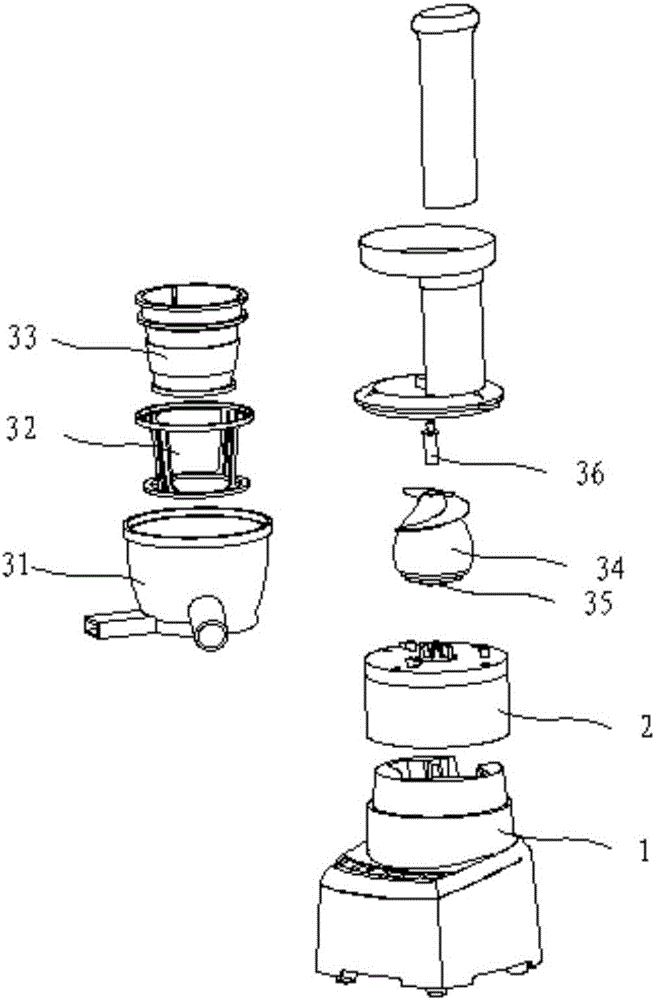

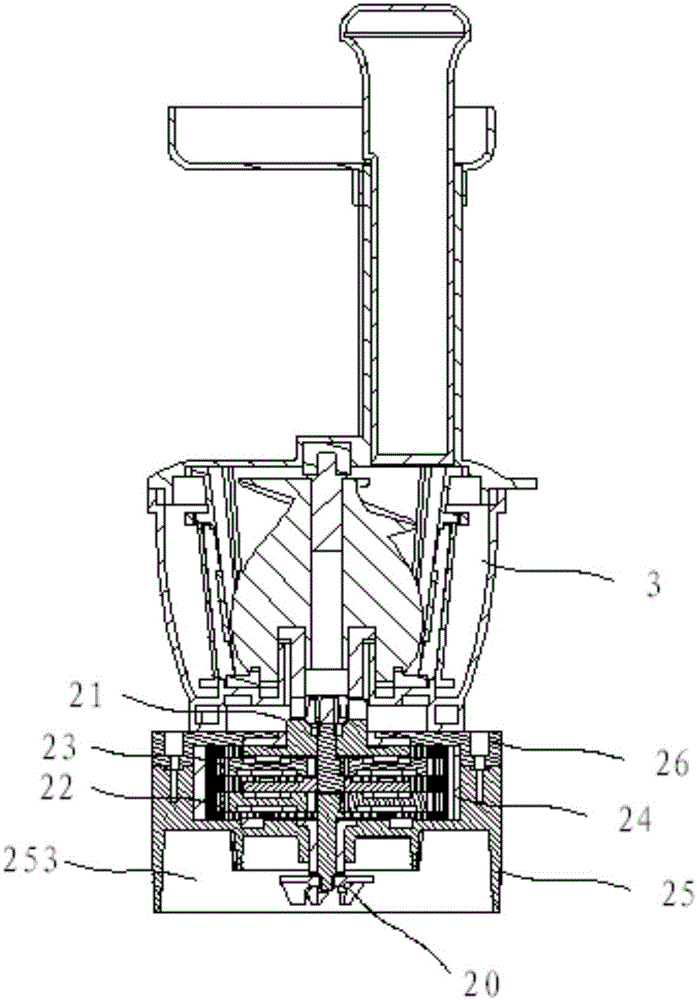

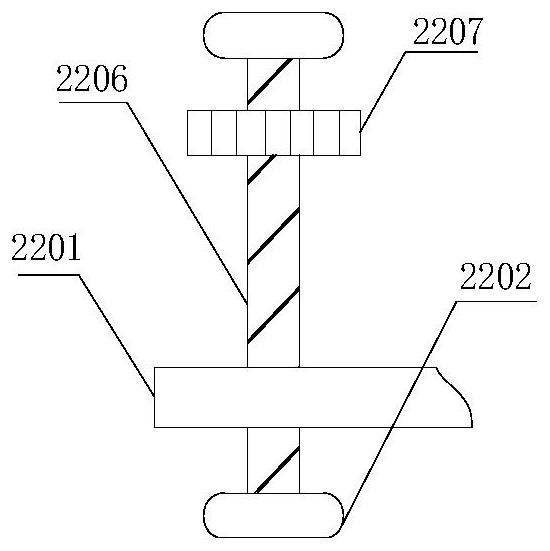

a juicer

The invention discloses a juice extractor which comprises a speed reduction mechanism, a holder and a squeezing mechanism. The holder is detachably arranged at the two ends of the speed reduction mechanism and comprises a motor therein. The speed reduction mechanism is provided with an input end in rotary connection with the motor and with at least one output end. The squeezing mechanism is in rotary connection to one of the output ends. The beneficial effects of the invention reside in that the holder, the speed reduction mechanism, the squeezing mechanism and a rapid cutting mechanism are all independent components and all the components can be detachably connected. The juice extractor is easy to assemble and convenient to use and clean.

Owner:SIMATELEX MANUFACTORY

Full-automatic cutting device for thermal insulation sandwich panel

InactiveCN113695660ATo achieve the purpose of cuttingAvoid manual cuttingShearing machinesDriving apparatusThermal insulationElectric machinery

The invention relates to the technical field of production and processing of thermal insulation sandwich panels, and discloses a full-automatic cutting device for a thermal insulation sandwich panel. The full-automatic cutting device comprises a bottom plate, two side plates, a top plate and supporting legs, wherein a cutting mechanism and a moving mechanism are arranged above the bottom plate; the cutting mechanism comprises a motor, a first worm and a cutting knife; the moving mechanism comprises a moving rod, a limiting block, a concave plate, a second worm, a first worm gear, a threaded rod and a second worm gear; the top of the bottom plate is fixedly connected with the bottoms of the side plates; the tops of the side plates are fixedly connected with the bottom of the top plate; and the bottom of the bottom plate is fixedly connected with the tops of the supporting legs. According to the full-automatic cutting device for the thermal insulation sandwich panel, the second worm can drive the second worm gear to rotate through rotation of the first worm gear, so that the threaded rod can rotate, and finally, the moving rod drives the clamped thermal insulation sandwich panel to move, so that the purpose of automatic cutting is achieved.

