Shearing machine

A technology of shearing machine and cutter, which is applied in metal processing and other directions, can solve the problem of low shearing efficiency, achieve the effect of improving shearing efficiency and avoiding manual shearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

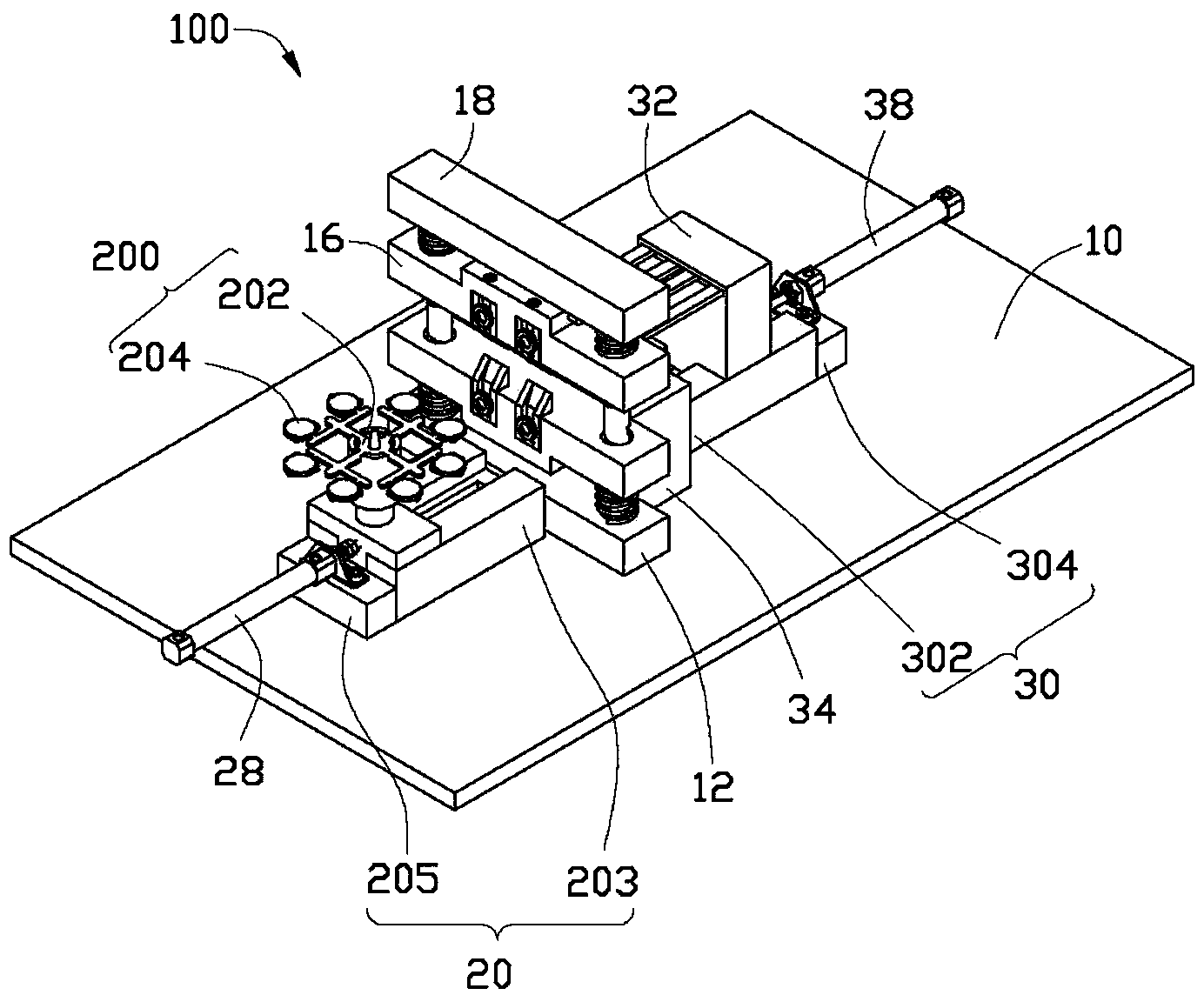

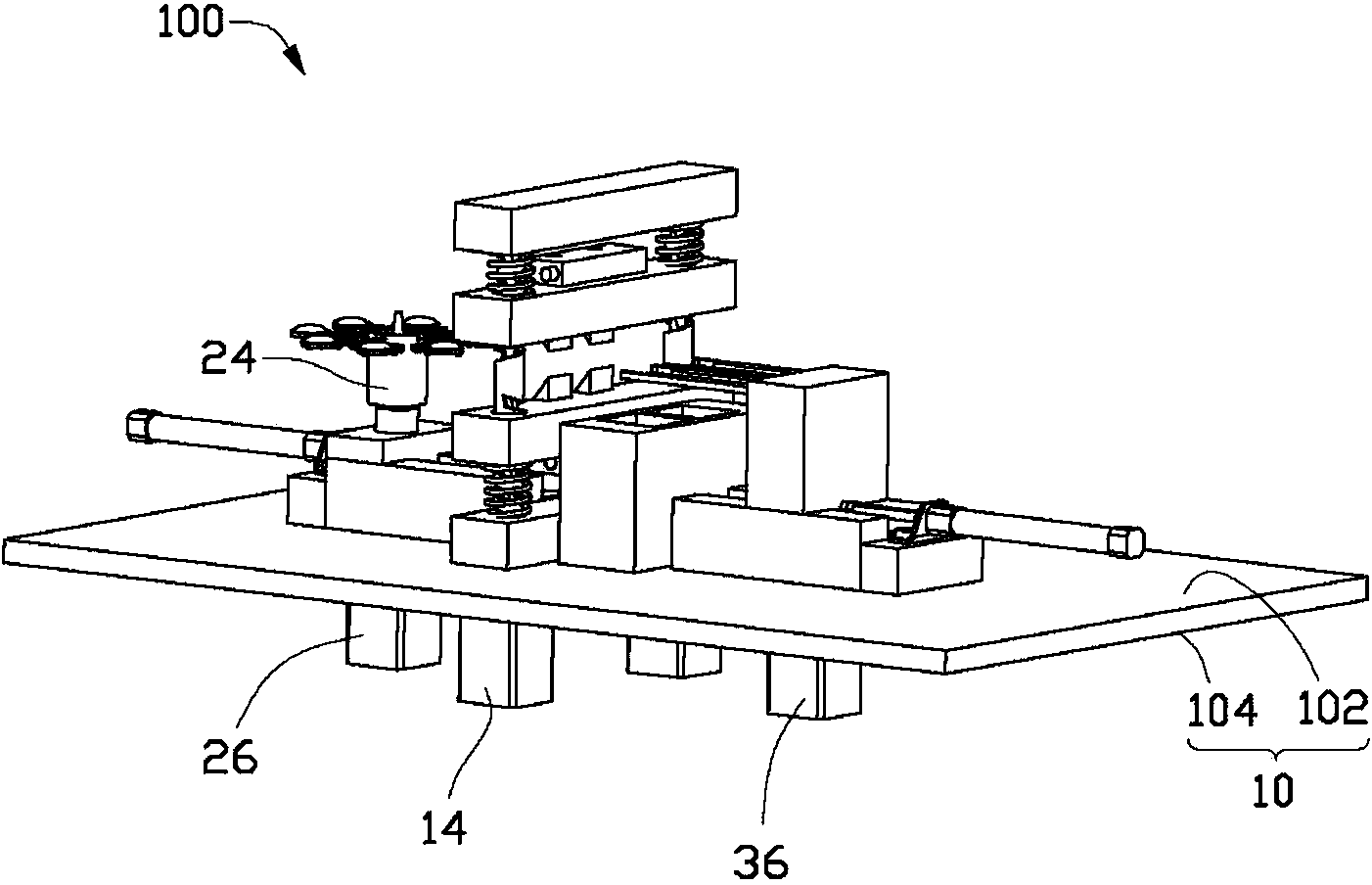

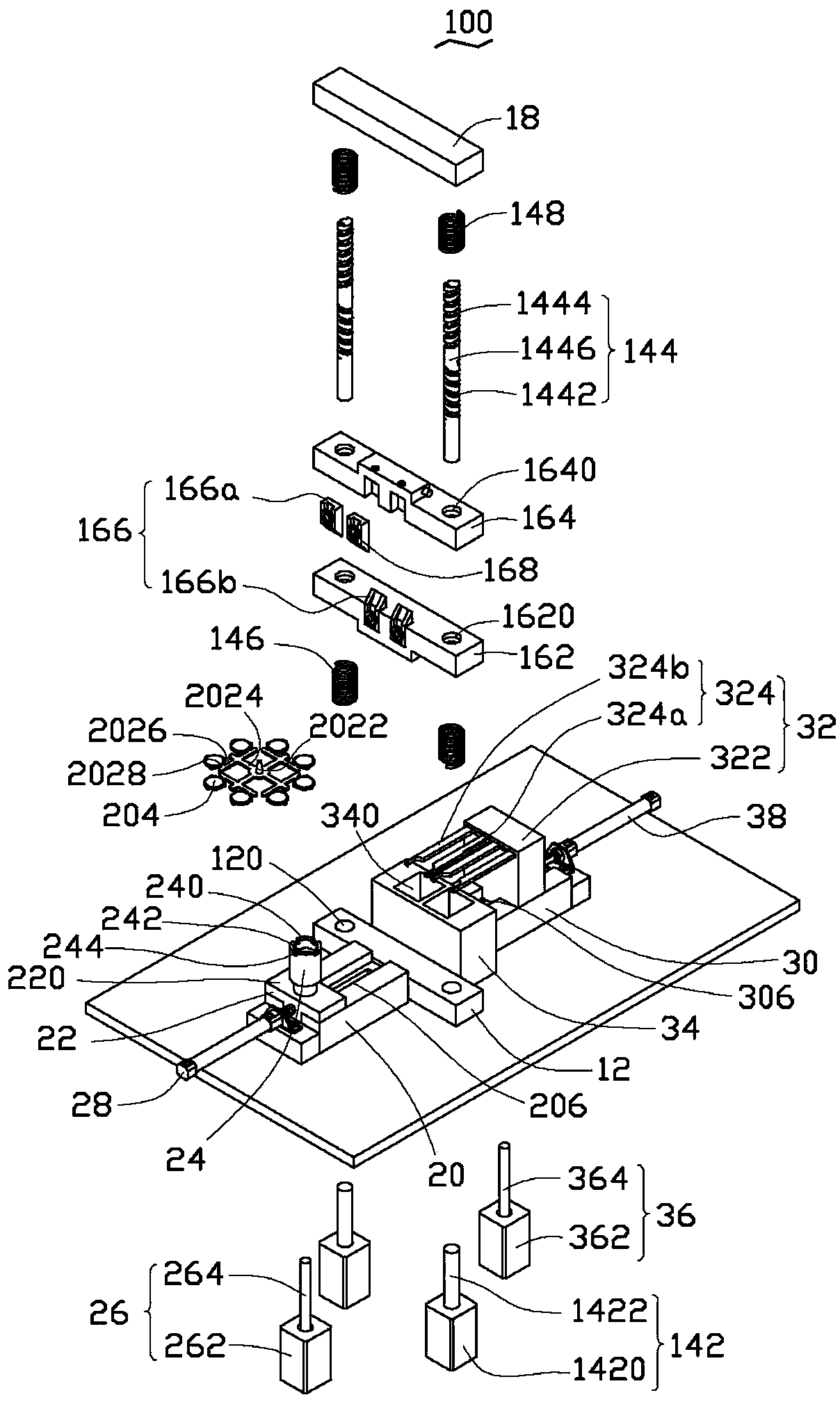

[0018] see figure 1 , is the shearing machine 100 provided in the first embodiment of the present invention, which is used for shearing the initial product 200 of injection molding. In this embodiment, the initial product 200 is a product after injection molding of an eight-cavity optical element (such as a lens), which includes a blank 202 and eight optical elements 204 .

[0019] The head 202 includes a rod body 2022 , four main branches 2024 , eight secondary branches 2026 and eight connecting parts 2028 . The four main branches 2024 extend perpendicular to one end of the rod body 2022 , and the four main branches 2024 are evenly distributed around the rod body 2022 , that is, the angles between adjacent main branches 2024 are all 90 degrees. Two secondary branches 2026 vertically extend from one end of each main branch 2024 away from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com