Printed wiring board containing gold at different thicknesses and manufacturing method thereof

A printed circuit board, thin gold technology, applied in the direction of conductive pattern formation, etc., can solve the problems that the wire cannot be etched, the anti-plating dry film cannot resist the attack of gold-plating solution, etc., and achieve the effect of high mass production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present application will be further elaborated below through specific examples.

[0038] In this embodiment, a method for preparing a printed circuit board containing multiple gold thicknesses, the outer surface of the printed circuit board includes a thin gold region (thickness is 1.0 μm) and a thick gold region (thickness is 3.0 μm) , the line density is: 0.1mm≤line width≤0.5mm, 0.1mm≤pitch≤0.5mm; the preparation method includes the following steps:

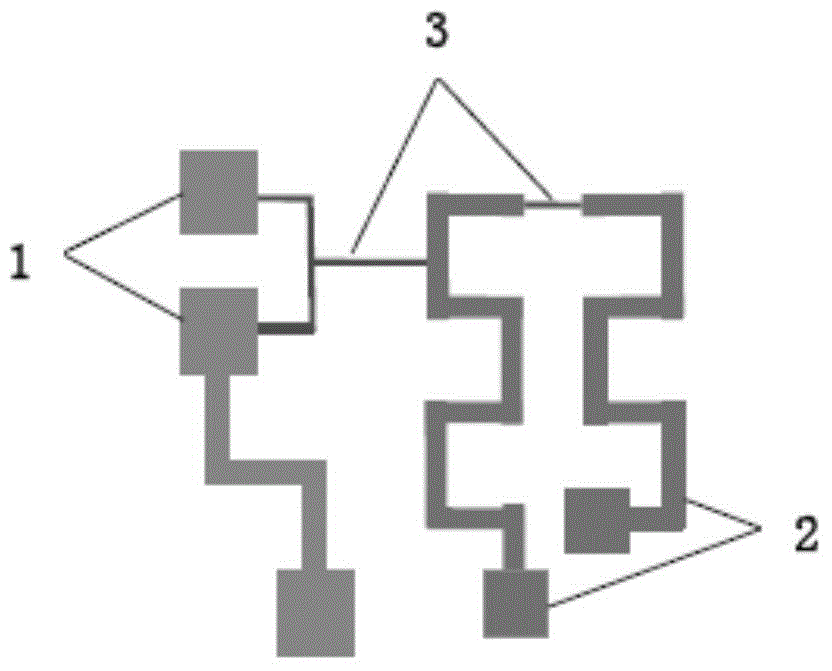

[0039] (1) The first graphics transfer: make the required thin gold area and thick gold area and gold-plated wires on the outer surface of the printed circuit board, such as figure 1 As shown, 1 is a thin gold area, 2 is a thick gold area, and 3 is a gold-plated wire;

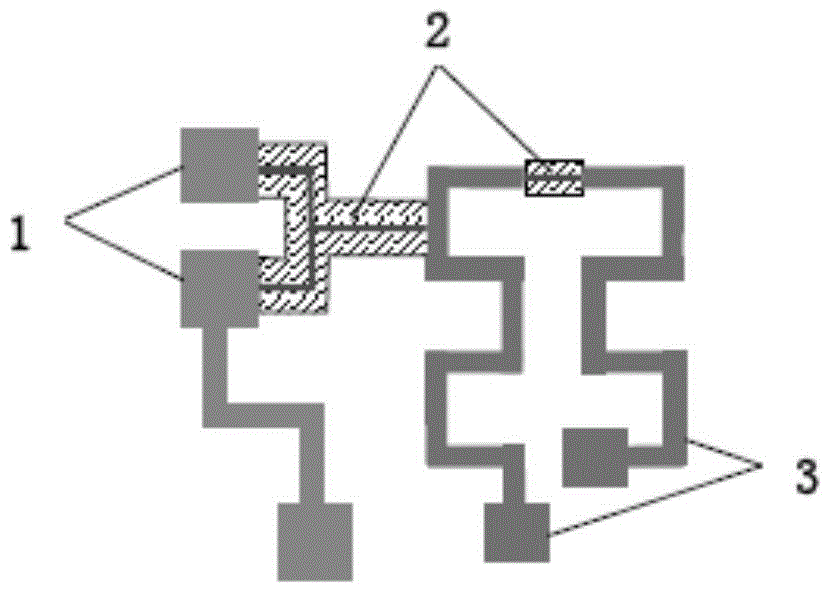

[0040] (2) Wet film printing: The printed circuit board obtained in step (1) is subjected to wet film printing and developing operations to expose thin gold areas and thick gold areas, such as figure 2 shown;

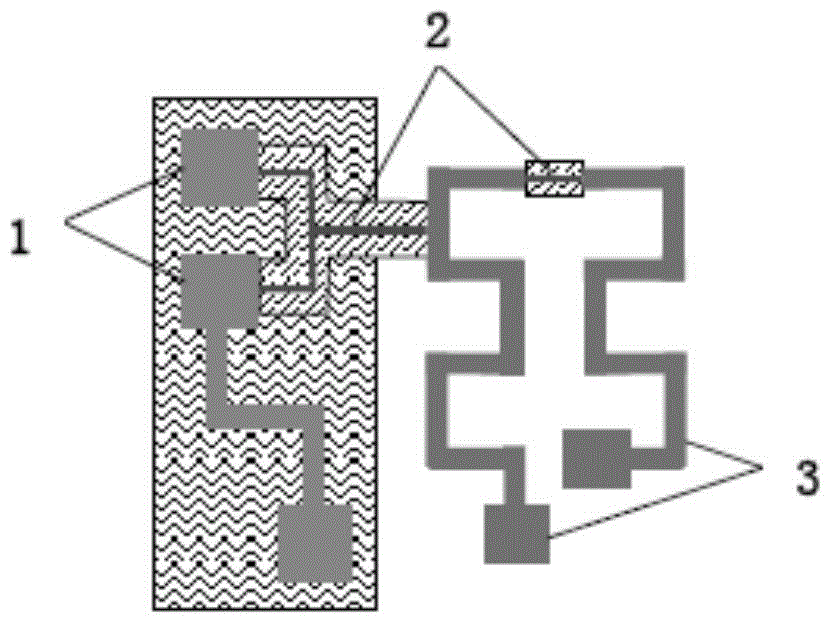

[0041] (3) gold plating for the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com