Automatic precise electronic product substrate function detection device

An automatic detection device, precision electronic technology, applied in the direction of electronic circuit testing, transportation and packaging, conveyor objects, etc., can solve the problems of long PCB board time, low operating efficiency, and accuracy guarantee effects, so as to reduce the detection time, reduce Labor cost, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

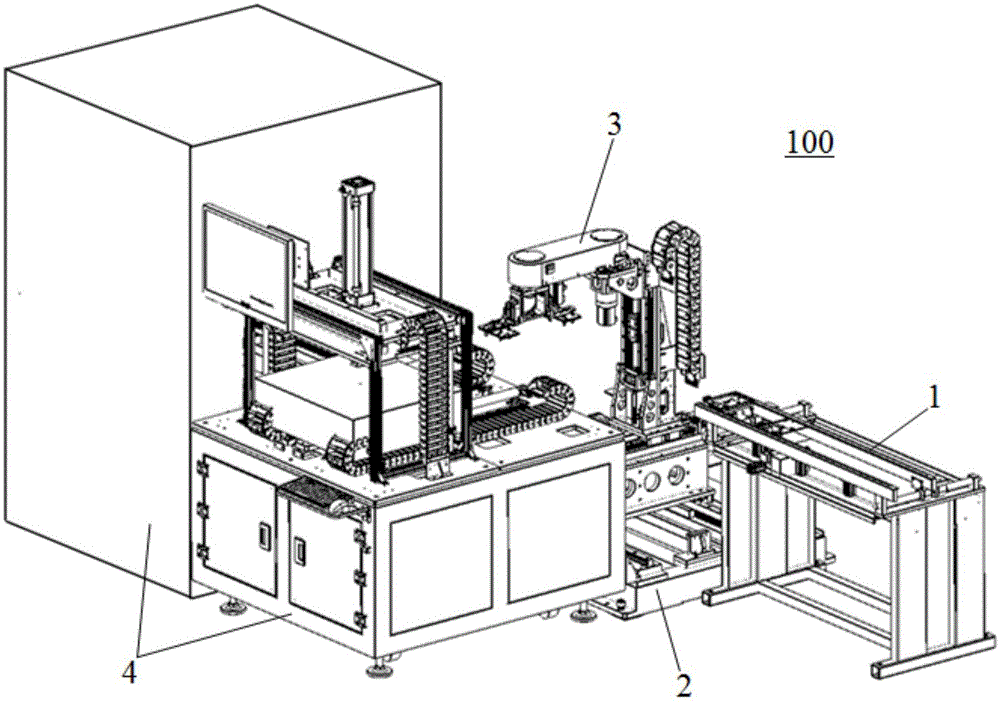

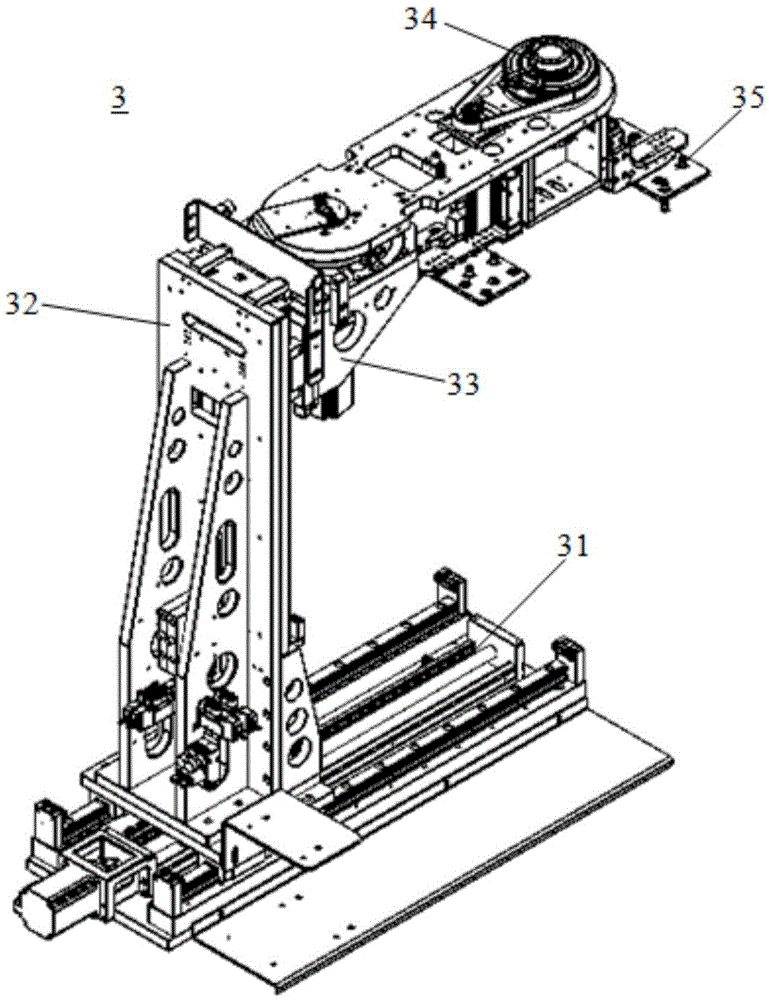

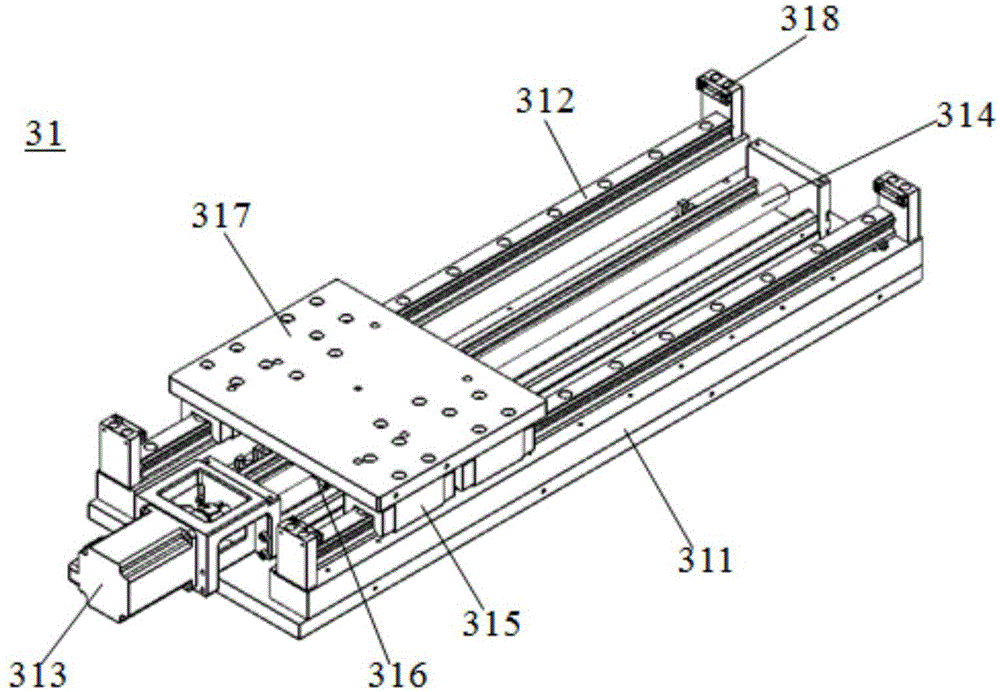

[0042] Please refer to figure 1 , the present embodiment is an automatic detection device 100 for precision electronic product substrate functions, which includes a feeding line device 1 , a track device 2 , a handling device 3 fixed on the track device 2 , and a multi-unit detection unit 4 .

[0043] Please refer to Figure 7 , Figure 8The feeding assembly line device 1 includes a second base 11, support rods 12 fixed on both ends of the upper surface of the second base 11 and parallel to each other, a fixing member 13 sleeved on the support rod 12 and movable to adjust its position, fixed on The material conveying device 14 on the fixing member 13, the sixth driving device 15 fixed on the second base 11 and used to drive the material conveying device 14, and a number of equidistantly arranged on the material conveying device 14 are used to block incoming materials. The blocking cylinder 16 of the product, the static eliminator 17 fixed on the second base 11 for eliminatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com