Ultrasonic image shoot training system

A technology of ultrasonic imaging and training system, which is applied in the field of ultrasonic imaging shooting training system, which can solve problems such as difficulty in ensuring normal use, easy failure of paper feeding mechanism, and high requirements for paper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

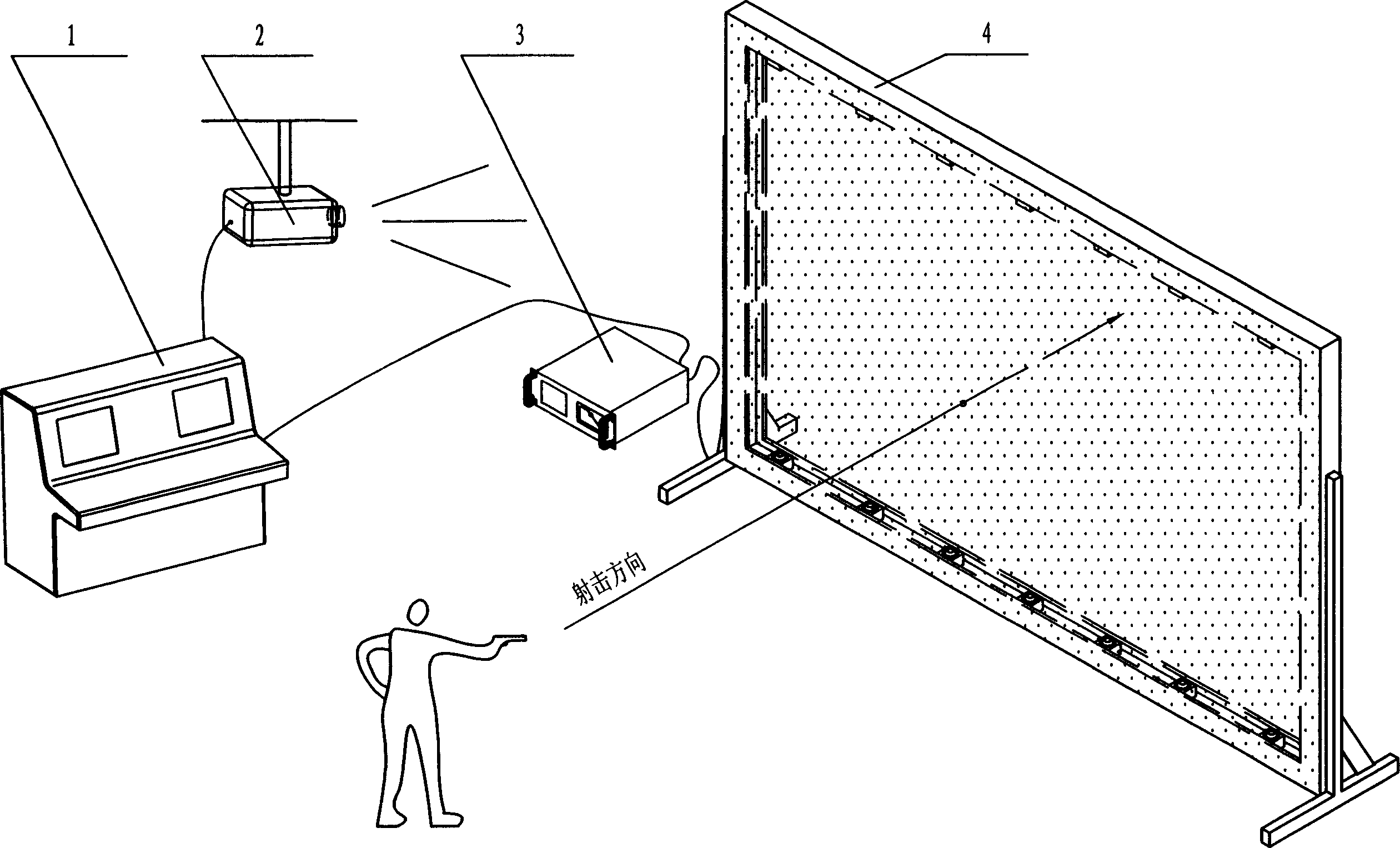

