Polar plate reclaiming mechanism of full-automatic plate coating machine for accumulator plate

A reclaiming mechanism and fully automatic technology, which is applied in secondary battery manufacturing, conveyor objects, transportation and packaging, etc., can solve the problems of low cost, complex structure, and low processing efficiency of conveyor belts, and achieve low cost and good mechanism structure. Simple, ergonomic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

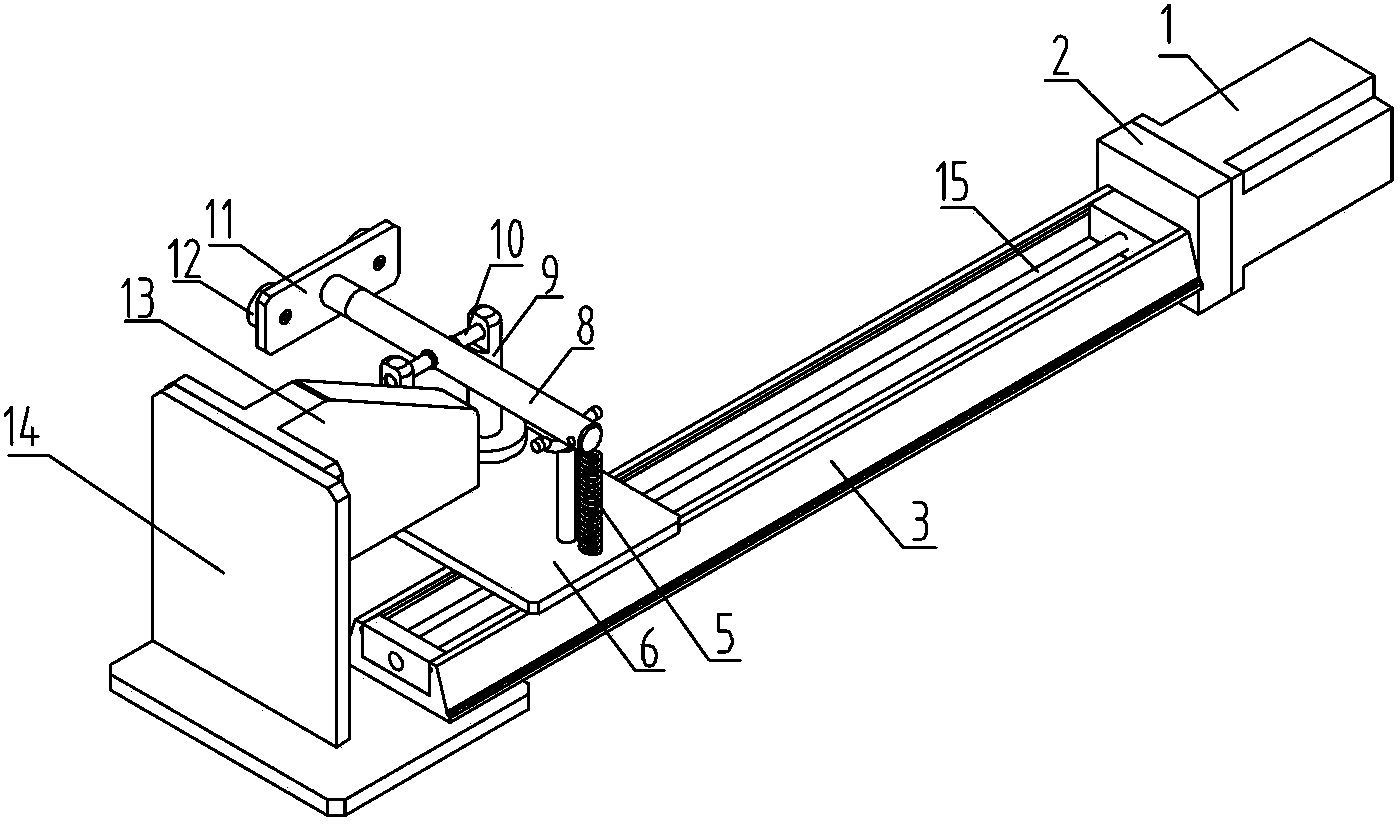

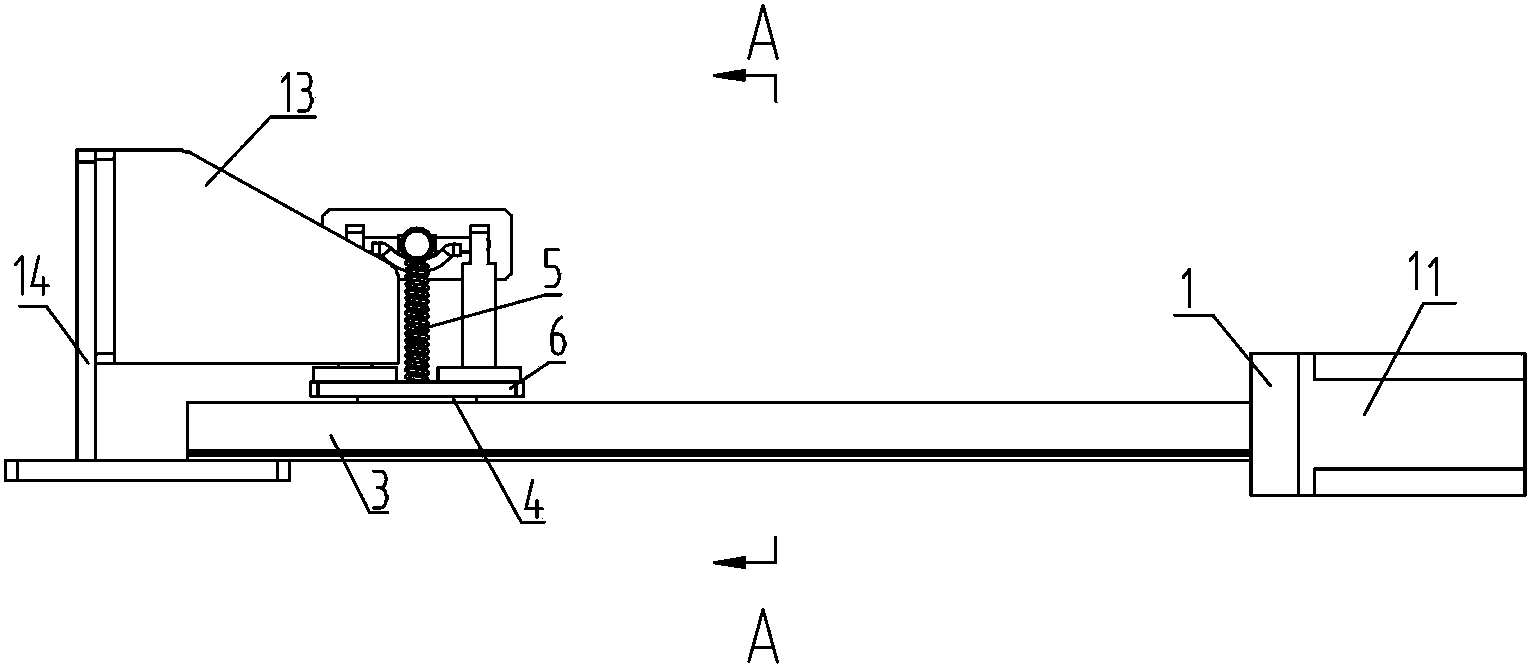

