Feeding component and feeding robot adopting same

A technology of robots and components, applied in the direction of thin material handling, conveyor objects, winding strips, etc., can solve the problems of low degree of automation, high labor intensity, wrong loading of coil materials, etc., to reduce labor intensity and improve automation level , Improve the effect of running stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

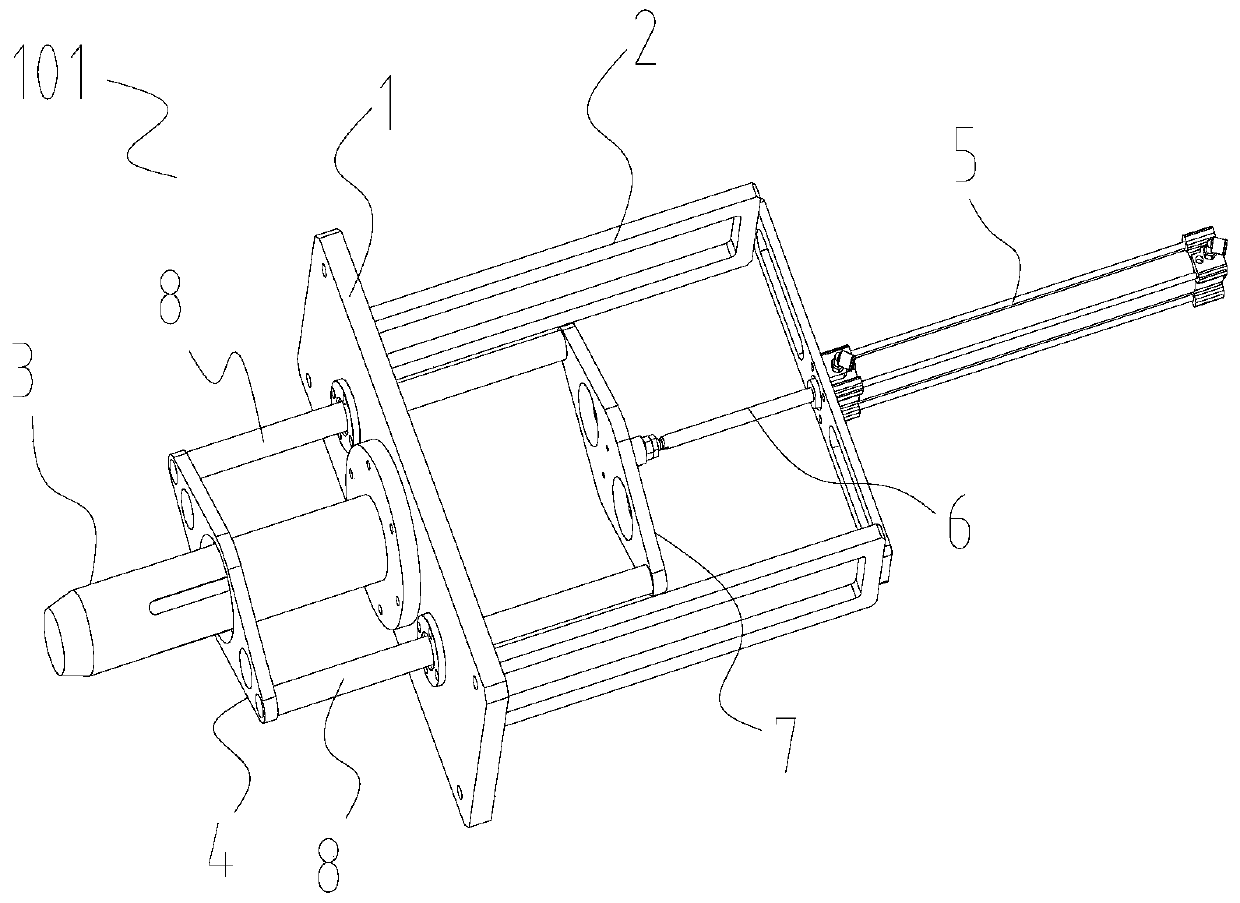

[0020] like figure 1 As shown, a feeding assembly 101 includes a base plate 1, a mounting frame 2 is fixed on one side of the base plate 1, and an inflatable shaft 3 for feeding is installed on the other side. A push plate 4 is provided, and the mounting frame 2 is provided with a cylinder 5 for driving the push plate 4 to move axially along the inflatable shaft 3 , and the piston rod of the cylinder 5 moves in a direction perpendicular to the base plate 1 during operation. The push plate 4 is sleeved on the inflatable shaft 3, and a connection part for transmitting the cylinder force is also provided between the cylinder 5 and the push plate 4. The connection part has an output shaft 6 connected with the cylinder 5, and a connection part connected with the output shaft. The connecting plate 7 and the guide rod 8 passing through the base plate 1 and connecting the connecting plate 7 and the push plate 4 .

[0021] In addition, there are two guide rods 8 arranged symmetrically...

