Device and method for cutting angle iron

A technology of cutting equipment and cutting method, which is applied in the direction of welding equipment, metal processing equipment, gas flame welding equipment, etc., can solve the problems of cumbersome procedures, low processing efficiency, waste of materials, etc., and achieve simplified processing procedures, improved processing efficiency, and guaranteed The effect of cutting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

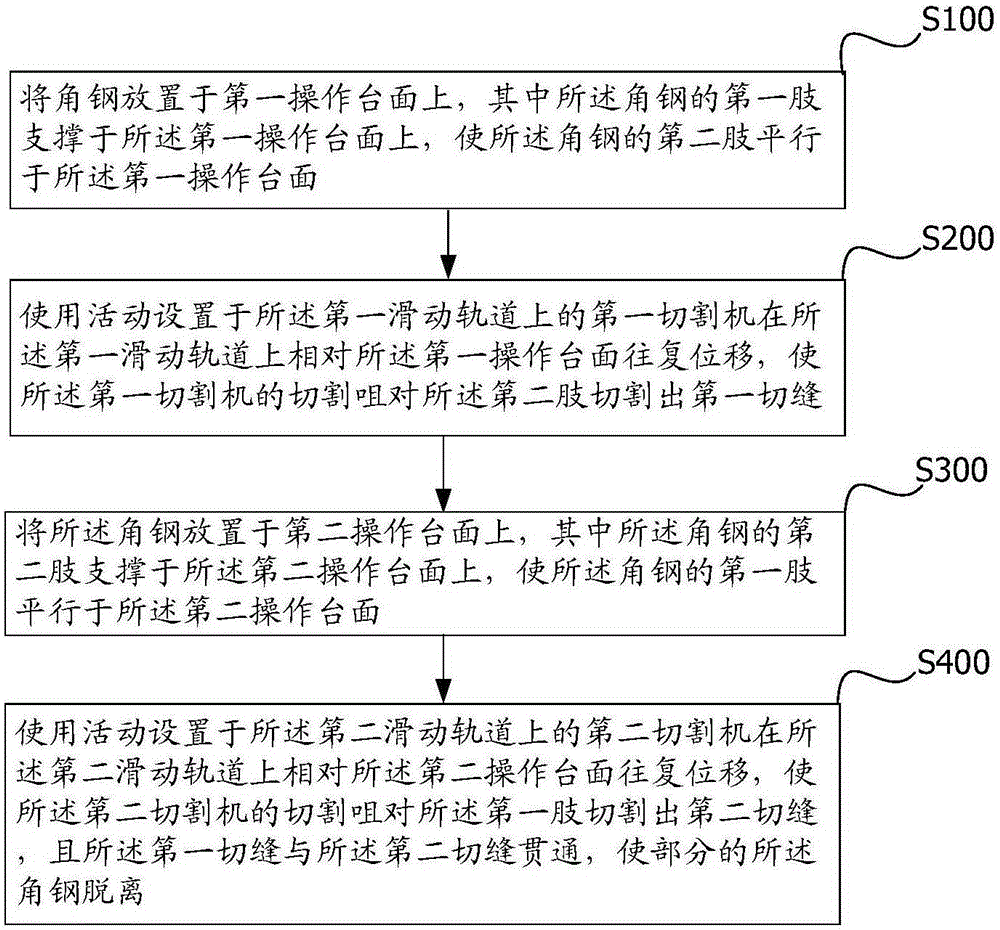

[0045] figure 1 It is a schematic flow chart of an angle steel cutting method provided by the present invention.

[0046] Please refer to figure 1 As shown, the angle steel cutting method provided by the first embodiment of the present invention includes:

[0047] S100: placing the angle steel on the first operating table, wherein the first leg of the angle steel is supported on the first operating table, so that the second leg of the angle steel is parallel to the first operating table;

[0048] S200: Use the first cutting machine movably arranged on the first sliding track to move back and forth on the first sliding track relative to the first operating platform, so that the cutting nozzle of the first cutting machine Cut the first slit in the two limbs;

[0049] S300: Place the angle steel on a second operating table, wherein the second leg of the angle steel is supported on the second operating table, so that the first leg of the angle steel is parallel to the second op...