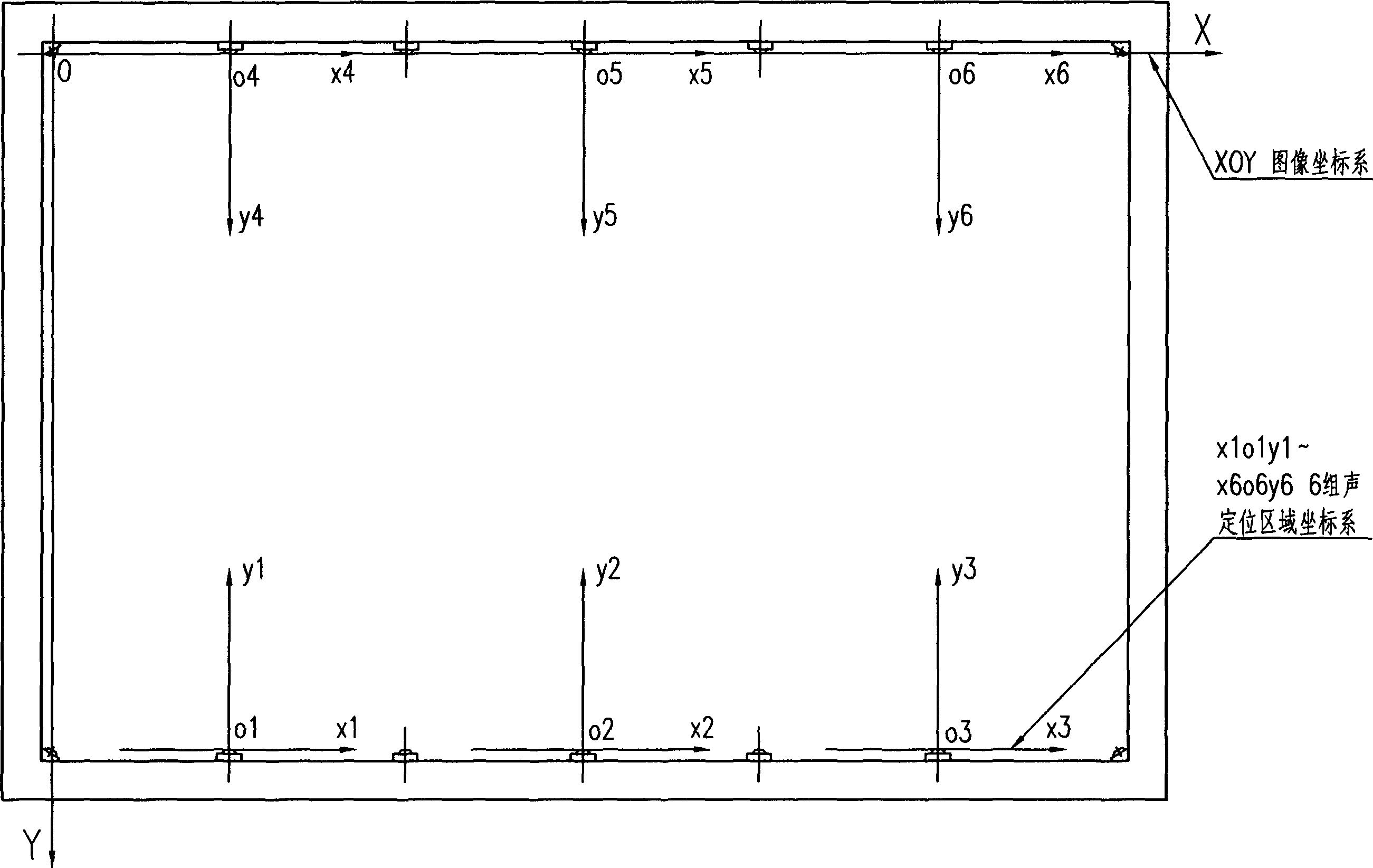

[0019] Refer to attached Figure 1~4 , The ultrasonic image shooting training system includes a large ultrasonic image screen, a signal acquisition processor 3, an industrial control computer for positioning and calculation, a communication circuit, an image control and playback computer 1, a CCD camera, a video image acquisition card, and a projector 2.