Embodiment 2

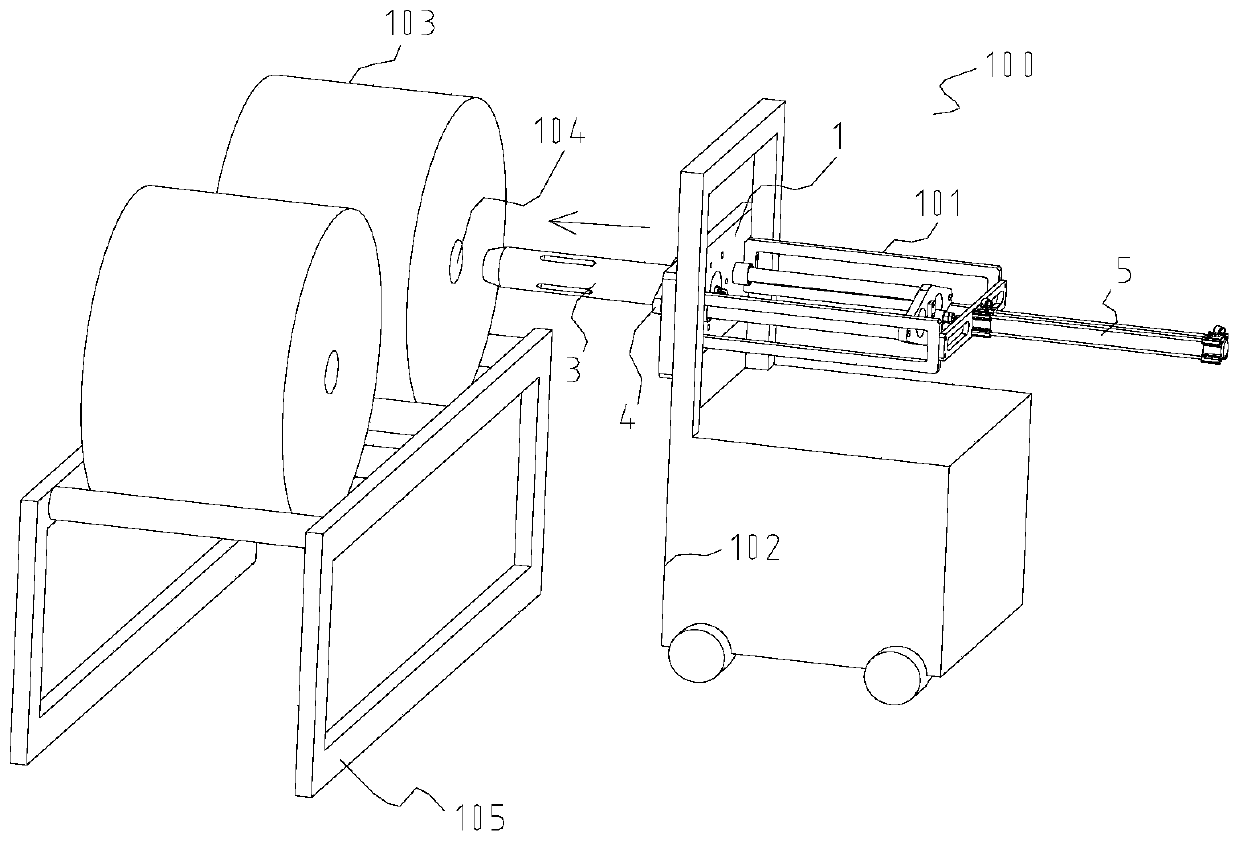

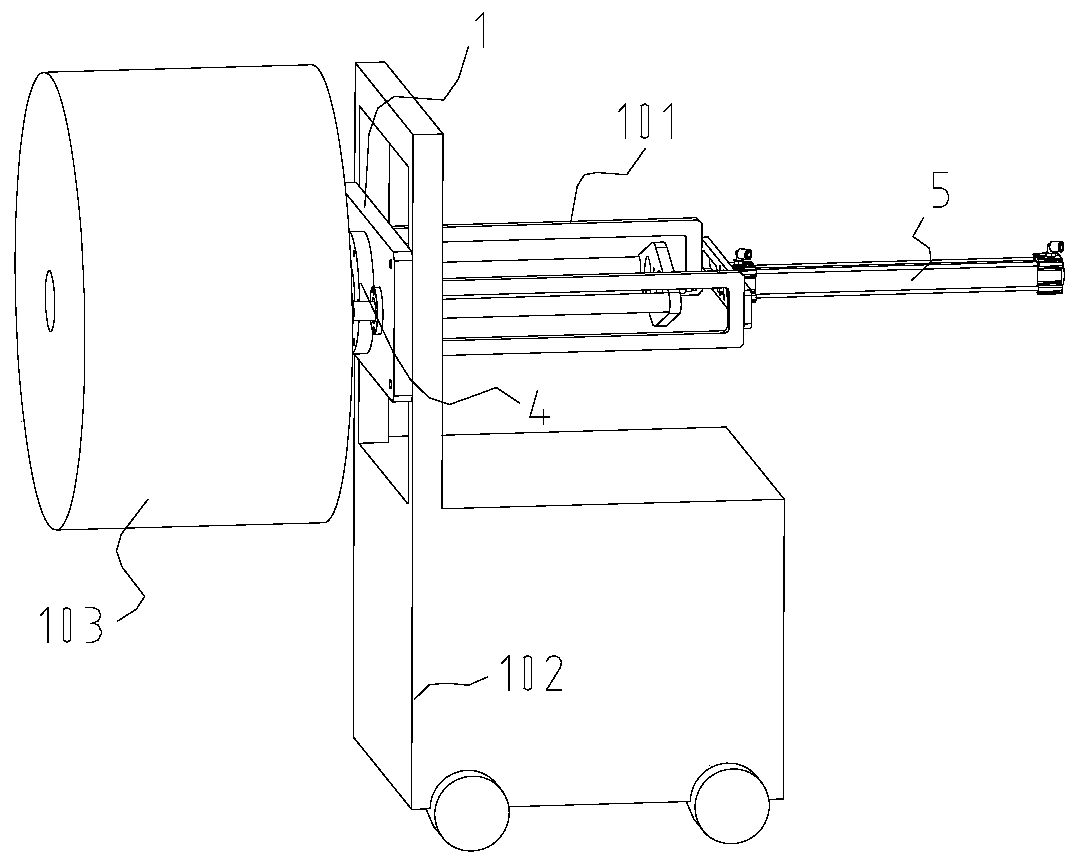

[0024] like Figures 2 to 4 As shown, an automatic feeding robot 100 is used to transport the coiled material 103 with the central hole 104 from the material rack 105 to the unwinding position 106. When the coiled material 103 is placed on the material rack 105, the central hole 104 The axis is parallel to the ground direction. Typically, the size of the central hole 104 is 70-80mm.

[0025] The above-mentioned automatic loading robot 100 includes: an automatic guided trolley 102 , a loading assembly 101 as described in Embodiment 1, and a compressed gas storage and control assembly for driving the inflatable shaft 3 and the cylinder 5 . The automatic guided vehicle 102 adopts magnetic navigation or laser navigation.

[0026] The automatic guided vehicle 102 can move along a predetermined trajectory according to instructions. The substrate 1 of the feeding assembly 101 is mounted on the automatic guided vehicle 102 and can move up and down in a direction perpendicular to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com