Wheel-type X-ray flaw detection robot device

A flaw detection device, X-ray technology, used in manipulators, material analysis using radiation, manufacturing tools, etc., to achieve the effects of high precision, reduced failure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

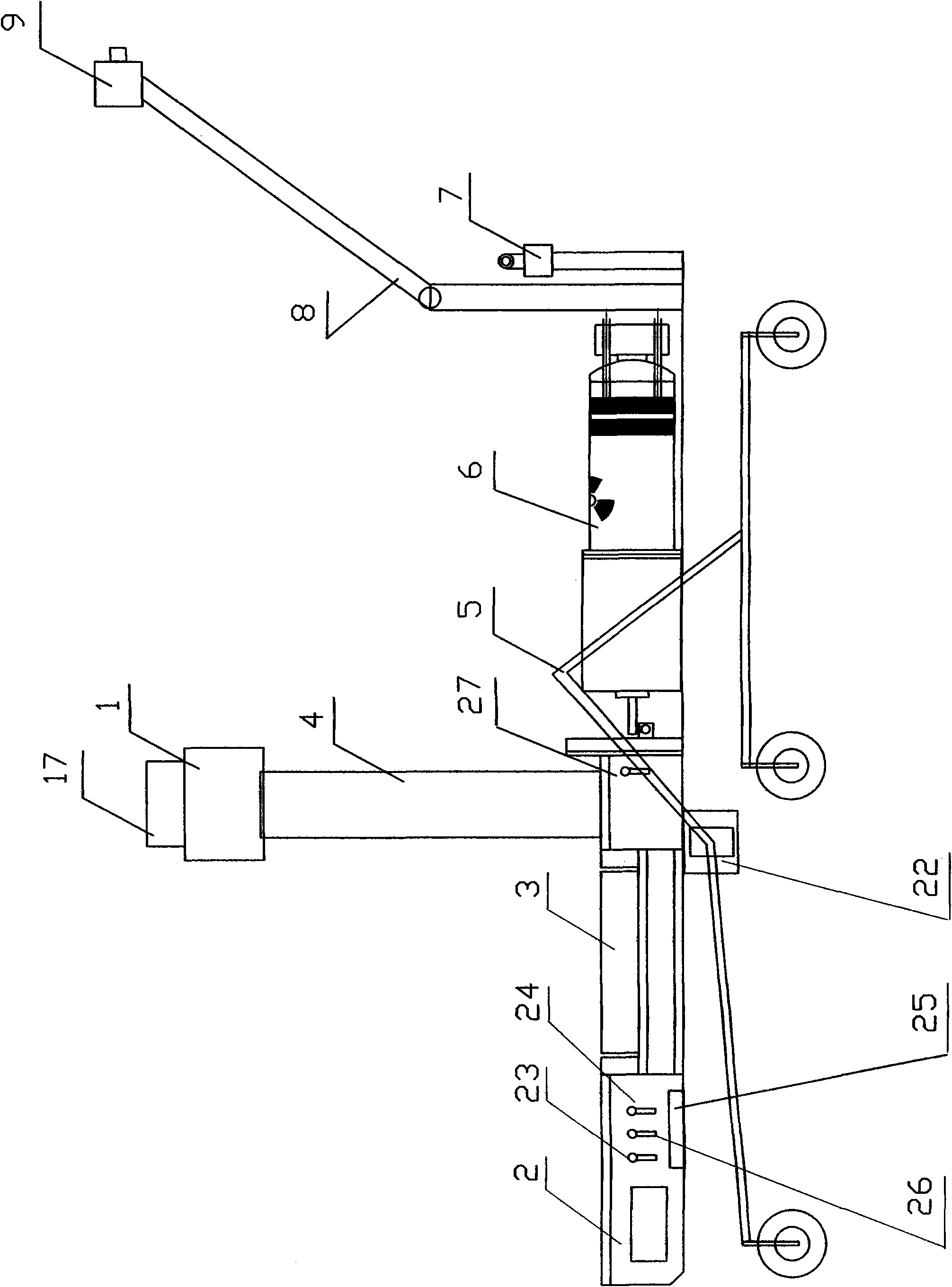

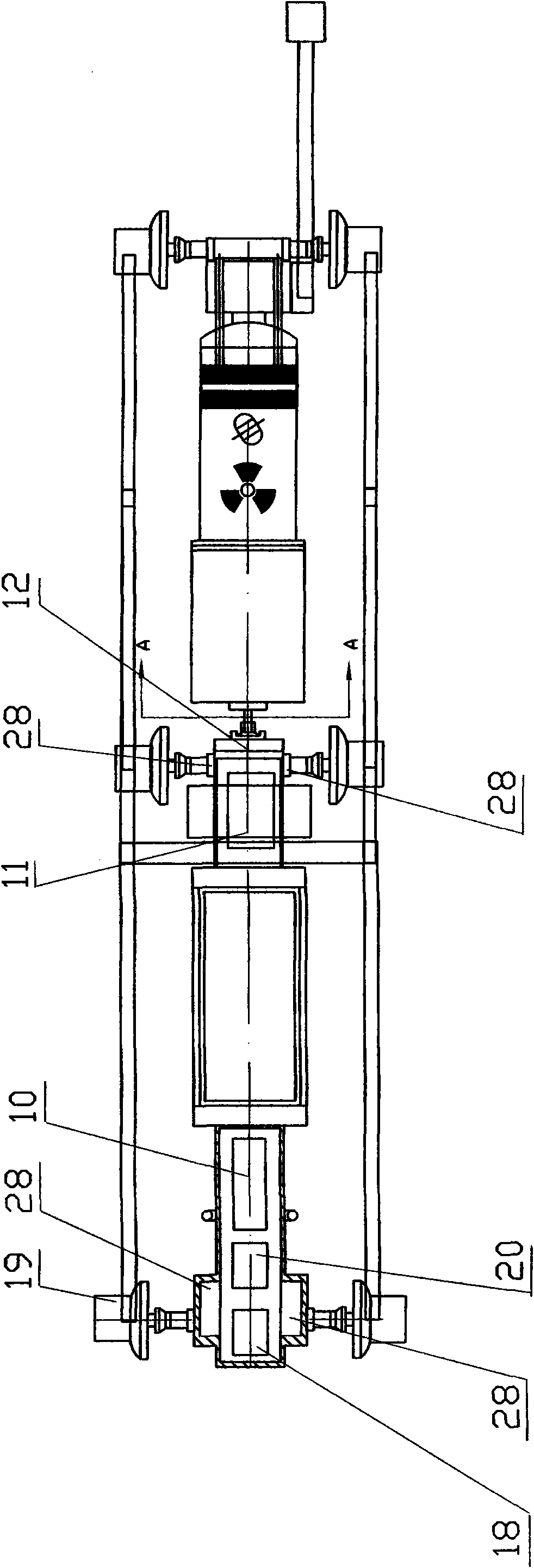

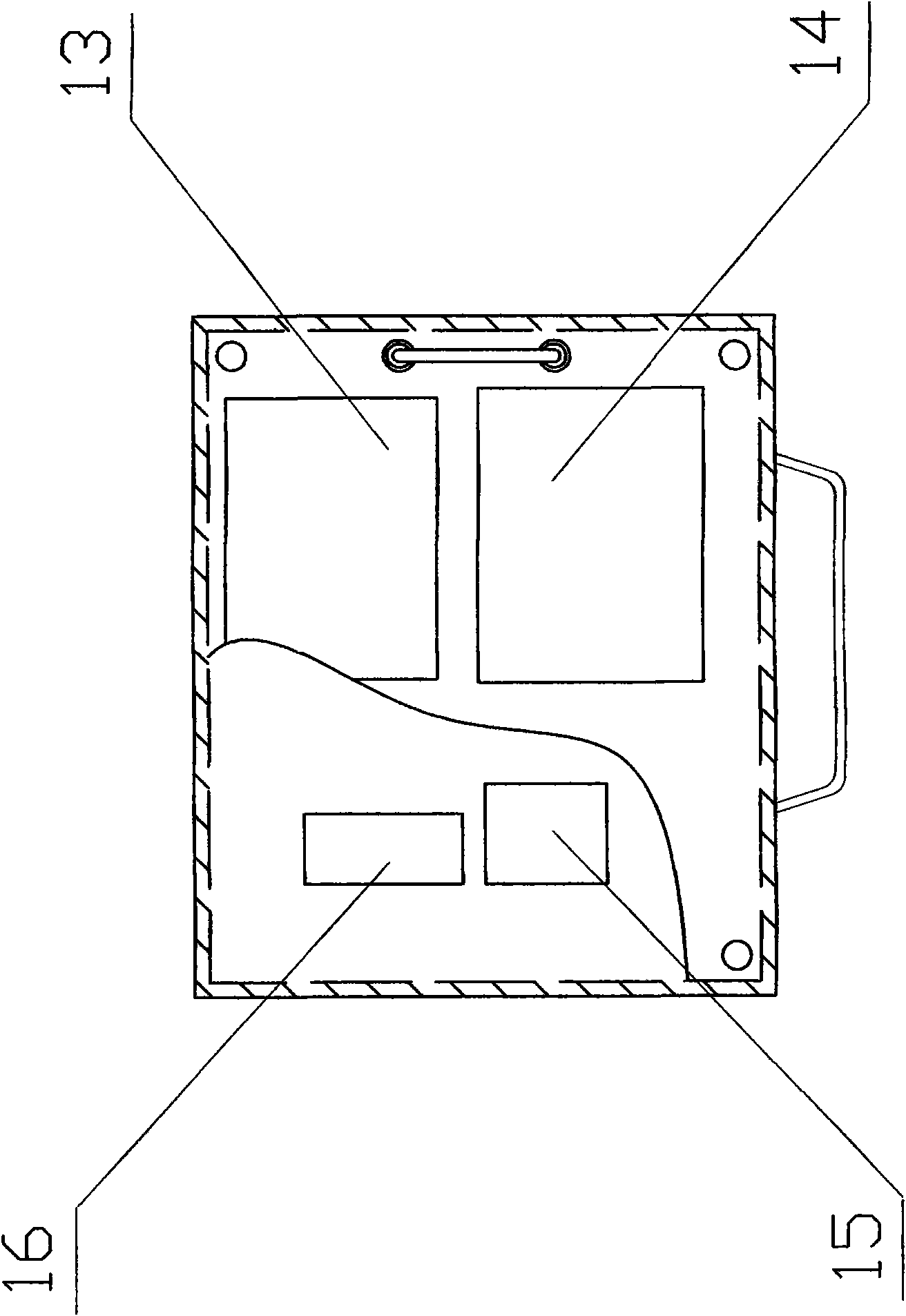

[0023] The structure and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] A wheeled X-ray flaw detection robot device, such as figure 1 , figure 2 , image 3 As shown, the lifting mechanism 22 at the robot body place is connected with the suspension bracket 5 middle end, the suspension bracket 5 adjustment motor 12 is housed on the lifting mechanism 22, and the servo motor 19 is housed on both sides of the front end of the suspension bracket 5, and the servo motor 19 axis Running wheel 21 is housed on it, and servomotor 19 and running wheel 21 identical with front end are housed in suspension bracket 5 middle end both sides and rear end both sides. Due to the error of the radius of the robot's running wheel and the size of the robot's structure, the sliding during motion, and the undulation of the ground, the cumulative error is very large, and it is impossible to perform long-term positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com