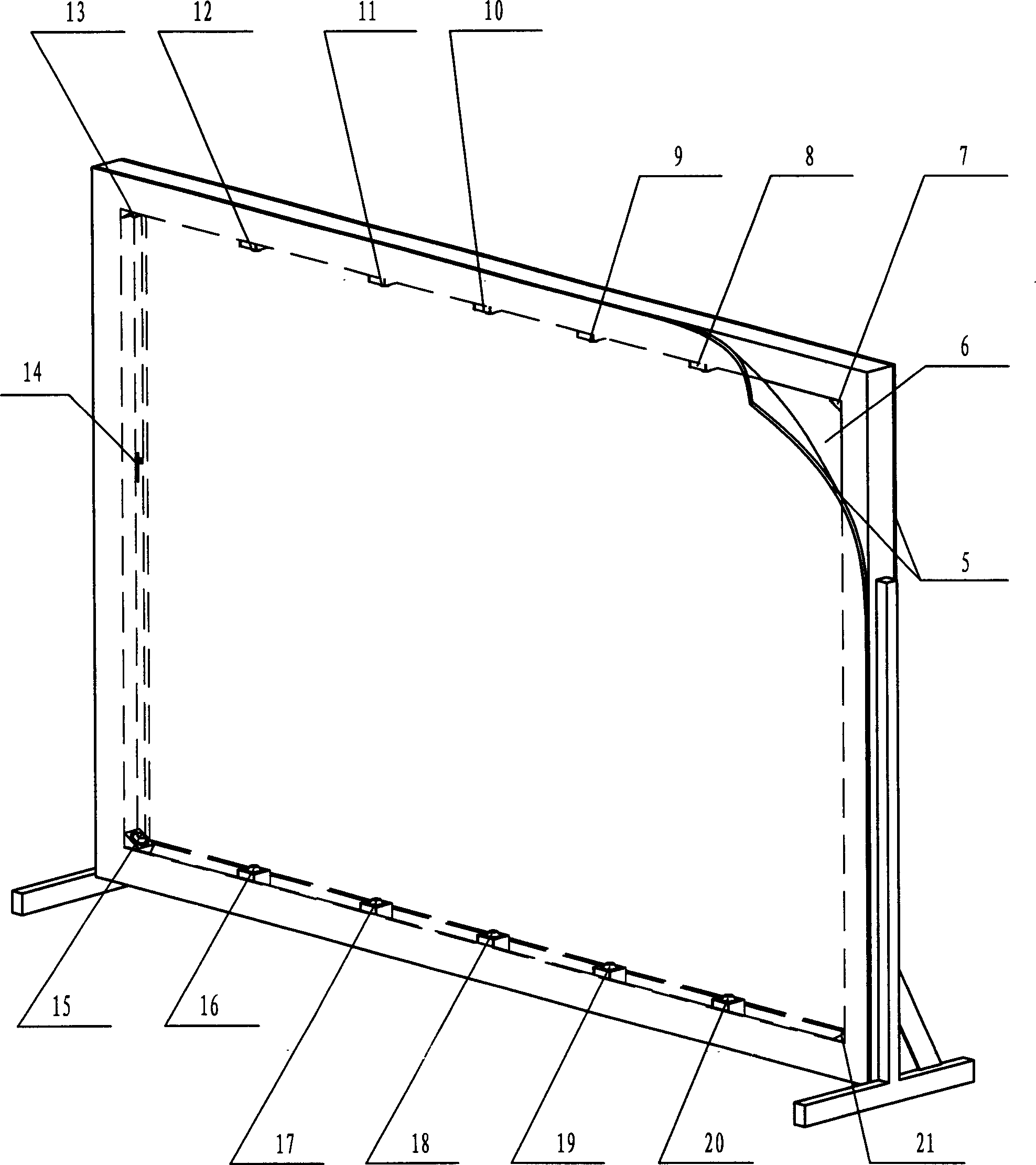

[0020] The large ultrasonic image screen has a frame 4, and high-purity rubber plates 5 are installed on both sides of the frame. An acoustic cavity 6 is formed in the middle of the frame. When the bullet passes through the acoustic cavity 6, sound waves can be transmitted freely. The rubber plate 5 is light white and should be consistent in color. Its airtightness should be guaranteed during installation to prevent external interference waves from entering. The acoustic cavity of the rubber plate 5 is composed of two pieces of natural pure rubber with a hardness of 42°±5° at the front and rear. Its elongation rate is 500%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com