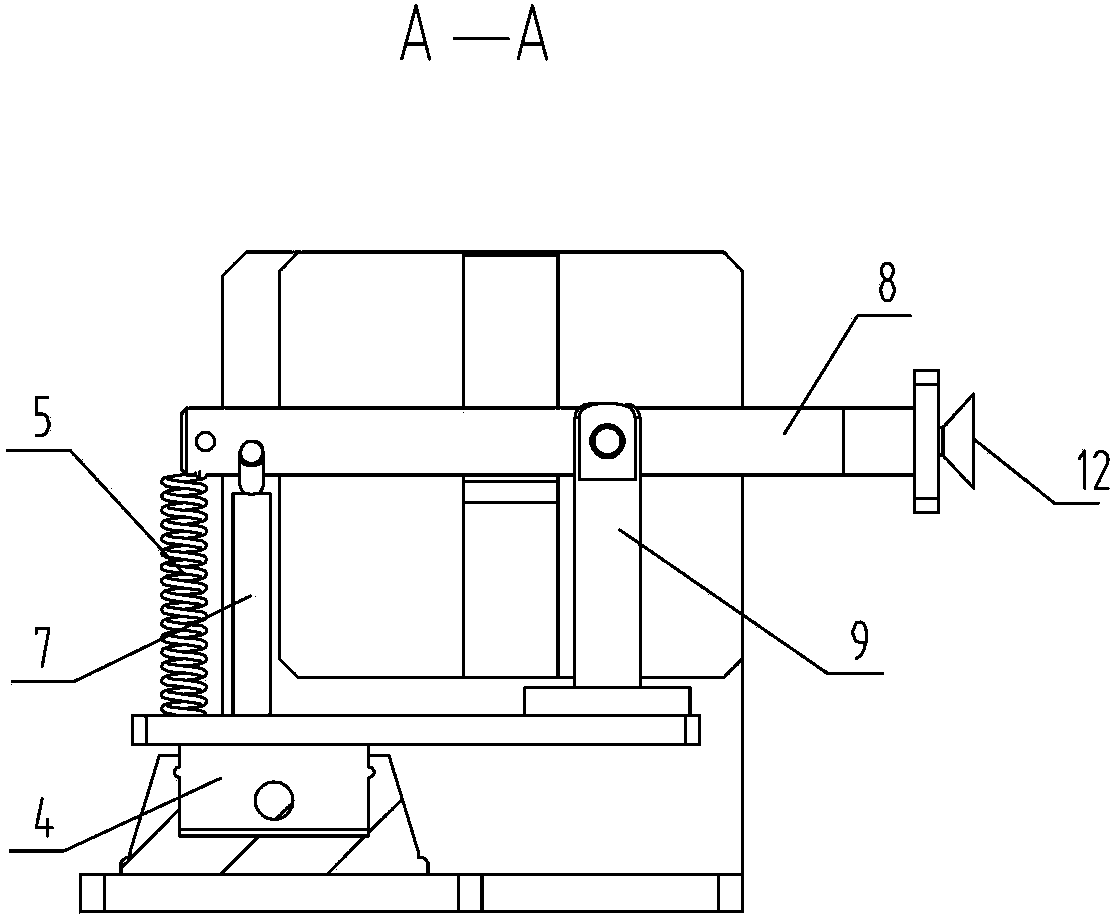

[0014] Such as figure 1 -- Figure 4 As shown, the plate retrieving mechanism of the fully automatic battery plate wrapping machine of this embodiment includes a servo motor 1, and the servo motor 1 is connected to a KK module through a connecting flange seat 2, and the KK module The group includes a threaded rod 15, a base 3, and a slider 4. The threaded rod 15 is connected with the output shaft of the servo motor 1 through a coupling, and the slider 4 has mounting holes. 4, a sliding base 6 is fixed, and two vertical and parallel support rods 9 are installed on the sliding base 6, and the two support rods 9 are connected by a connecting shaft 10, and a take-up lever 8 passes through the connection Shaft 10, the suction cup holder 11 is installed on one end of the described material taking lever 8, two negative pressure suction cups 12 are installed on the described suction cup holder 11, the described negative pressure suction cup 12 is connected to the air source equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com