Embodiment 2

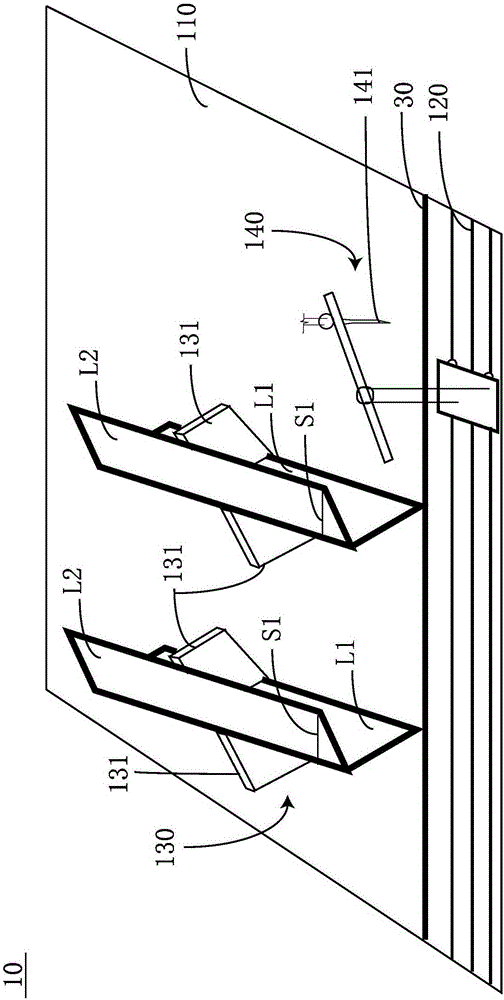

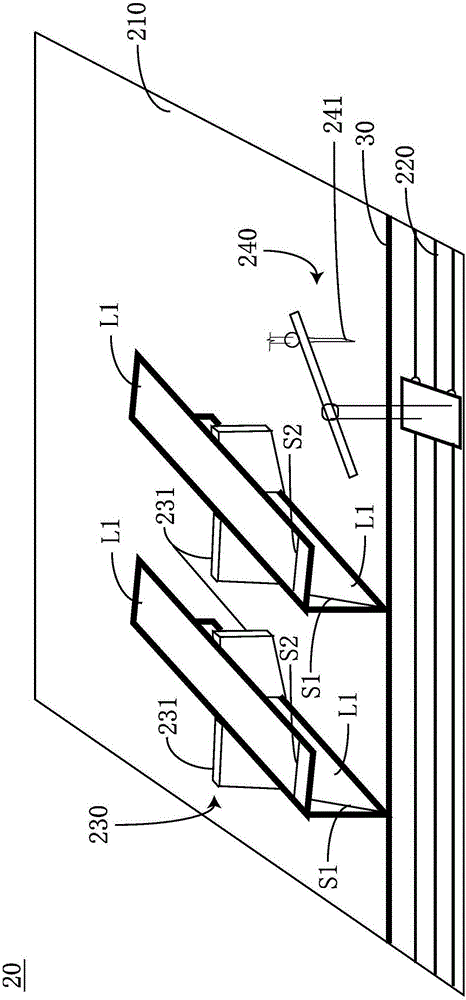

[0060] figure 2 , 3 It is a structural schematic diagram of an angle steel cutting equipment provided by the present invention.

[0061] Please refer to figure 2 , 3 , an angle steel cutting equipment disclosed in the present invention, the angle steel is commonly known as angle iron, which is a long strip of steel whose two sides are perpendicular to each other and form an angle. There are equilateral angle steel and unequal angle steel. The so-called equilateral angle steel means that the two side widths are equal, and the so-called unequal side angle steel means that the two side widths are not equal. The present invention does not make too many limitations, that is, the equipment of the present invention is suitable for both equilateral angle steel and unequal angle steel. It should be pointed out that the sides of the angle steel can also be called limbs, that is, each angle steel has two limbs, which are distinguished by the first limb L1 and the second limb L2 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com