Owner:安徽瑞业钢构股份有限公司

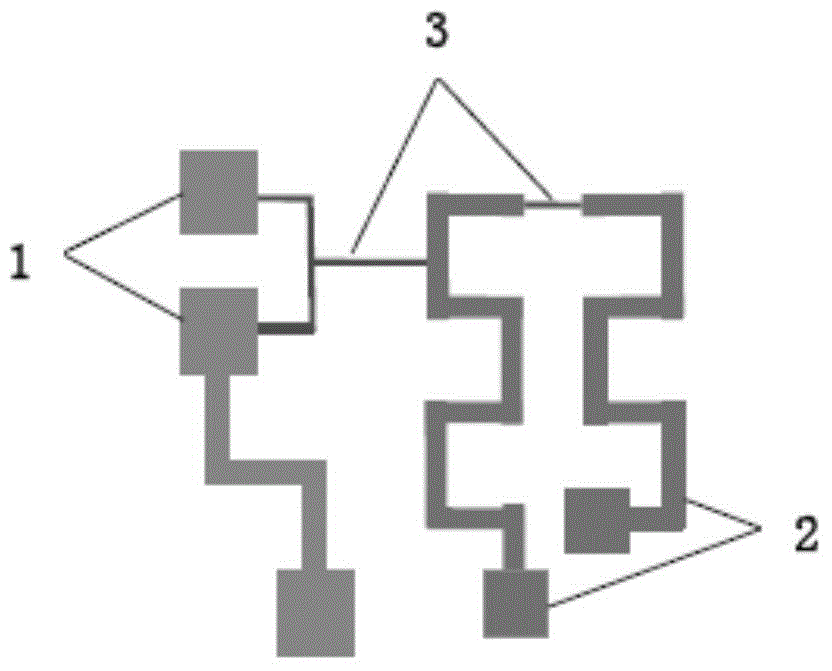

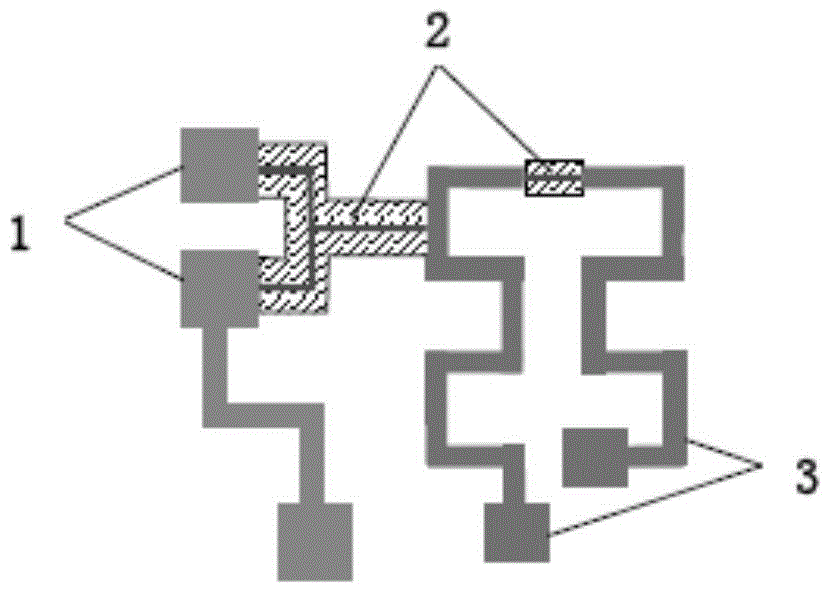

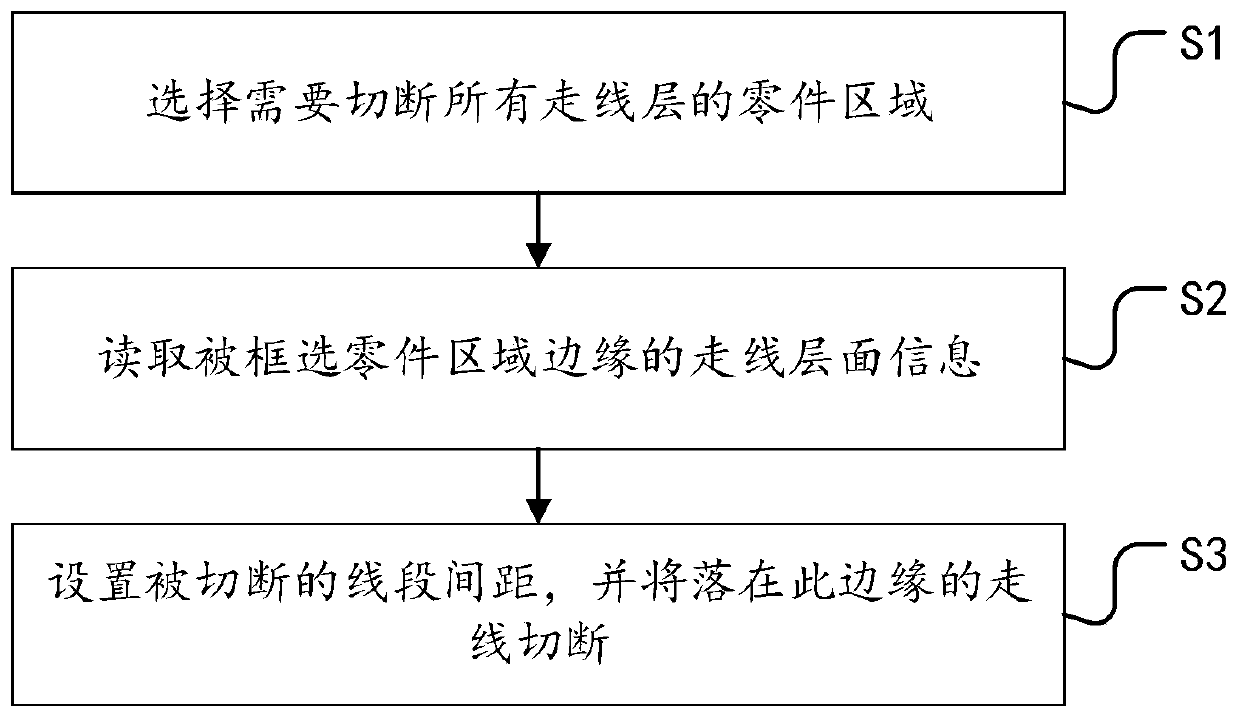

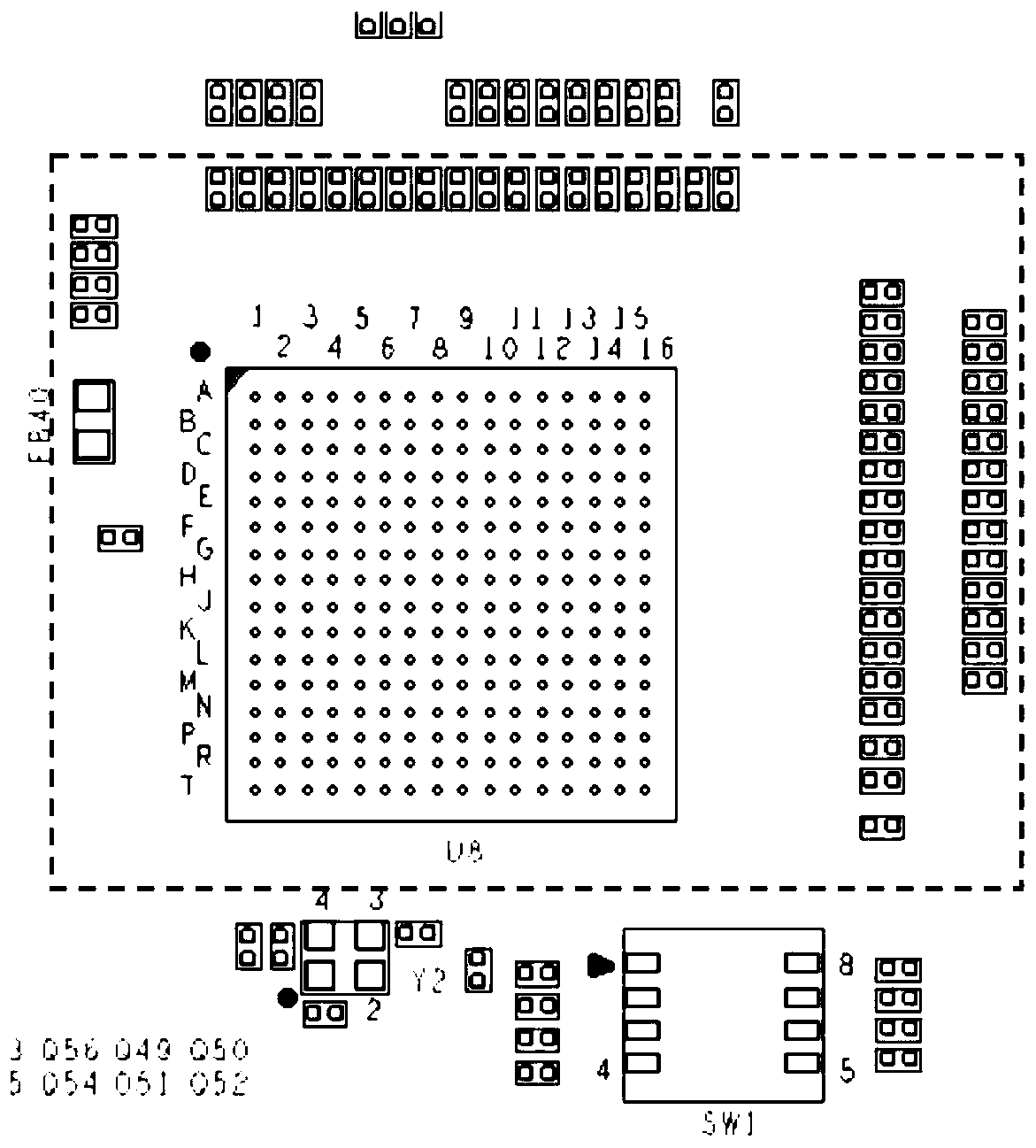

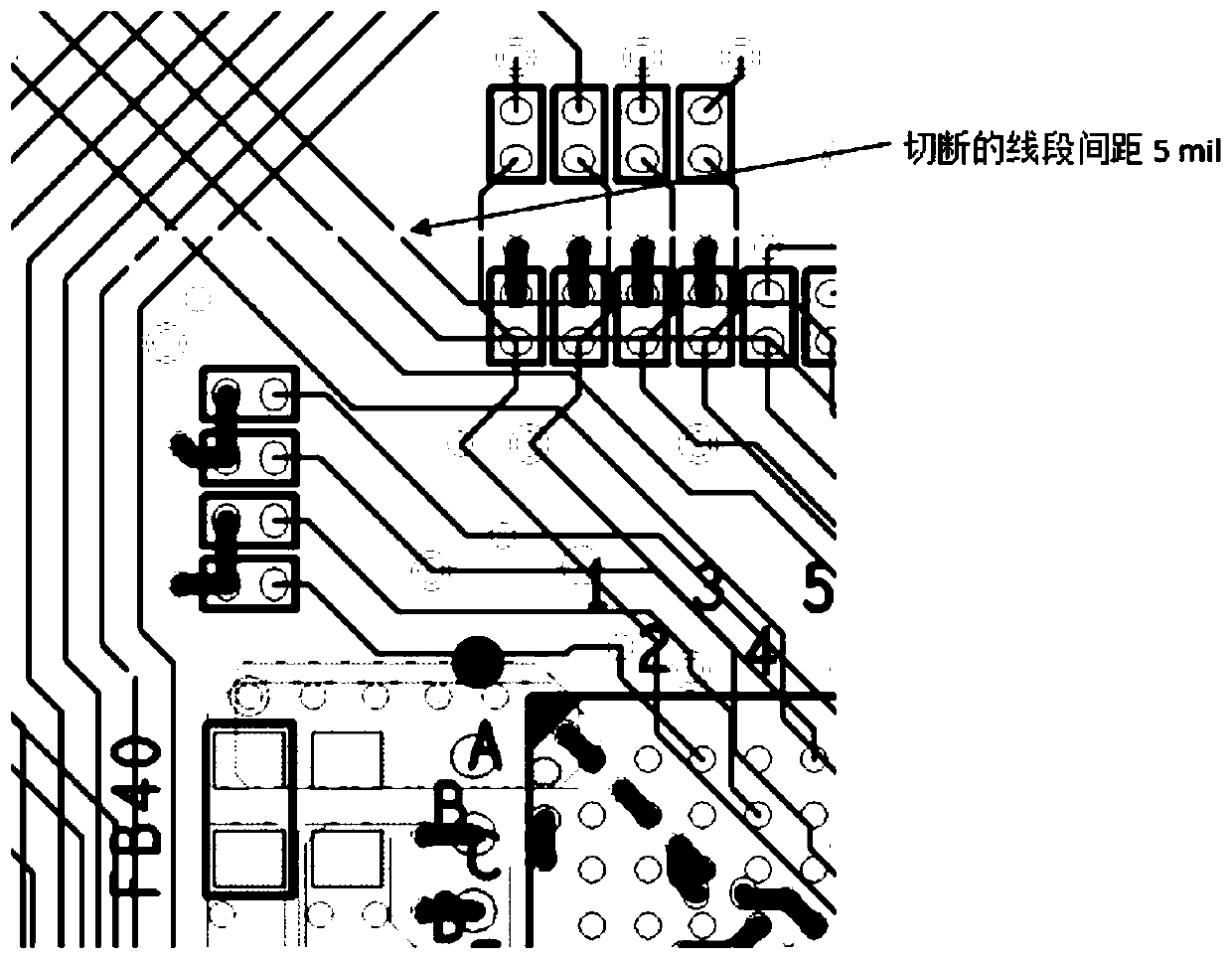

Design method and system for cutting all layers of line segments of part

InactiveCN110083907AAvoid manual cuttingImprove design efficiencyCAD circuit designSpecial data processing applicationsEngineeringDesign methods

The invention provides a design method and system for cutting all layers of line segments of a part. The design method comprises the steps of selecting a part area where all wiring layers need to be cut; reading the routing layer information of the edge of the framed part area; and setting the distance between the cut line segments, and cutting off the wires on the edge. According to the invention, the cut-off design operation is carried out in the form of operating the Skill