Granular-material-clogging-based hybrid driving rigidity-controllable continuum robot

A hybrid drive and continuum technology, applied in the field of flexible robots, can solve the problems of reducing control accuracy and not being able to actively resist compression loads, achieving good adaptability and improving stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

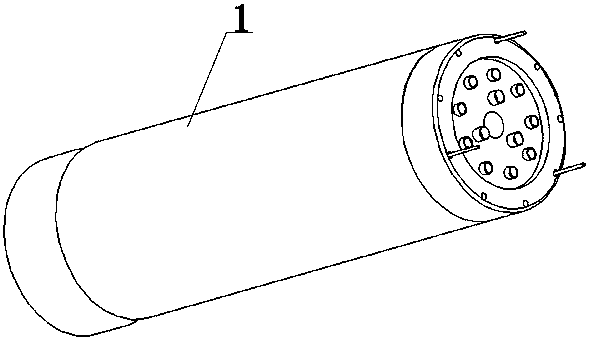

[0040] Such as Figure 1-7 As shown, a hybrid-driven controllable stiffness continuum robot based on granular blocking, the robot includes a first continuum unit 1,

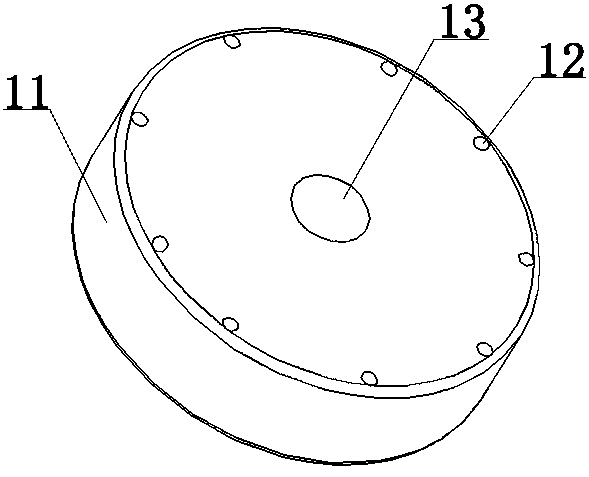

[0041] The first continuum unit 1 includes a flexible support outer cylinder 22, which is a hollow cylindrical structure made of silicone material, and three flexible support outer cylinder through-holes 23 are evenly distributed along the circumferential direction of its two ends and correspondingly opened. A plastic inner pipe 26 is arranged concentrically;

[0042] In the annular area between the inner wall of the flexible support outer cylinder 22 and the outer wall of the plastic inner pipe 26, three partitions 24 are uniformly arranged along the circumferential direction of the annular area, dividing the annular area into three sealed cavities, each The interior of the sealed cavity is filled with granular bodies 25;

[0043] The plastic inner pipe 26 is a hollow cylindrical structure, and an artificial p...

Embodiment 2

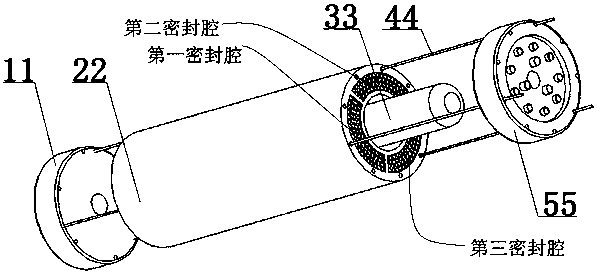

[0049] Such as Figure 8 , 9 As shown, a hybrid-driven controllable stiffness continuum robot based on granular blockage, the robot includes three identical single continuum units connected in series end to end, which are respectively the first continuum unit 1 and the second continuum unit 2. The third continuum unit 3;

[0050] The first continuum unit 1 or the second continuum unit 2 or the third continuum unit 3 includes a flexible support outer cylinder 22, which is made of silica gel material, which is a hollow cylindrical structure, and is evenly distributed along the circumferential direction of its two ends. There are 9 through holes 23 in the outer cylinder of flexible support, and a plastic inner pipe 26 is arranged concentrically inside;

[0051] In the annular area between the inner wall of the flexible support outer cylinder 22 and the outer wall of the plastic inner pipe 26, three partitions 24 are uniformly arranged along the circumferential direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com