Automatic feeding device

An automatic feeding and tray technology, which is applied to conveyor objects, transportation and packaging, etc., can solve problems such as high labor costs, unqualified products, non-conformities, etc., to improve production efficiency, high degree of automation, and protect product components. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] It should be noted that this embodiment is preferably applied to the production and manufacture of LED lamps.

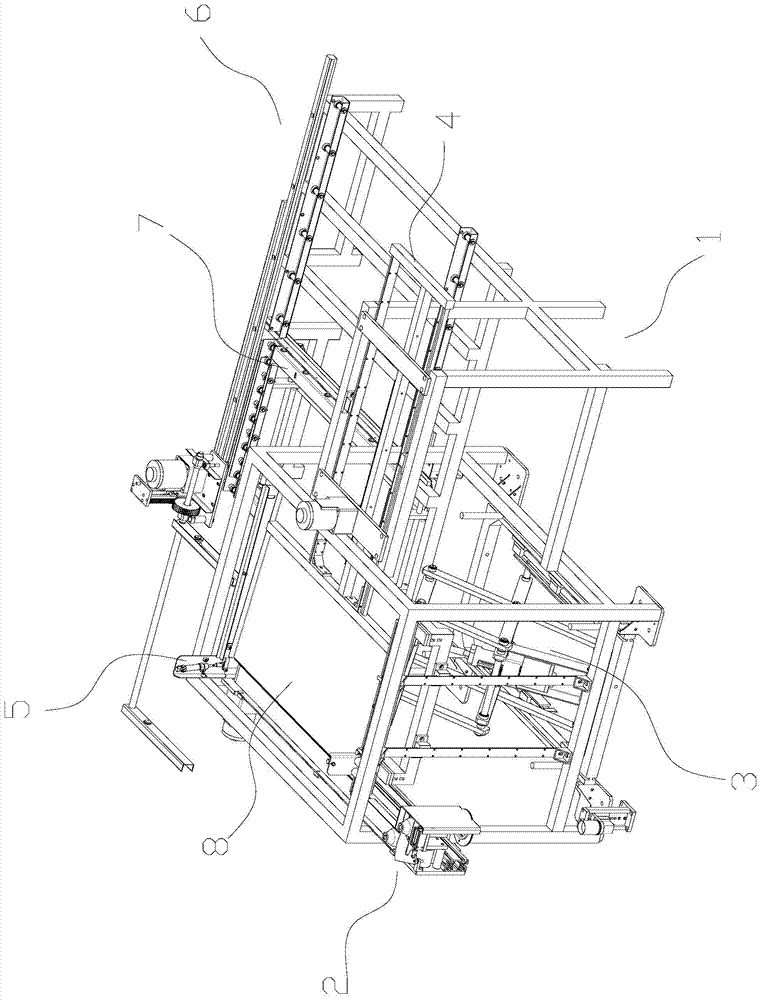

[0040] see figure 1 , an automatic feeding device, comprising a frame 1, a transmission mechanism 2, a lifting mechanism 3, a pushing mechanism 4, a pulling mechanism 5, a retrieving mechanism 6, a roller frame 7 and a product component tray 8, one side of the transmission mechanism 2 Connected with rack 1, located in the front row of rack 1, at the high position of rack 1; on the other side of the transmission mechanism 2, located in the front row of rack 1, there are lifting mechanism 5, lifting mechanism 3 and pushing mechanism in sequence 4 is installed on the frame 1, and one lifting mechanism 5 is installed on each side of the two ends of the transmission mechanism 2, the lifting mechanism 3 can vertically lift between the high position and the position, and the pushing mechanism 4 is at the high position of the frame 1; 6 is installed on the frame 1, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com