Automatic shoelace buckle threading machine and application thereof

An automatic wear and shoelace buckle technology, applied in the application, footwear, apparel and other directions, can solve the problems of low production efficiency, unable to meet the needs of automatic production, and difficult to unify the specifications of shoelace buckles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

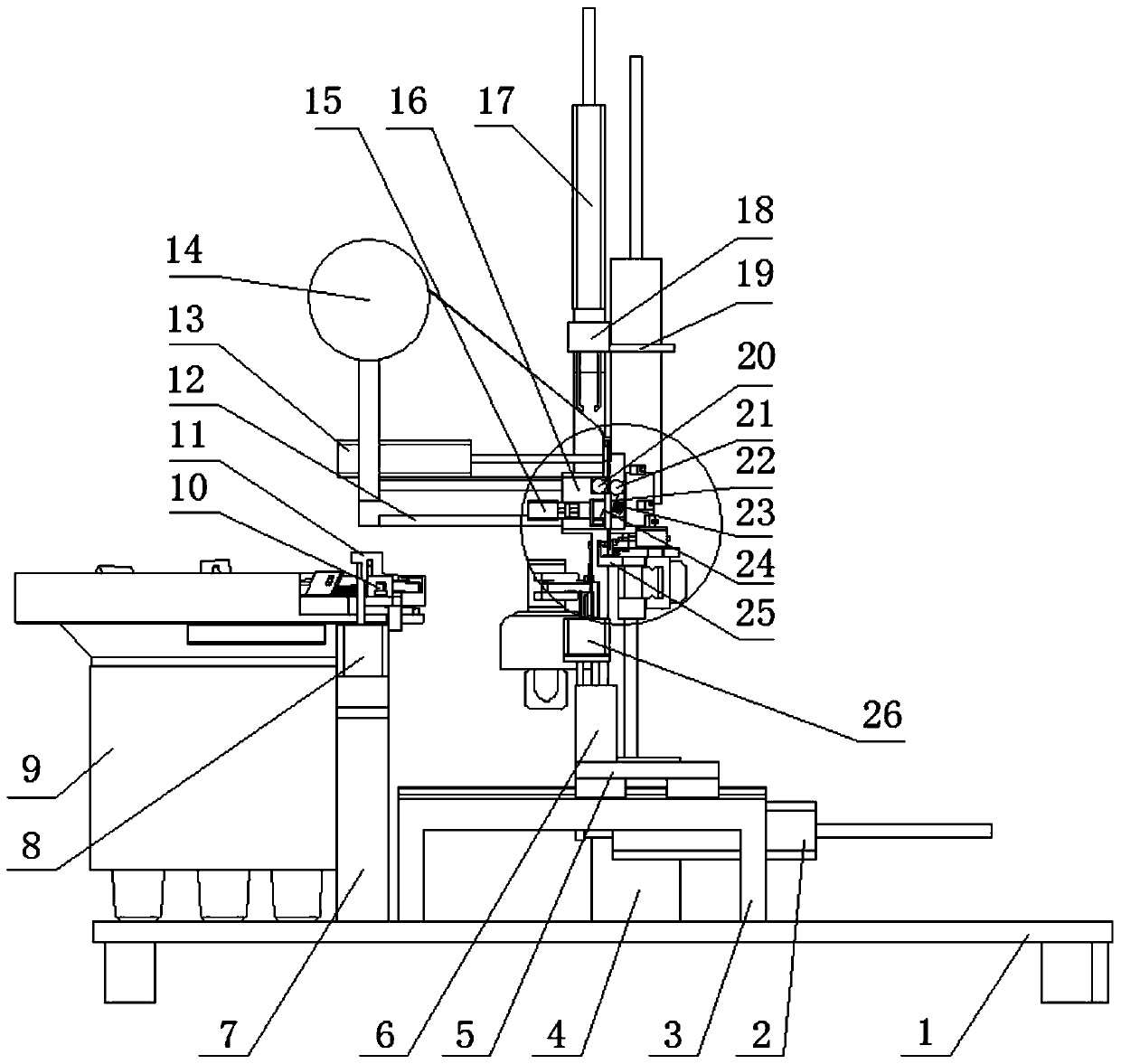

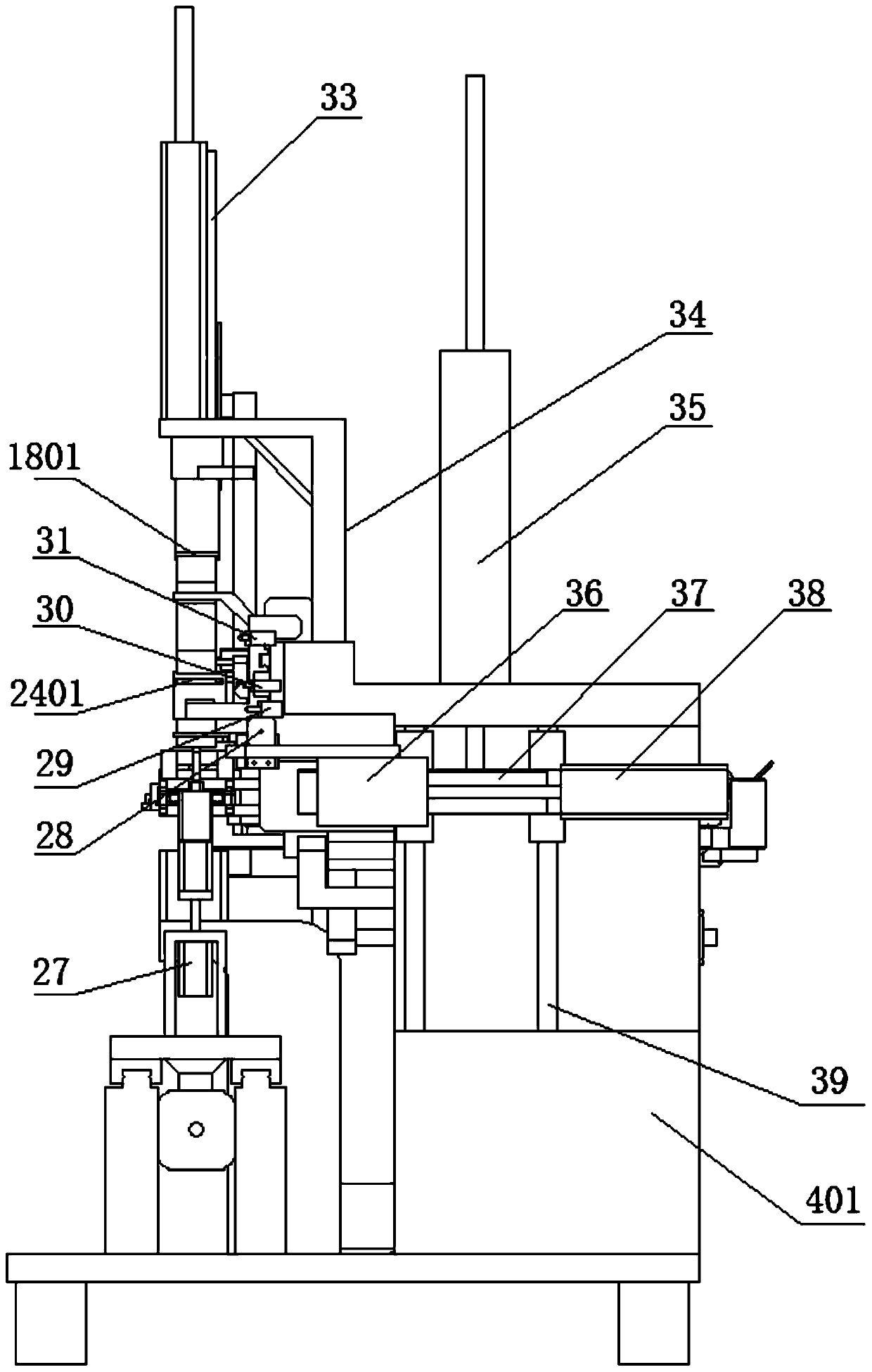

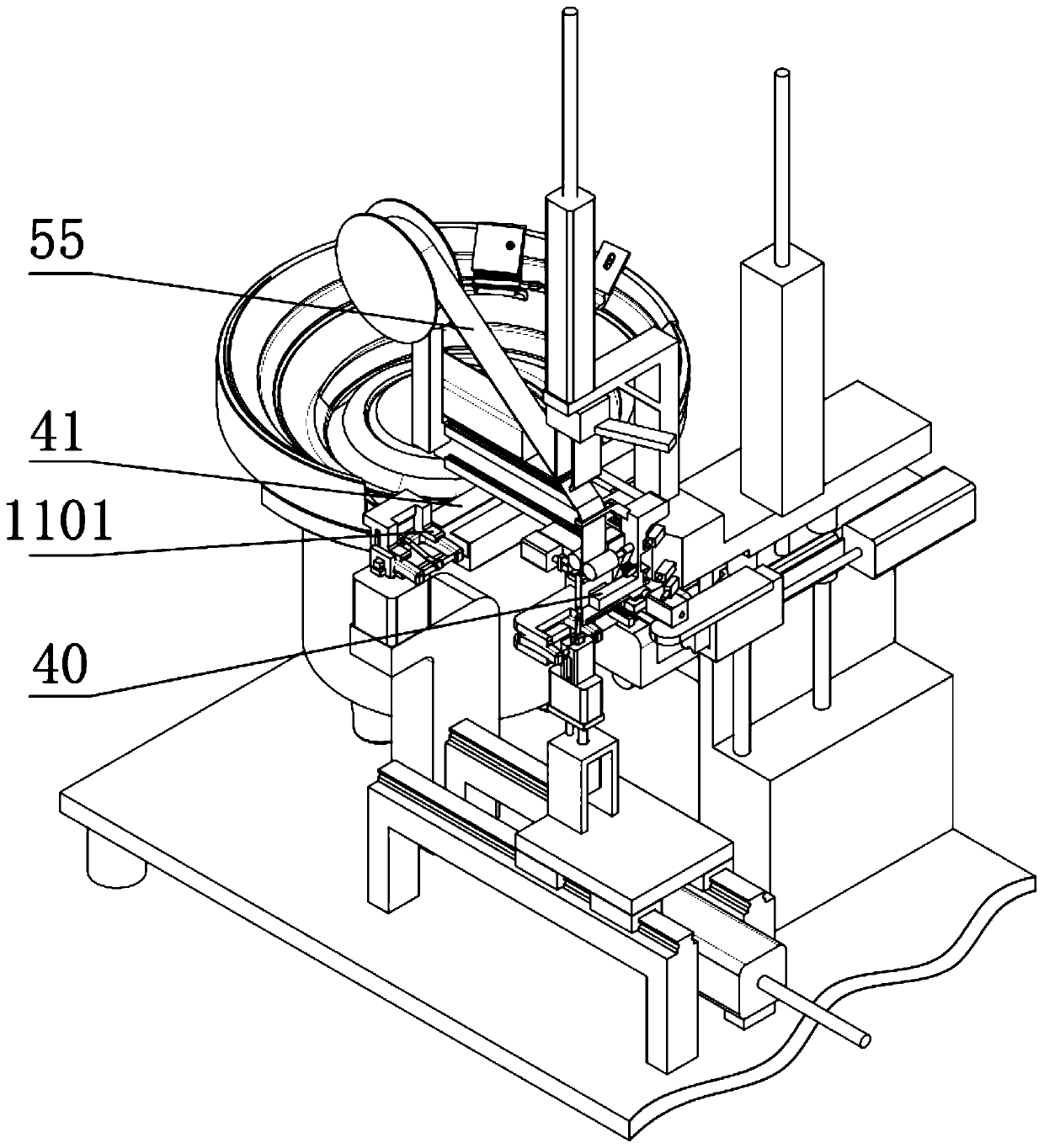

[0041] Such as Figure 1-Figure 10 As shown, the present invention relates to a shoelace buckle automatic threading machine, which is used for processing and manufacturing shoelace buckles used on leather shoes and leather goods. The button threading machine includes a support 1 on which a buckle feeding device 9 and a leather strip runner 14 are provided for feeding metal buckles 32 and leather strips 55 respectively. The button feeding device 9 is a vibrating plate or a manual feeding device, and a discharge slideway 41 is installed at the discharge port of the button feeding device 9, corresponding to the button discharge slideway on the machine base 1 The 41 discharge port is vertically equipped with a press cylinder 8 through a support 7, and the upper end of the cylinder rod of the press cylinder 8 is located at the top of the discharge slideway 41 discharge port and is connected with a press frame 11. A guide groove is arranged on the top, and the side plate at the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com