program; framing and selecting a part area needing to cut off all the wiring layers; reading the routing layer information of the edge of the framed part area; according to the method, the lines falling on the edge are cut off, all layer line segments of the part are cut off, a program for cutting off all the layer line segments of the part is compiled, then the Skill program is put into the Skill menu, all the layer line segments of the part can be cut off by executing the Skill program, manual cutting off of allthe layer line segments of the part is avoided, and the design efficiency is improved.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Automatic winding device for acetate cloth tape of automobile wiring harness

ActiveCN111816376BReduce processing costsReduce stepsManufacturing wire harnessesAdhesive beltConveyor belt

The invention belongs to the field of automobile wiring harness manufacturing, and in particular relates to an automatic winding device for acetate cloth adhesive tape of automobile wiring harness, which includes a workbench, which is rotatably connected with a conveyor belt, and is obliquely provided with a winding plate, which is detachable An adhesive tape is connected, and the adhesive tape is matched with a wire harness, and the wire harness and the conveyor belt are rolled and connected, and the winding plate is connected with the wire harness through a shearing mechanism. In the present invention, by setting an automatic winding device for the acetate cloth tape of the automobile wire harness, it is possible to effectively prevent workers from manually winding the wire harness during processing, improve the working efficiency of the wire harness winding, reduce the winding processing cost of the automobile wire harness, and promote the suitable range.

Owner:山东望声电子科技有限公司

Shearing machine

InactiveCN104339396AAvoid manual cuttingImprove shear efficiencyMetal working apparatusEngineeringMechanical engineering

The invention relates to a shearing machine for shearing a primary product. The shearing machine comprises a workbench, a base, a shearing device and a first driving device, wherein the base is fixedly arranged on the workbench; the shearing device is arranged on the base; the shearing device comprises at least one pair of knives, and two knives in each pair of knives are spaced from one another and oppositely aligned; the first driving device is fixedly arranged on the workbench; the first driving device is used for driving the at least one pair of knives to approach one another and cut the primary product put between each pair of knives so as to separate an optimal element of the primary product from a material head of the primary product.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

