Automobile wire harness acetate cloth adhesive tape automatic winding device

A technology for automotive wire harnesses and winding devices, which is applied in the manufacture of wire harnesses, electrical components, circuits, etc., and can solve the problems of low winding efficiency, time-consuming and laborious, and poor winding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

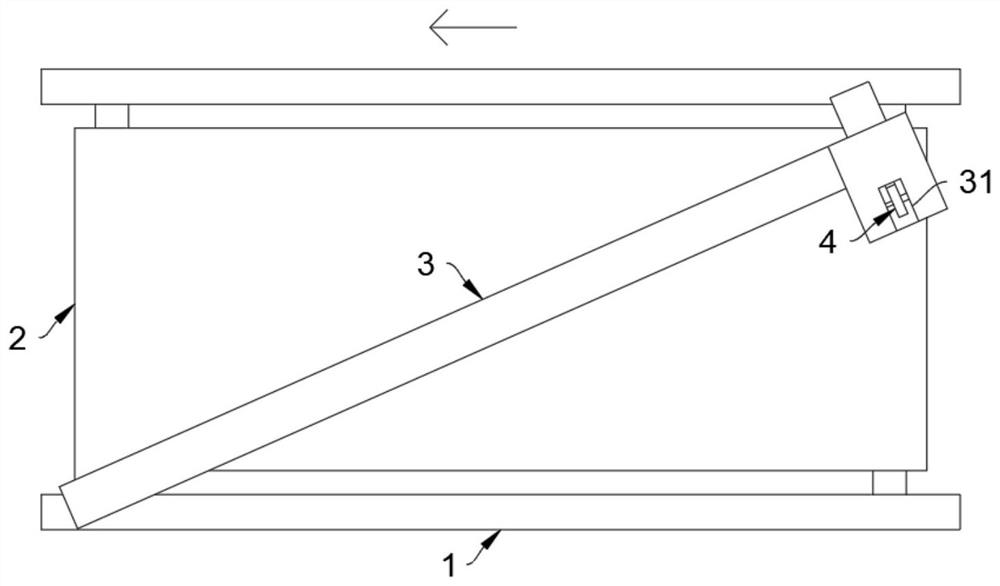

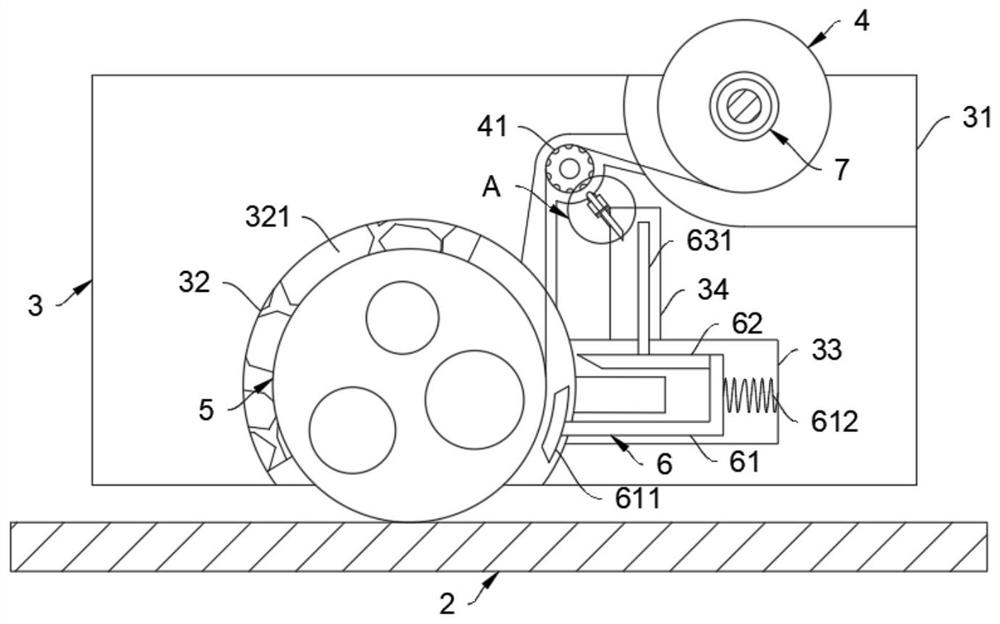

[0029] Such as Figure 1-4 As shown, the automatic winding device for acetate cloth tape of automobile wiring harness includes a workbench 1, which is rotatably connected to a conveyor belt 2. It should be noted that the workbench 1 is symmetrically provided with pillars for supporting the device. The driving device is used for driving and conveying to ensure the smooth progress of the winding work of the device.

[0030] The workbench 1 is provided with a winding plate 3 inclined. It should be noted that the inclination angle between the winding plate 3 and the workbench 1 is between 30°-45°, so as to avoid gaps in the tape 4 during the winding process of the wire harness 5 and improve the winding effect of the wire harness 5 , the distance between the winding plate 3 and the conveyor belt 2 is 3-5 mm, which ensures that the wire harness 5 and the conveyor belt 2 roll during the winding process, and improves the winding efficiency.

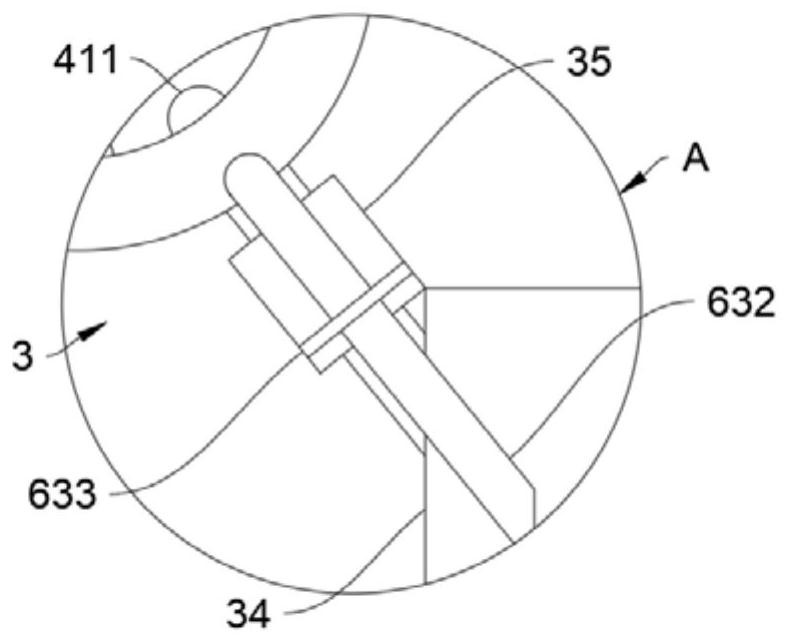

[0031] The winding plate 3 is detachably ...

Embodiment 2

[0039] Such as Figure 5-6 Shown, the difference between this embodiment and embodiment 1 is:

[0040] The blade 62 is inclined, and the blade 62 includes a cutter head 621 and a blade body 622, and the cutter head 621 and the blade body 622 are slidably connected. The telescopic slot 624 is slidably connected. When the device performs pop-up cutting, the blade 62 moves to the end and contacts the tape 4 for cutting. At this time, the telescopic slot 624 makes the position of the knife head 621 perform a secondary pop-up action, improving the cutting effect of the device. , when the shear mechanism 6 is recovered, the cutter head 621 slides and shrinks with the inclined blade body 622 under the action of its own gravity, so as to facilitate the next ejection and shearing work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com