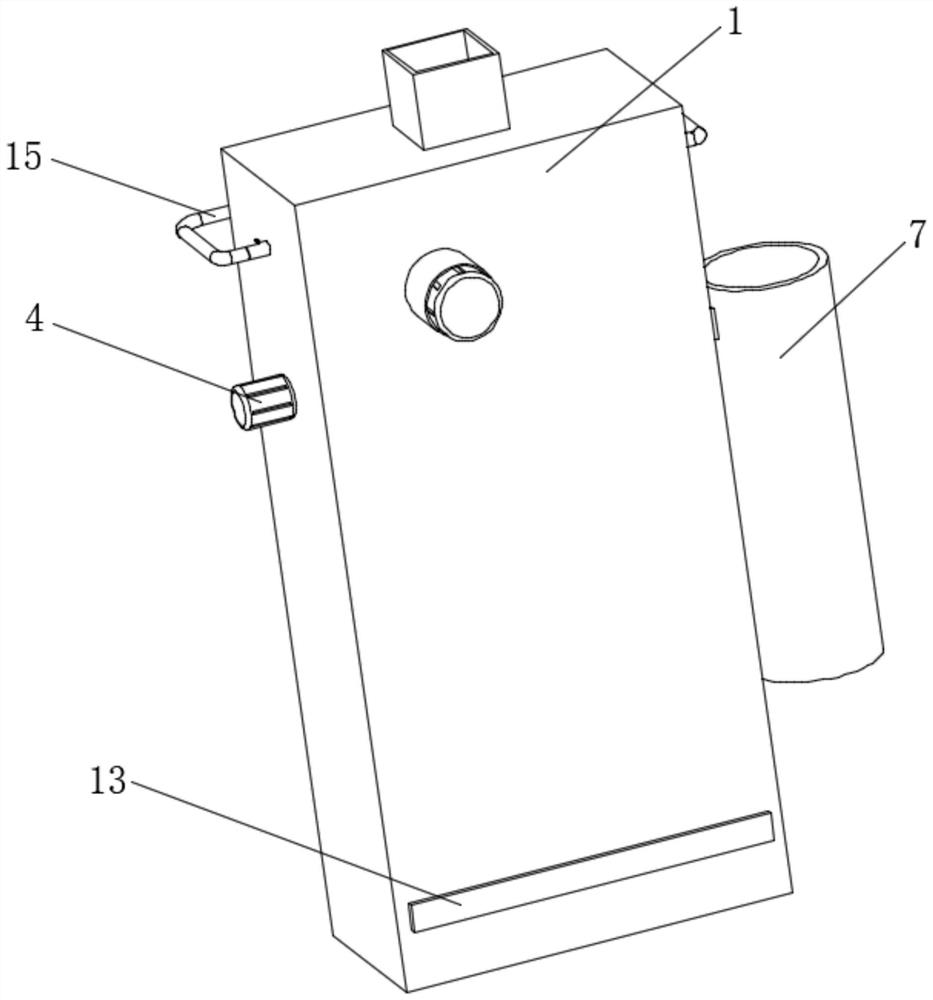

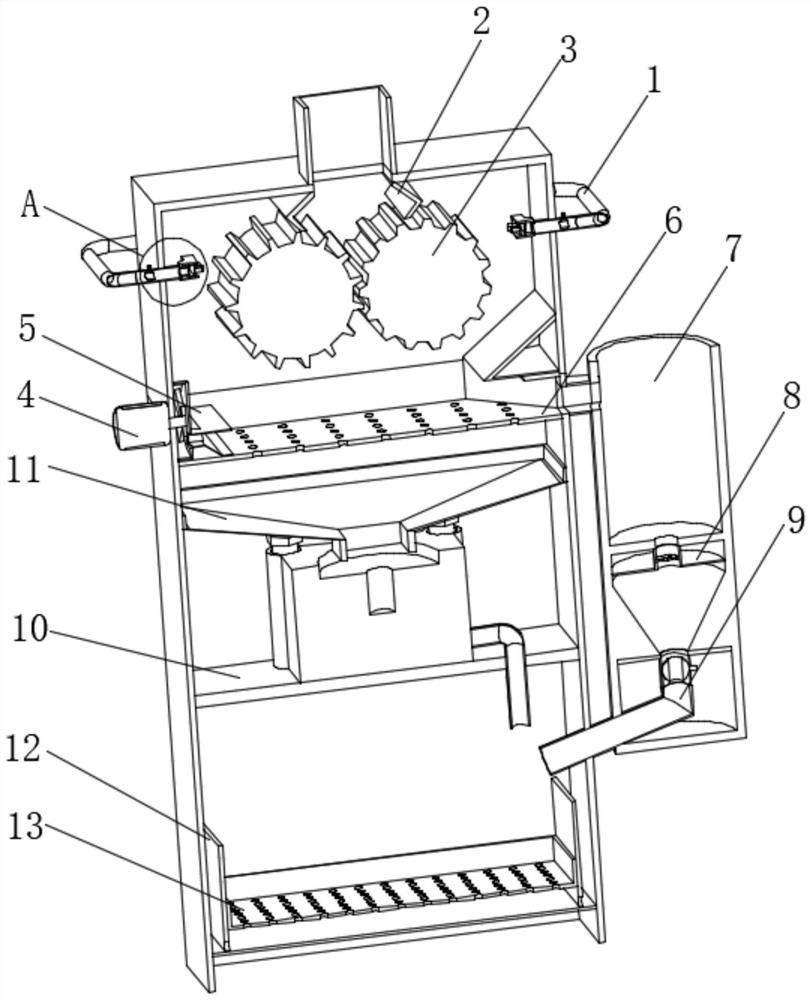

Extraction device for preparing ampelopsis grossedentata

ActiveCN114405625ASimple processAvoid manual cuttingSievingScreeningEngineeringMechanical engineering

The invention discloses an extraction device for preparing ampelopsis grossedentata, and relates to the technical field of ampelopsis grossedentata preparation, in particular to an extraction device for preparing ampelopsis grossedentata, which comprises a main box body, the top of the inner cavity of the main box body is fixedly connected with a material baffle, the inner cavity of the main box body is rotatably sleeved with a stirring roller, and the outer part of the main box body is provided with a fan. The right end of the fan is fixedly connected with an air guide pipe, and the bottom of the air guide pipe is fixedly connected with a filter plate. According to the extraction device for preparing the ampelopsis grossedentata, after being fed into the main box body from the top of the main box body, ampelopsis grossedentata raw materials fall into the middle of a stirring roller after being limited by a material baffle and fall onto the top of a filter plate after being cut by the stirring roller, and then an air guide pipe is started; the preliminarily processed ampelopsis grossedentata coarse material is blown into the extraction generator through the air guide pipe for specific extraction, so that manual cutting of the ampelopsis grossedentata raw material is avoided, the whole process of ampelopsis grossedentata preparation is accelerated, and the practicability of the device is improved.

Owner:江西富牛生态农业发展有限公司

Rubber floor gluing and laying device

The invention relates to the field of floor laying, in particular to a rubber floor gluing and laying device. According to the rubber floor gluing and laying device, automatic grinding and dust removal treatment can be achieved, glue can be automatically smeared and stricken, rolling treatment can be conducted on a rubber floor, and the rubber floor can be cut. According to the technical scheme, the rubber floor gluing and laying device comprises a laying table, a power motor, a first gear, a second gear, a first discharging shaft, a second discharging shaft, a pressing shaft, a connecting plate, a gluing table, a connecting rod and the like; a discharging groove is formed in the laying table, a discharging groove is formed in the laying table, and the discharging groove communicates with the discharging groove. According to the rubber floor gluing and laying device, gluing treatment can be automatically conducted on the ground under manual pushing, and rubber floor laying can be conducted on the glued ground.

Owner:美洲豹装饰股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com